Patents

Literature

56results about How to "Strong anti-blocking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

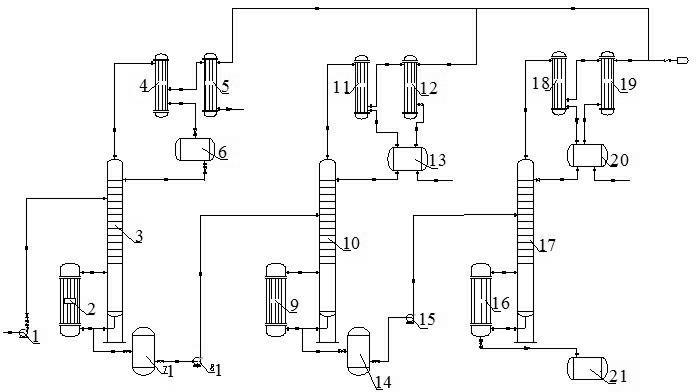

Method for preparing polymethoxy dimethyl ether through reaction and rectification of fixed bed

ActiveCN104355973AHigh catalytic activityEasy to separateOrganic chemistryOrganic compound preparationMolecular sieveTower

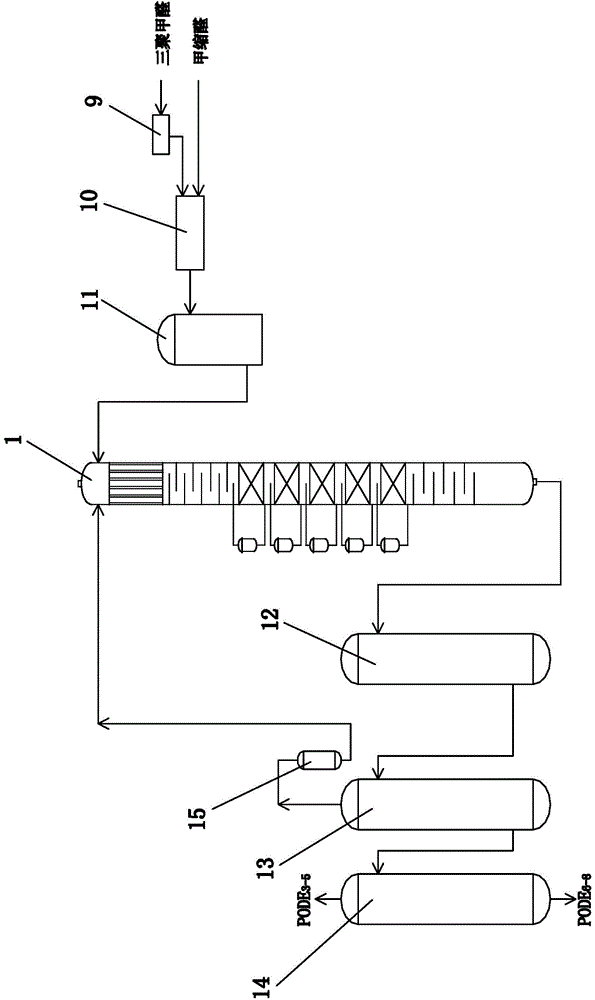

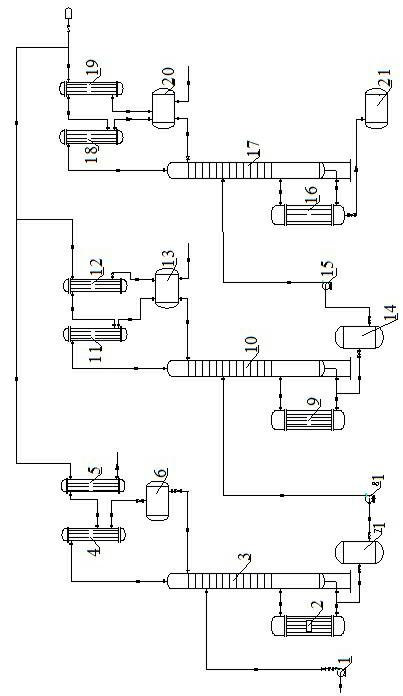

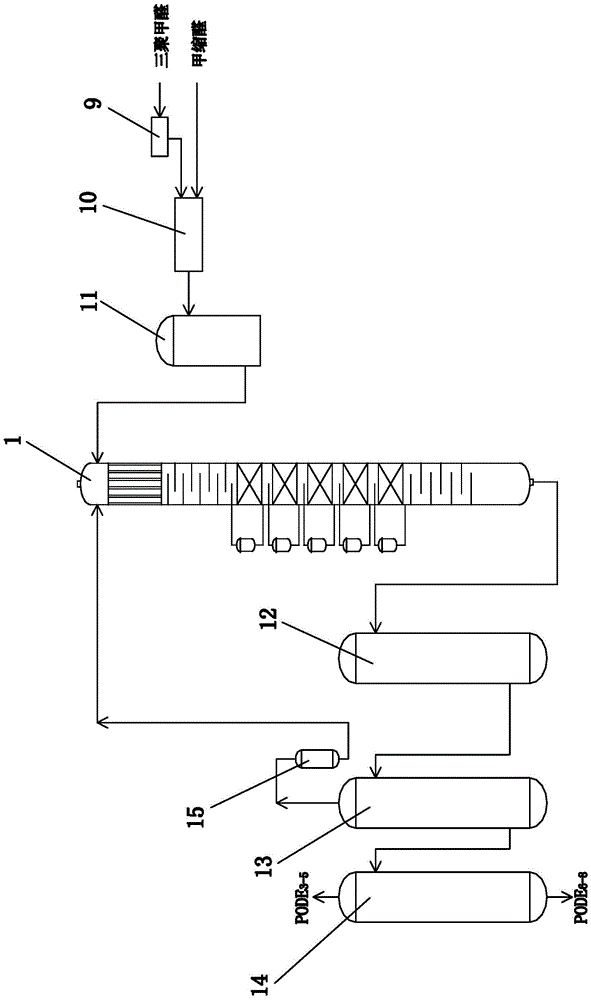

The invention discloses a method for preparing polymethoxy dimethyl ether through reaction and rectification of a fixed bed. The method comprises the following steps: (1) preheating trioxymethylene, uniformly mixing the preheated trioxymethylene and methylal, and feeding the trioxymethylene and the methylal which are uniformly mixed into a fixed bed reactor for an etherification reaction; (2) feeding materials after the etherification reaction into a reaction rectifying tower for the reaction and the rectification, and discharging PODE2-8 from the tower bottom of the reaction rectifying tower; (3) transporting the PODE2-8 to a dewatering tower loaded with a 3A molecular sieve for dehydration, then transporting the dehydrated PODE2-8 into a first refining tower, transporting materials which are discharged from the tower bottom of the first refining tower into a second refining tower, discharging PODE3-5 from the tower top of the second refining tower, and discharging PODE6-8 from the tower bottom of the second refining tower. When the method disclosed by the invention is used for preparing the PODE3-8, the yield of the polymethoxy dimethyl ether can reach 95%, wherein the products of the PODE3-8 can reach 80%-95%, and after refinement, the PODE3-5 of which the quality purity reaches 99.9% can be obtained.

Owner:XIAN SHANGHUA TECH DEV CO LTD

Extraction and dephenolization process of coal gasification wastewater

InactiveCN1834040AHigh partition coefficientSolve the problem of ineffective extraction of polyphenolsMultistage water/sewage treatmentWater/sewage treatment by extractionCoal gasification wastewaterHigh concentration

This invention discloses a method to remove high-concentration hydroxybenzenes from coal-gasification sewage, that is, coal-gasification sewage containing hydroxybenzenes and isobutyl methyl ketone as extracting solvent are mixed and separated so as to obtain solvent phase and remnant aqueous phase liquid. Solvent and crude hydroxybenzene are extracted from the solvent phase by distillation. Multiple-class reflux extraction is carried out towards remnant aqueous phase liquid and rudimental solvent is further extracted from the extract. Facilities involved in this method include a static mixer, an oil-water separator, a hydroxybenzene distillation tower and an extraction tower. Extracting coal-gasification sewage containing high-concentration hydroxybenzenes with the method provided by this invention, total hydroxybenzene extraction ratio can be as high as 92%. Besides, it also has the advantages of simple technique, soft conditions and recyclable extraction solution.

Owner:SOUTH CHINA UNIV OF TECH

Method for rectifying trichlorosilane

InactiveCN102234112AImprove energy savingIncrease productionHalogenated silanesSilicon tetrachlorideImpurity

The invention relates to a method for rectifying trichlorosilane, and belongs to the technical field of trichlorosilane rectification and purification. The method comprises the following steps of: feeding trichlorosilane-containing crude synthesis liquid into a preparation tower and rectifying to separate and remove most light impurity components from a raw material; discharging the liquid subjected to impurity removal by the preparation tower from a tower bottom, and feeding into a trichlorosilane rectifying tower to obtain a trichlorosilane product at a tower top; and feeding the material in a tower kettle into a silicon tetrachloride rectifying tower, and evaporating a silicon tetrachloride product on the top of the silicon tetrachloride rectifying tower. By the method, energy can be saved by 60 percent, and an energy-saving effect is obvious; and by a continuous rectification technology, yield is greatly improved while the energy is saved.

Owner:河南尚宇新能源股份有限公司

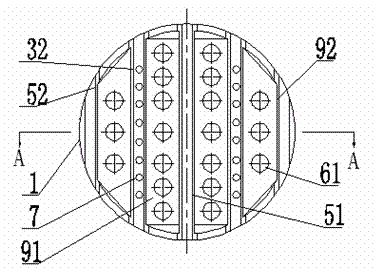

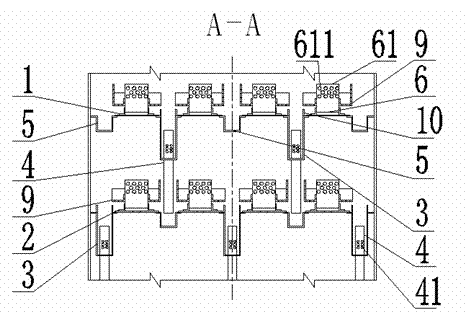

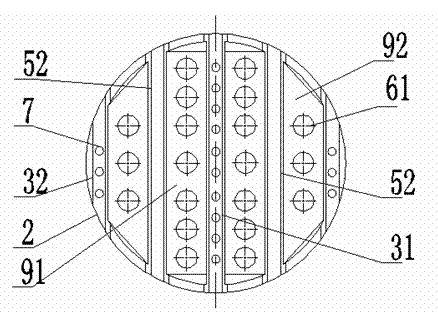

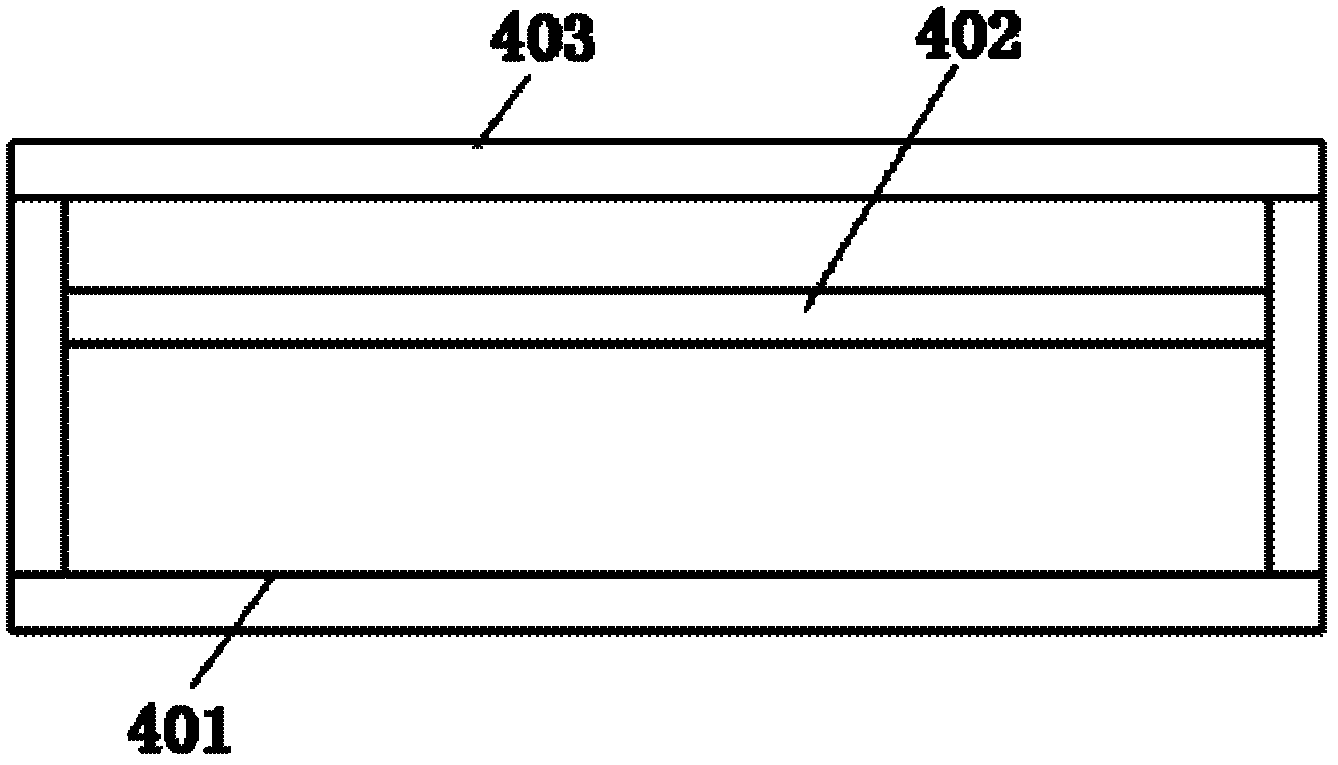

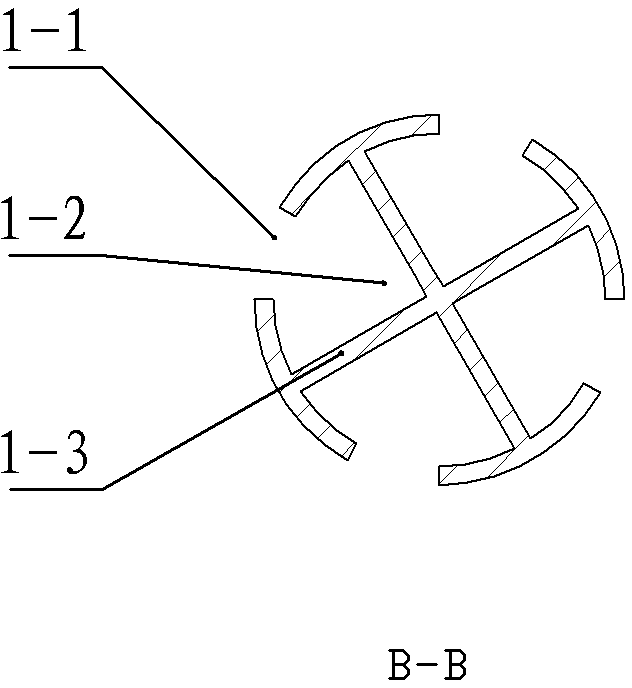

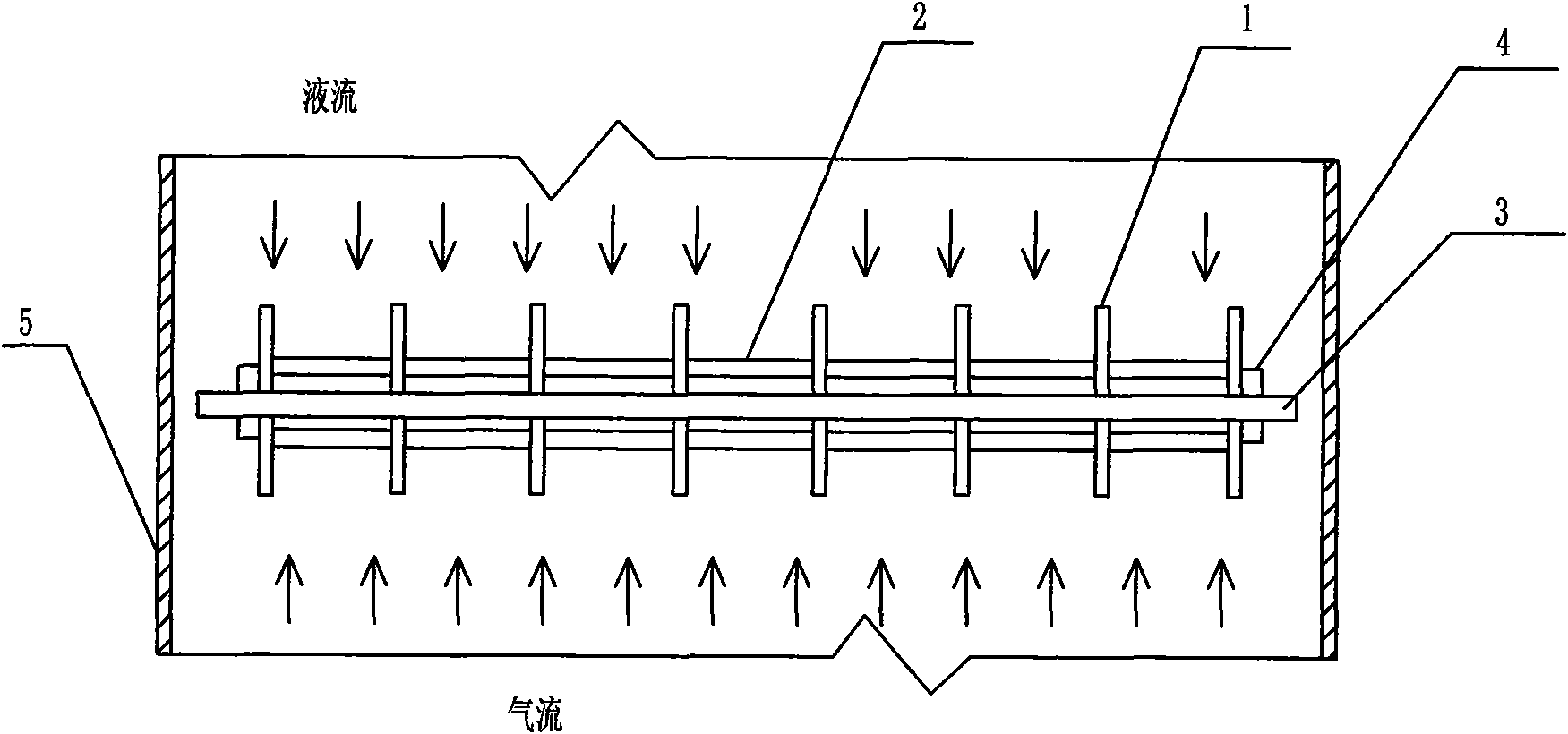

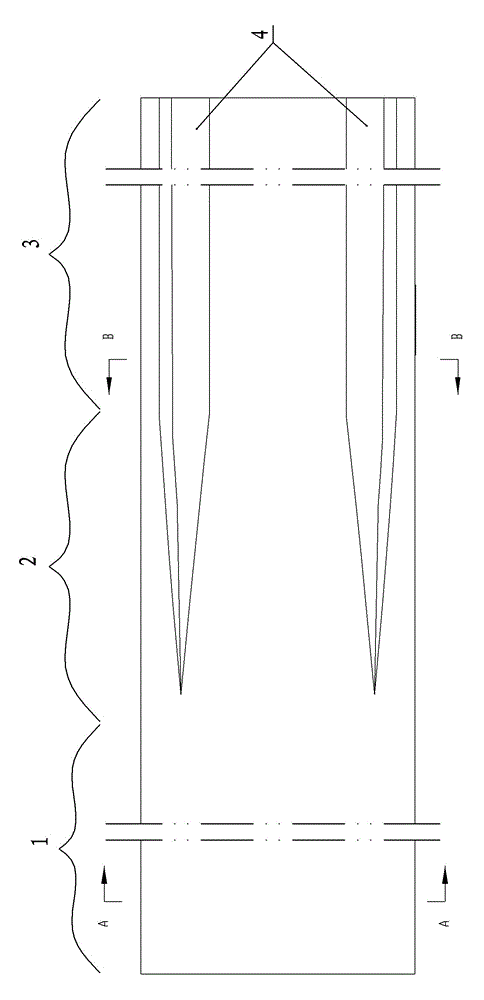

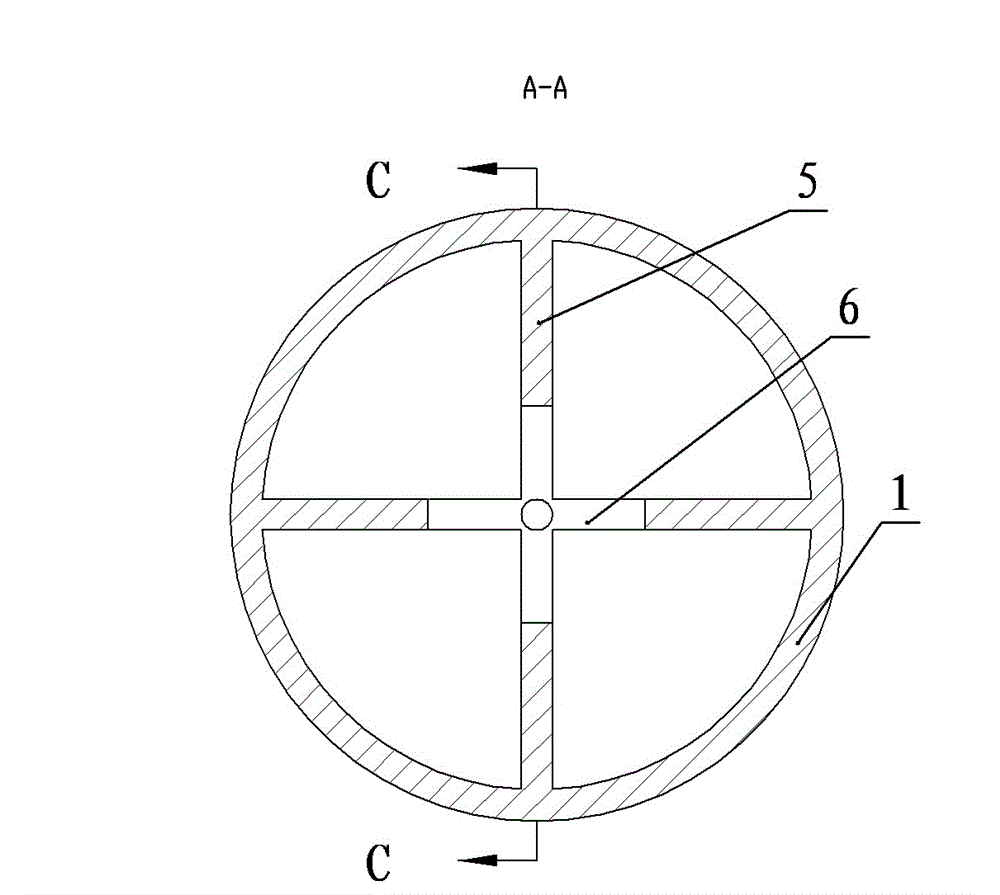

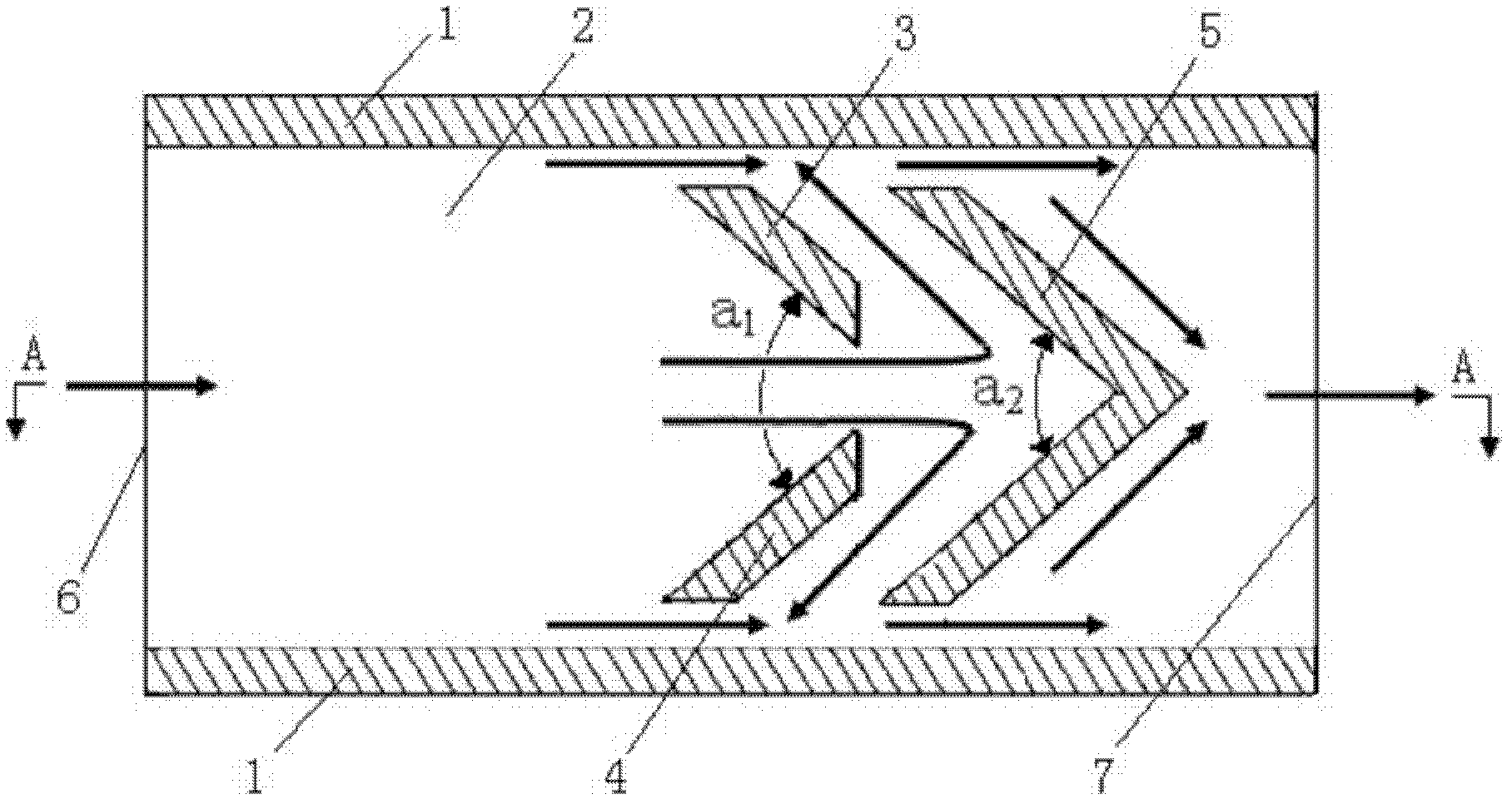

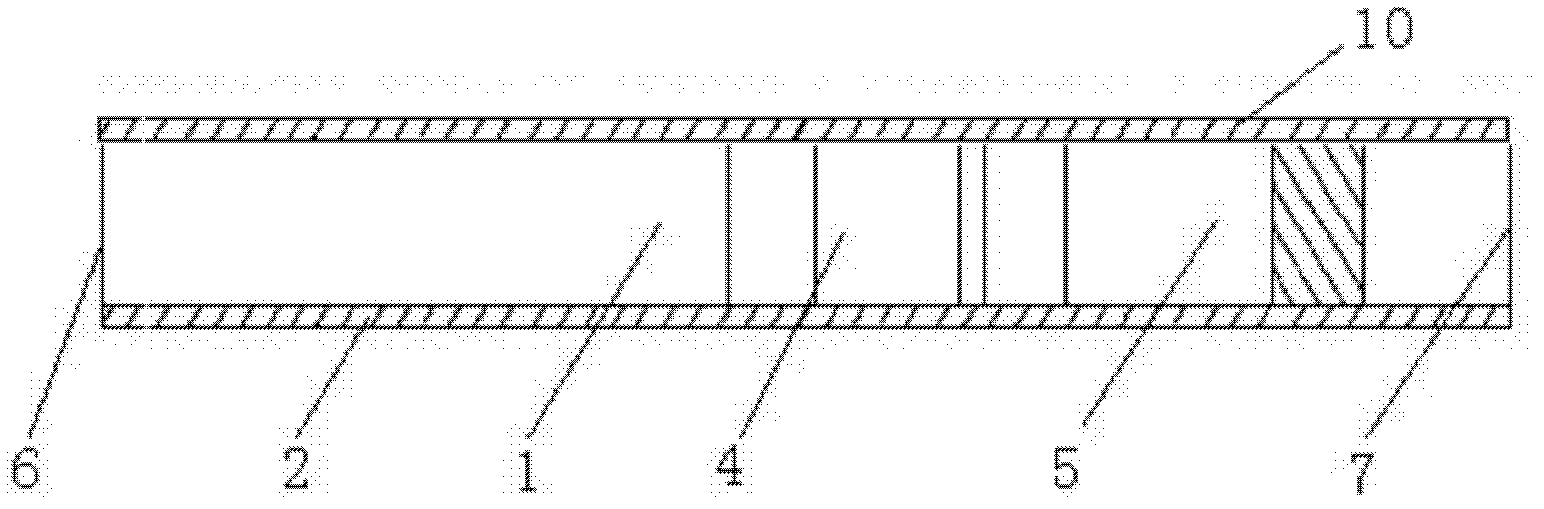

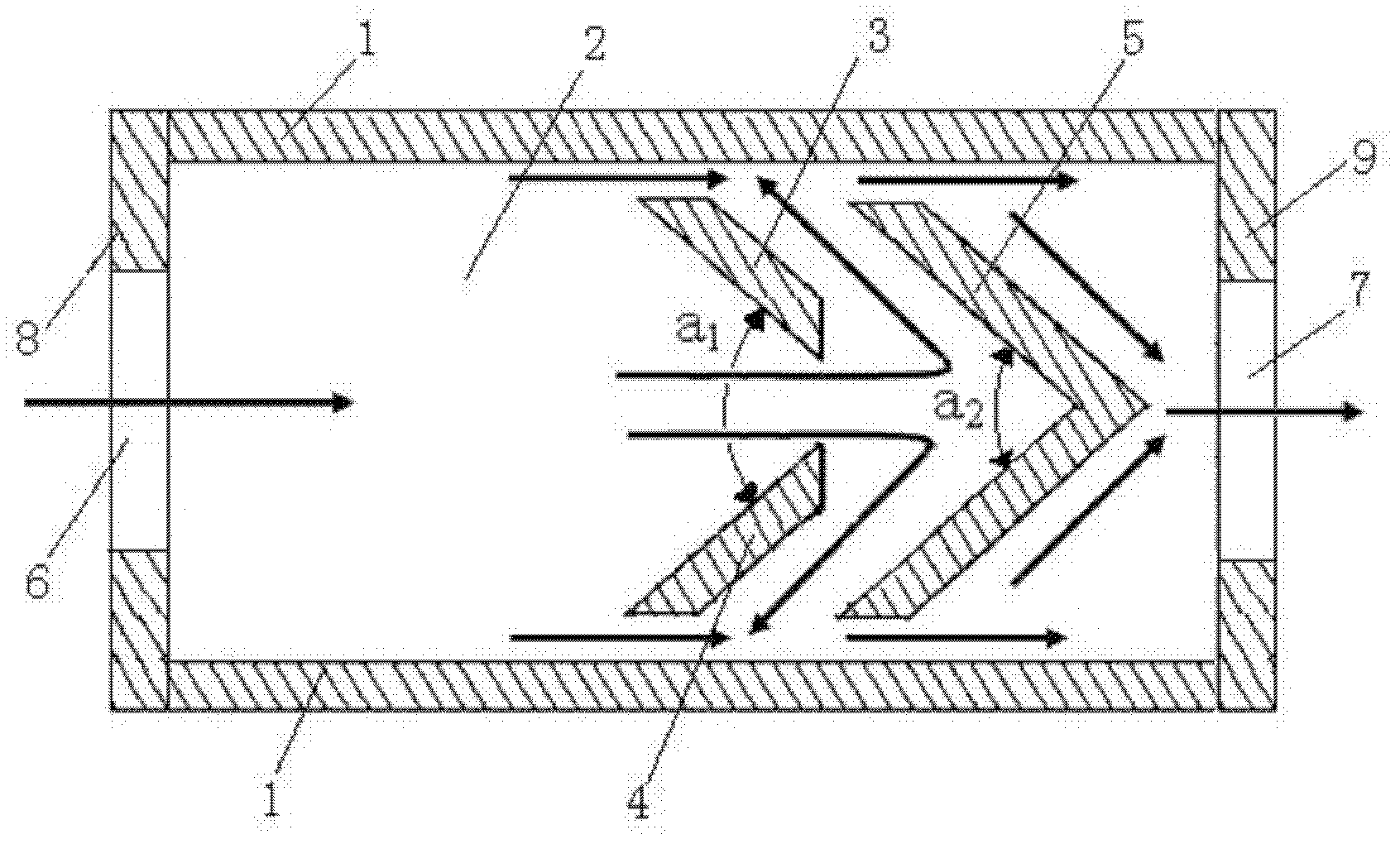

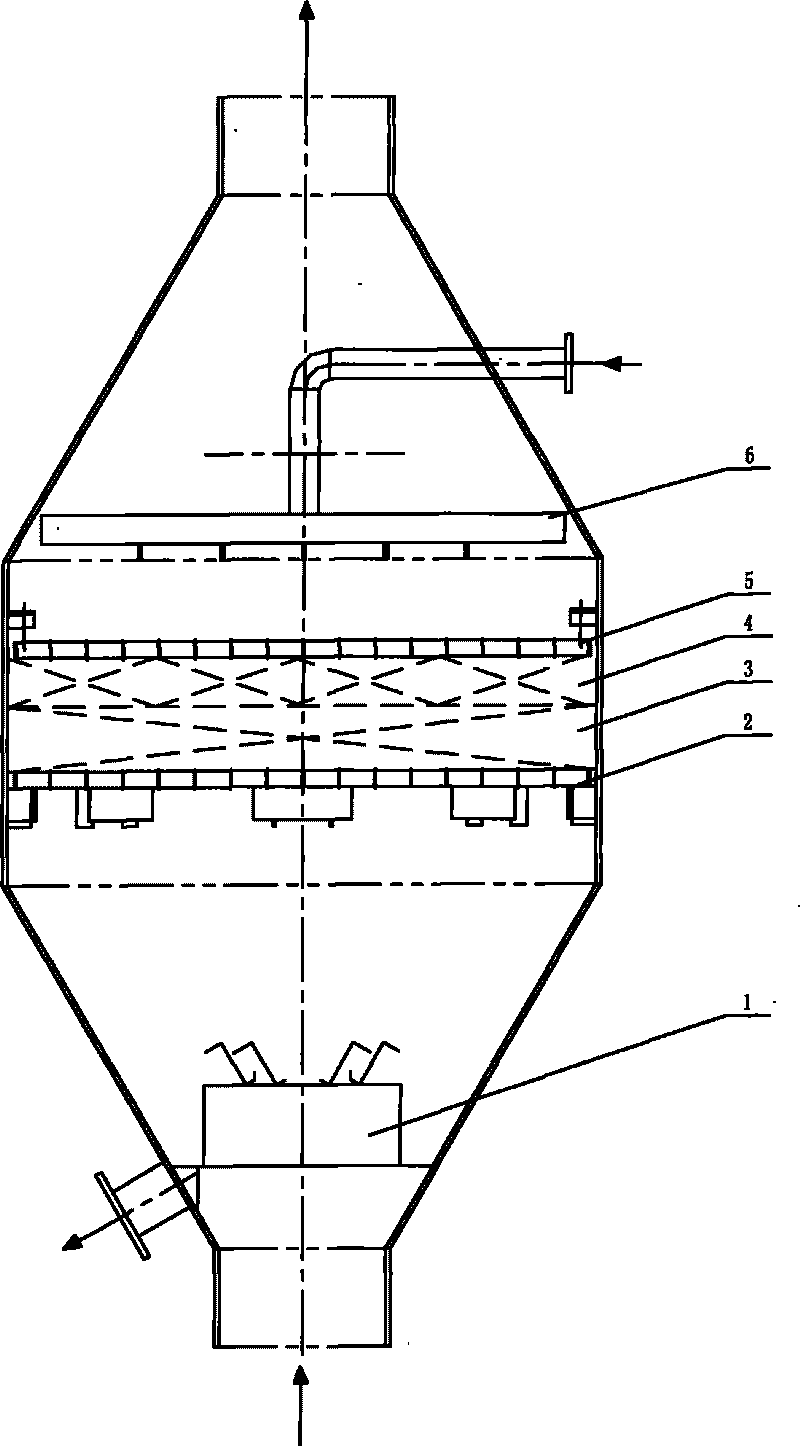

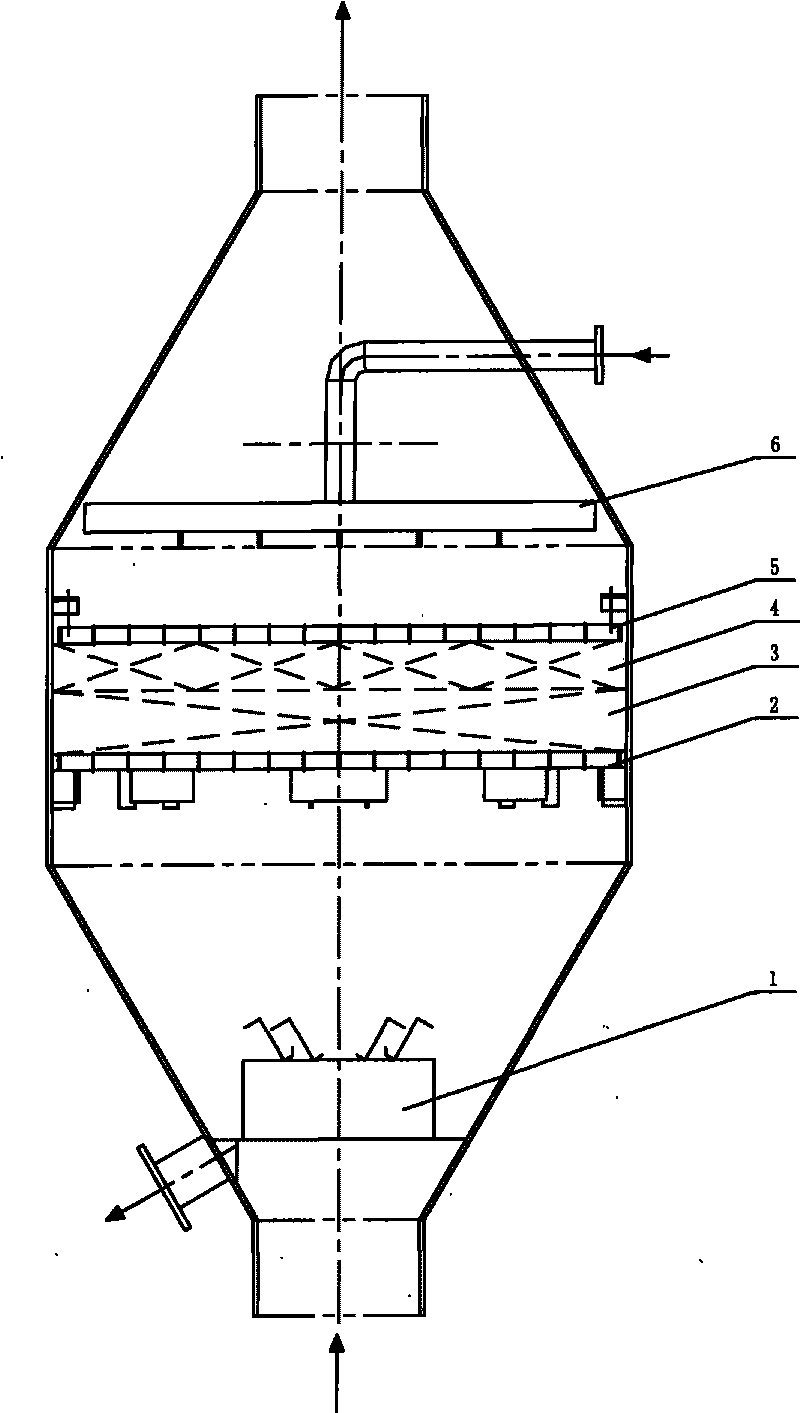

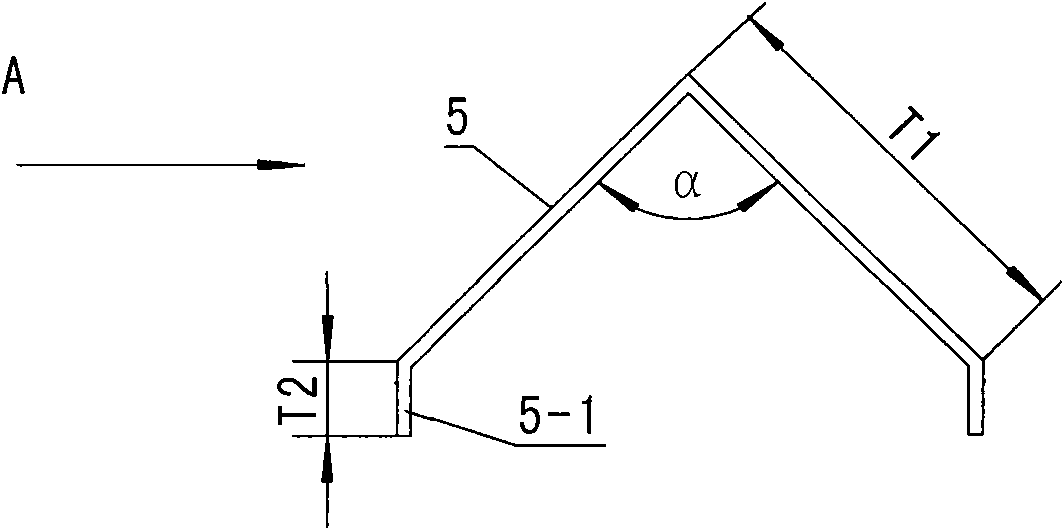

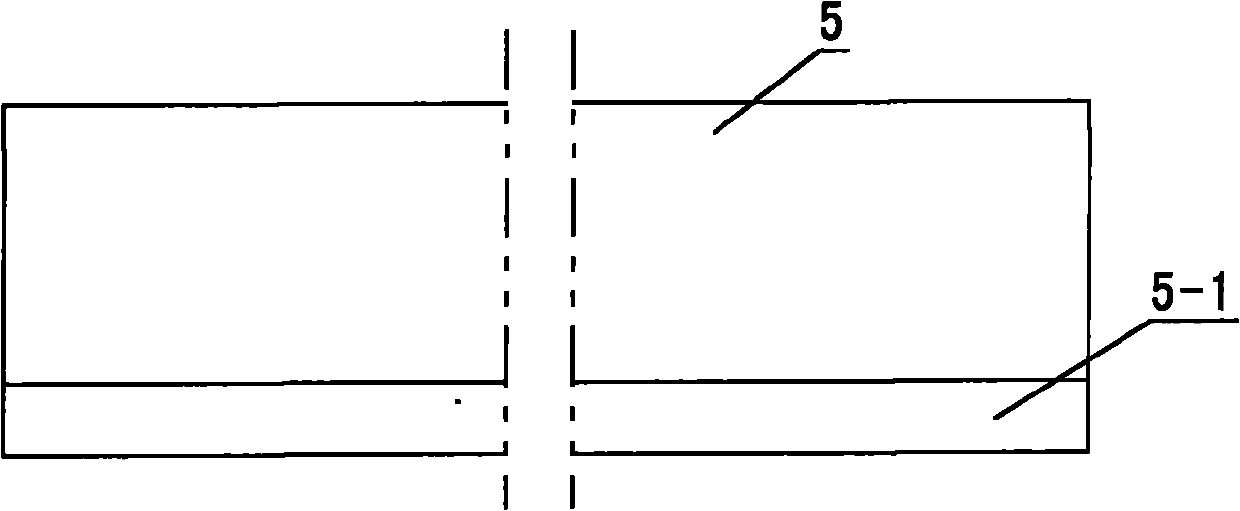

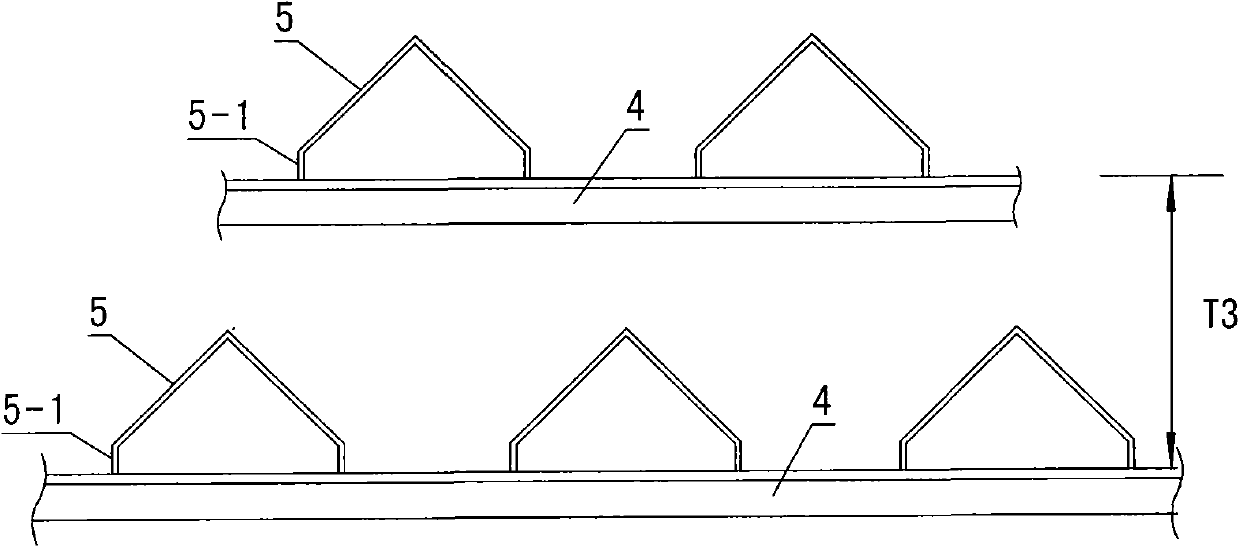

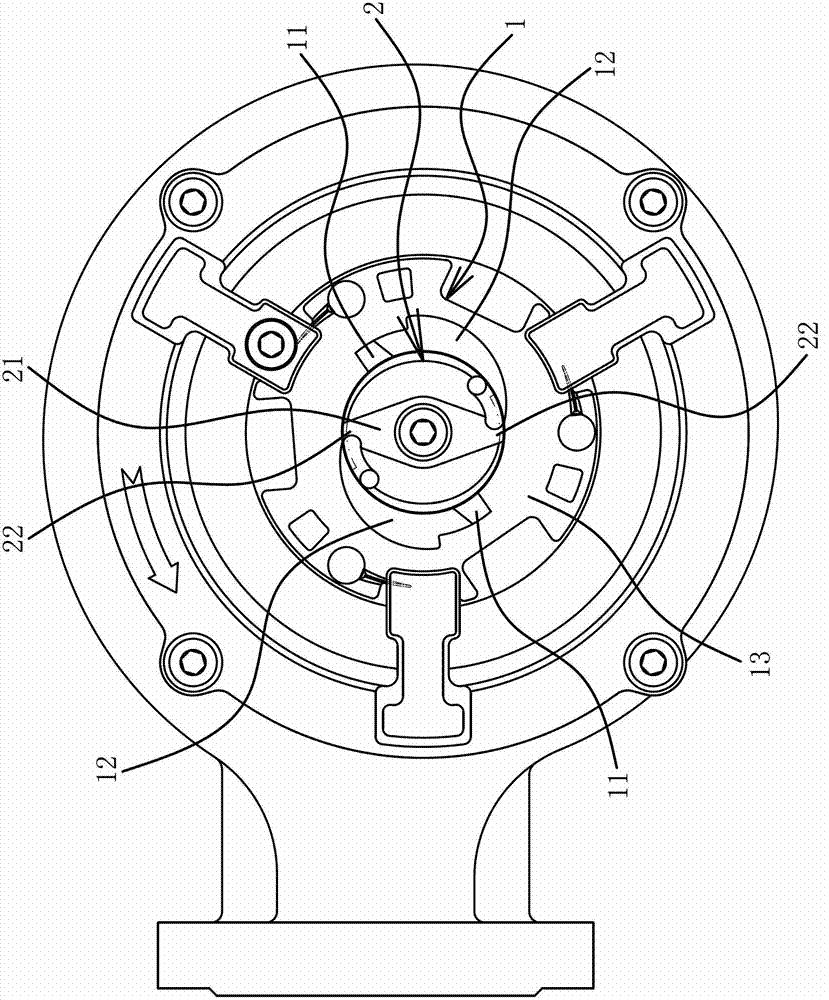

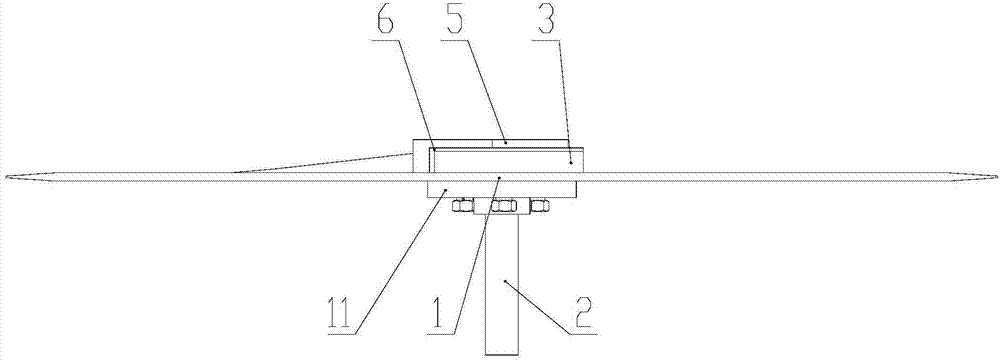

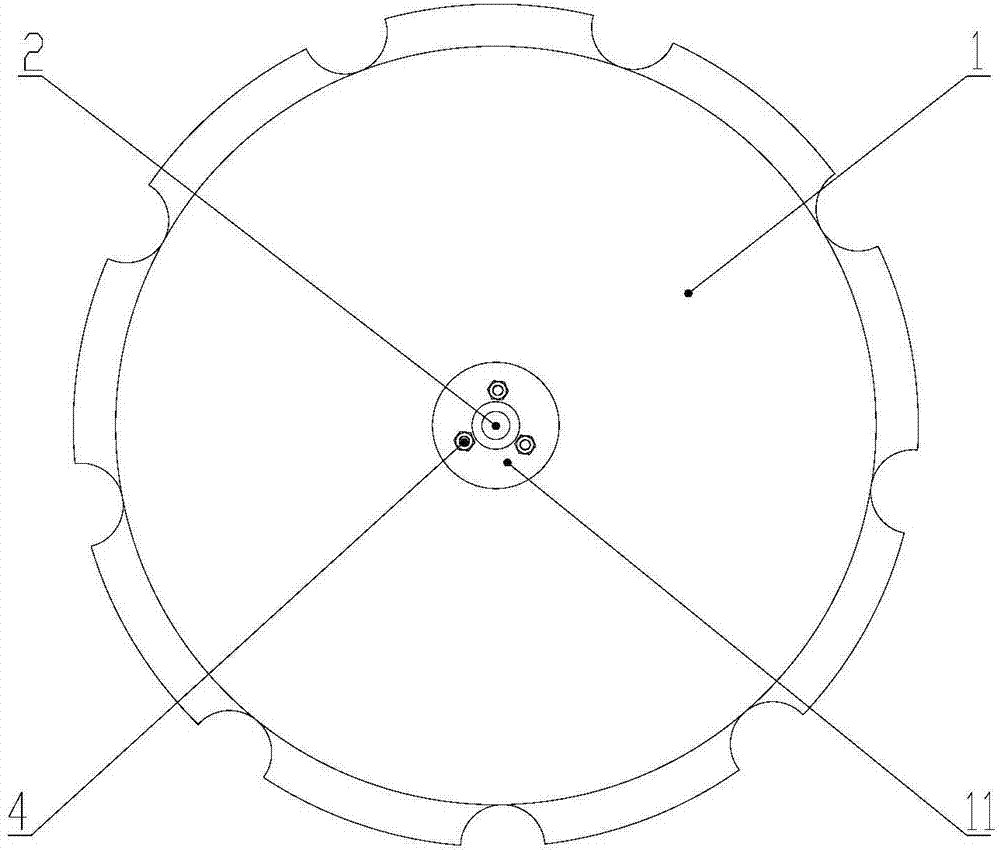

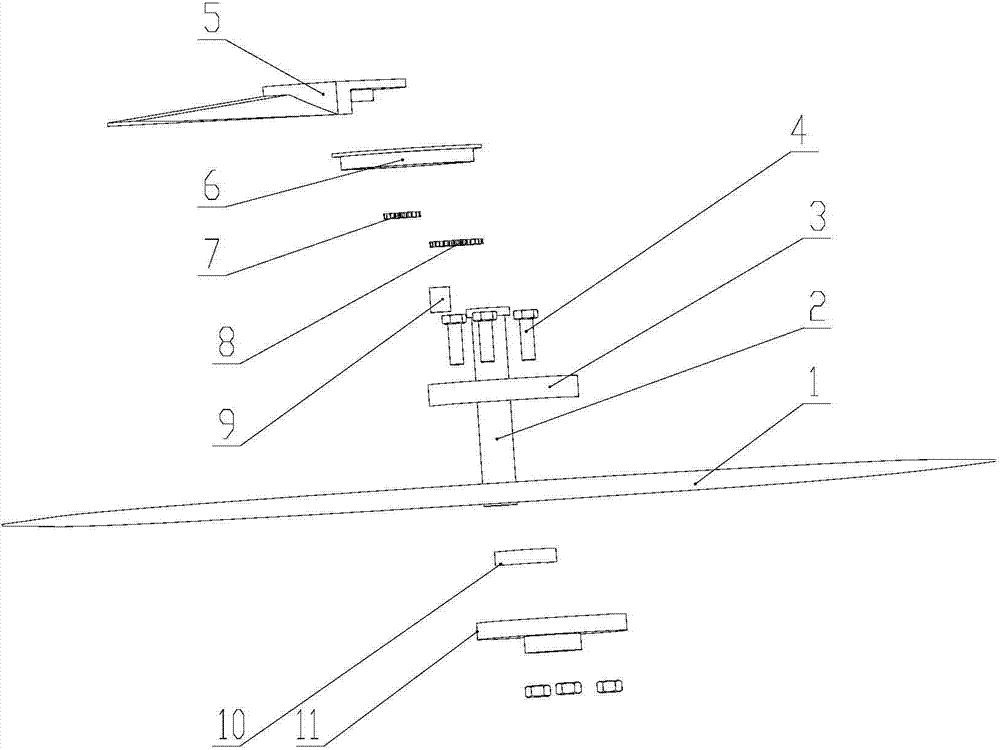

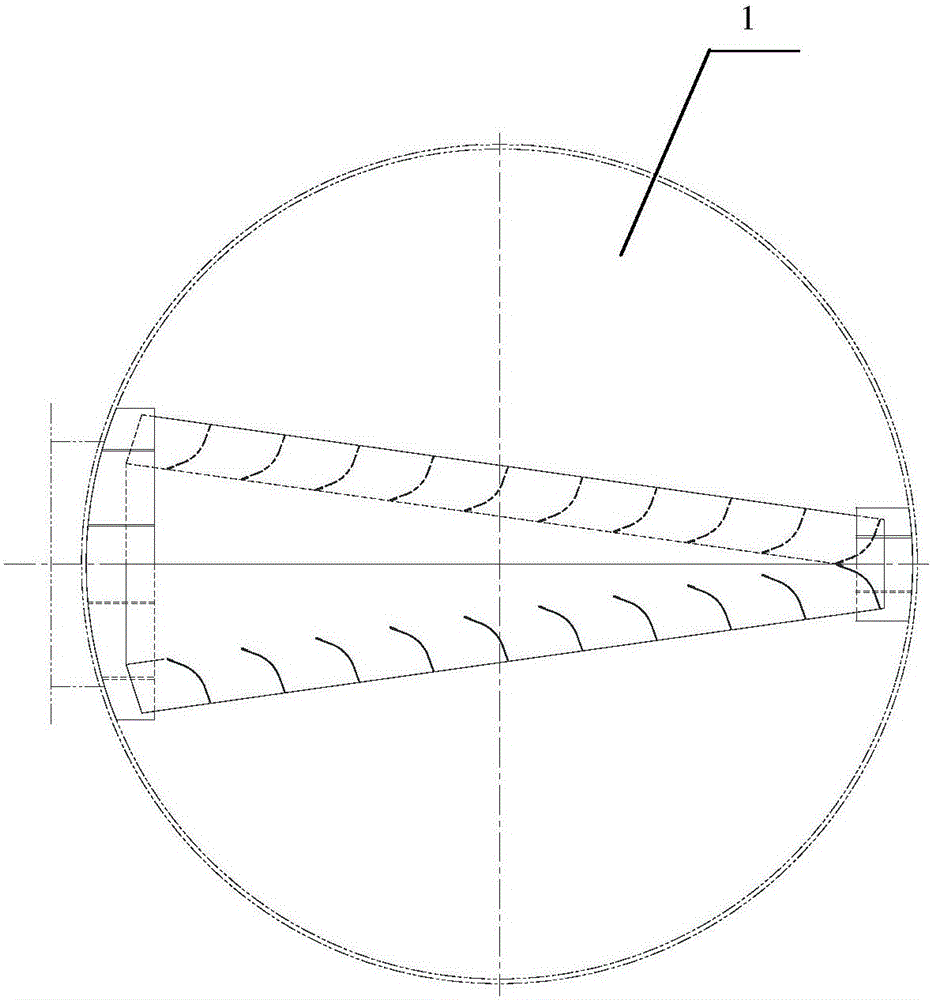

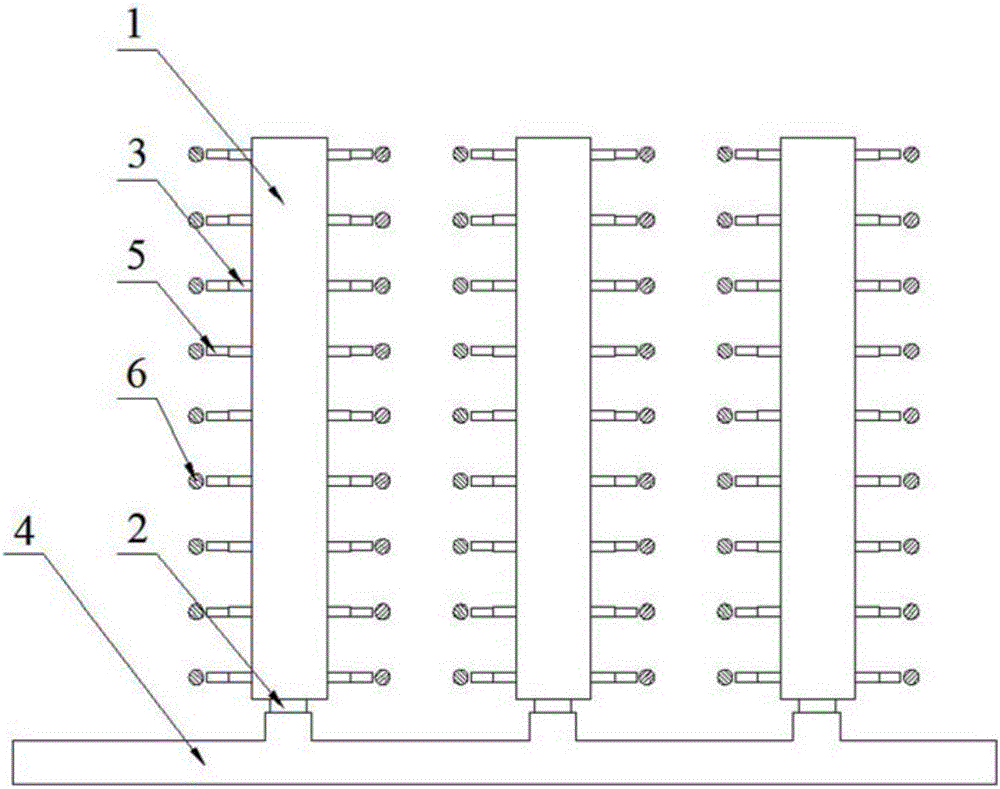

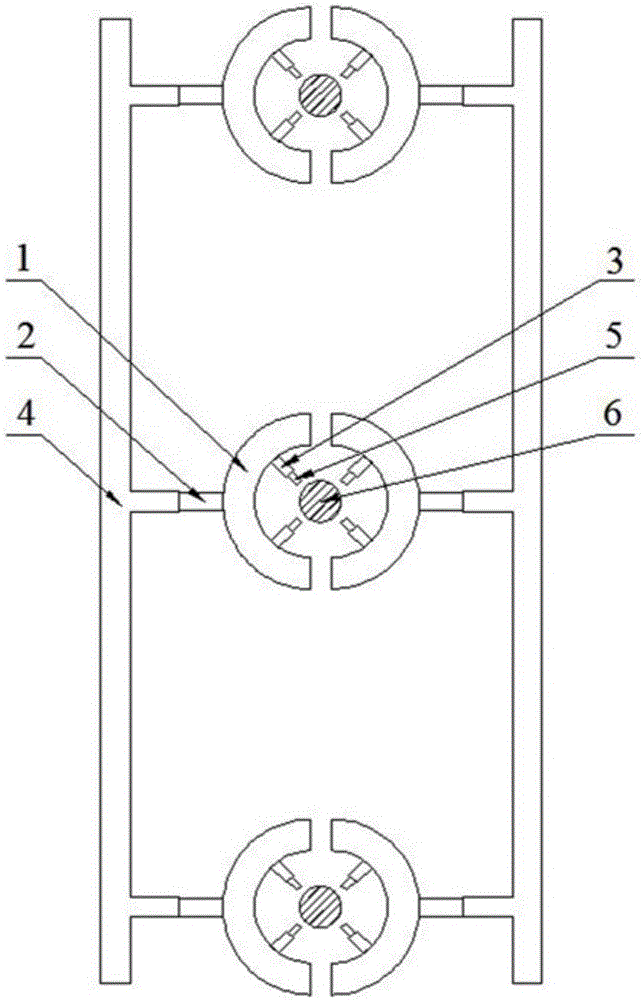

Flow-separation back-mixing-free spraying tower disc

ActiveCN102961888AStrong anti-blockingLess foamingDispersed particle separationDistillation separationSpray towerMechanical engineering

The invention discloses a flow-separation back-mixing-free spraying tower disc. The tower disc is formed by combining an upper-layer tower disc and a lower-layer tower disc; and each tower disc comprises liquid descending grooves, liquid descending pipes, liquid accepting grooves, three-dimensional spraying and mass transferring units and liquid guide grooves. The flow-separation back-mixing-free spraying tower disc is characterized in that the long-strip-shaped liquid accepting grooves are formed in the horizontal position of the center of the tower disc; each long-strip-shaped liquid descending groove is arranged between each two adjacent liquid accepting grooves; liquid descending openings are designed in the bottoms of the liquid descending grooves; each liquid descending opening corresponds to one liquid descending pipe, and each liquid descending pipe stretches and is fixed in each liquid descending groove; the three-dimensional spraying and mass transferring units are arranged among the liquid descending grooves and the liquid accepting grooves; the liquid guide grooves, which are flow-separation-plate-type liquid guide grooves, are arranged on the peripheries of cap covers of the three-dimensional spraying and mass transferring units; one liquid guide groove corresponds to one three-dimensional spraying and mass transferring unit; the shapes and the structures of the upper and lower tower discs are the same basically; and one set of liquid descending pipes on the lower edge of one liquid descending groove of the upper-layer tower disc correspond to one liquid accepting groove of the lower-layer tower disc in a staggered manner, so that the upper-layer tower disc and the lower-layer tower disc are combined into the double-layer flow-separation back-mixing-free spraying tower disc.

Owner:TIANJIN CHUANGJU TECHNOLGOY

A kind of method for preparing polyoxymethylene dimethyl ether by fixed-bed reactive distillation

ActiveCN104355973BHigh catalytic activityEasy to separateOrganic chemistryOrganic compound preparationMolecular sieveFixed bed

The invention discloses a method for preparing polymethoxy dimethyl ether through reaction and rectification of a fixed bed. The method comprises the following steps: (1) preheating trioxymethylene, uniformly mixing the preheated trioxymethylene and methylal, and feeding the trioxymethylene and the methylal which are uniformly mixed into a fixed bed reactor for an etherification reaction; (2) feeding materials after the etherification reaction into a reaction rectifying tower for the reaction and the rectification, and discharging PODE2-8 from the tower bottom of the reaction rectifying tower; (3) transporting the PODE2-8 to a dewatering tower loaded with a 3A molecular sieve for dehydration, then transporting the dehydrated PODE2-8 into a first refining tower, transporting materials which are discharged from the tower bottom of the first refining tower into a second refining tower, discharging PODE3-5 from the tower top of the second refining tower, and discharging PODE6-8 from the tower bottom of the second refining tower. When the method disclosed by the invention is used for preparing the PODE3-8, the yield of the polymethoxy dimethyl ether can reach 95%, wherein the products of the PODE3-8 can reach 80%-95%, and after refinement, the PODE3-5 of which the quality purity reaches 99.9% can be obtained.

Owner:XIAN SHANGHUA TECH DEV CO LTD

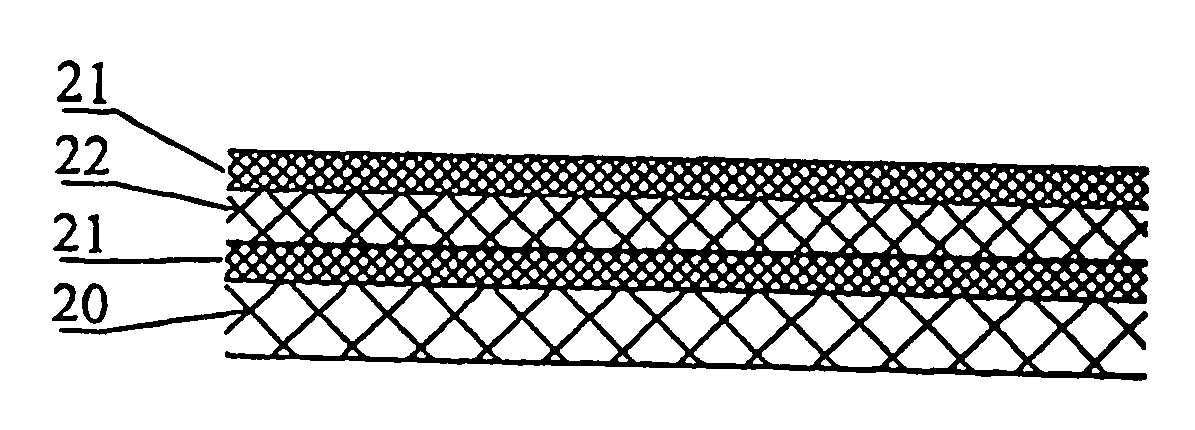

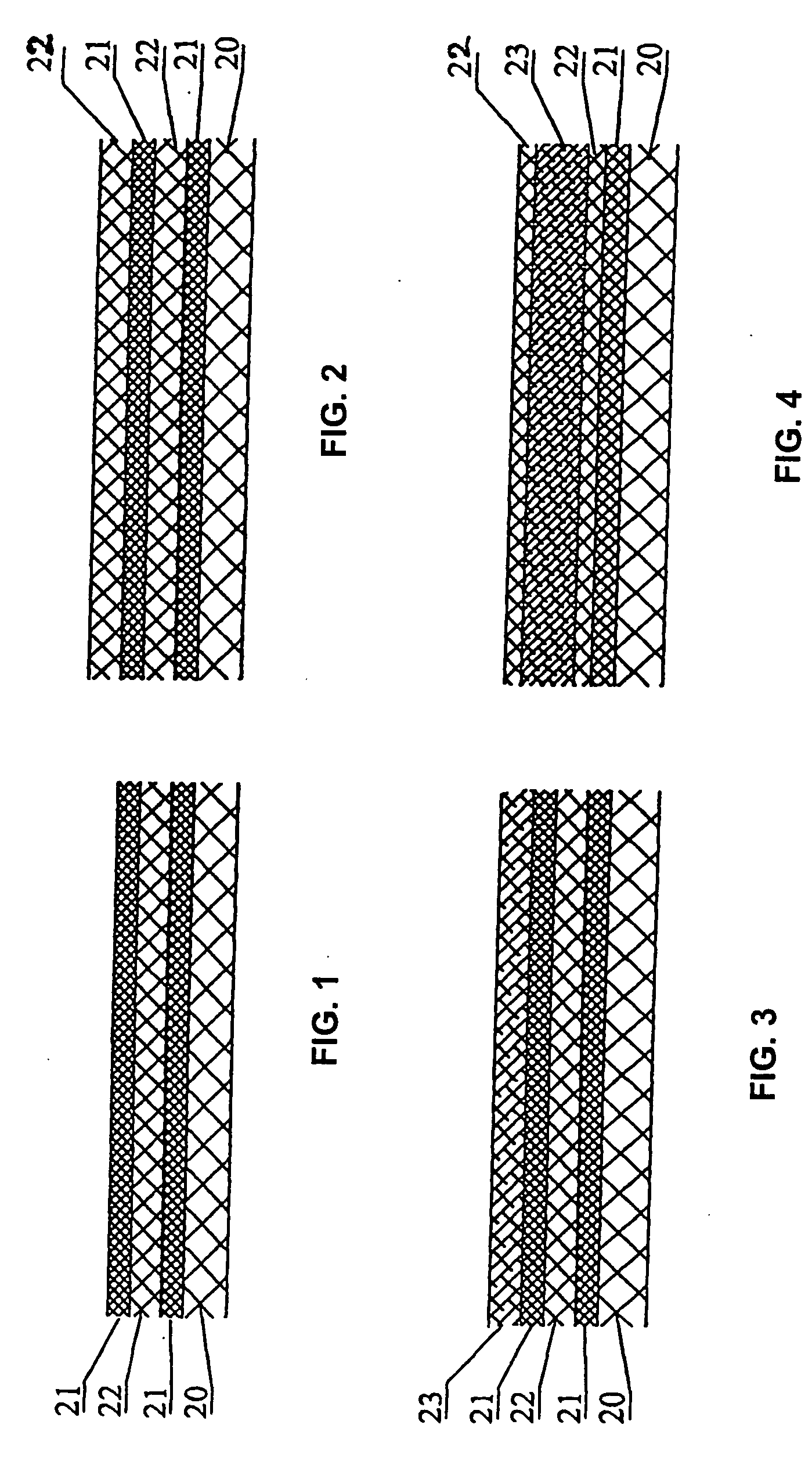

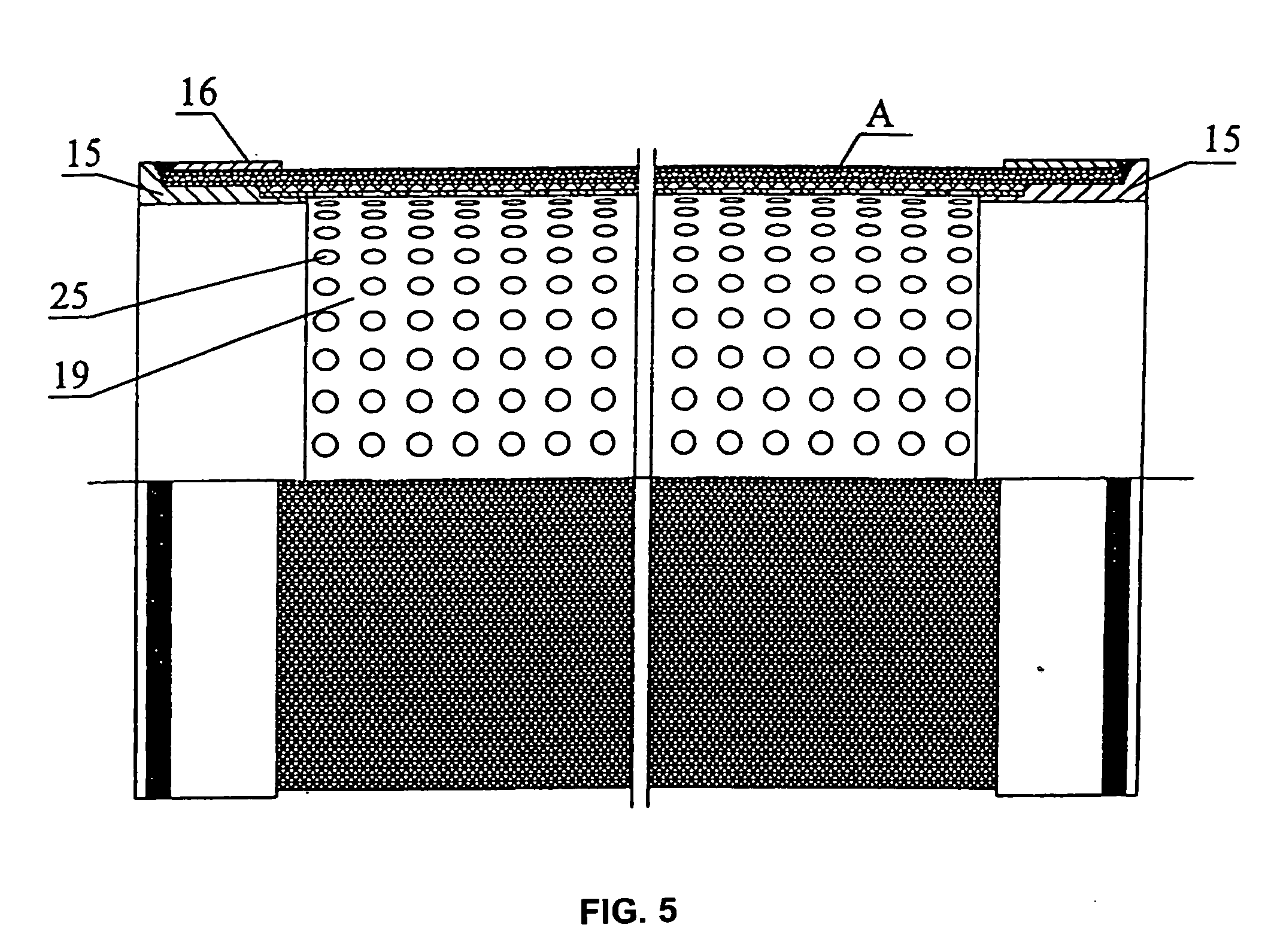

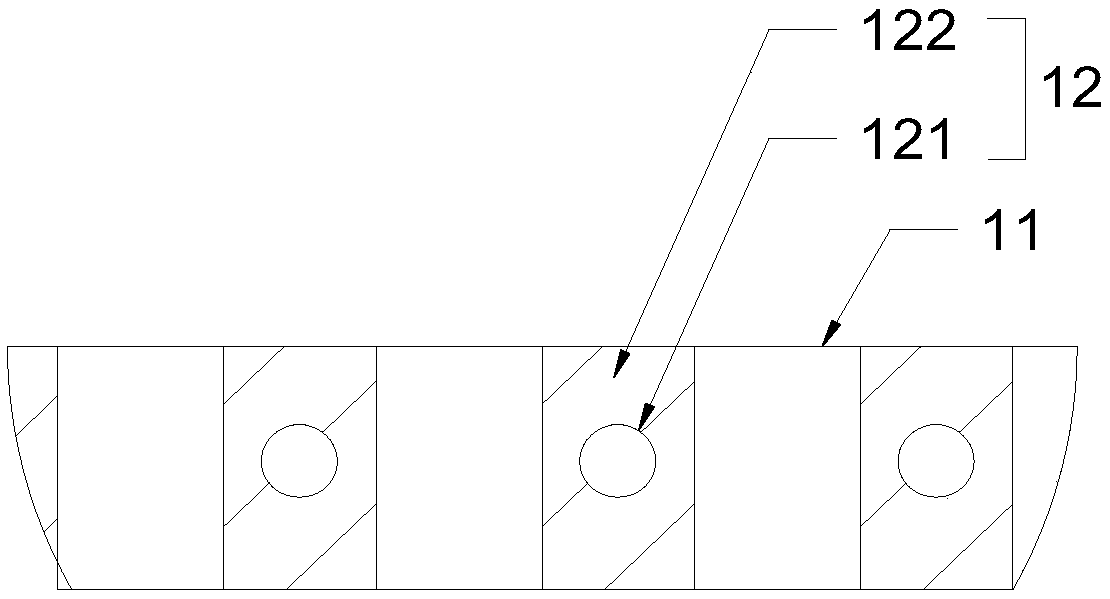

Composite filtering mesh, a sand control sleeve and a sand control screen pipe with the composite filtering mesh

InactiveUS20070114171A1Easy to controlLarge seeping flow areaFluid removalStationary filtering element filtersParticulatesPunching

The present invention discloses a filtering mesh for an oil well, a sand control sleeve and a sand control screen pipe using the filtering mesh. The filtering mesh at least comprises a bottom diffusion mesh (20) and one or more twill weave meshes (21) fixed on the bottom diffusion mesh (20); one or more twill weave meshes (21) are applied in filtrating solid particulates in a stratum fluid, and the bottom diffusion mesh (20) is applied in diffusing the filtrated fluid. The bottom diffusion mesh (20) is a woven mesh or a punching steel plate mesh with 5-50 meshes; the aperture of the twill weave mesh (21) is 40-400 micron. The present invention also relates to a sand control sleeve formed of the filtering mesh, a tubular inner protective shroud (19) and a supporting ring (15). This invention further relates to a sand control screen pipe formed of the filtering mesh, a multi-holes base pipe (1), a tubular inner protective shroud (19), an outer protective shroud (3) and a supporting ring (15).

Owner:BEIJNG HINEN HITECH PETROLEUM TECH DEV

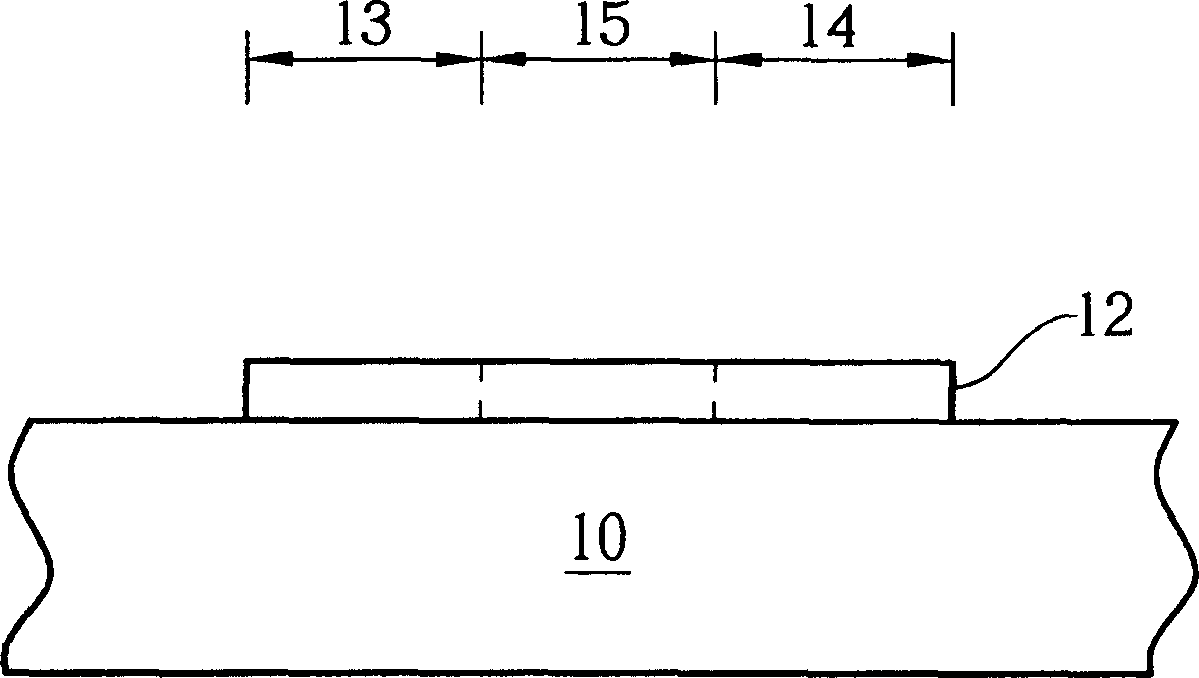

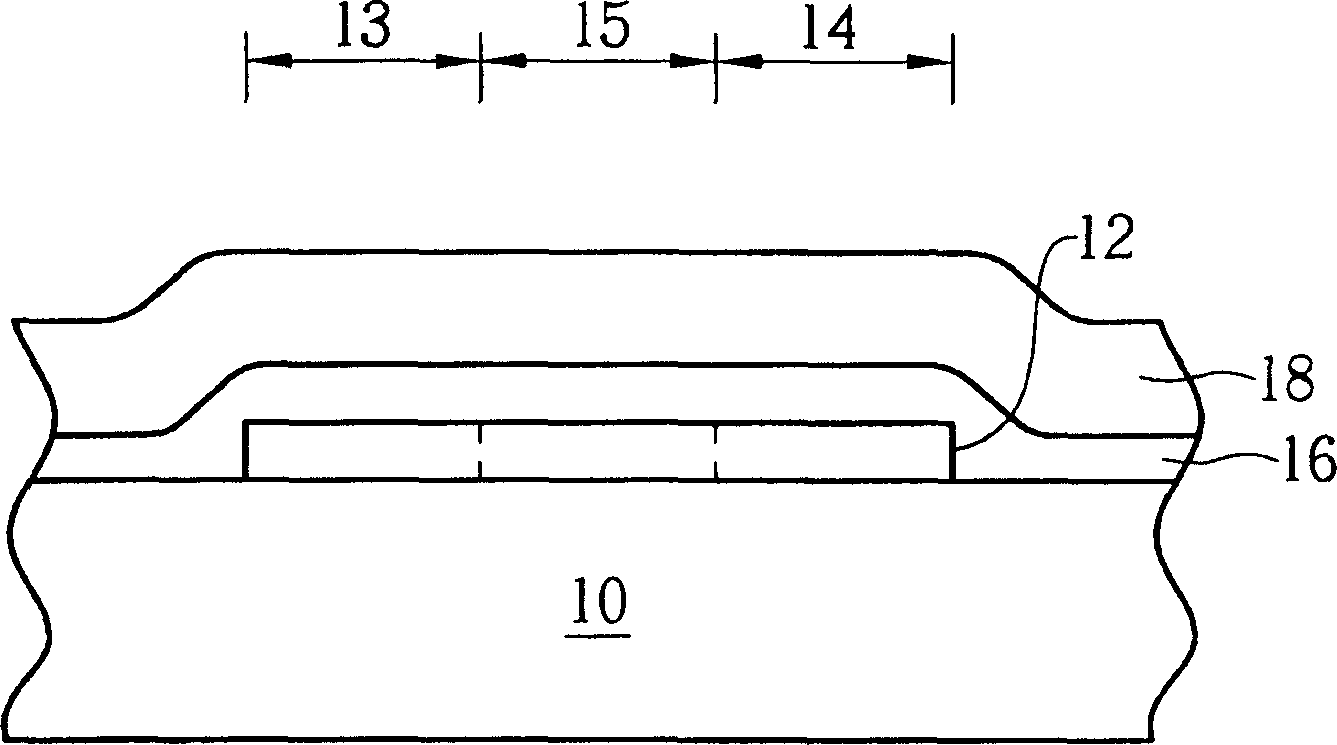

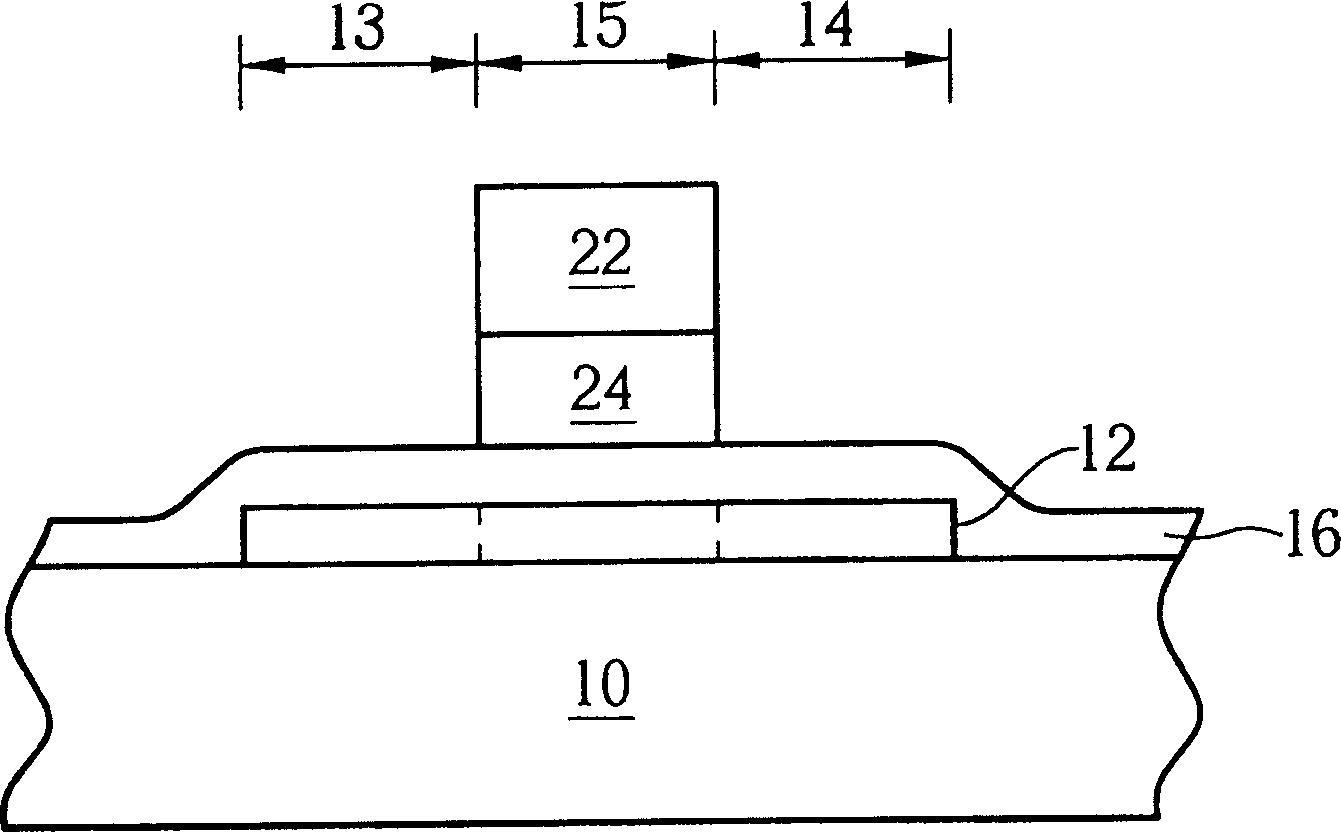

Method for manufacturing low-temperature polysilicon thin-film transistor

InactiveCN1567549AImprove moisture resistanceHigh dielectric strengthSemiconductor/solid-state device manufacturingGas phaseOptoelectronics

The invention relates to a method of making low temperature polycrystalline silicon thin film transistor (LTPS TFT), firstly forming a polycrystalline silicon layer containing a channel region, successively making first and second plasma enhancement chemical gas phase deposition procedures so as to in sequence form a silicon oxide layer with tetraethyl silicon hydroxide as the principal and a compound grid insulating layer composed of a silicon nitride layer, and finally forming a grid electrode and source / drain of the LTPS TFT.

Owner:TPO DISPLAY

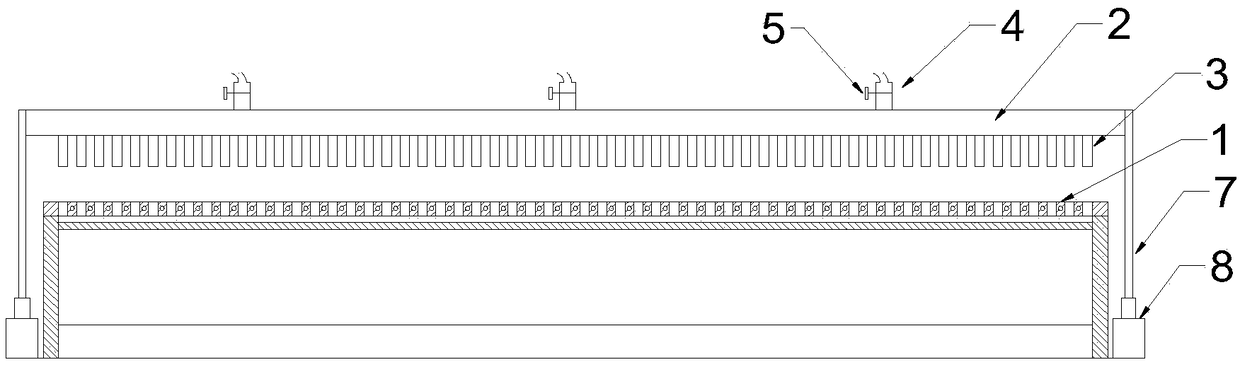

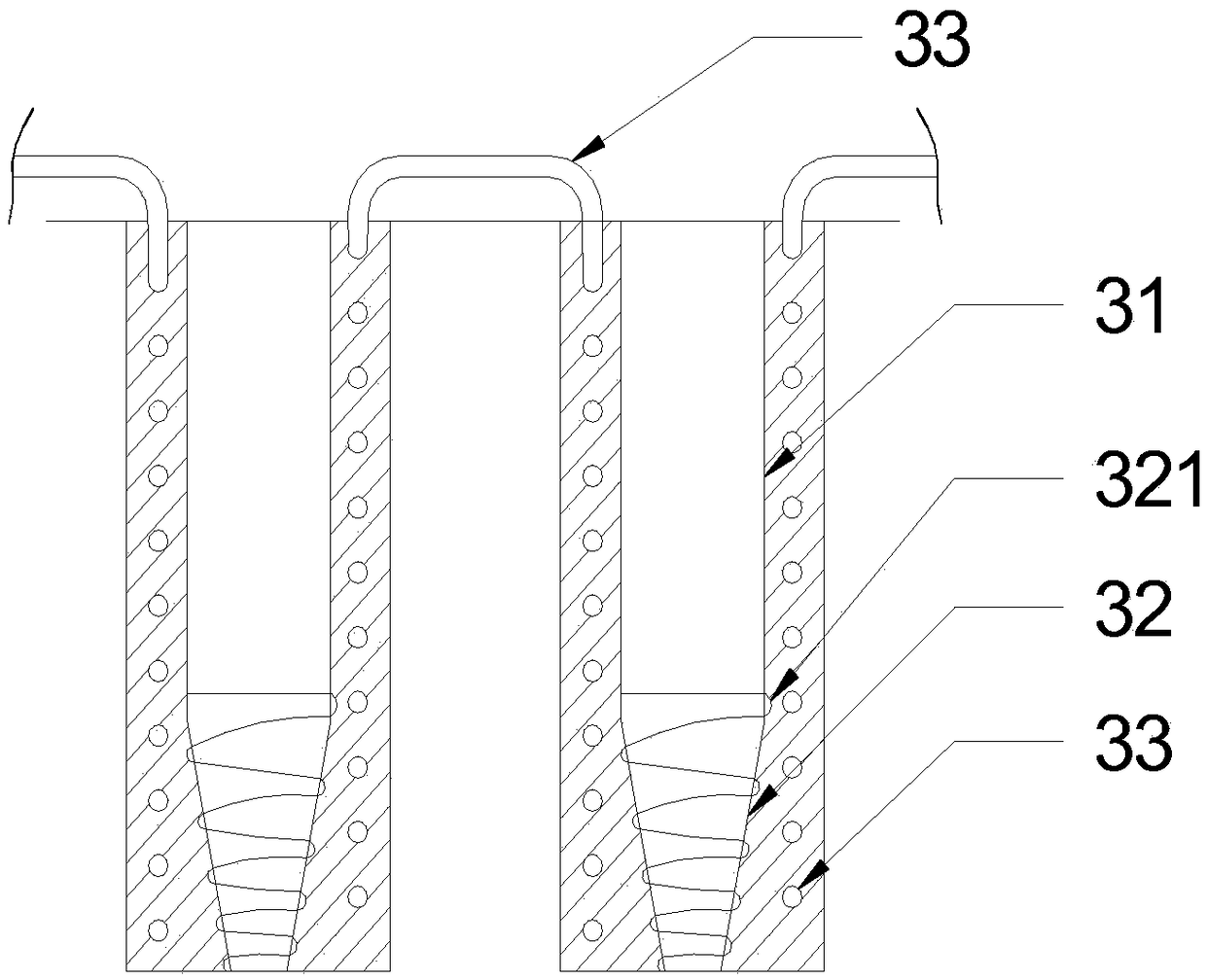

Sieve plate device preventing hole blocking in screening blind area

The invention provides a sieve plate device preventing hole blocking in a screening blind area. The sieve plate device comprises a compressed air system and a sieve body which are arranged sequentially from top to bottom. The sieve body comprises a sieve net provided with a plurality of sieve holes. The compressed air system comprises a flat air bag matched with the sieve net in shape. A pluralityof acicular air pipes corresponding to the sieve holes are arranged at the bottom of the air bag. Each acicular air pipe comprises an upper pipe end communicating with the air bag, and a lower pipe end communicating with the outside air, wherein the pipe hole of the upper pipe end is of a straight cylinder structure, and the pipe hole of the lower pipe end is of a wide-end-up conical structure. Aplurality of compressed air inlet pipes are arranged at the top of the air bag and are connected with outside compressed air pipelines. The compressed air system with the acicular air pipes is arranged above a sieve plate, the acicular air pipes blow air to the sieve holes of the sieve net to blow off viscous matter blocking the sieve holes, blocking prevention efficiency is high, and cost for cleaning the sieve net can be lowered effectively.

Owner:JIANGSU YIYIHEHUA SCREENING EQUIP CO LTD

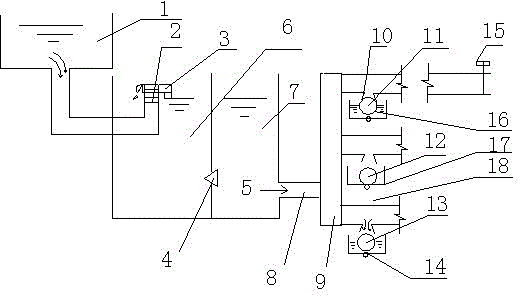

Pumpless float type constant and uniform low-pressure trickle irrigation device

InactiveCN102939888AStrong anti-blockingImproves irrigation uniformityWatering devicesCultivating equipmentsWater storage tankInlet valve

The invention discloses a pumpless float type constant and uniform low-pressure trickle irrigation device, which comprises a water delivery part, a pipe network part and a water dropper part, wherein the pipe network part consists of a main pipe, a branch pipe and a capillary; the water delivery part comprises a water storage tank and an adjustable main pipe water pressure adjusting mechanism; the adjustable main pipe water pressure adjusting mechanism comprises a water supplementing pipe, a slide water supplementing switch, a water transfer tank and a constant water level tank; an unidirectional inlet valve is arranged between the water transfer tank and the constant water level tank; one end of the water supplementing pipe is connected with the water storage tank; the other end of the water supplementing pipe is connected with the interior of the water transfer tank; the slide water supplementing switch is arranged in the water transfer tank and slidingly connected with the slide water supplementing pipe; and the water storage tank is arranged at the upper end of the water transfer tank. Compared with the prior art, the device does not adopt a water pump, but depends on the gravity flow to provide a continuous power source for trickle irrigation; the outflow rate of orifices are identical basically; and the device is excellent in anti-blocking performance and convenient to overhaul, saves water and energy and is appropriate for popularization in vast rural areas.

Owner:HOHAI UNIV

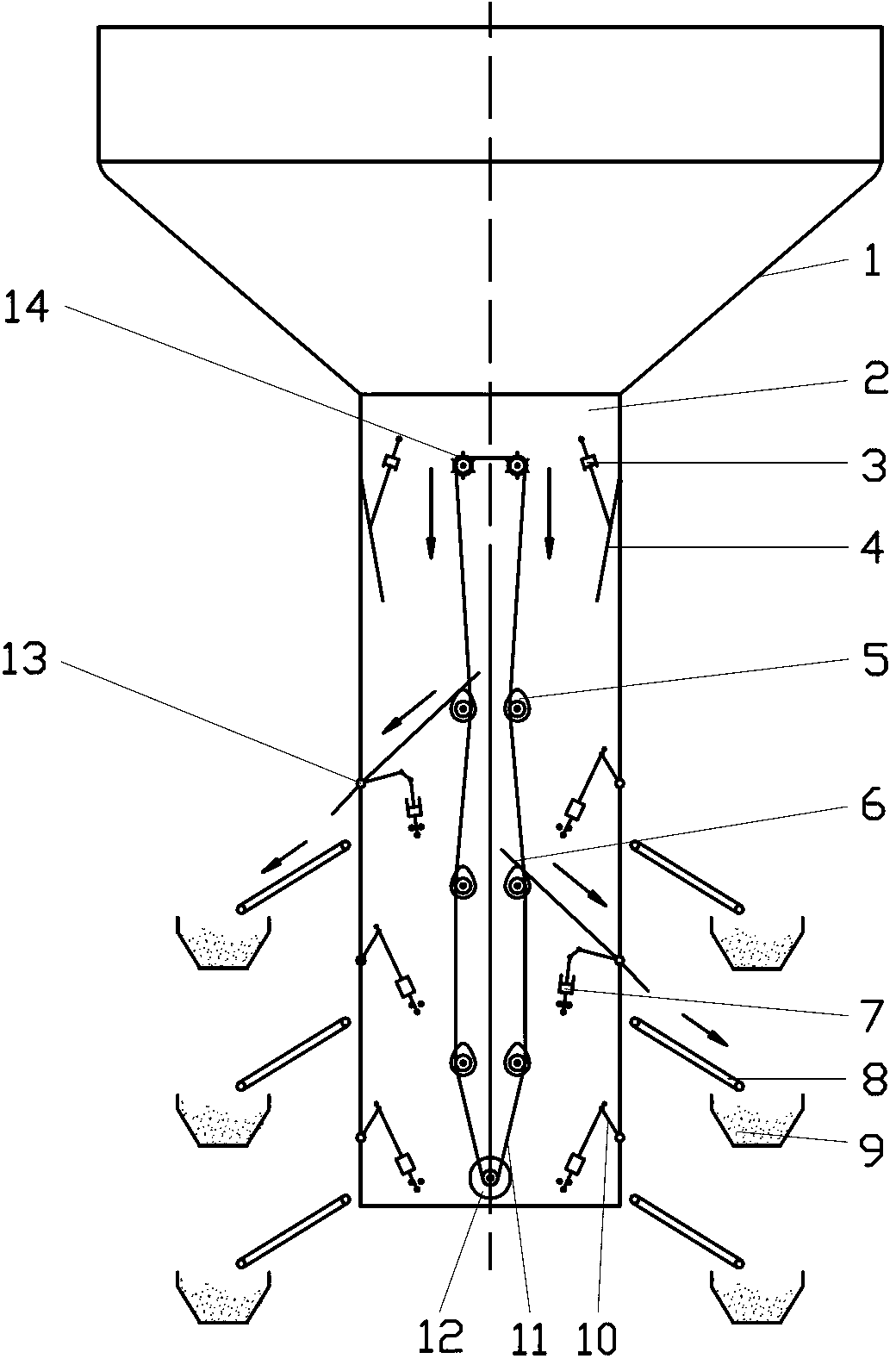

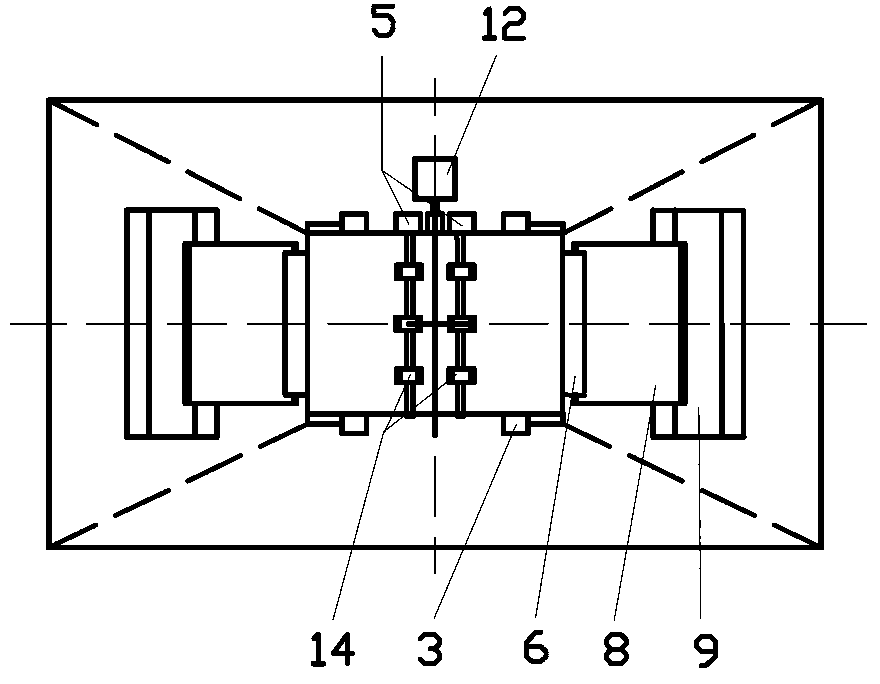

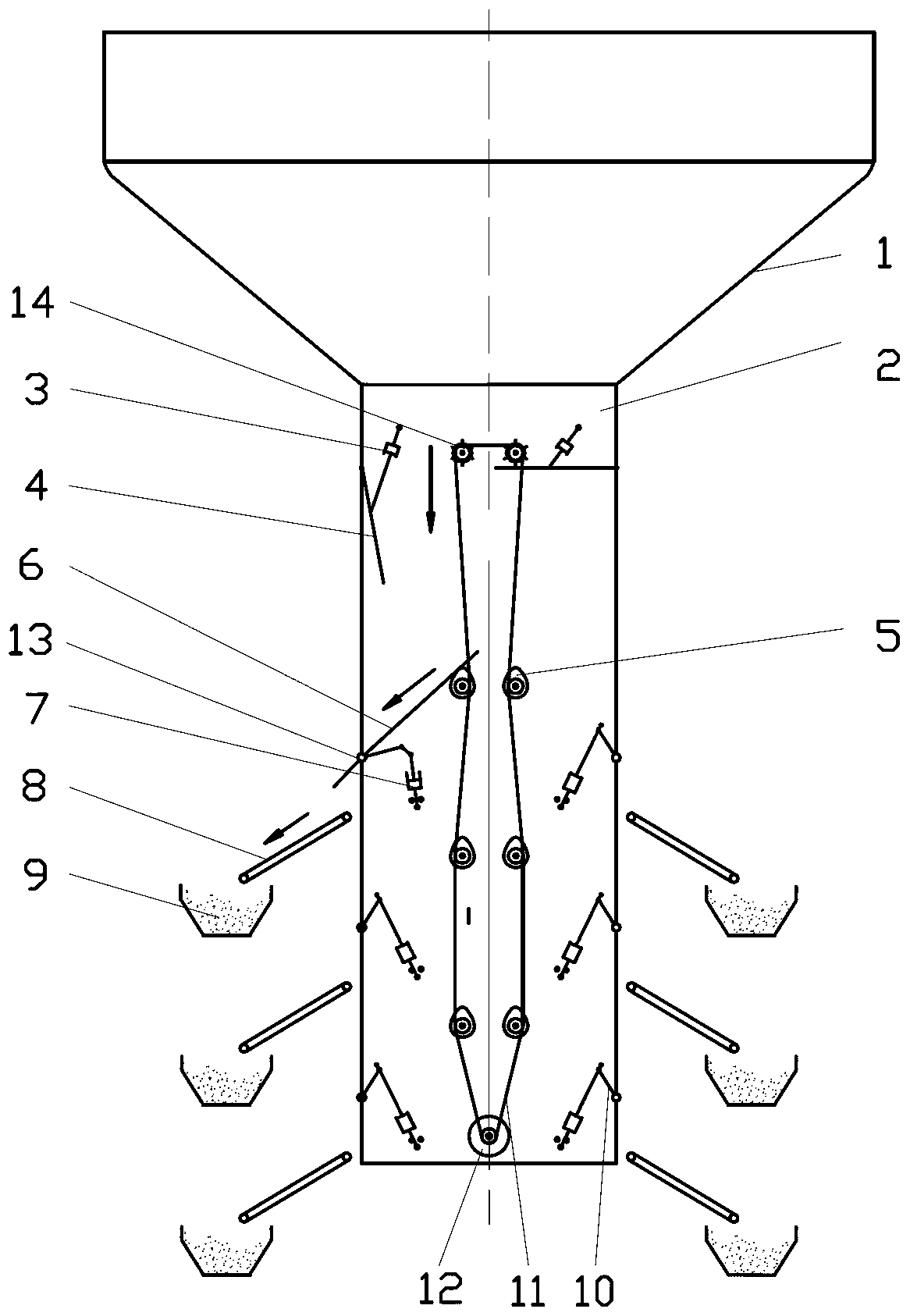

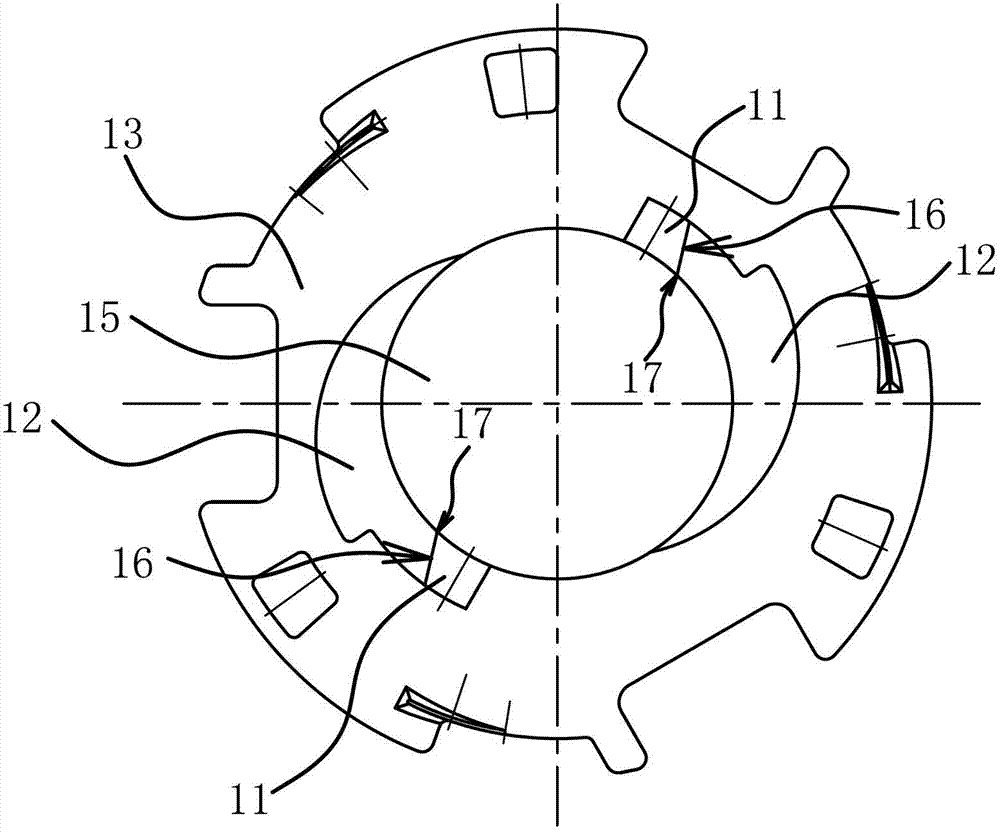

Automatic material dividing device with anti-blocking function

ActiveCN103256617AReduce in quantitySimple structureConveyor partsLump/pulverulent fuel feeder/distributionEngineeringThrough transmission

The invention discloses an automatic material dividing device with an anti-blocking function. A storage hopper is arranged at the top end of a material dividing box. A material blocking board is arranged at the lower end of a connecting part of the storage hopper and the material dividing box. Material stirring wheels are arranged at the upper end near a closing position of the material blocking board. The material blocking board is connected with a material blocking board driving device. Material dividing units are symmetrically arranged on two sides of the material dividing box. Each set of material dividing units comprises a cam mechanism, a material dividing board, a material dividing board dividing device, a conveyor belt and a small storage hopper. Positions of the cam mechanisms correspond to positions of the material stirring wheels. Each material dividing board is arranged on one side, near a box body of the material dividing box, of each cam mechanism. The material dividing board driving devices are connected with the material dividing boards. An opening is formed in a position, corresponding to the material dividing boards, of the material dividing box. The material dividing boards are arranged on rotary shafts arranged at the lower end of the opening of the material dividing box. The conveyor belts and the small storage hoppers are arranged around the opening. A variable frequency motor is arranged at the bottom end of the material dividing box, and is connected with the cam mechanisms and the material stirring wheels through transmission chains. A material storage function and the anti-blocking function are combined, and the automatic material dividing device with the anti-blocking function has the advantages of being capable of dividing materials continuously, high in efficiency and strong in anti-blocking ability.

Owner:NANJING UNIV OF SCI & TECH

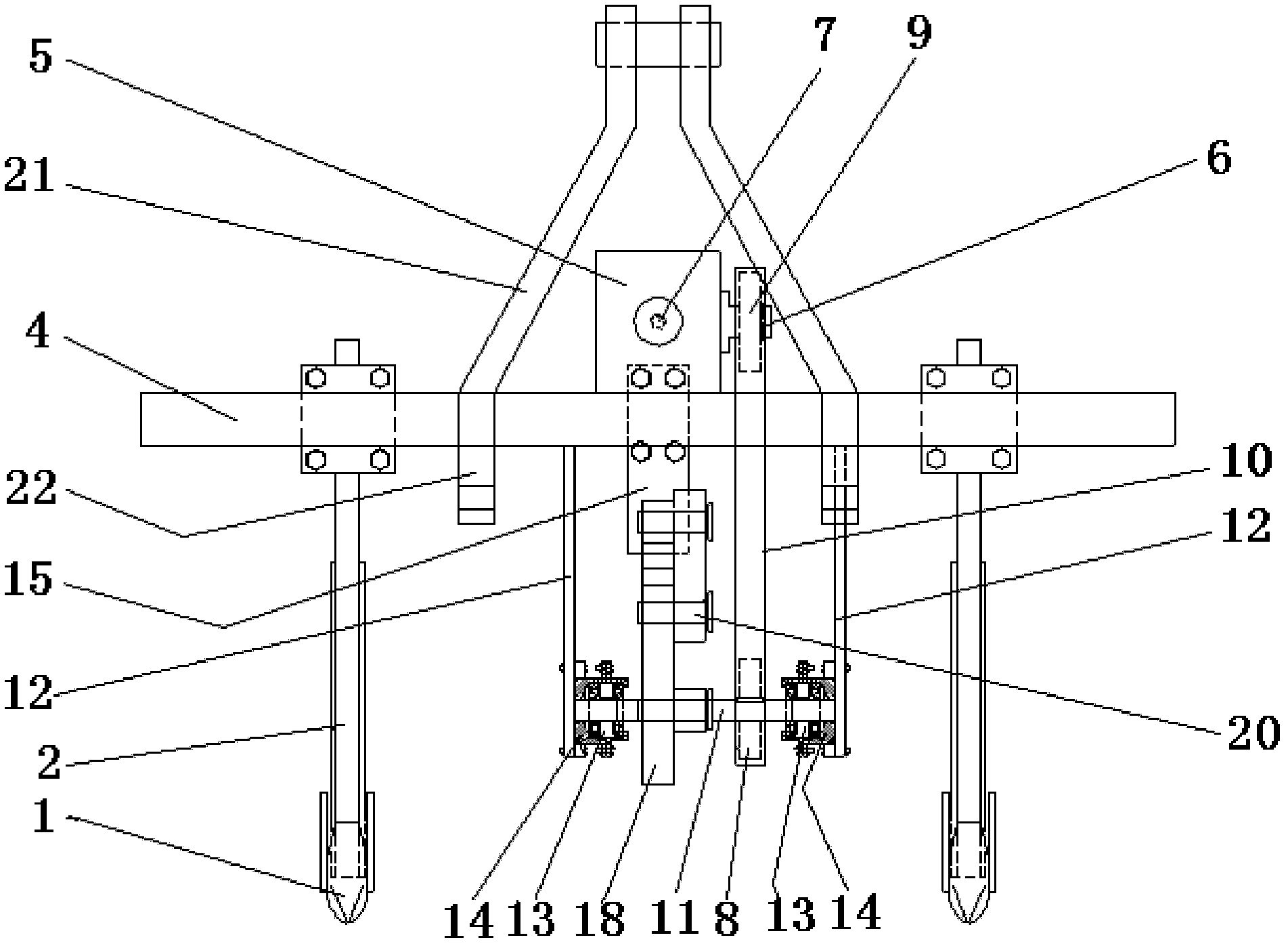

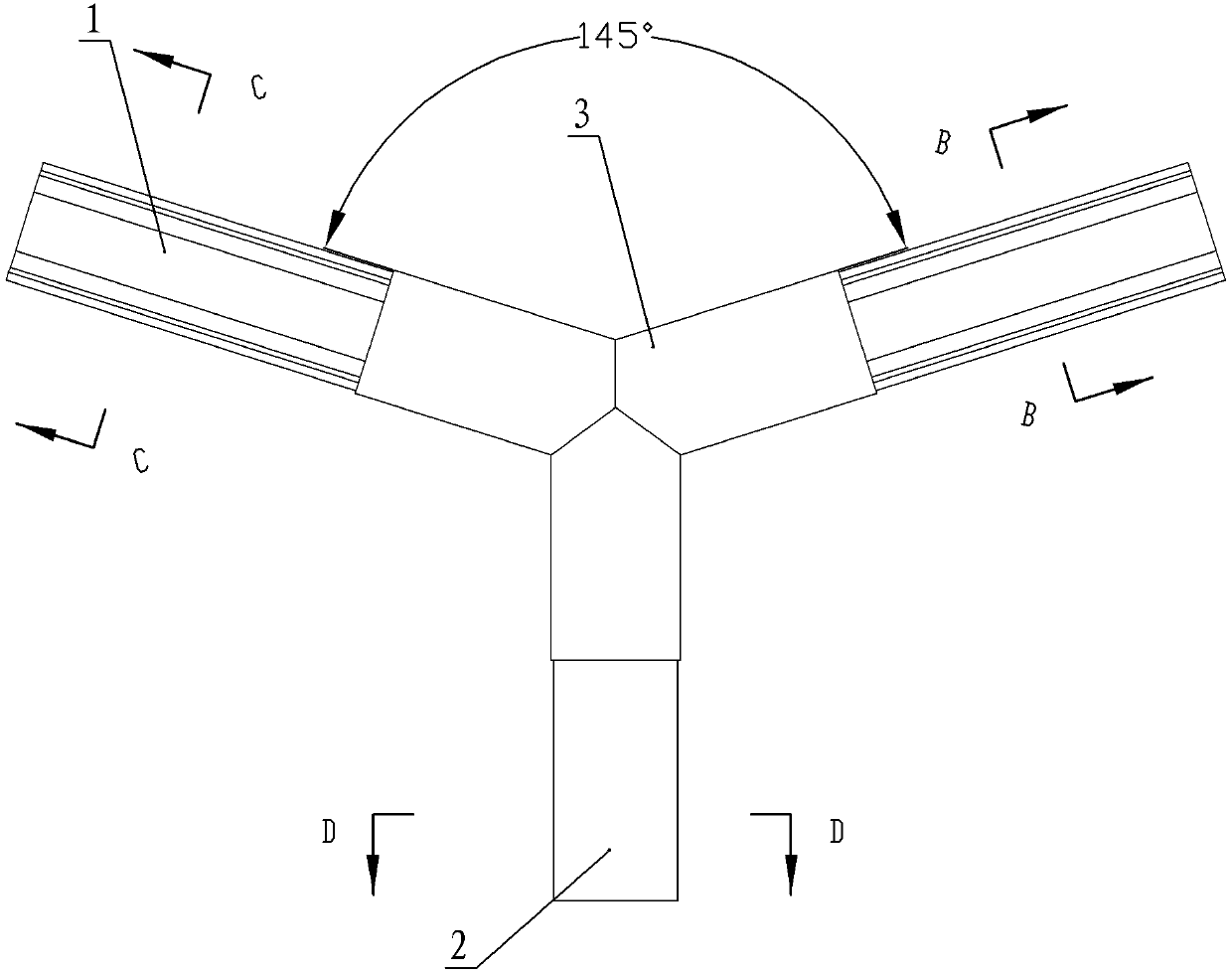

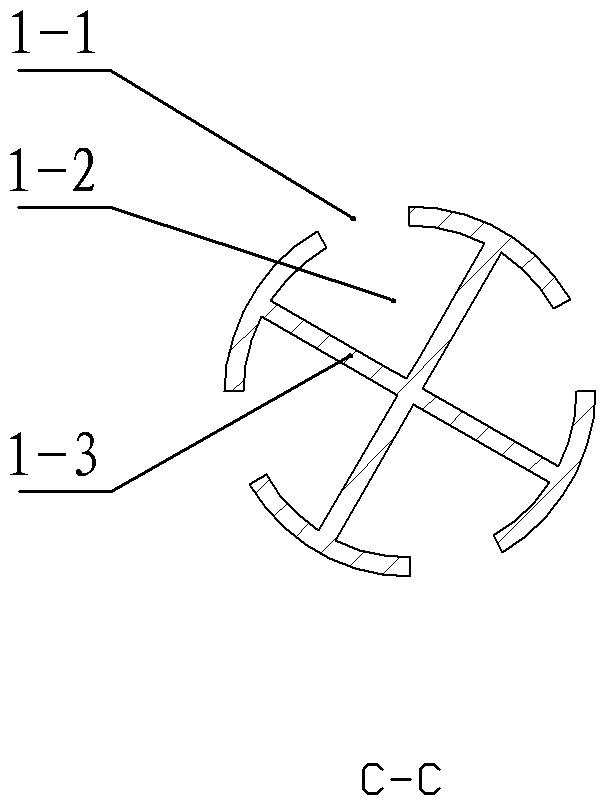

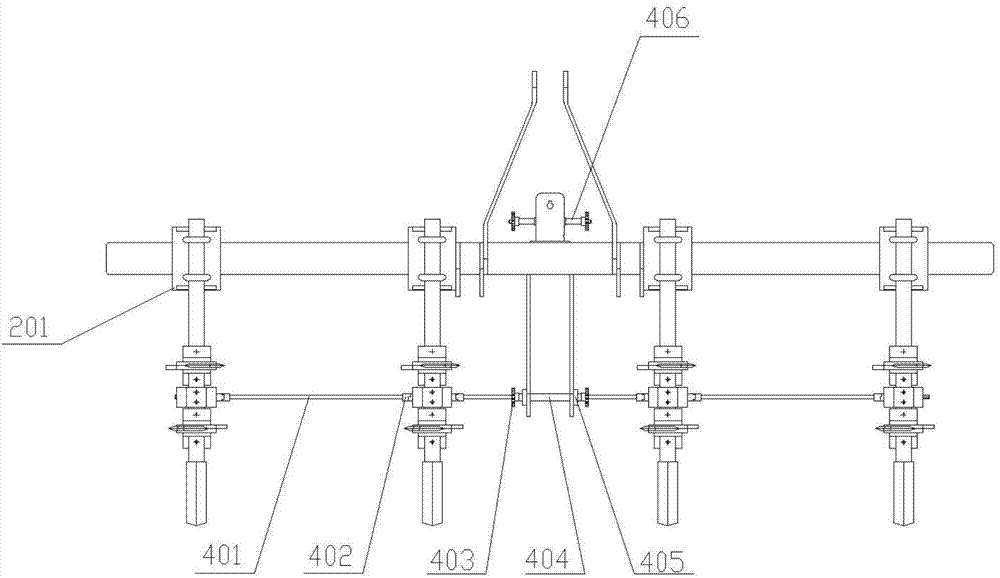

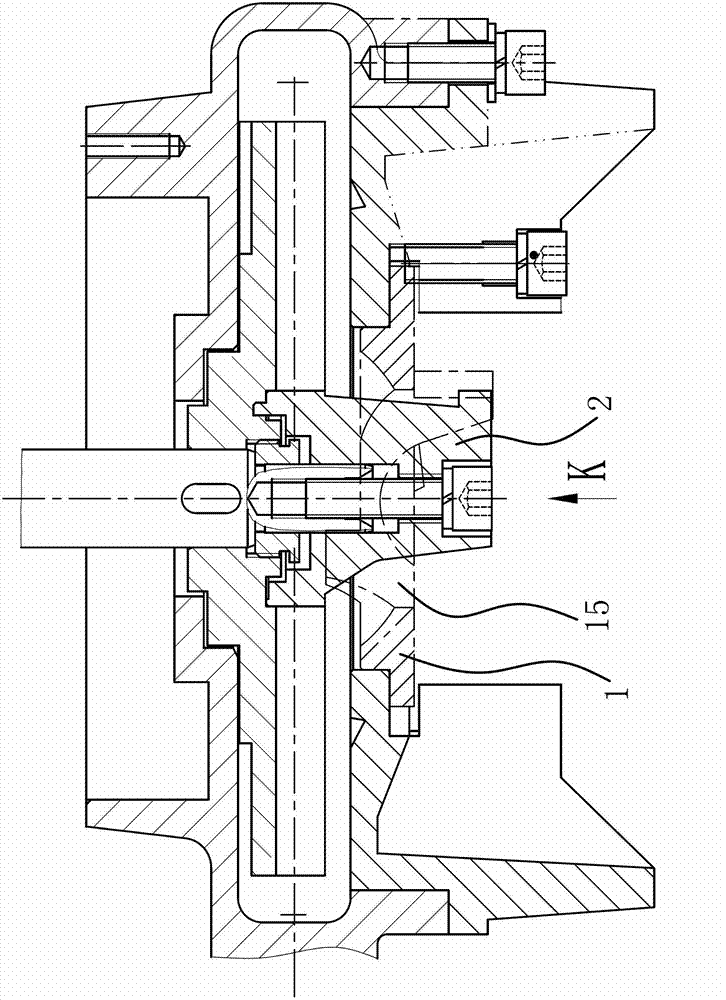

Active driving lever type anti-blocking mechanism

InactiveCN102197723ASimple structureReduce power consumptionSpadesPlantingReciprocating motionDrive shaft

The invention belongs to the technical field of agricultural machinery, and in particular relates to an active driving lever type anti-blocking mechanism. The active driving lever type anti-blocking mechanism comprises a rack, furrowing blades, a power transferring device and an anti-lockage device, wherein the furrowing blades are symmetrically fixedly connected on the rack; the power transferring device is arranged on the rack between the two adjacent furrowing blades; the power output by a tractor is transferred to the anti-blockage device arranged between the adjacent furrowing blades; the anti-blockage device comprises a three-connecting-rod moving mechanism which is formed by an anti-blockage device swinging arm, a connecting section of an anti-blockage device driving lever and an anti-blockage device rotating arm; the anti-blockage device driving lever is driven by a driving shaft of the anti-blockage device to reciprocate front and back or up and down so that straws between the adjacent furrowing blades is lifted to the part in back of the furrowing blades so as to achieve the active anti-blockage function. The active driving lever type anti-blocking mechanism disclosed by the invention has a simple structure; and the front end of the straw lifting section of the driving lever is not inserted into soil when the anti-blockage device driving lever reciprocates, therefore, the active driving lever type anti-blocking mechanism has the advantages of having low power consumption and high anti-blockage capacity, being capable of realizing no-tillage seeding in a condition of high straw coverage, being applicable to no-tillage corn seeding machines, and being beneficial to promoting the popularization of conservation tillage.

Owner:CHINA AGRI UNIV

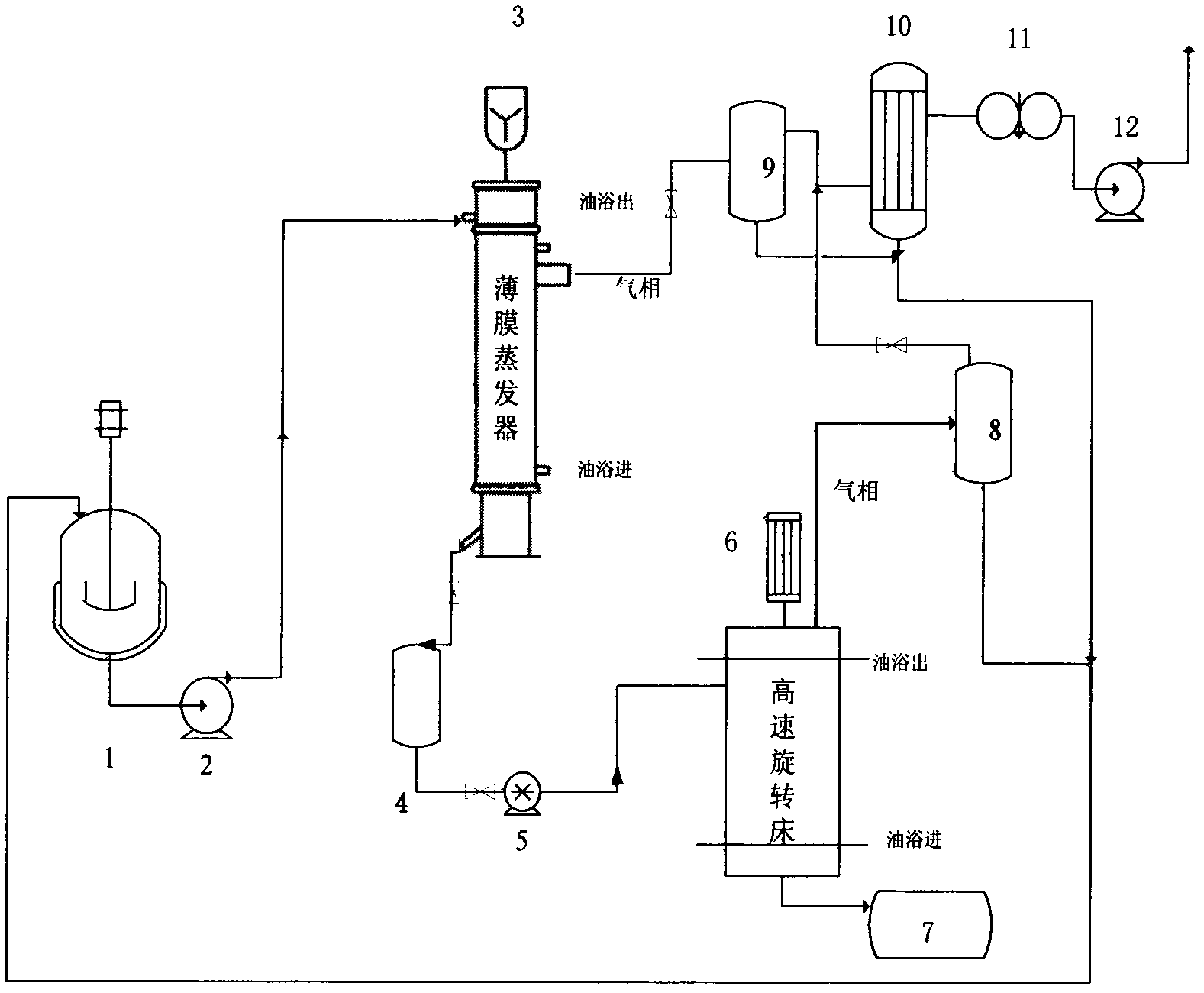

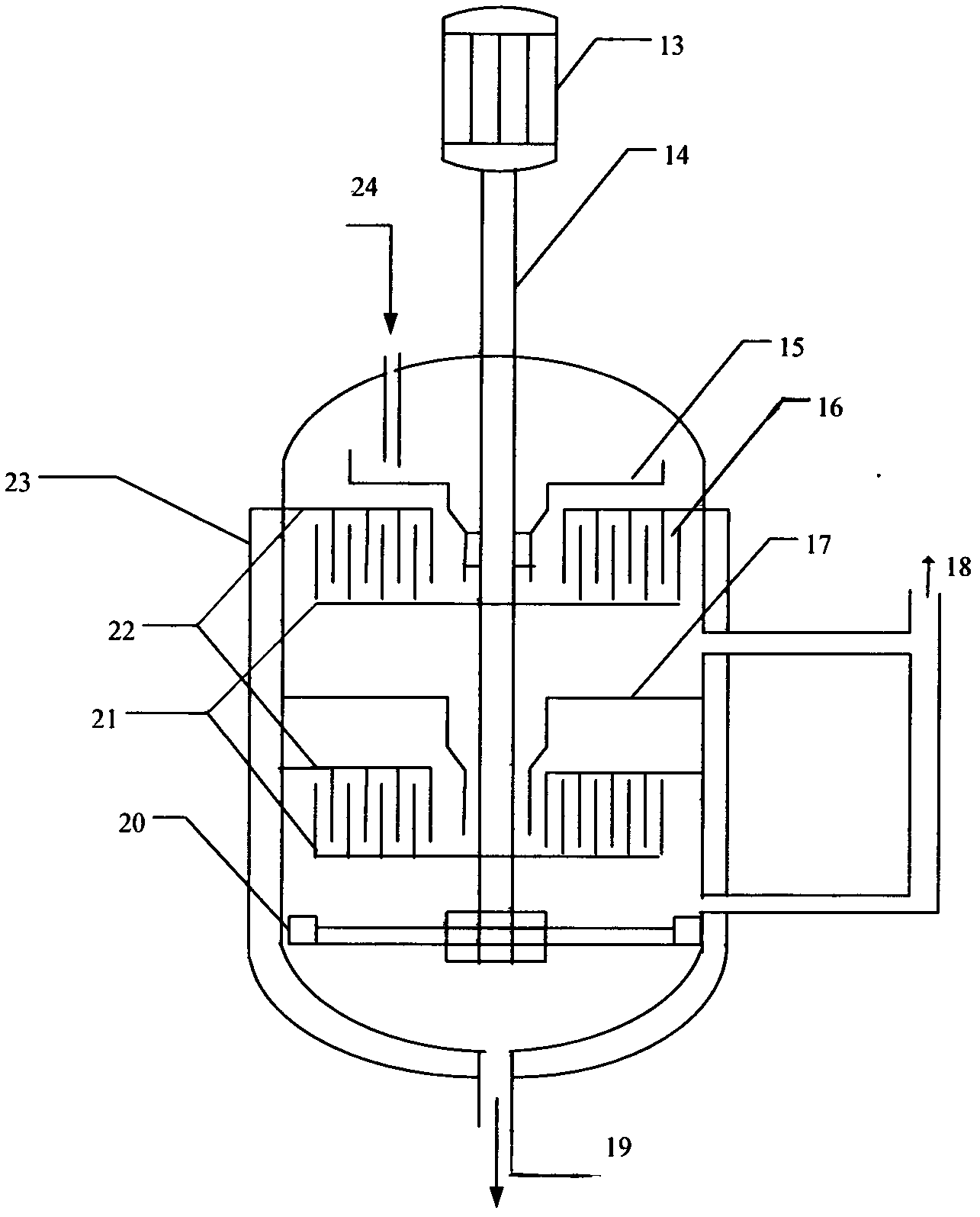

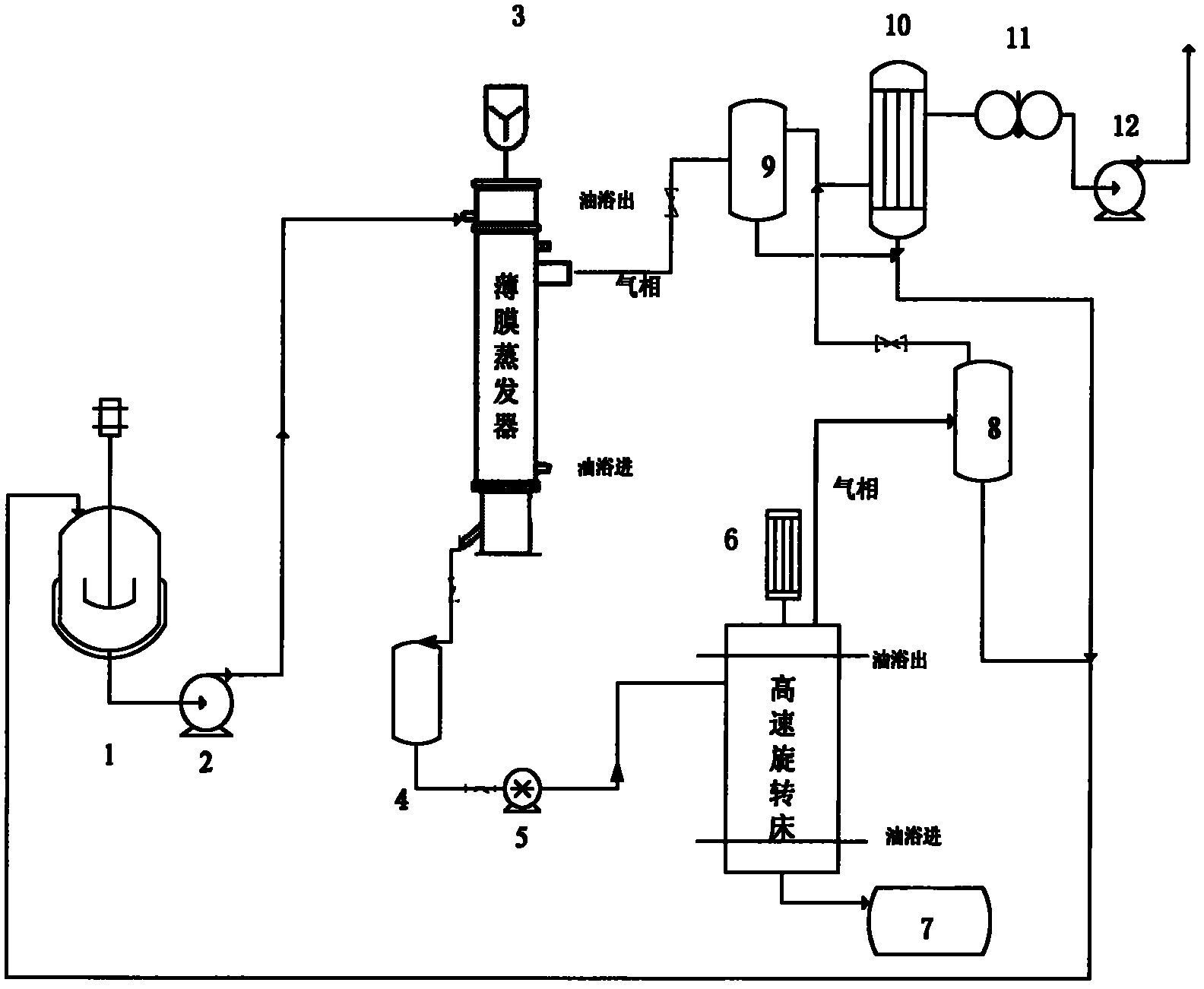

Method for preparing polyurethane curing agent

ActiveCN102432790ALarge amount of processingImprove gas-liquid mass transfer efficiencyUrea derivatives preparationOrganic compound preparationWeight distributionEvaporator

The invention discloses a method for preparing a polyurethane curing agent. The method comprises the following steps of: firstly, evaporating a curing agent obtained by polymerizing an isocyanate monomer through an external cold type film evaporator to remove part of free isocyanate monomer; and secondly, separating heavy components separated by the external cold type film evaporator through a high-speed rotary bed to obtain a product with lower free monomer content, wherein the content of the free isocyanate monomer is 0.05-0.6 percent by weight. The method disclosed by the invention has theadvantages of small size of equipment, high separation speed, high quality of products, high recovery rate of the monomer, capability of meeting the requirements of environmental friendliness, relatively low requirement on filed and little investment. According to the method, the content of the free isocyanate monomer in the polyurethane curing agent is reduced without remarkably increasing the relative molecular weight and molecular weight distribution of polyisocyanates and the downstream application is facilitated.

Owner:WANHUA CHEM GRP CO LTD +1

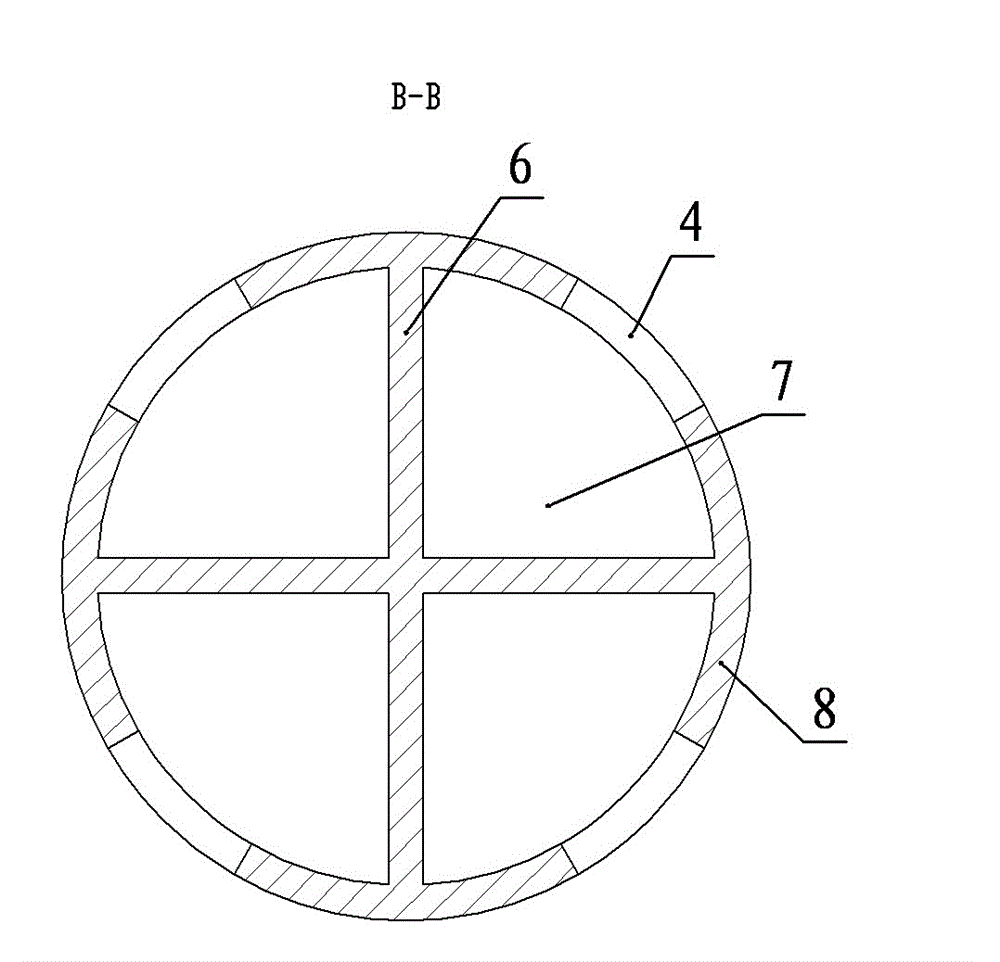

High-flow anti-blocking Y-shaped drainage guide pipe

The invention relates to a high-flow anti-blocking Y-shaped drainage guide pipe. The guide pipe is in a shape similar to Y shape, and comprises two groove pipe sections, a sealed pipe section and a tee, wherein the tee is connected with the groove pipe sections and the sealed pipe section. The guide pipe is characterized in that the interior of each groove pipe section is provided with support bodies which are arranged in a radial form, each groove pipe section is divided into N drainage passages by the support bodies, the cross section of each drainage passage is a fan area, the outer wall of each groove pipe section is provided with N strip groove ports used as drainage ports corresponding to the fan areas, the interior of the sealed pipe section is provided with N ribs, the axial center of each rib is convex, and N is greater than or equal to 3. The high-flow anti-blocking Y-shaped drainage guide pipe has the advantages that the flow quantity is high; the sealed pipe section is provided with the ribs, and after the sealed pipe section is bent, the flow through capability is also realized, and the anti-blocking performance is high; the strip groove ports are used as the drainage ports, so the flow through capability is high, and especially for helical strip groove ports, the flow through capability is higher; by additionally arranging a center pipe, a flushing hole and a flushing liquid supply pipe, the flushing capability is realized, and the groove pipe can be applied to the occasions requiring flushing and drainage.

Owner:郑州迪奥医学技术有限公司

Grid packing and packing structure

InactiveCN101623617AReduce resistanceHigh porosityChemical/physical/physico-chemical processesTwo gridTower

The invention relates to grid packing and a packing structure. The grid packing comprises a plurality of grid plates which are arranged in parallel; each grid plate is provided with more than two through holes; a pipe spacer is arranged between every two grid plates; pull rods in a number corresponding to the number of the through holes alternately penetrate through the grid plates and the pipe spacers; both ends of each pull rod are provided with fastening pieces so that the grid plates and the pipe spacers are connected into a whole; each pull rod is a screw with threads at both ends; and each fastening piece is a nut which is in threaded connection with the screw. The packing structure applied to a packing tower comprises a plurality of layers of grid packing which is arranged vertically; the grid plates of the grid packing are perpendicular to the cross section of the packing tower, and two vertical adjacent layers of the grid packing are staggered and arranged at 45 degrees. The grid plates of the grid packing have small thickness, smooth surfaces, stable integrity, large specific surface area in use, strong anti-clogging capability, little resistance and long service life, thereby being practical, high-efficiency and energy-saving packing.

Owner:HANGZHOU HUANA TOWER TECH

High-flow anti-blockage drainage pipe

The invention relates to a high-flow anti-blockage drainage pipe comprising an outer slotted pipe section, a closed pipe section and a transition section which connects the two pipe sections; the inside of the slotted pipe section is a drainage channel in which radial support bodies divide the cross section of the pipe into N sector areas; the outer wall of the pipe body is provided with N strip-shaped notches which correspond to the sector areas as drainage ports; N ribs which are protruded to an axis are arranged in a closed pipeline; and in the transition section, the ribs are connected with the support bodies, and N is more than or equal to 3. The drainage pipe has high flow, the ribs are arranged in the closed pipeline, and the high-flow anti-blockage drainage pipe has flow capacity and high anti-blockage performance after being bent.

Owner:郑州迪奥医学技术有限公司

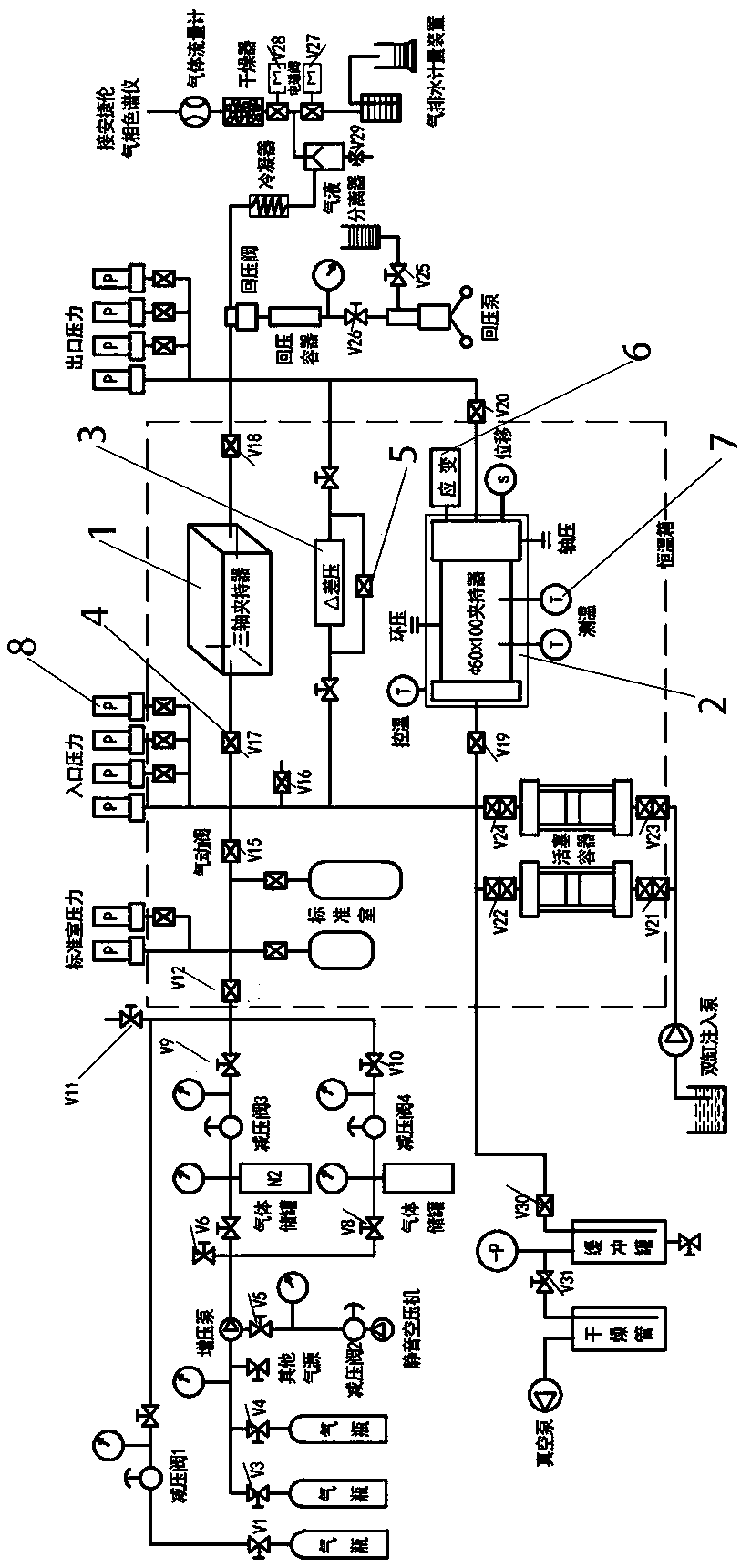

Rock and gas multi-process coupling test device for unconventional natural gas

InactiveCN108318666AGuaranteed measurement accuracySolve the accuracy problemEarth material testingDifferential pressureEngineering

The application provides a rock and gas multi-process coupling test device for unconventional natural gas, the device is characterized by comprising a first clamping mechanism, a second clamping mechanism and a differential pressure sensor, wherein pipelines at both ends of the first clamping mechanism and the second clamping mechanism are provided with first electromagnetic valves; pipelines at both ends of the differential pressure sensor are provided with manual valves; the differential pressure sensor 3 is connected in parallel with a second electromagnetic valve. The aim of designing anddeveloping the device is that the system can carry out a true triaxial experiment on shale carbonaceous, the system finds out a relationship of permeability of a coalbed methane reservoir in the developing process and an effective stress element and can reasonably determine a development mode of coalbed methane.

Owner:JIANGSU TUOCHUANG SCI INSTR CO LTD

Bidirectional water flow channel

InactiveCN102550366AEliminate energyStrong water flow turbulenceWatering devicesCultivating equipmentsWater flowEngineering

The invention discloses a bidirectional water flow channel, which comprises a base plate, wherein a water inlet is arranged at the front section of the base plate; a water outlet is arranged at the rear section of the base plate; a water baffle outer side wall is symmetrically arranged at the left side and the right side of the base plate in parallel; a first water dividing plate, a second water dividing plate and a water baffle piece are arranged on the base plate and between the two water baffle outer side walls; the first water dividing plate and the second water dividing plate are symmetrically arranged left and right at intervals to form a splayed water dividing piece; the water baffle piece is V-shaped and is arranged at the rear part of the water dividing piece at intervals; the openings of the water dividing piece and the water baffle piece both face the direction of the water inlet; water flowing channels are formed between the outer wing of the first water dividing plate and the outer side wall of the water baffle plate, between the outer wing of the second water dividing plate and the outer side wall of the water baffle plate, and between the outer ring of the water baffle piece and the outer side wall of the water baffle plate; and the symmetric lines of the water dividing piece and the water baffle piece are both coaxial with the center line of the base plate. The bidirectional water flow channel is simple in structure, stable in flow, strong in anti-blocking performance, small in manufacturing deviation, low in production cost and long in service life.

Owner:XIAN UNIV OF TECH

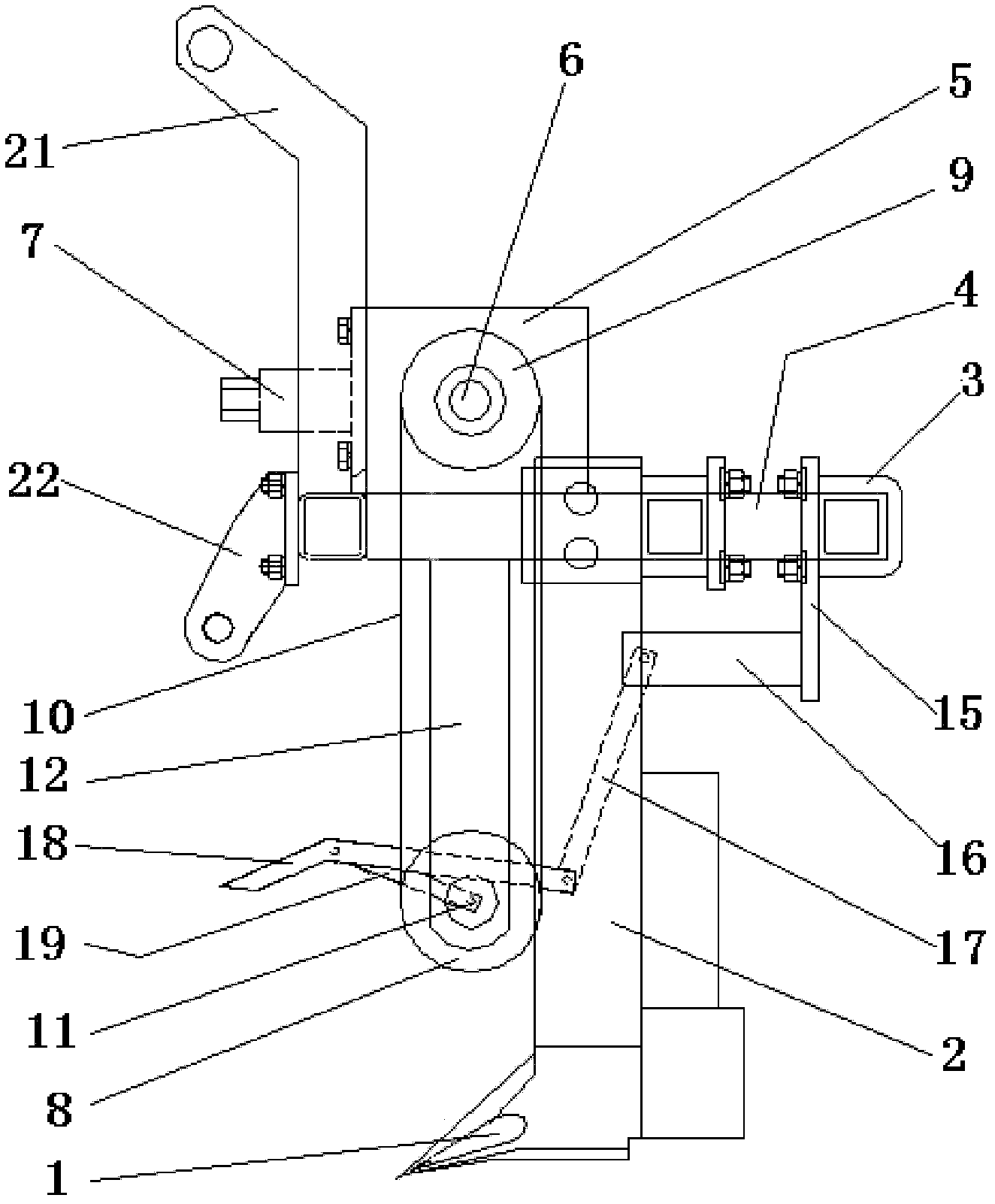

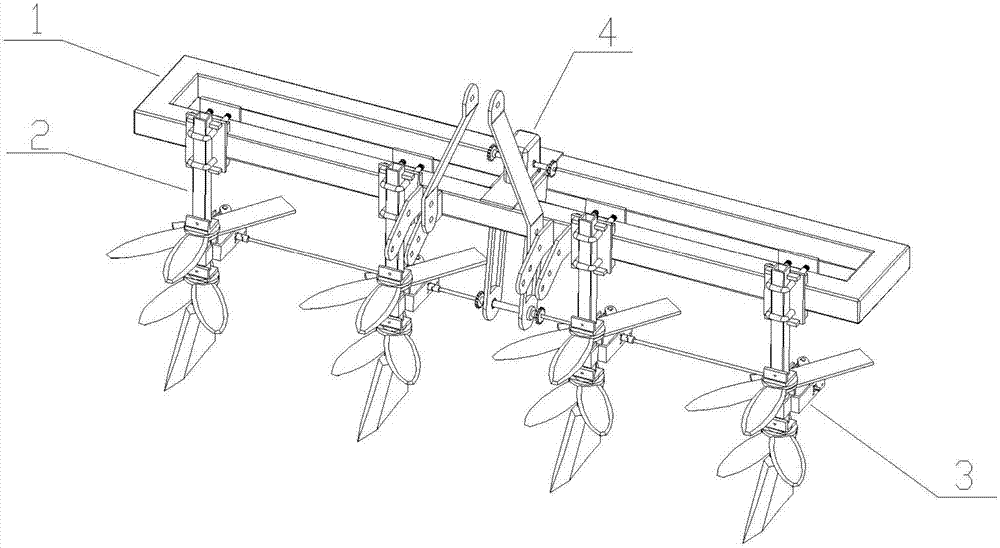

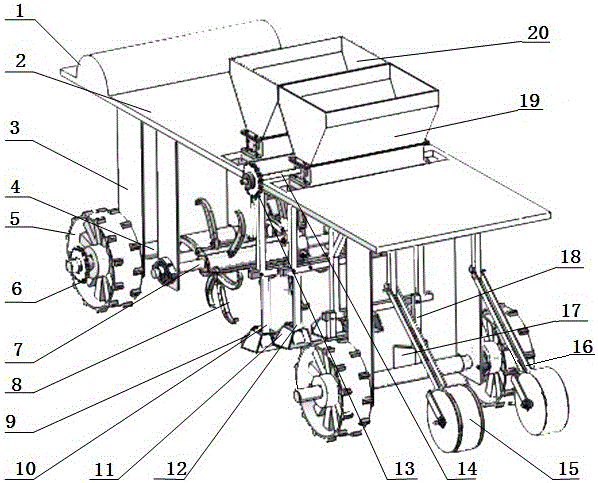

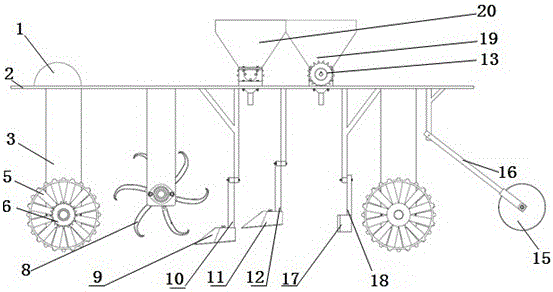

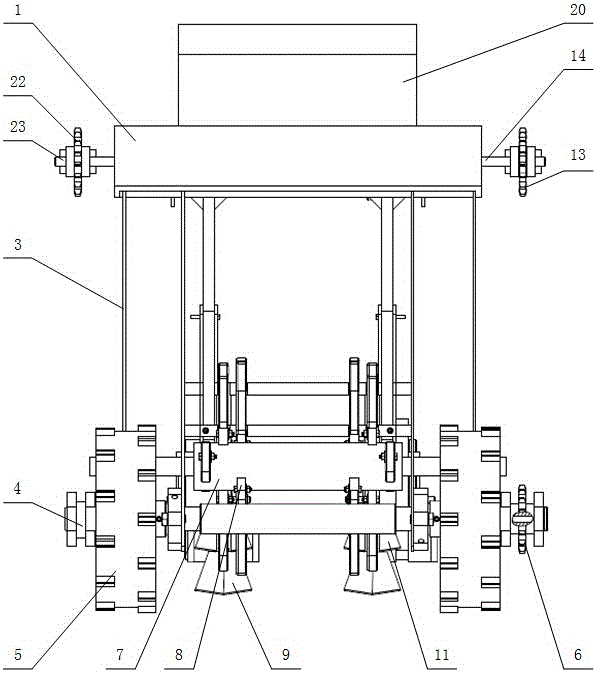

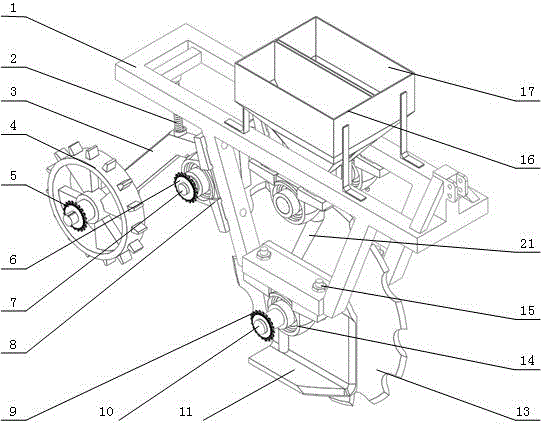

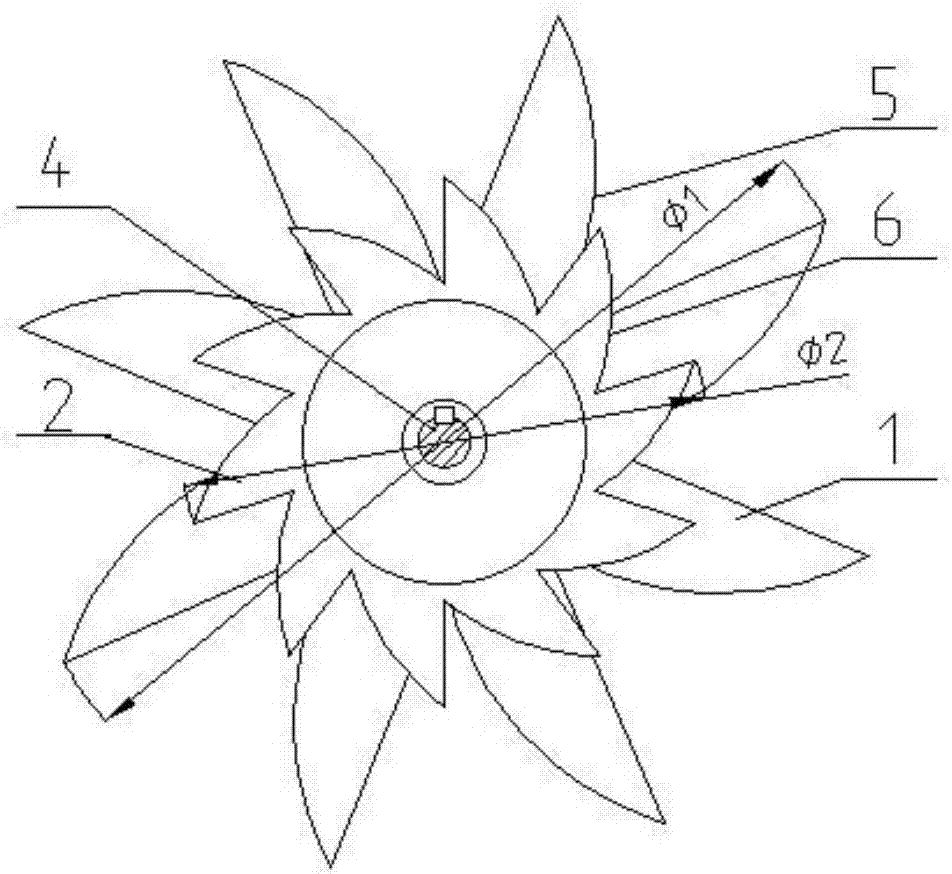

Horizontal partitioning no-tillage anti-blocking device

ActiveCN104770113AStrong shear forceStrong anti-blockingPlantingFurrow making/coveringAgricultural engineeringAgricultural machinery

The invention belongs to the technical field of agricultural machinery, and particularly relates to a horizontal partitioning no-tillage anti-blocking device. The anti-blocking device comprises a frame and a plurality of ditchers fixedly connected to the frame, wherein a horizontal partitioning anti-blocking apparatus is arranged on a handle of each ditcher; each horizontal partitioning anti-blocking apparatus comprises an upper double-edge stationary knife and a lower double-edge stationary knife which are fixed on the handle of the ditcher, and double-edge moving knives driven by a power transmission device and matched with the two double-edge stationary knives respectively; and the two double-edge moving knives can rotate to and fro within a certain range, and are matched with the double-edge stationary knives to complete cutting. The moving and stationary knife mechanism can be used for cutting straws in front of the ditchers, and when straws cannot be fed, the upper and lower moving knives can rotate outwards oppositely to push weed and straws in front of the ditcher to two sides of the ditchers, so the anti-blocking device has strong anti-blocking capability and can realize no-tillage sowing under large coverage of straws.

Owner:CHINA AGRI UNIV

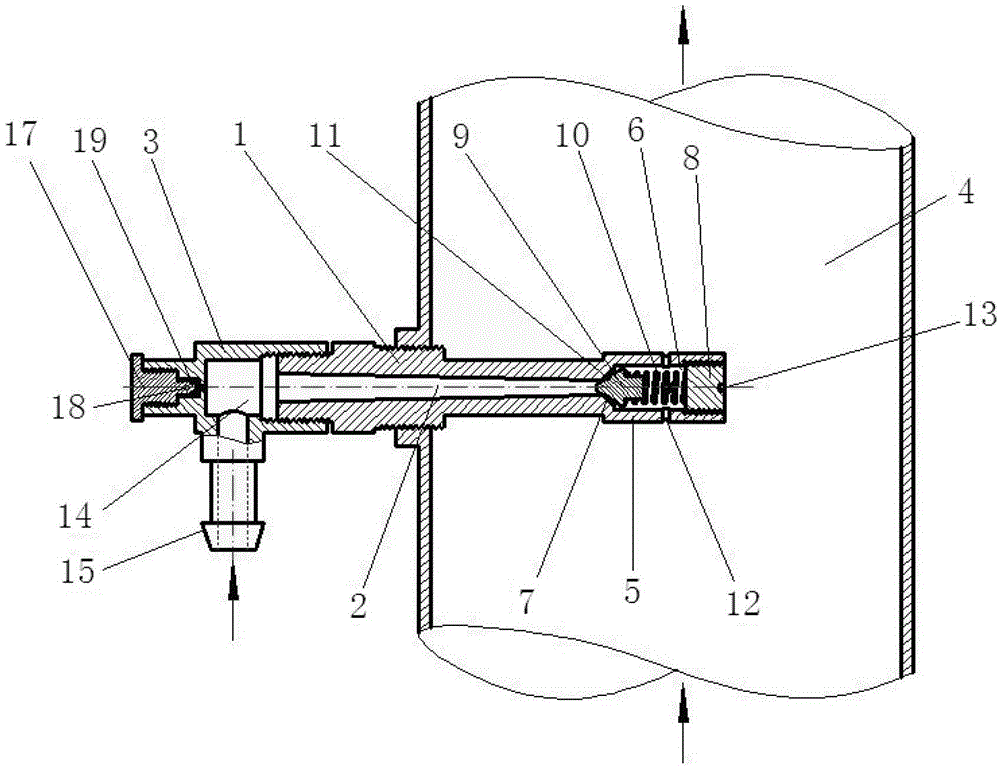

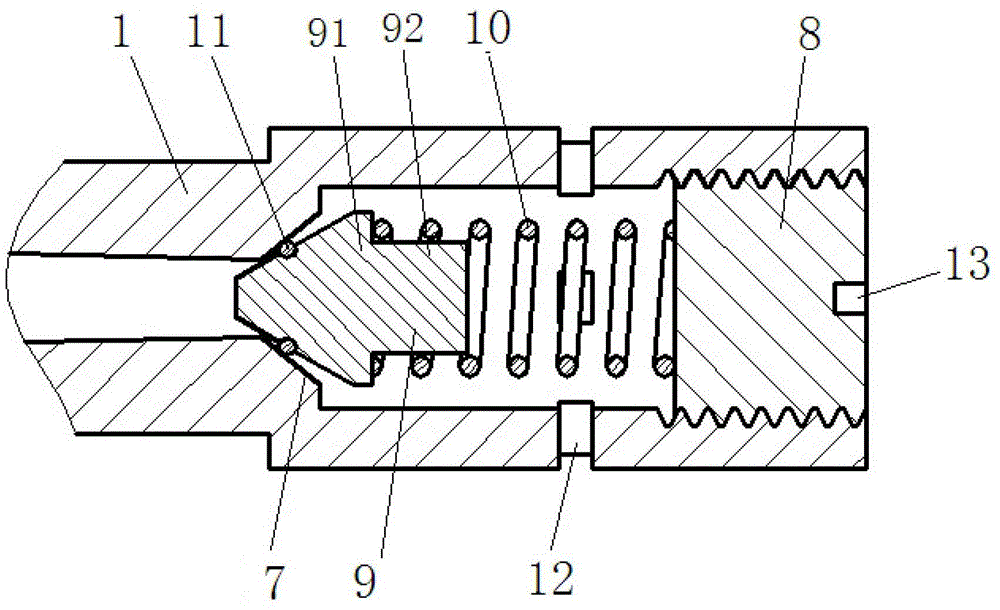

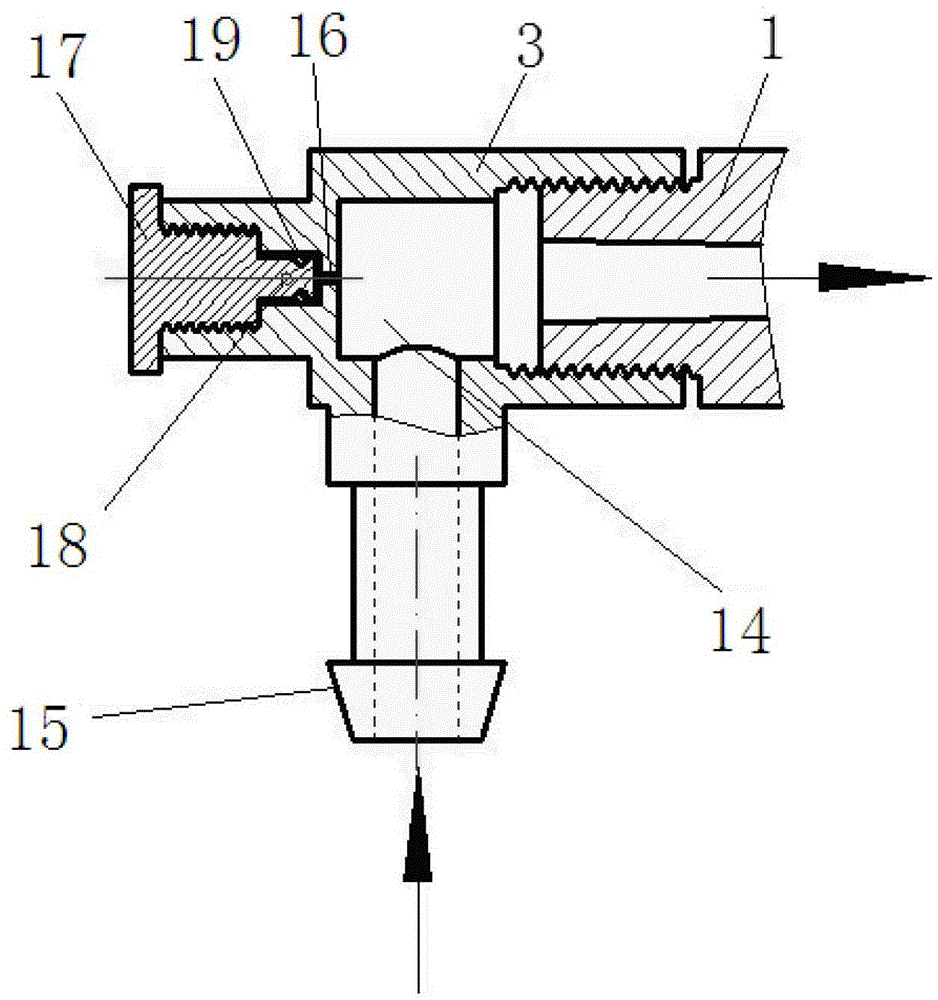

Injection nozzle for sprinkling irrigation and fertilization of circular sprinkling irrigation machine

ActiveCN102909140ASimple structureLow costSpray nozzlesPressurised distribution of liquid fertiliserWater flowWater irrigation

The invention relates to an injection nozzle for sprinkling irrigation and fertilization of a circular sprinkling irrigation machine, which is characterized by comprising a strip-shaped nozzle body; a contraction type flow passage which is gradually narrowed down is formed inside the nozzle body; one wider end of the flow passage of the nozzle body is connected with a nozzle cap, the other end of the nozzle body is inserted into a water inlet pipe of the circular sprinkling irrigation machine, and a nozzle head is integrally arranged at the end part of the nozzle body; a nozzle flow passage communicated with the contraction type flow passage is formed inside the nozzle head, and the other end of the nozzle head is connected with a blockage; a blocking plug and a spring are arranged in the nozzle head flow passage; a plurality of nozzle outlets are formed in the circumferential direction of the nozzle head; one end of the nozzle cap is connected with the nozzle body, and an exhaust device is arranged at the other end of the nozzle cap; and an inside flow passage is formed in the nozzle cap and is communicated with the contraction type flow passage in the nozzle body, a fertilizer inlet pipeline is vertically arranged on the outer wall of the nozzle cap, one end of the fertilizer inlet pipeline is communicated with the inside flow passage of the nozzle cap, and the other end of the fertilizer inlet pipeline is connected with a water outlet pipeline of a fertilizer liquid pressing device. The injection nozzle has good mechanical performance and hydraulic performance, has the function of preventing the backflow of water and is suitable for the sprinkling irrigation and the fertilization of the circular sprinkling irrigation machine.

Owner:CHINA AGRI UNIV

Mist catching separation device

InactiveCN101721859AStrong anti-blockingGood separation effectDispersed particle separationCorrosionEngineering

The invention discloses a mist catching separation device, which comprises a pressing grid and a support frame. The pressing grid and the support frame are sequentially fixed in a tower body or a container from top to bottom; a mist catching wire mesh is arranged between the pressing grid and the support frame; the mist catching wire mesh and a plate coalescent pack are laminated between the pressing grid and the support frame; and the plate coalescent pack is positioned under the mist catching wire mesh. The mist catching separation device adopts a structure that the mist catching wire mesh is combined with the plate coalescent pack to form a liquid-mist separation component, the plate coalescent pack has strong anti-blocking so as to realize initial mist separation, and the mist subjected to the initial separation is subjected to secondary separation of the mist catching wire mesh to achieve better separation effect; therefore, the use range of the mist catching separation device is broadened, equipment corrosion is excellently reduced, service life is prolonged, treatment capacity is improved, valuable materials are recycled, environment is protected, atmospheric pollution is lightened and the like.

Owner:天津天大凯泰化工科技有限公司

Flow crossing-baffling composite gasoline fractionating tower of ethylene device

InactiveCN101785931AAvoid cloggingNo clogging will occurGasoline stabilisationFractional distillationTO-18Gasoline

The invention discloses a flow crossing-baffling composite gasoline fractionating tower of an ethylene device. Micro baffling plates which are arrayed in an interlaced manner are arranged in parallel up and down at a quenching oil circulating section, and a vertex angle of each micro baffling plate is within 90 to 139 DEG; symmetrical bevel edges at the two sides of the vertex angle of the baffling plate are provided with symmetrical vertical folded edges; flow-crossing sieve plates with the diameter of sieve holes within Phi18 to 24mm are arrayed up and down at a medium oil circulating section; flow-crossing sieve plates with the diameter of the sieve holes within Phi13 to 24mm are arrayed up and down at a diesel oil separating section; and flow-crossing sieve plates with the diameter of sieve holes within Phi13 to 18mm are arrayed up and down at a gasoline separating section. The gasoline fractionating tower of the invention overcomes the problem of polymer blockage frequently occurring in the present plate-type fractionating tower and has the remarkable advantages of strong impact and vibration resisting capability, low tower pressure, high ethylene yield, obvious energy saving effect and long-term stable running.

Owner:TIANJIN UNIVTECH CO LTD

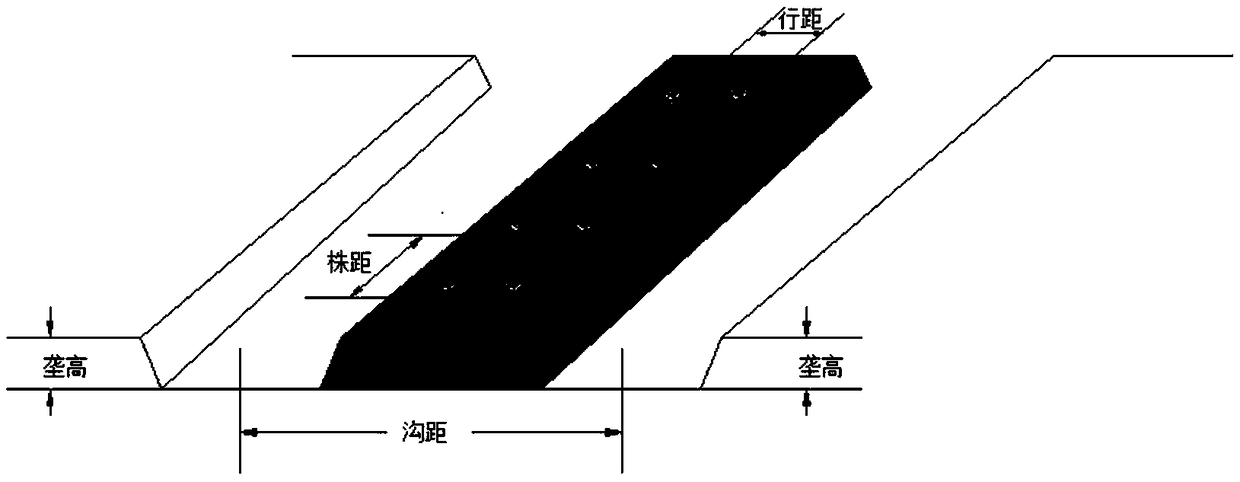

Fagopyrum tataricum no-tillage planter

InactiveCN106385814AReduce human laborMeet the sowing requirementsSpadesPloughsAgricultural engineeringProtection sex

The invention relates to a fagopyrum tataricum no-tillage planter, and belongs to the field of agricultural machinery design. The fagopyrum tataricum no-tillage planter comprises a rack assembly, an anti-blocking furrowing assembly, a fertilization and seeding assembly, a soil covering and pressing assembly and a transmission assembly, wherein the anti-blocking furrowing assembly, the fertilization and seeding assembly, the soil covering and pressing assembly and the transmission assembly are fixedly mounted on the rack assembly. By adopting the fagopyrum tataricum no-tillage planter, fagopyrum tataricum no-tillage planting in a corn stubble land can be achieved, procedures of furrowing, fertilization, seeding, soil covering and pressing can be completed at one time, the human labor can be reduced, seeding requirements can be met, and the operation efficiency can be improved; due to adoption of a straight blade rotary blade, an active anti-blocking technique is achieved, good anti-blocking properties can be achieved, the soil disturbance is small, and a small amount of power is consumed; the fagopyrum tataricum no-tillage planter is simple in structure and convenient to adjust, and has a great significance in popularizing protective cultivation in corn and coarse cereal planting areas.

Owner:KUNMING UNIV OF SCI & TECH

Cutting assembly for stainless steel cutting submersible pump

The invention provides a cutting assembly for a stainless steel cutting submersible pump, belonging to the technical field of water pumps and solving the problems of low cutting performance and poor blockage resistance existing in the traditional cutting assembly of the stainless steel cutting submersible pump. The cutting assembly of the stainless steel cutting submersible pump comprises a static cutting pair with a circular through hole and a dynamic cutting pair coaxially penetrating in the through hole; a medium channel by which a medium goes from one port of the through hole of the static cutting pair to the other port is arranged between the outside part of the dynamic cutting pair and the inner edge of the static cutting pair; the outside part of the dynamic cutting pair is provided with a dynamic cutting edge part; and the inner edge part of the static cutting pair is provided with a static cutting edge part opposite to the dynamic cutting edge part and used for forming the cutting pairs. The cutting assembly for the stainless steel cutting submersible pump only comprises the static cutting pair and the dynamic cutting pair and has the advantages of simple structure and reasonable design and layout.

Owner:TAIZHOU HAPPY WATER PUMP

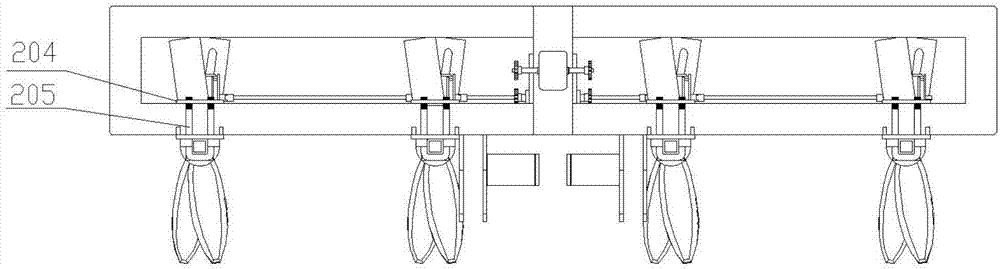

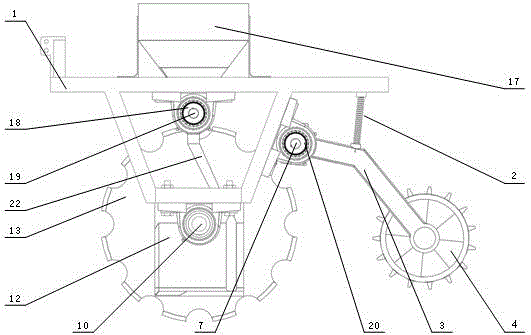

Active no-tillage planter

InactiveCN106068820AReduce human laborMeet the sowing requirementsPlantingAgricultural rollersAgricultural engineeringSprocket

The invention relates to an active no-tillage planter, and belongs to the field of agricultural machines. The active no-tillage planter comprises a rack assembly, an anti-blocking furrowing assembly, a fertilizing and sowing assembly, an earthing and pressing assembly and a transmission assembly, wherein the anti-blocking furrowing assembly, the fertilizing and sowing assembly, the earthing and pressing assembly and the transmission assembly are fixedly installed on the rack assembly. The anti-blocking furrowing assembly comprises a driving chain wheel, a driving shaft, an L-type furrowing cutter I, an L-type furrowing cutter II and a disc stubble cutting cutter, wherein the driving chain wheel is installed at one end of the driving shaft, the disc stubble cutting cutter is installed on the driving shaft, and the L-type furrowing cutter I and the L-type furrowing cutter II are arranged at the two sides of the disc stubble cutting cutter respectively. No-tillage sowing operation in the hilly and mountain area can be achieved, the processes of anti-blocking furrowing, fertilizing, sowing and pressing are completed at a time, human labor is relieved, the sowing requirement is met, and operation efficiency is improved; the active anti-blocking technology is achieved, the anti-blocking performance is high, soil disturbance is small, and power consumption is low. The active no-tillage planter is simple in structure and convenient to adjust.

Owner:KUNMING UNIV OF SCI & TECH

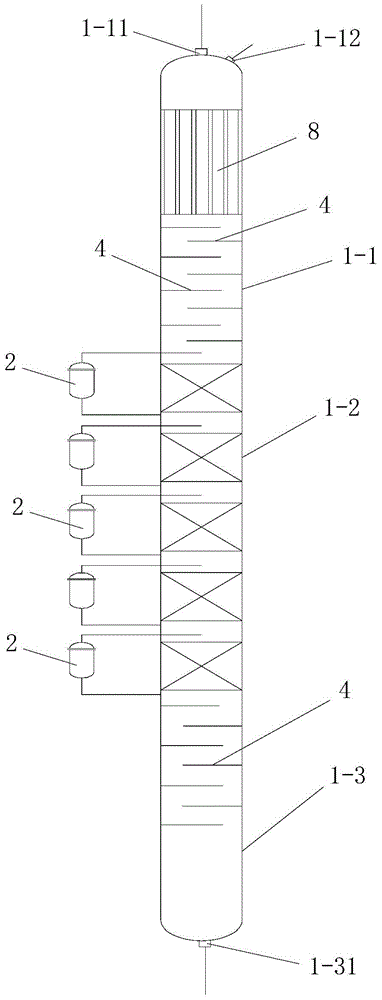

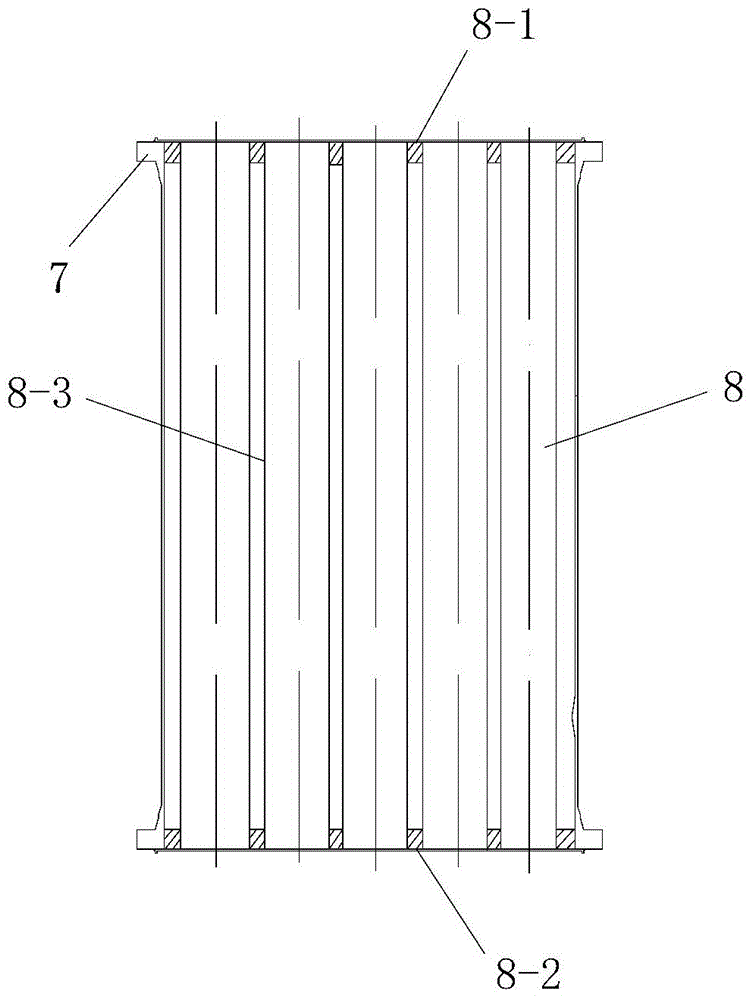

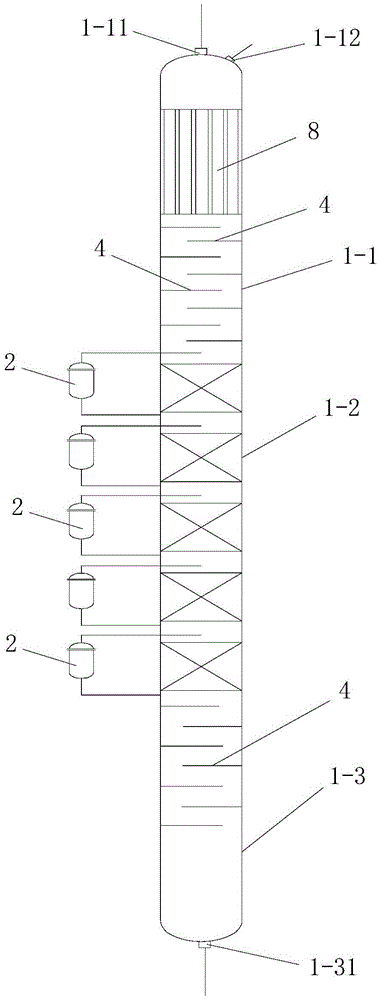

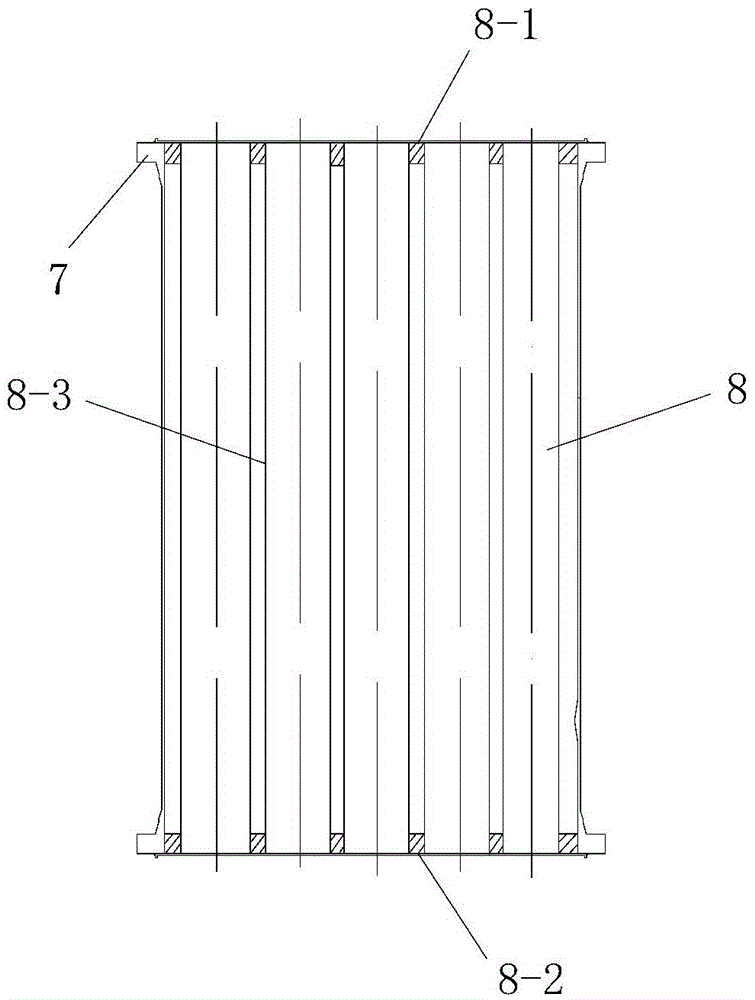

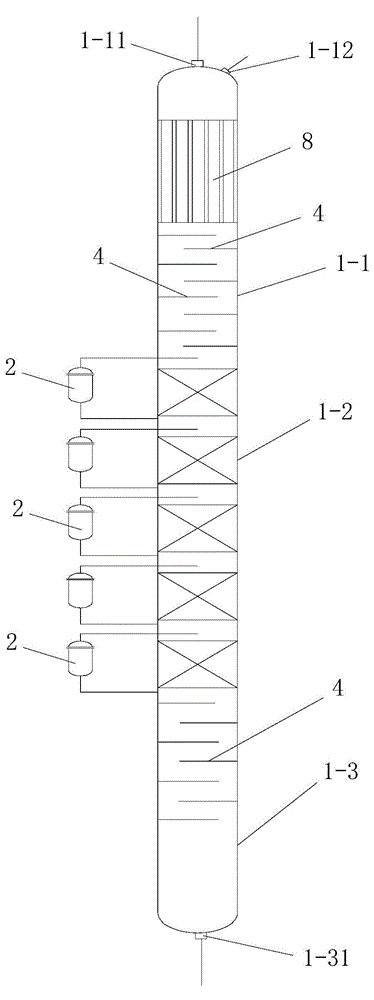

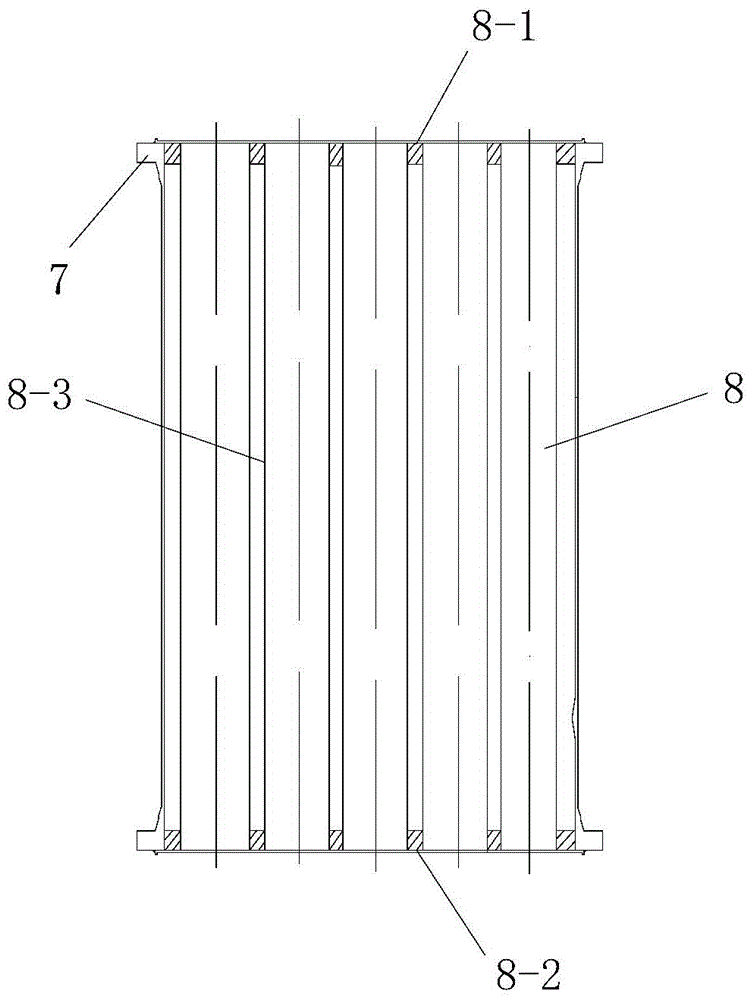

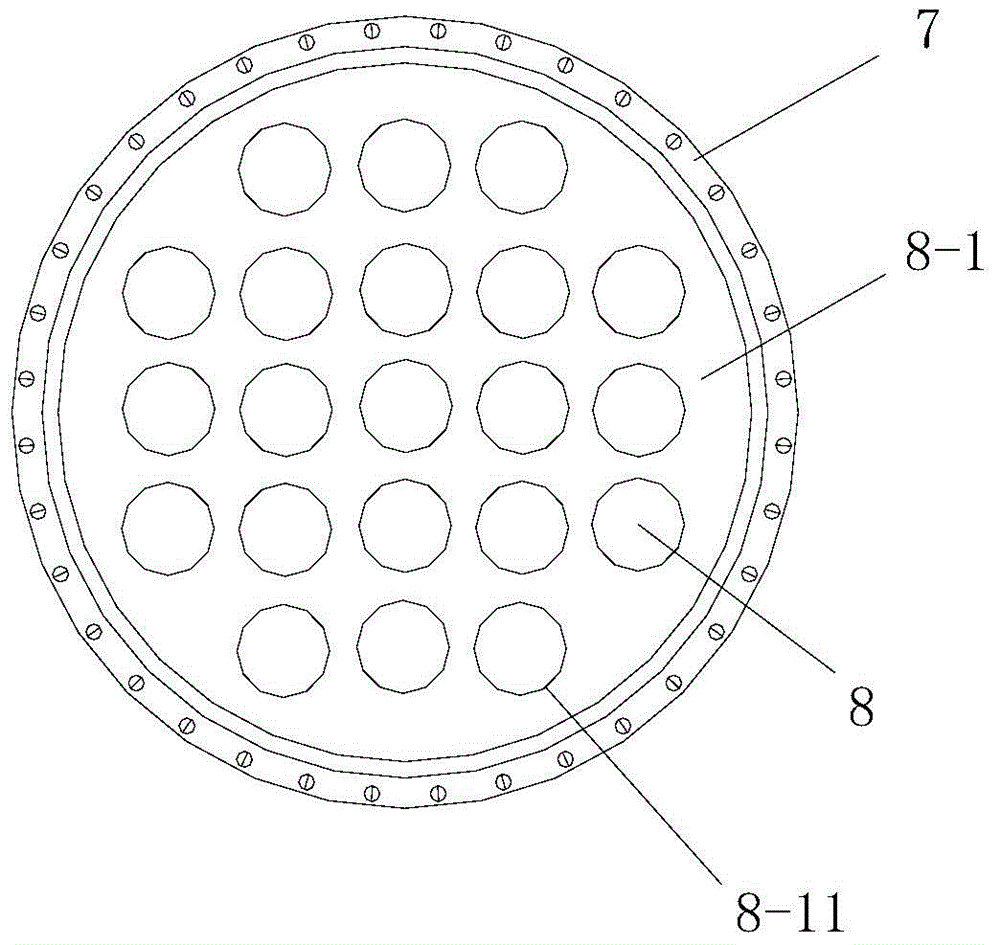

A cluster rectification device with side line reactor

ActiveCN104289006BSimple structureReasonable designChemical/physical processesFractional distillationEngineeringTower

The invention discloses a bundling rectification device with lateral line reactors. The bundling rectification device comprises a rectification tower body and a plurality of lateral line reactors, wherein the rectification tower body comprises an upper tower body, an intermediate tower body and a lower tower body; the upper part of the upper tower body is provided with a bundling rectification section, and the lower part of the upper tower body is provided with an upper tower plate arrangement section; the interior of the bundling rectification section is divided into a plurality of bundling rectification regions; all the bundling rectification regions are small-aperture rectification towers; a plurality of tower plates are arranged in the lower tower body; the intermediate tower body is divided into a plurality of packing sections from top to bottom; the multiple lateral line reactors are respectively mounted on the outer sides of the multiple packing sections; packing beds are arranged in all the packing sections, and each packing bed comprises a packing layer, as well as a liquid distributor and a liquid collection disk, which are positioned on the upper side and the lower side of the packing layer. The bundling rectification device is simple in structure, reasonable in design, easy to use and operate and good in use effect; the defects that an existing reaction rectification tower is larger in size, higher in investment cost, lower in reaction conversion rate and product yield, poorer in use effect and the like can be overcome.

Owner:XIAN SHANGHUA TECH DEV CO LTD

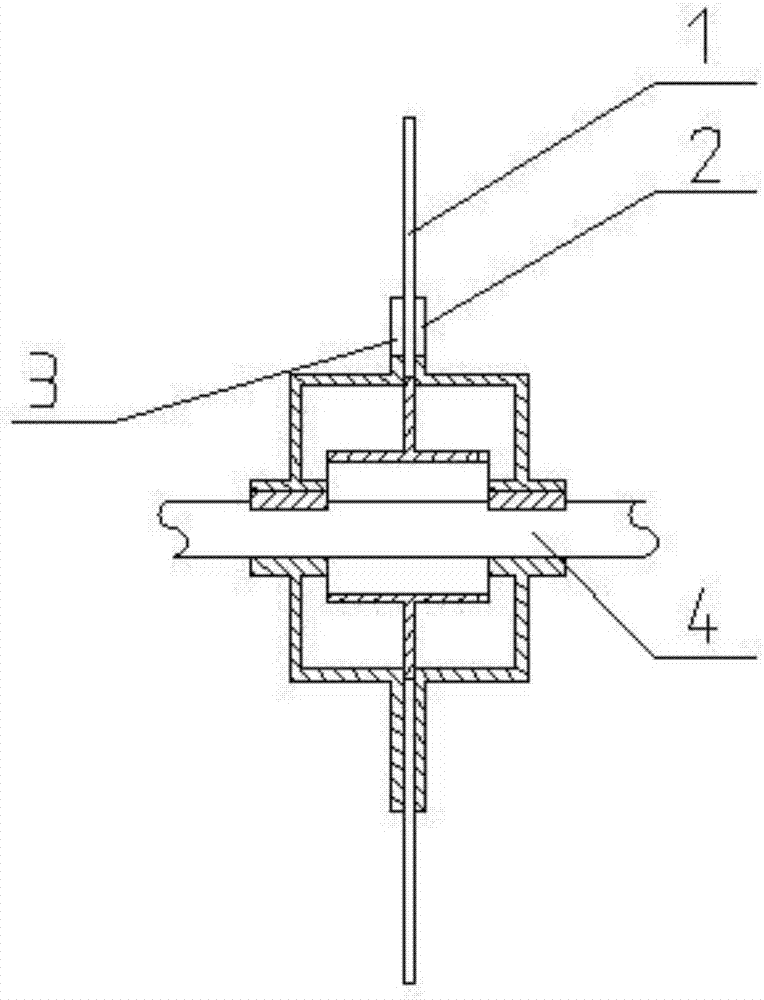

Converse speed-difference follow-up wedge-shaped shovel type apparatus for cleaning weeds and soil on disc surface

ActiveCN104285545AReduce disturbanceReduce energy consumptionPlantingFurrow making/coveringCircular discGear wheel

The invention belongs to the technical field of agricultural machines, and especially relates to a converse speed-difference follow-up wedge-shaped shovel type apparatus for cleaning weeds and soil on a disc surface. A disc shaft is connected with a disc via a shaft sleeve, and the center position of the upper surface of the disc is provided with a gear box in which a gear shaft is installed; the disc shaft is sleeved by a large gear, the gear shaft is sleeved by a small gear, and the small gear is engaged with the large gear; and one end of the gear shaft penetrates the cover of the gear box, and is fixedly connected with one end of a Z type wedge-shaped shovel. When the apparatus works, the disc rotates and drives the disc shaft to rotate, the rotating disc shaft drives the wedge-shaped shovel to conversely rotate on the disc surface via the gear group and the gear shaft, thereby realizing the purpose of cleaning weeds and soil on the disc surface. The gear box installed on the disc surface is designed in a modularization manner, and the apparatus is simple in structure and convenient to mount and dismount, and can be directly installed on a conventional disc furrow opener.

Owner:CHINA AGRI UNIV

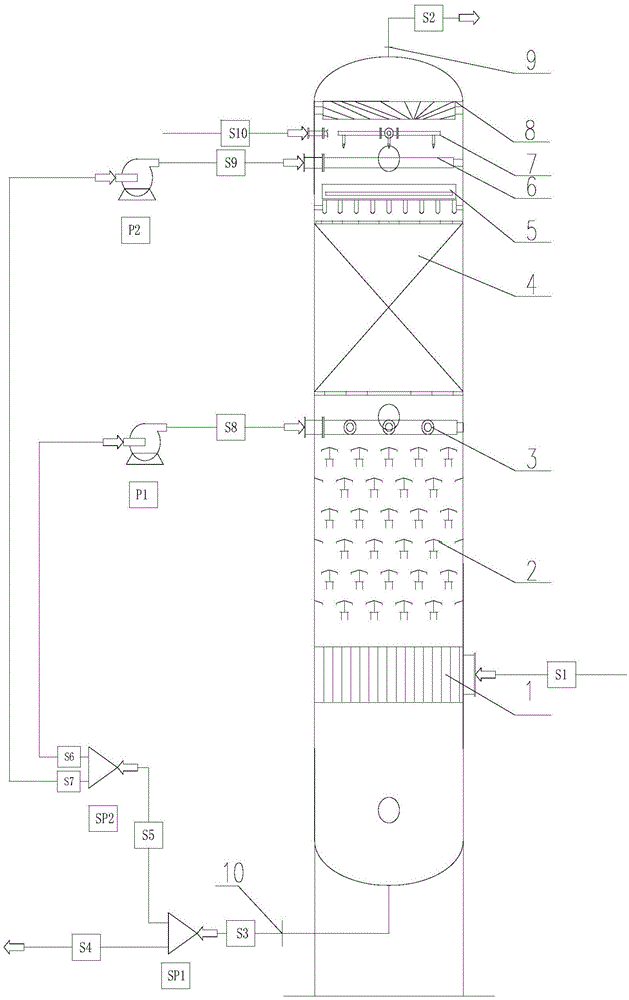

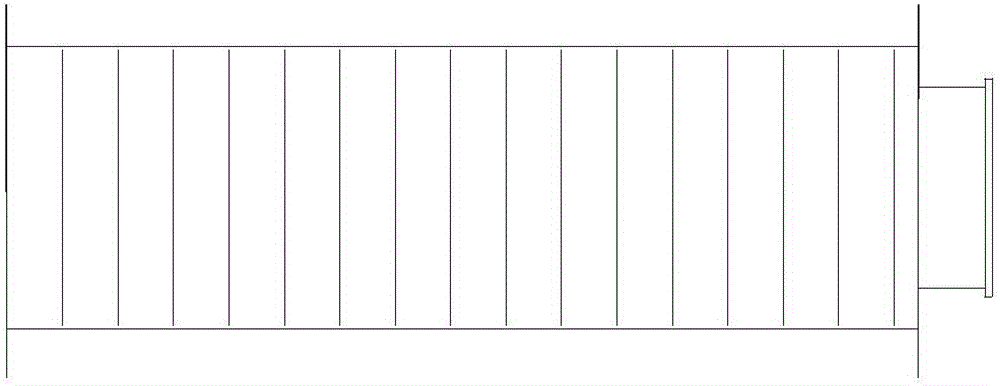

Multistage combined type high-efficiency heat-exchanging dust-removing device and using method thereof

InactiveCN106731399AReduce dosageSave energyCombination devicesTrickle coolersMaterial consumptionEngineering

The invention relates to a multistage combined type high-efficiency heat-exchanging dust-removing device, a dedusting tower comprises, from bottom to top in turn, a tower bottom gas distributor, an initial washing section tower tray, an initial washing section washing liquid distribution tube, a secondary flushing section grid filler, a secondary flushing section anti clogging liquid distributor, a secondary flushing section feeding distribution tube, a fresh washing liquid feeding distribution tube and a swirl plate demister. A dedusting tower circulating liquid is divided into two parts to enter the tower, one part is pumped onto the upper part of a herringbone baffle plate by a pump, and the other part is pumped onto the upper part of the grid filler by the pump. Through use of the multistage combined type high-efficiency heat-exchanging dust-removing device for treatment of a dust-containing gas, the amount of the fresh washing liquid can effectively be reduced, energy and material consumption are saved, by use of the multistage combined type high-efficiency heat-exchanging dust-removing device for treatment of the dust-containing gas, the washing liquid as a tower bottom liquid phase can be recycled, the liquid is basically sealed and recycled, and the washing heat-exchanging can be effectively improved. The multistage combined type high-efficiency heat-exchanging dust-removing device is every low in pressure drop, the whole tower pressure drop is less than 3kPa, and the anti blocking performance is strong.

Owner:TIANJIN UNIV

Matching planting method for multi-span greenhouse mechanical production

InactiveCN108934822AQuality improvementGood for survivalFruit crop cultivationGreenhouseScarification

The invention provides a matching planting method for multi-span greenhouse mechanical production. The method comprises the steps of chili seed preparation, seedling growing substrate preparation, chili seedling preparation, fertilizer applying for soil, deep scarificationploughing and rotary tillage, after the deep scarification ploughing and the rotary tillage, and soil is divided into a basic layer with large and compact particles and a soft growing layer; a ridger is used for ridging along the trend of a greenhouse; a multi-functional mulch applicator is adopted for completing the work ofdrip irrigation zone laying and mulching film laying; a full-automatic or semi-automatictransplanter is adopted for conducting transplanting and planting on chili seedlings with the seedling age of 45-50 days, the plant height of 15-18 cm and 6-8 main leaves, the chili seedlings are transplanted and planted in a growth layer, and seminal leaves are flush with the ground. According to the method,through mechanical planting for chili, it can be avoided that the soil is hardened or compacted manually, the root systems of the chili can effectively breath normally, the chili can conveniently absorb nutrition, and the problems that the labor intensity of manual planting for the chili is high, the amount of the labor used is large, and the production cost is gradually increased are solved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Three-cutter stubble cutting and straw cutting anti-blocking operation monomer of no-tillage planter

PendingCN106900272ASmall amount of ground breakingLess moisture retention effectCrop conditionersMowersSeederAgricultural science

The invention discloses a three-cutter stubble cutting and straw cutting anti-blocking operation monomer of a no-tillage planter and belongs to agricultural machinery. Left and right straw-breaking driving cutters are fixedly arranged on a power drive shaft oppositely; a stubble-cutting driven cutter rotationally sleeves outside the part between the left and right straw-breaking driving cutters on the power driver shaft; the outer diameter of the stubble-cutting driven cutter is greater than those of the left and right straw-breaking driving cutters; straw-breaking blades of the left and right straw-breaking driving cutters and a stubble-cutting blade of the stubble-cutting driven cutter all are Archimedean spiral lines. The monomer is capable of breaking underground stubbles and cutting off over-ground straws, and has the characteristics of being novel, reasonable and simple in structure, good in stubble-cutting and straw-breaking operation quality, small in ground-breaking amount, high in anti-blocking function, low in power consumption and reliable in use.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Water bag for courtyard fruit-and-vegetable infiltrating irrigation

InactiveCN106258825AEasy to transportEasy to carryWatering devicesCultivating equipmentsDiseaseLand resources

The invention discloses a water bag for courtyard fruit-and-vegetable infiltrating irrigation. The water bag is characterized in that the water bag is in a long-strip shape or semi-circle, whole sealing is not leaked, and water delivering pipe joints and a plurality of infiltrating irrigation pipe joints are arranged on the water bag. The water bag has the advantages that as the water bag is soft, the water bag is convenient to transport, carry and install and simplified, maintenance is relaxed, the maintenance management cost can be greatly reduced, land resources are saved, and the water bag is quite convenient to use, can be widely applied to a greenhouse and courtyard fruit-and-vegetable planting, and can be used for both the small family field and the large engineering field; as the water bag is thin, multiple pieces of sunshine can be absorbed, the water temperature is improved, warm water irrigation is achieved, and crop growth is facilitate; as the inter-row portions of crops are covered with the water bag, the water bag also has the mulching film covering function, the soil temperature can be improved, soil moisture evaporation is reduced, weed growth is inhibited, and diseases and pests are controlled.

Owner:GANSU DESERT CONTROL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com