Injection nozzle for sprinkling irrigation and fertilization of circular sprinkling irrigation machine

A technology of injection nozzles and sprinkler irrigation machines, which is applied in spraying devices, spraying devices, pressurized spreading methods of liquid fertilizers, etc. It can solve the problems of poor mixing effect of fertilizer liquid and irrigation water, no anti-backflow structure, and unsuitable circular inlet and outlet structures High-efficiency sprinkling irrigation and fertilization of sprinkler irrigation and other issues, to achieve the effect of strong replaceability, easy disassembly and washing, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

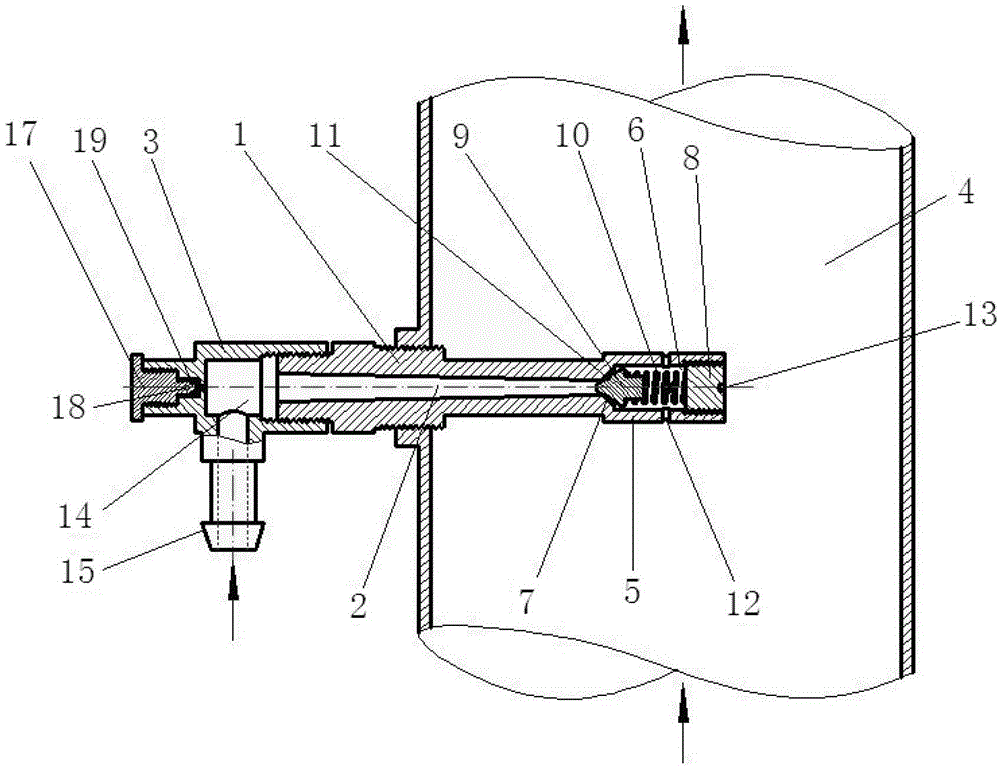

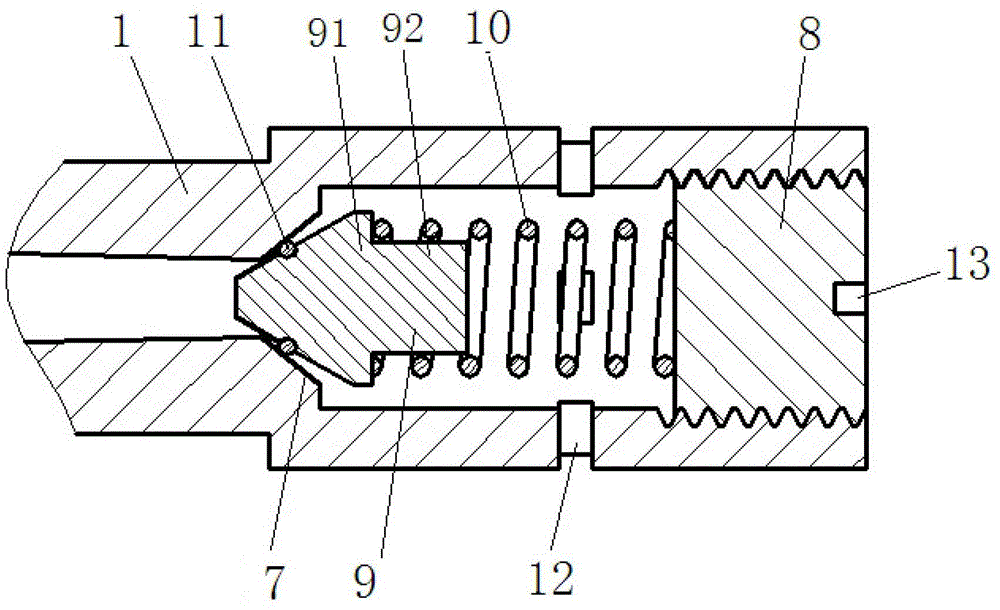

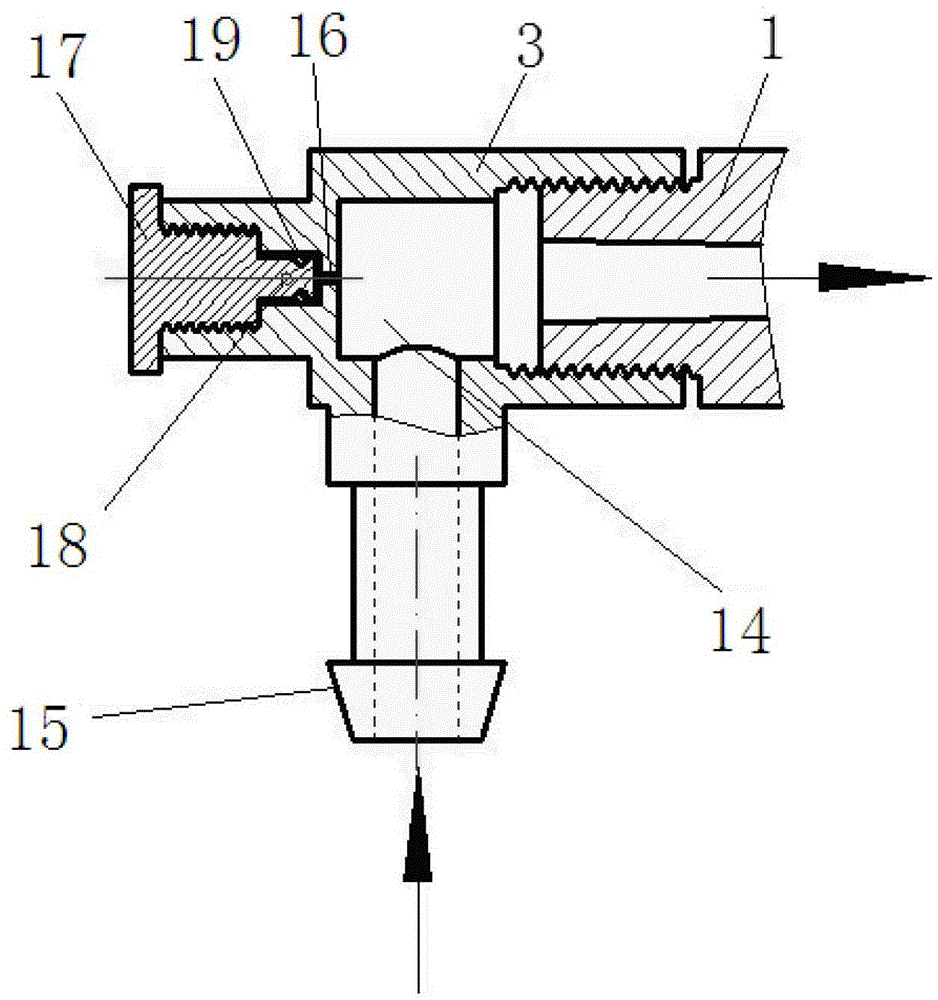

[0021] Such as figure 1 As shown, the present invention includes a strip-shaped nozzle body 1, inside the nozzle body 1 is provided with a shrinking flow path 2 gradually narrowing from width; the wider end of the flow path of the nozzle body 1 is threaded to a nozzle cap 3 , the other end of the nozzle main body 1 is inserted into the water inlet pipe 4 of the circular sprinkler, and is connected with the water inlet pipe 4 of the circular sprinkler by thread sealing, and the end of the nozzle main body 1 located in the water inlet pipe 4 of the circular sprinkler is integrated. There is a nozzle head 5, the nozzle head 5 is located near the central axis of the circular sprinkler water inlet pipe 4, the central axis of the nozzle body 1 is perpendicular to the central axis of the circular sprinkler water inlet pipe 4; the outer wall of the nozzle mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com