Patents

Literature

94results about How to "Reduce human labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

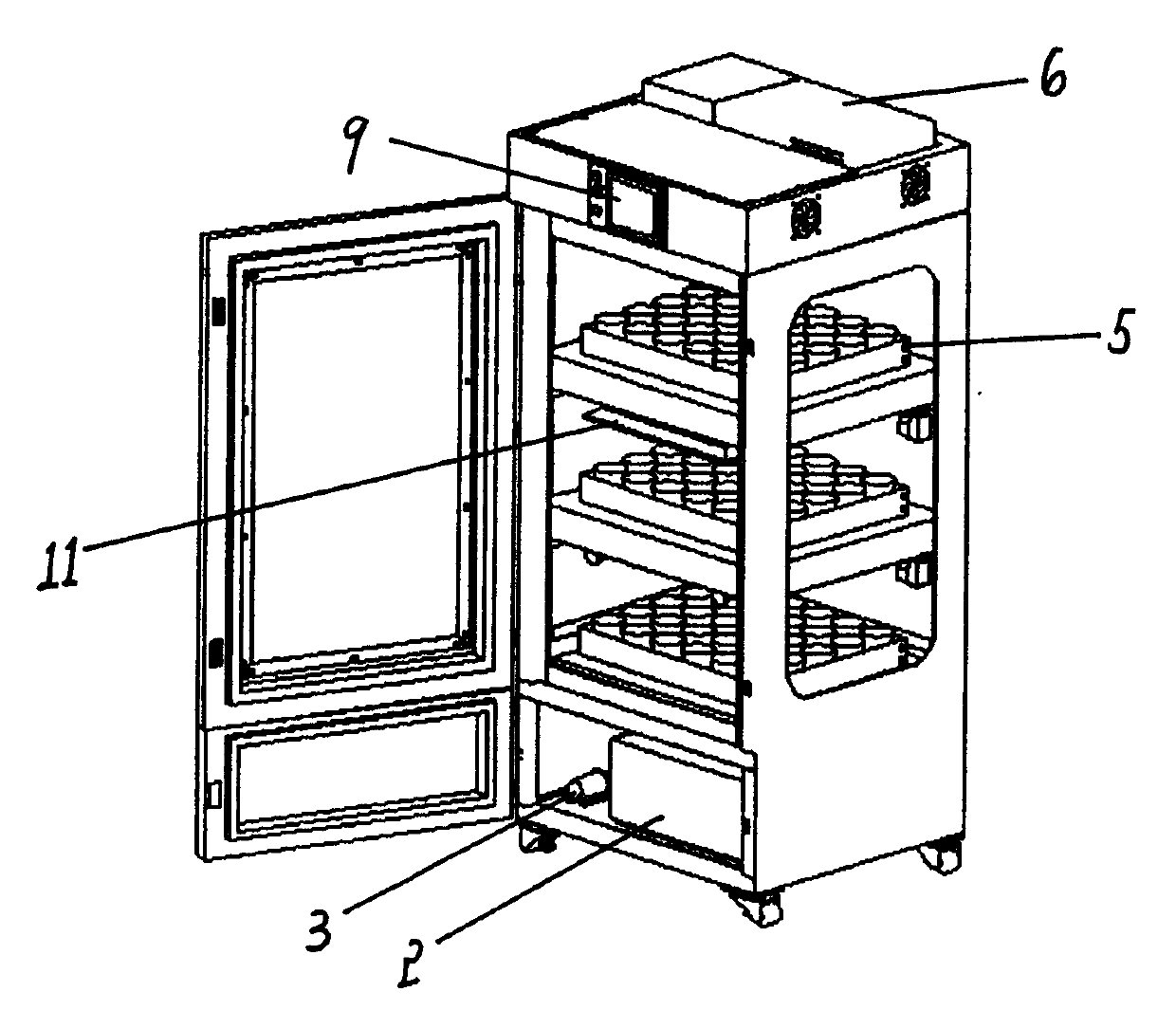

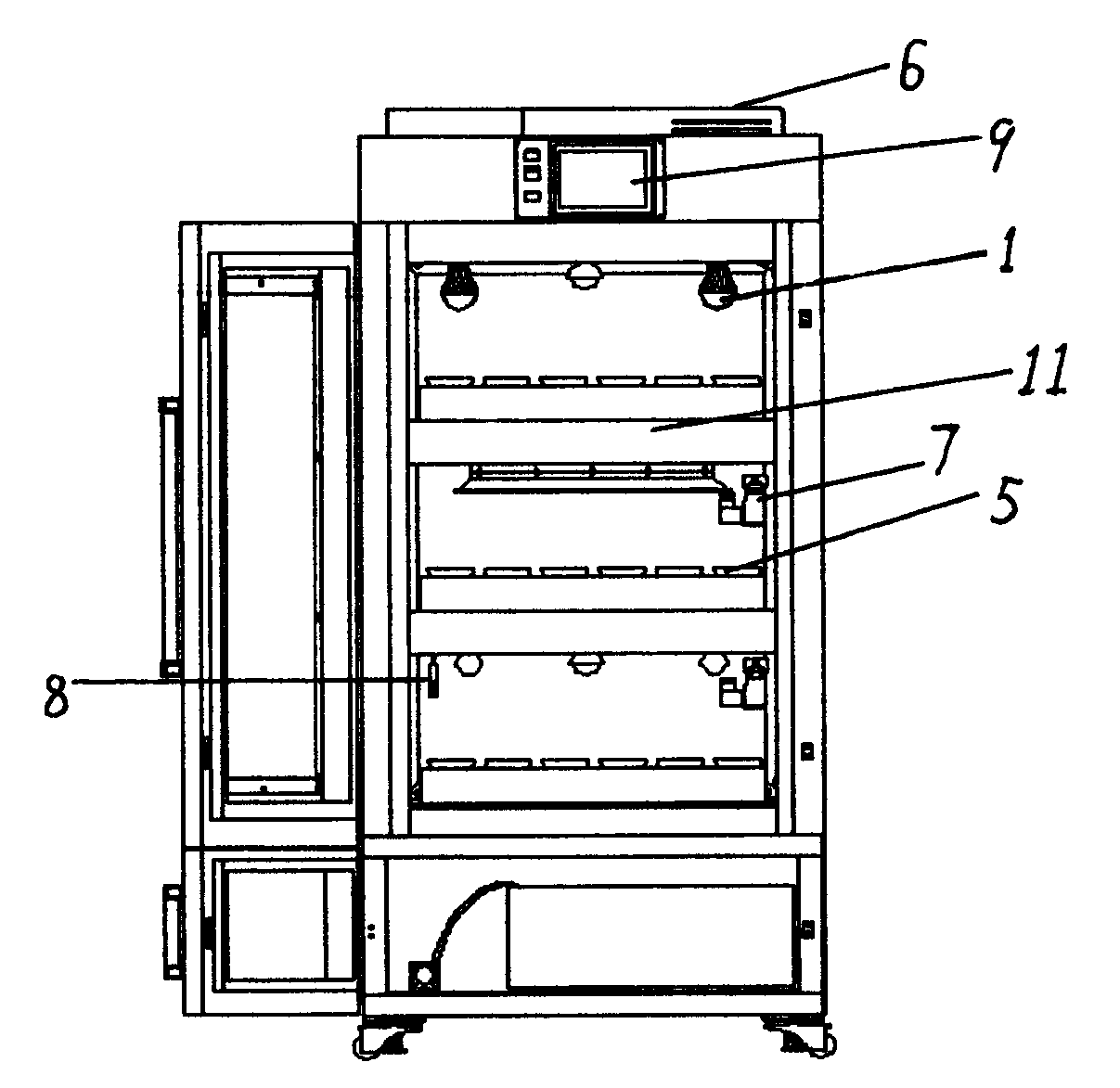

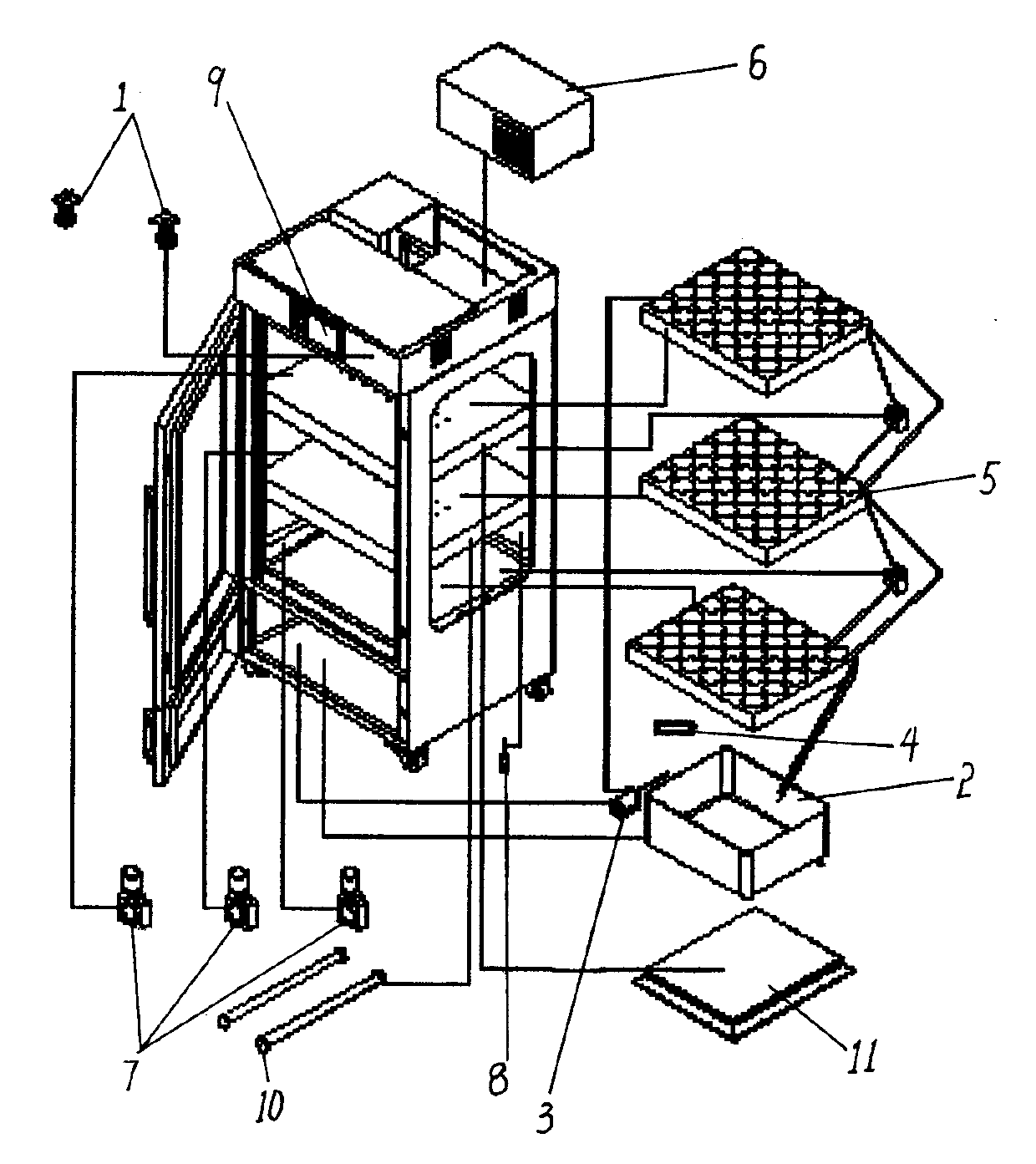

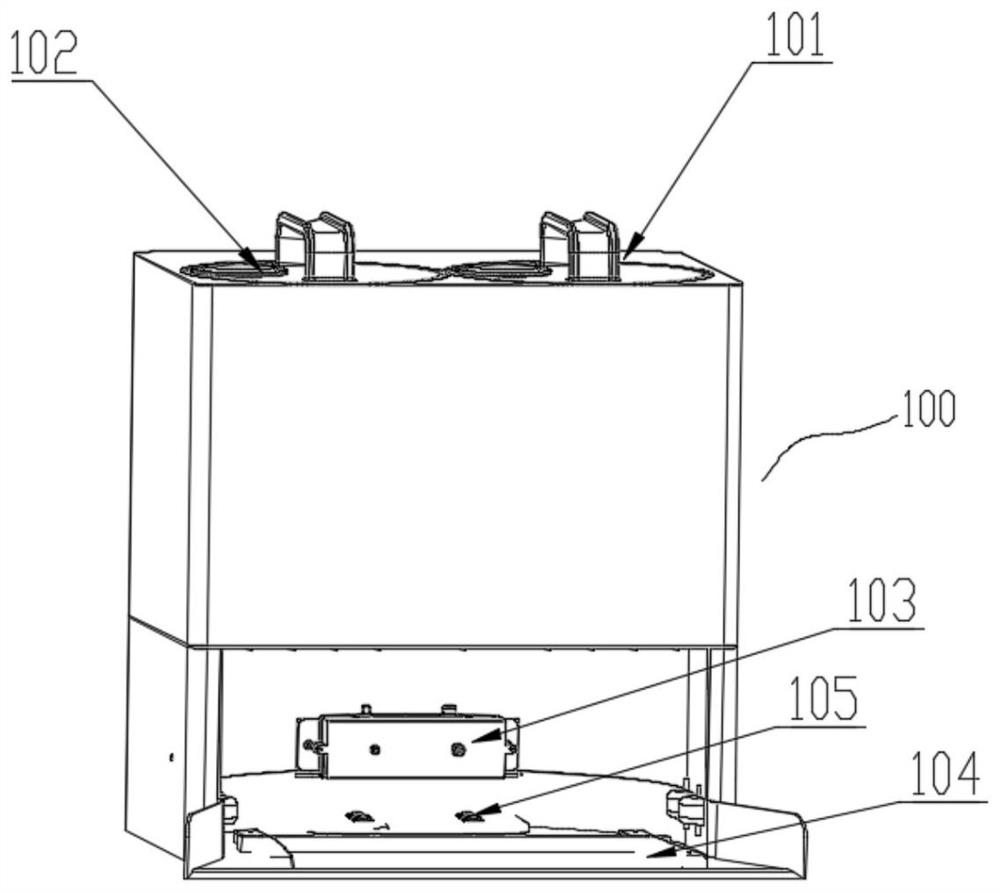

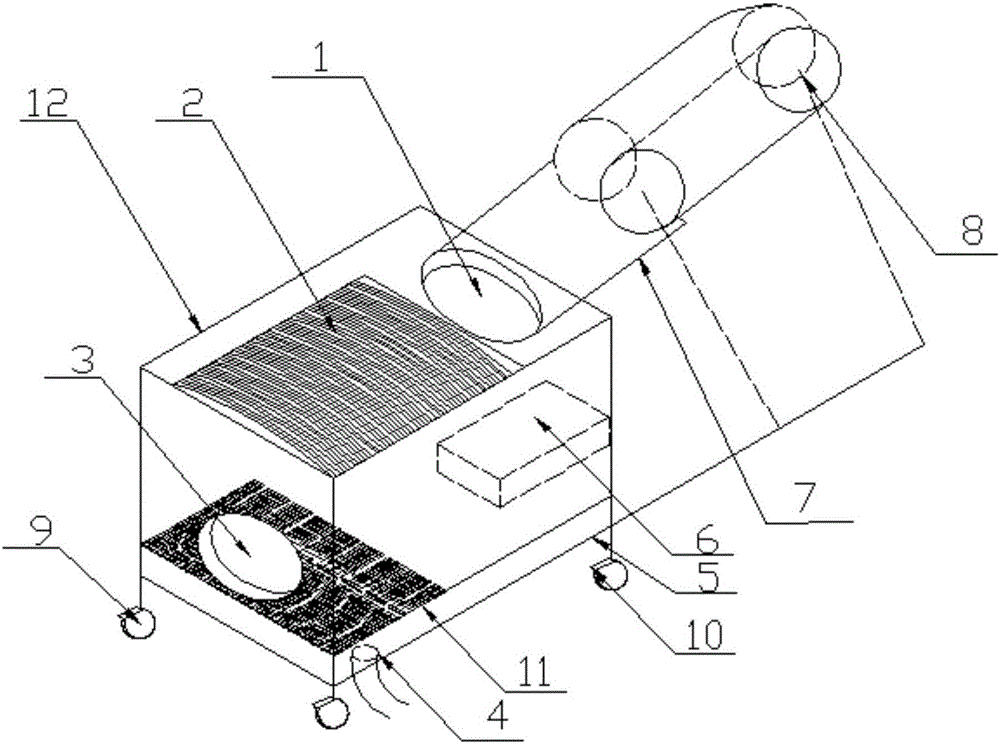

Miniature light-emitting diode (LED) plant factory

InactiveCN103098693AReduce human laborSmall footprintAgriculture gas emission reductionCultivating equipmentsPlant rootsNutrient solution

The invention relates to a miniature light-emitting diode (LED) plant factory. In the process of planting agricultural products, growing of plants is often limited by various needed factors. The miniature LED plant factory comprises an LED plant lamp, nutrient solution, a nutrient solution automatic cyclic utilization system, nutrient solution heating and sterilization, planting plate vermiculite substrate for fixing root systems, a temperature control system, a humidity control system, an automation control circuit, software control cultivation procedures of different vegetable planting processes and a temperature and humidity sensor. The LED plant lamp is used as a light source. A miniature water pump is utilized in the nutrient solution automatic cyclic utilization system, three-layer water level is controlled by a liquid valve, and the nutrient solution cyclic utilization system is communicated with a water tank. An electric heater unit is installed in the water tank and used for heating and sterilizing the nutrient solution regularly. The plant root systems are fixed and supplied with nutrient by applying of a vermiculite substrate. Temperature and humidity can be monitored and regulated, and matched control cultivation procedures can be called. The miniature LED plant factory can be suitable for growing of various plants, manpower work quantity is reduced, and lands are saved. The miniature LED plant factory is green, safe, energy-saving, environment-friendly and beneficial for popularization.

Owner:HUIZHOU WAI CHI ELECTRONICS CO LTD

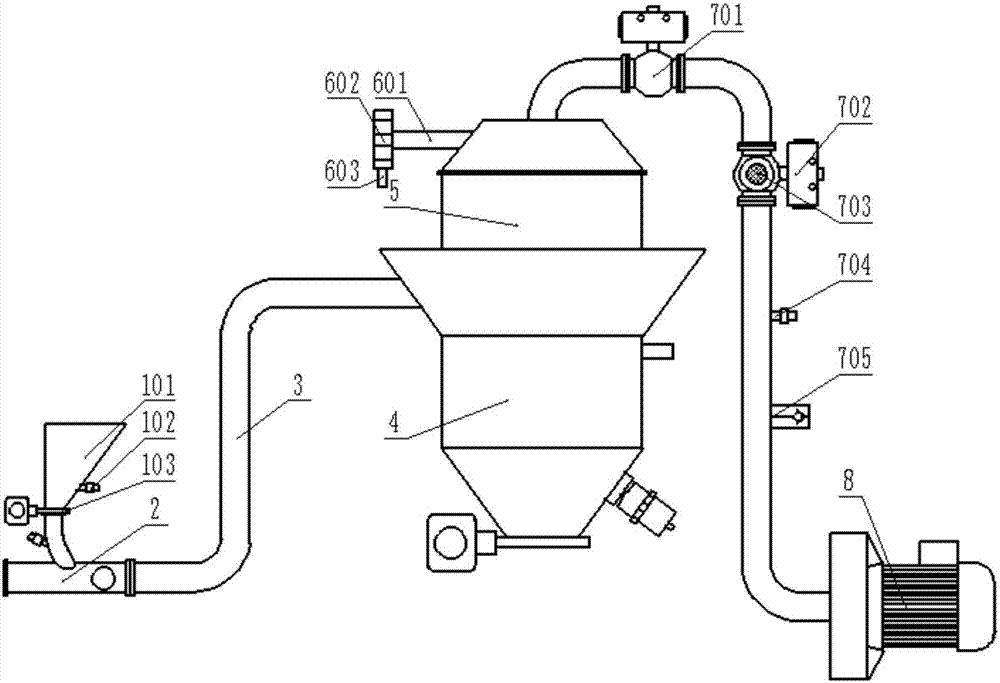

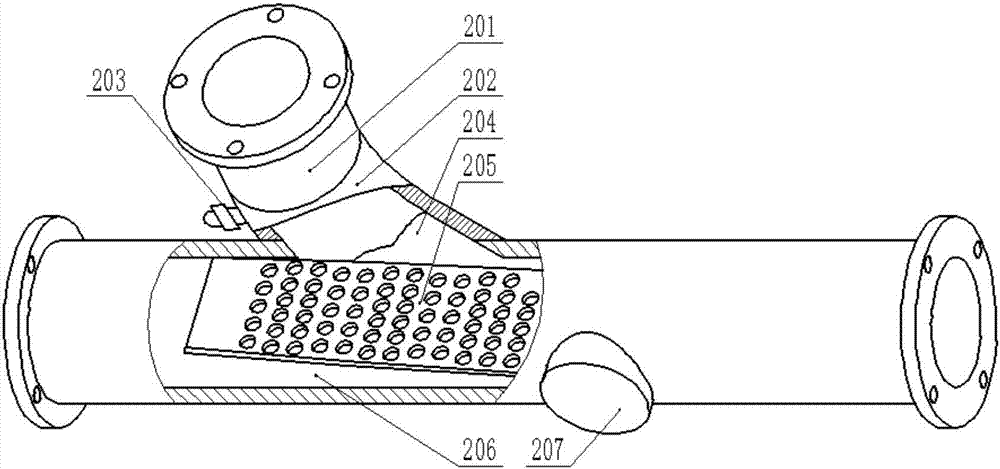

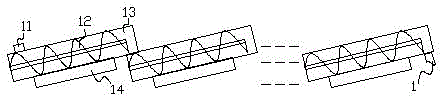

System and method for intermittent negative-pressure pneumatic conveying for powder

The invention provides a system and a method for intermittent negative-pressure pneumatic conveying for a powder. The system comprises a feeding device, a horizontal feeder, a conveying pipeline, a separator, a dust remover, a blowback device, an air source, auxiliary equipment and a control device. According to the system and the method, the possibility of arching in a hopper and adhesion onto the wall of the hopper, of materials, is lowered, through using an air nozzle air-supplementing device and the novel horizontal feeder; the safety of the system is improved through installing a safety valve and a vacuum pressure sensor; the cost is lowered and the floor area is reduced by virtue of the integrated structure of the separator and the dust remover; the filter effect is enhanced and the number of filters is reduced through designing a filter with a novel structure; a pneumatic component and an electromagnetic valve are matched by virtue of the characteristics of high flexibility and high reliability of a PLC; and the need of frequently starting up and turning off a fan in order to realize an intermittent conveying manner at the present stage is avoided through using a ball valve. The system provided by the invention has the advantages of being simple in structure, low in cost, high in automation degree, high in conveying speed and the like, and reduces human labour.

Owner:JIANGSU UNIV

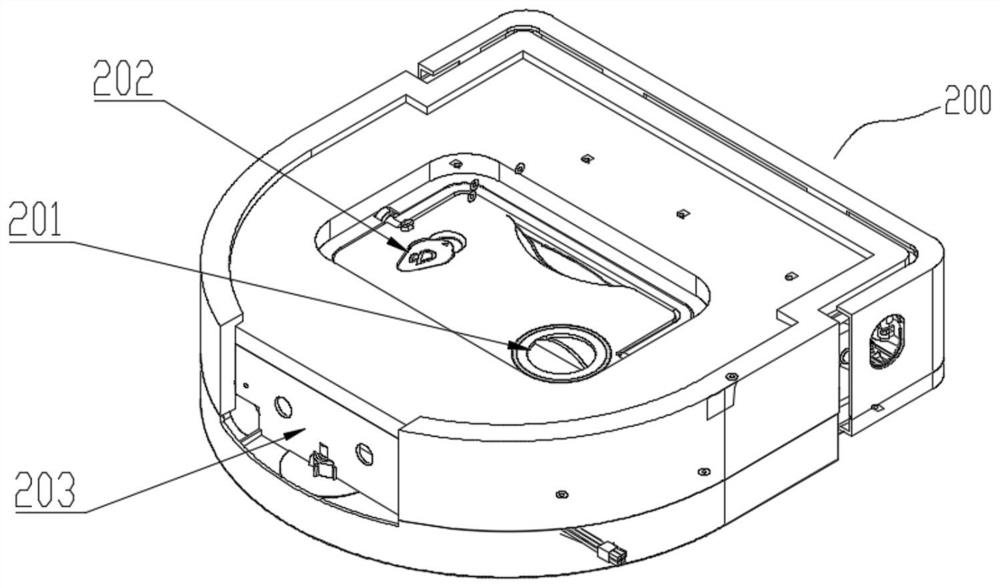

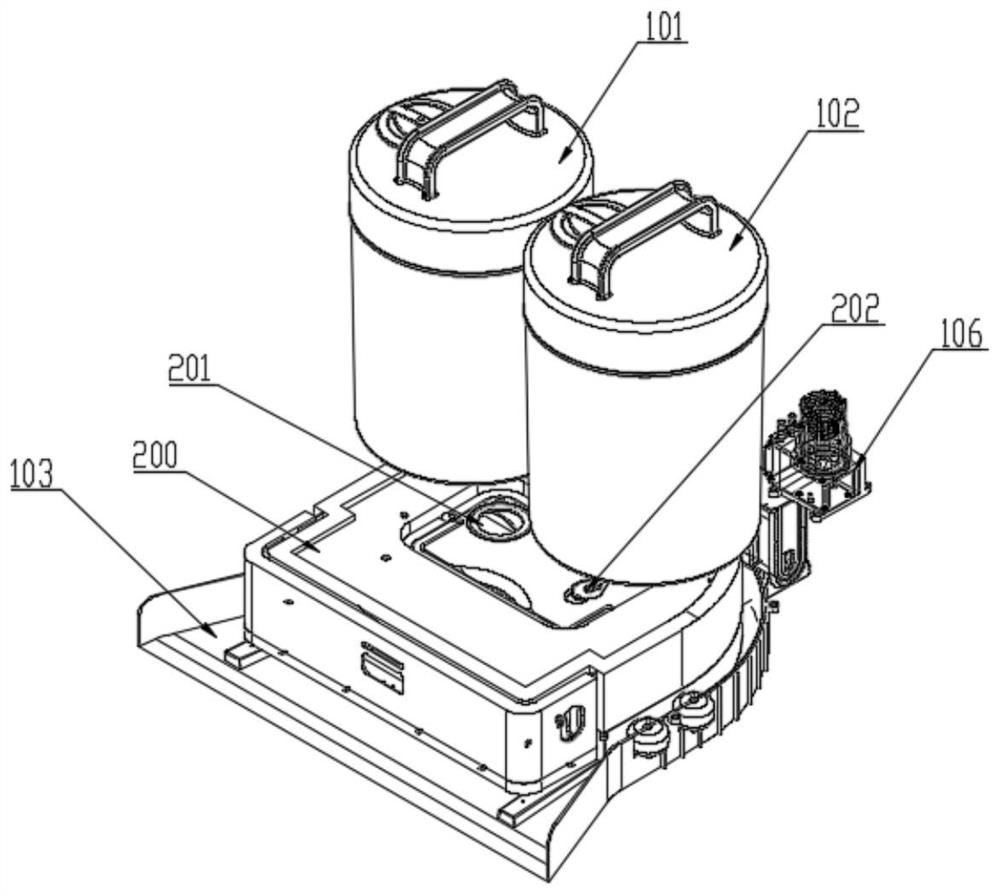

Workstation for cleaning robot, and cleaning robot

InactiveCN111839375AImprove experienceReduce human laborCarpet cleanersFloor cleanersProcess engineeringSewage

The embodiment of the invention provides a workstation for a cleaning robot, and the cleaning robot. The workstation for the cleaning robot comprises: a sewage recycling device which is used for recycling sewage from a sewage box of the cleaning robot; and a clear water supply device used for injecting clear water into the clear water box of the cleaning robot. According to the technical scheme, clear water can be automatically injected into the clear water box of the cleaning robot, and sewage in the sewage box of the cleaning robot can be automatically recycled and cleaned, so manual labor is reduced, and user experience is improved.

Owner:MIDEA ROBOZONE TECH CO LTD

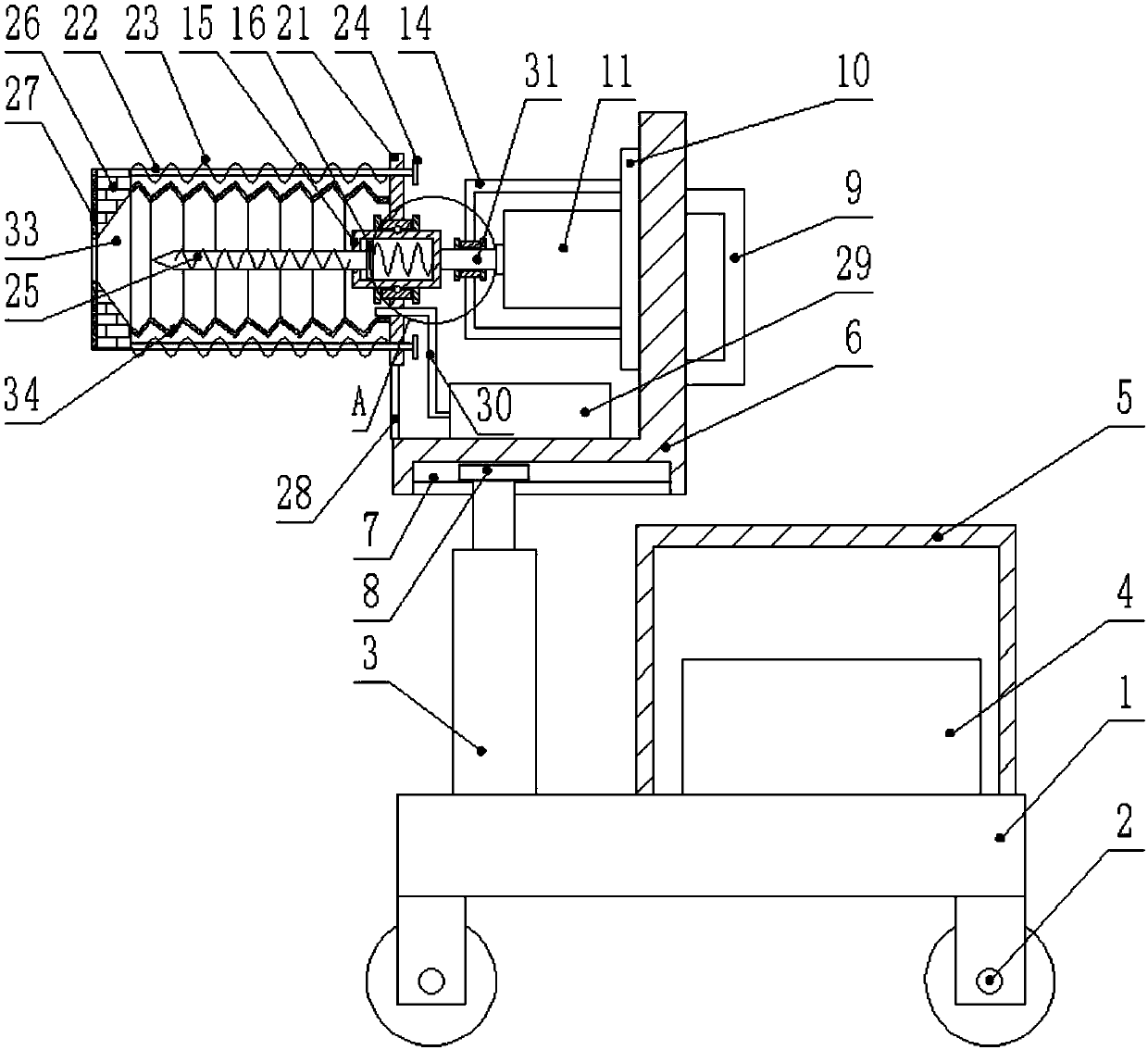

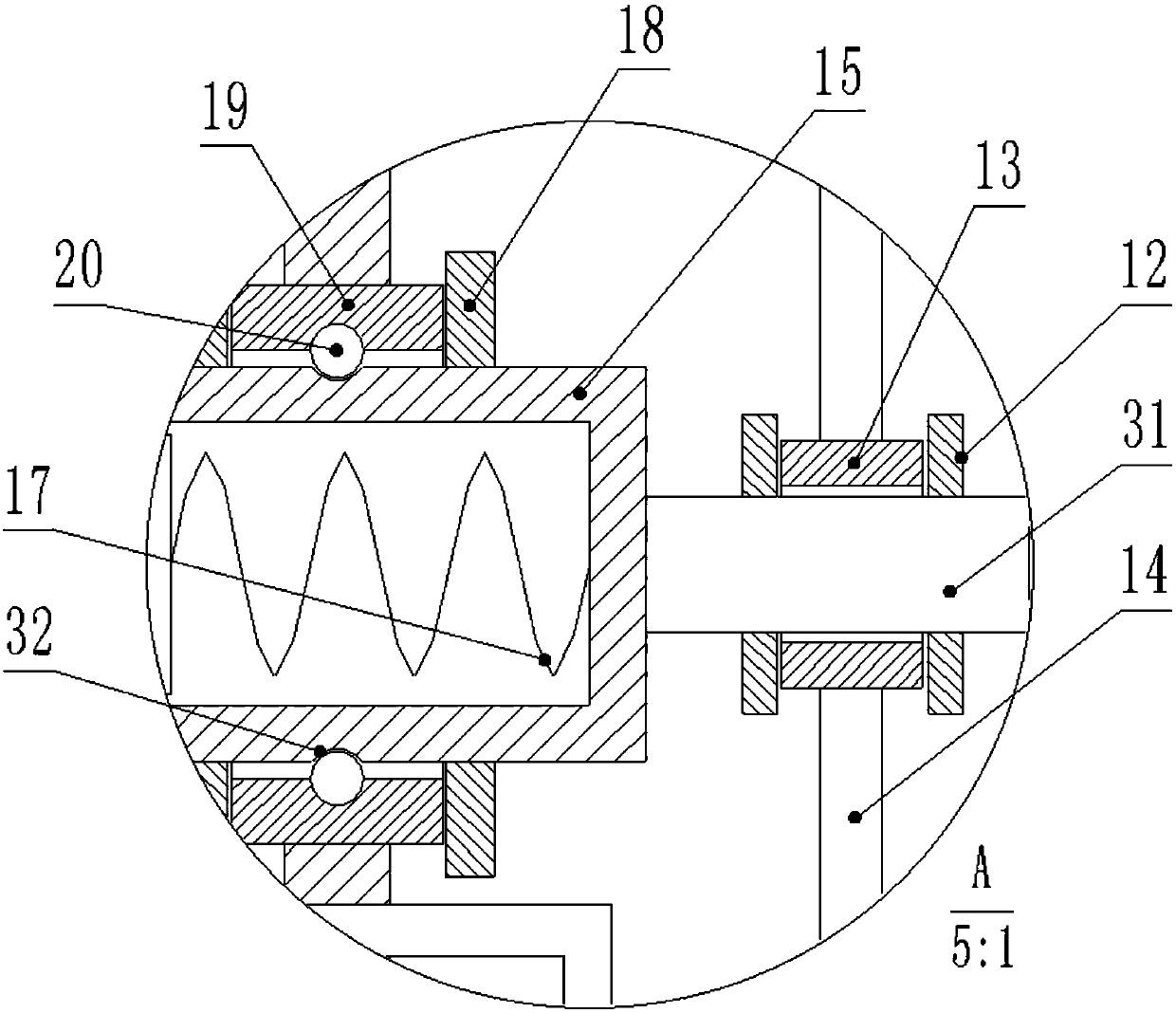

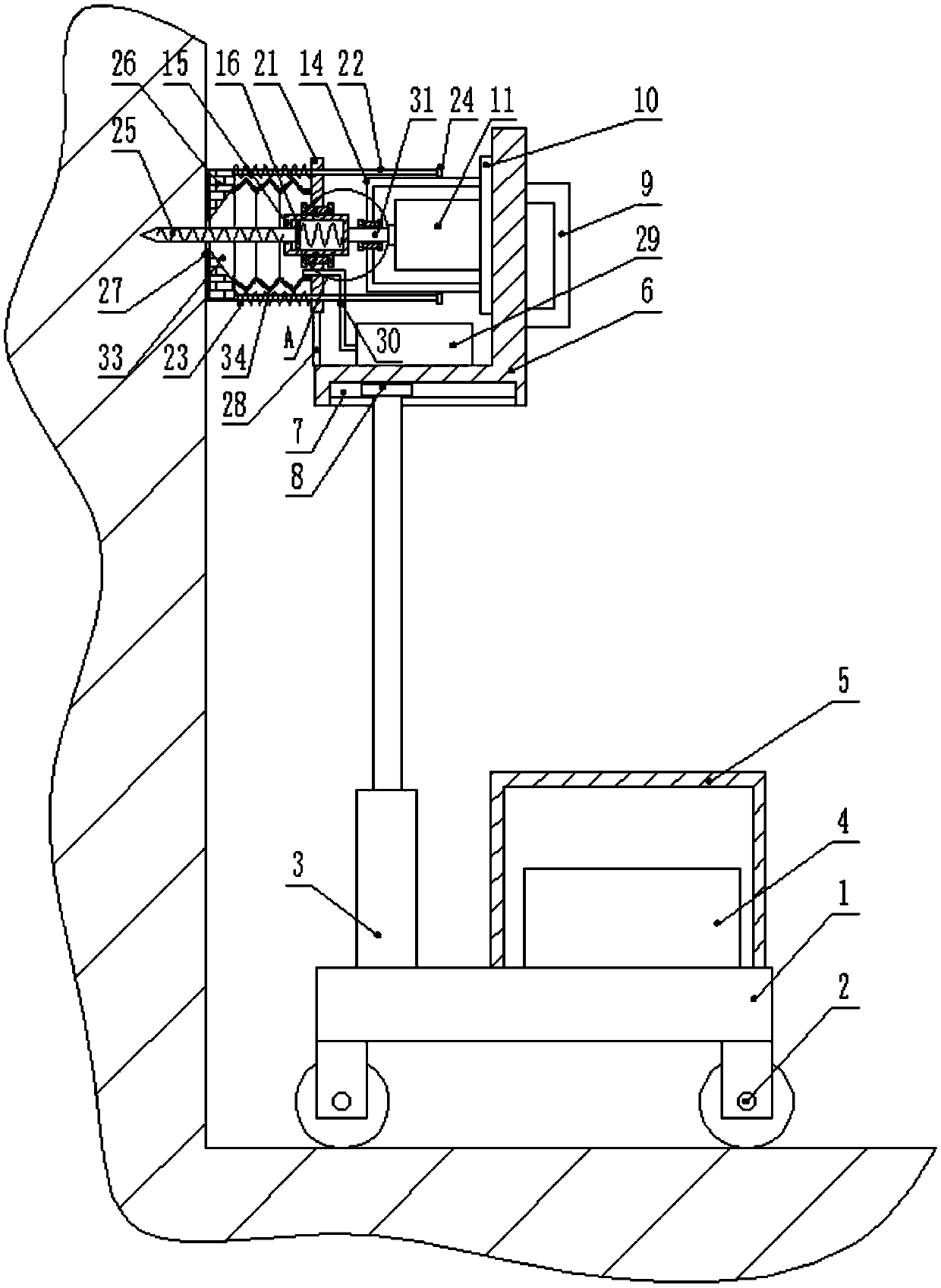

Dust-free electric drill for wall surface perforating

InactiveCN109624100AEasy to moveReduce human laborPortable power-driven toolsPortable drilling machinesEngineeringMaterial Perforation

The invention provides a dust-free electric drill for wall surface perforating. The dust-free electric drill for wall surface perforating comprises a base. Universal wheels are fixed to four corners of the bottom end of the base correspondingly. A hydraulic cylinder is fixed to one side of the top surface of the base. A cover body is fixed to the other side of the top surface of the base. A hydraulic station is arranged in the cover body. The bottom end of the hydraulic station is fixedly connected with the top surface of the base. An L-type fixing plate is arranged over a hydraulic cylinder.The dust-free electric drill is convenient to move due to the arrangement of the universal wheels and the base. Due to the arrangement of the hydraulic cylinder, a motor and a drill rod can be moved to required punching heights through the hydraulic cylinder to effectively replace the working mode of manually lifting the electric drill for perforating, and human labor is saved. Due to the arrangement of a disc and a telescopic hose, dust generated during perforating can be moved into the telescopic hose through a conical through hole in the disc and is then sucked into a dust collector througha connecting pipe, and the purpose of dust-free perforation operation is realized.

Owner:NORTHEASTERN UNIV

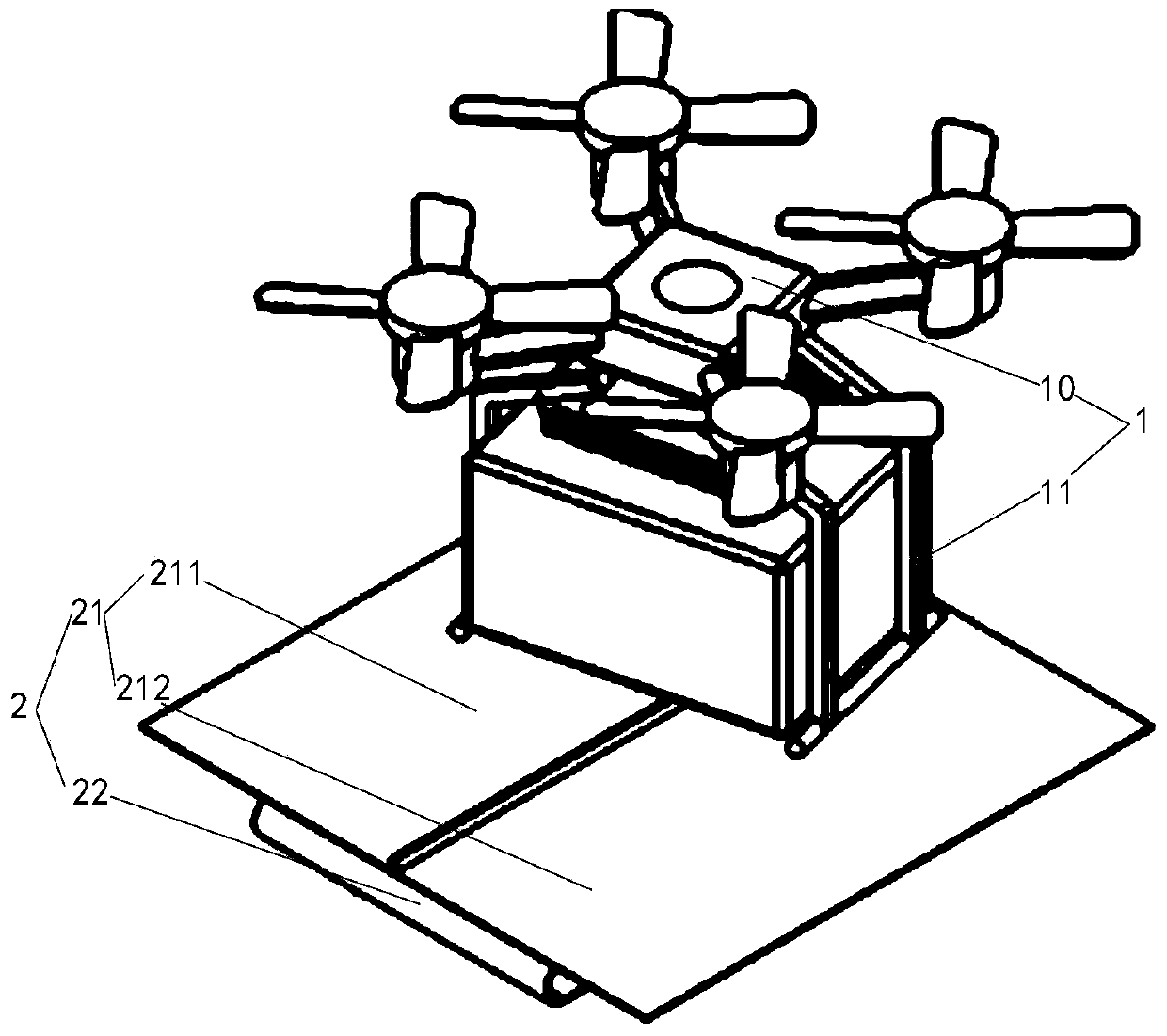

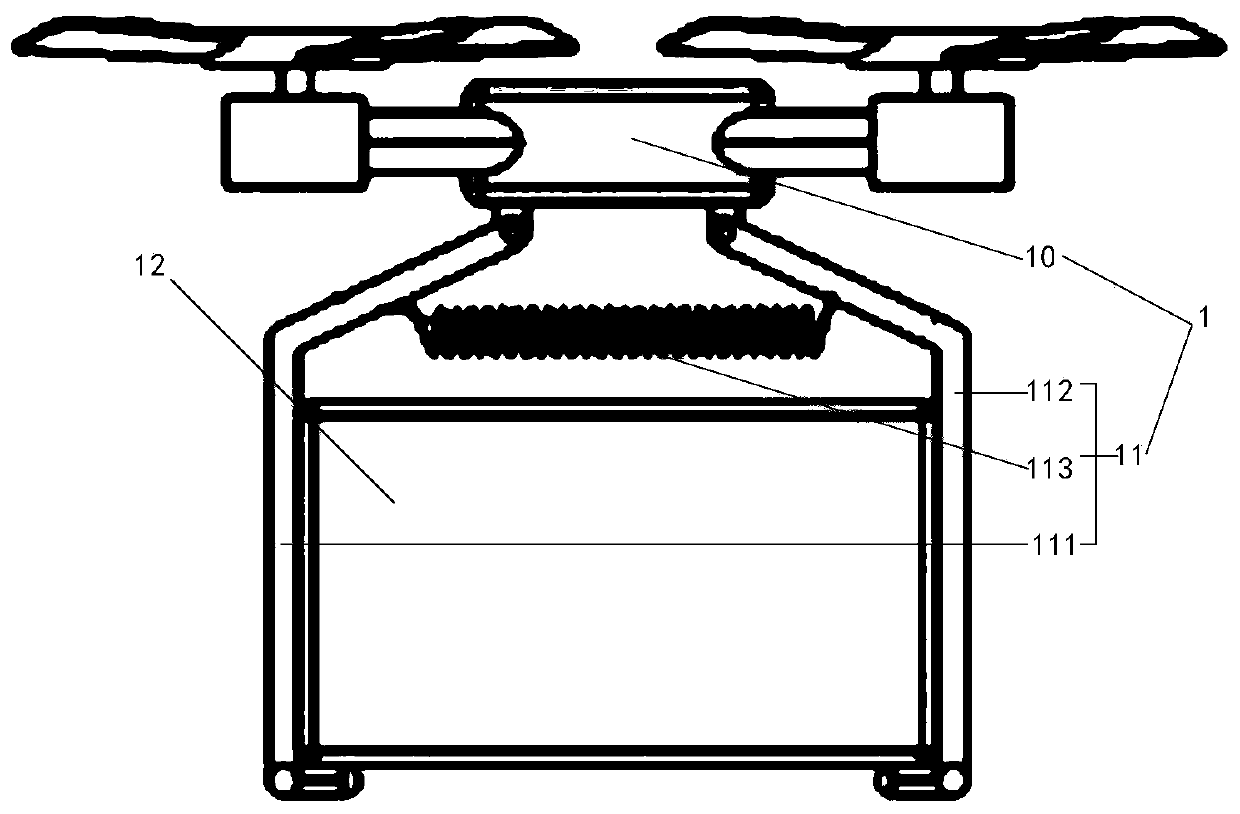

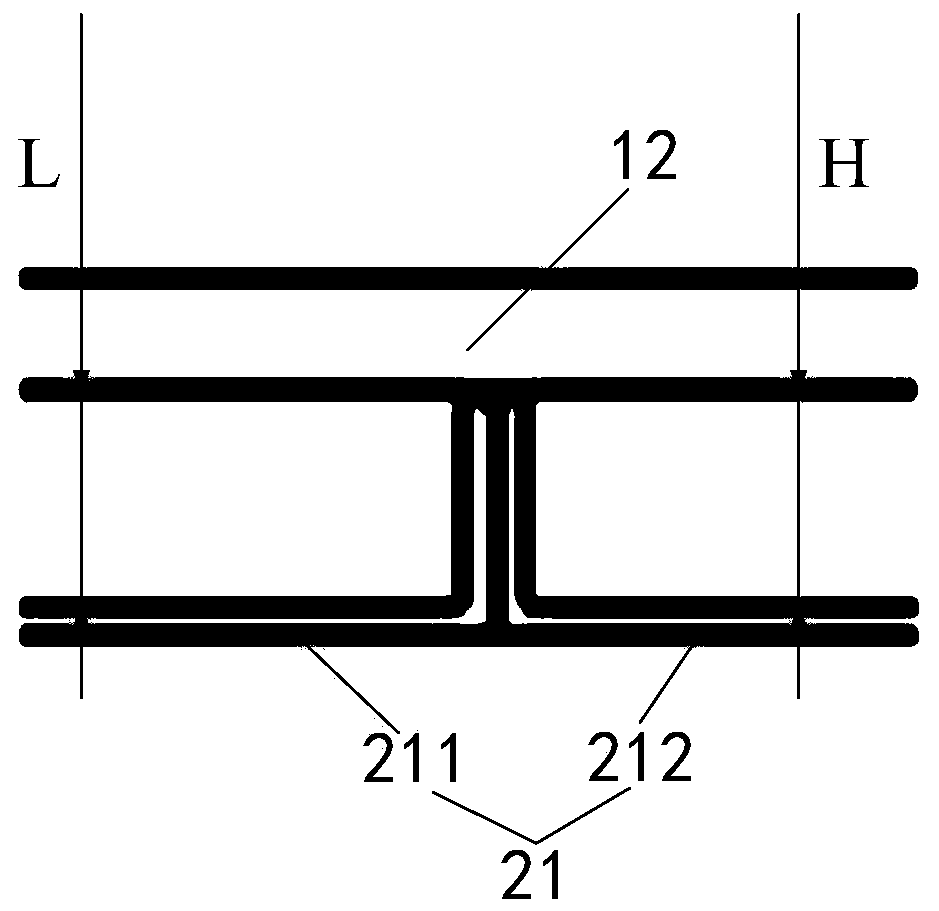

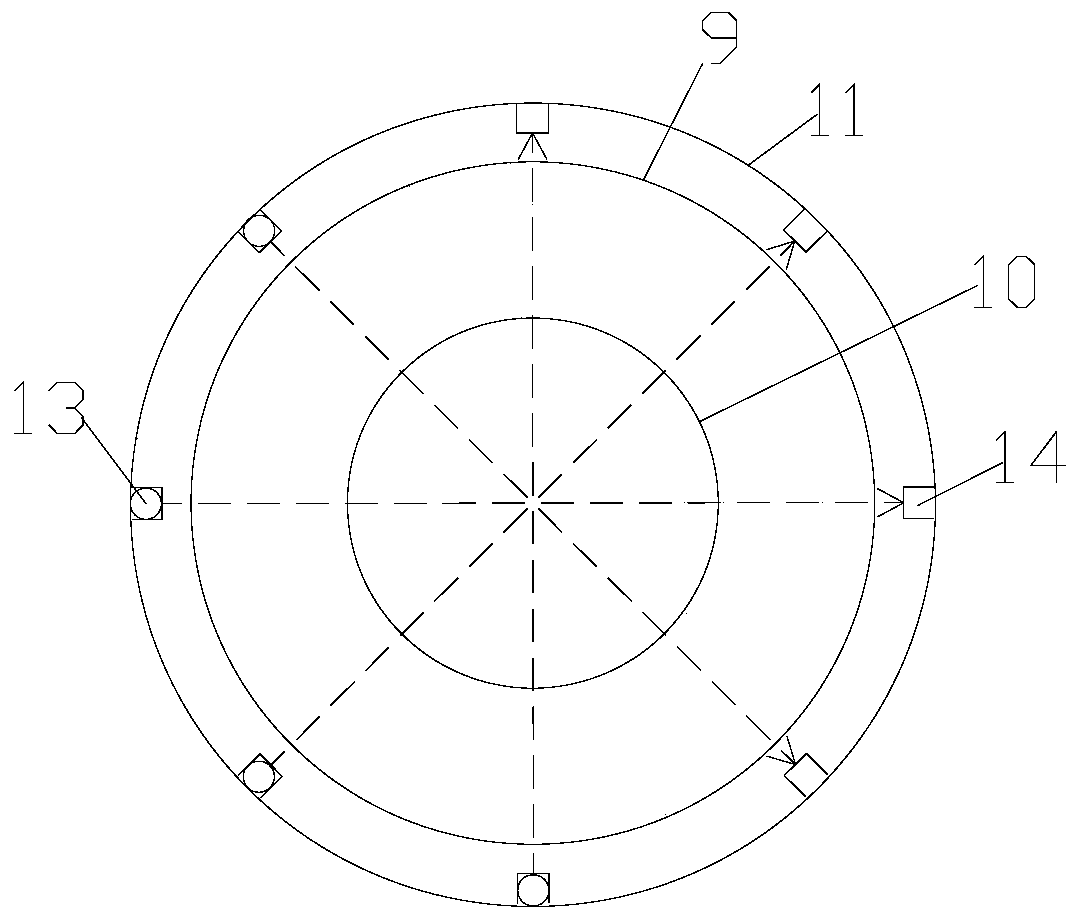

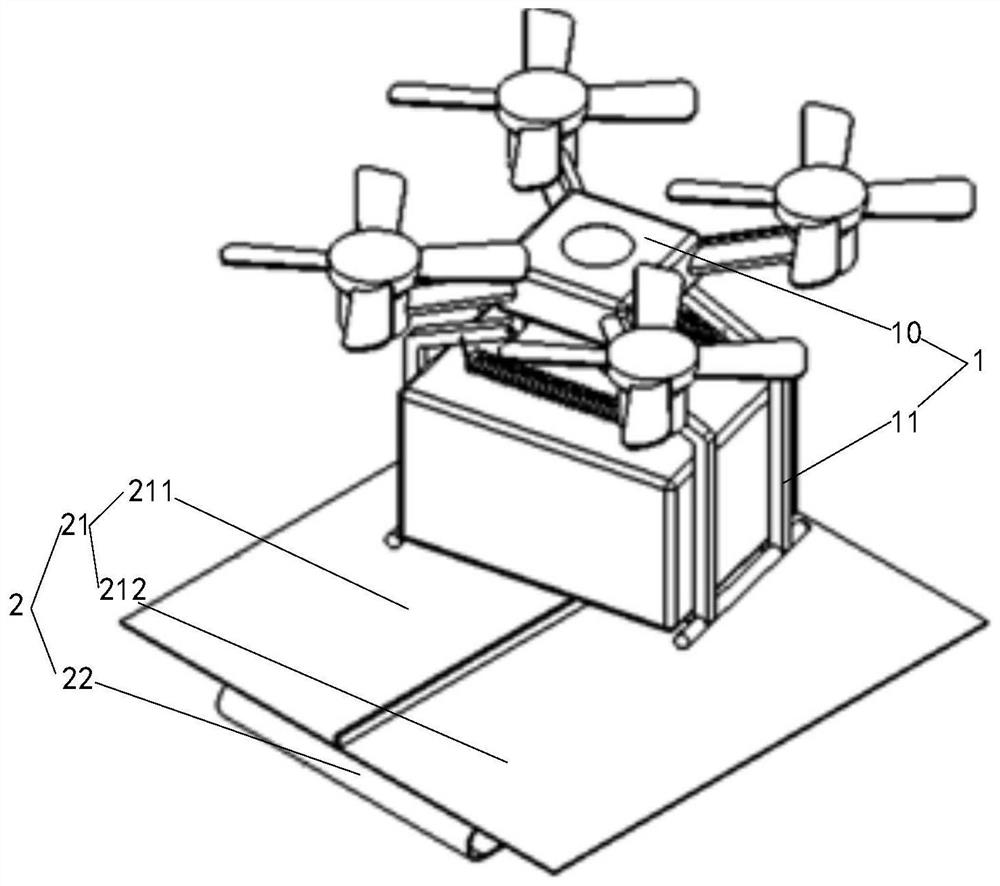

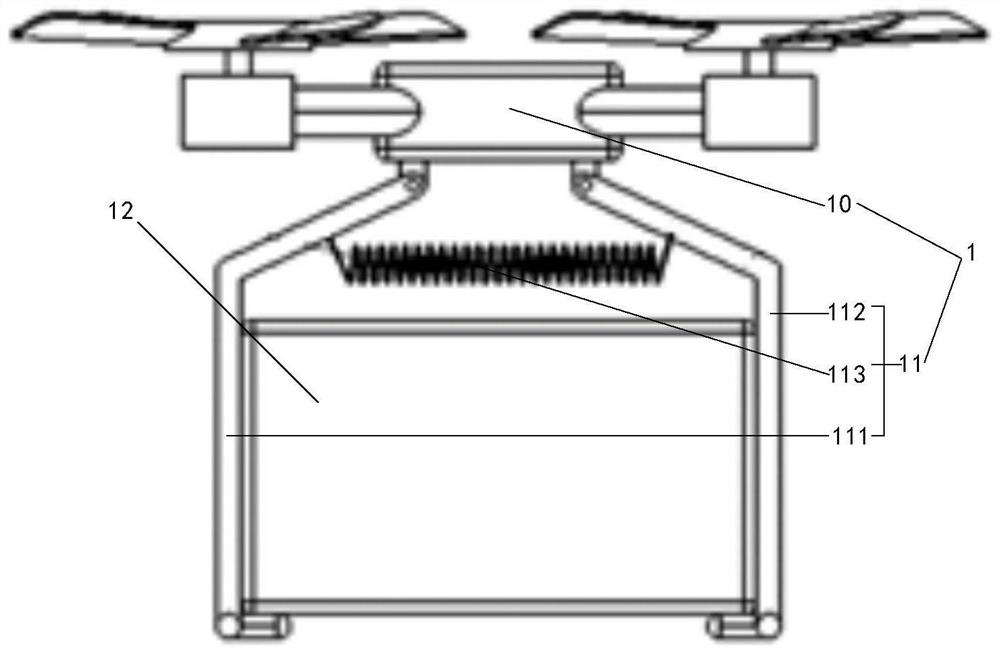

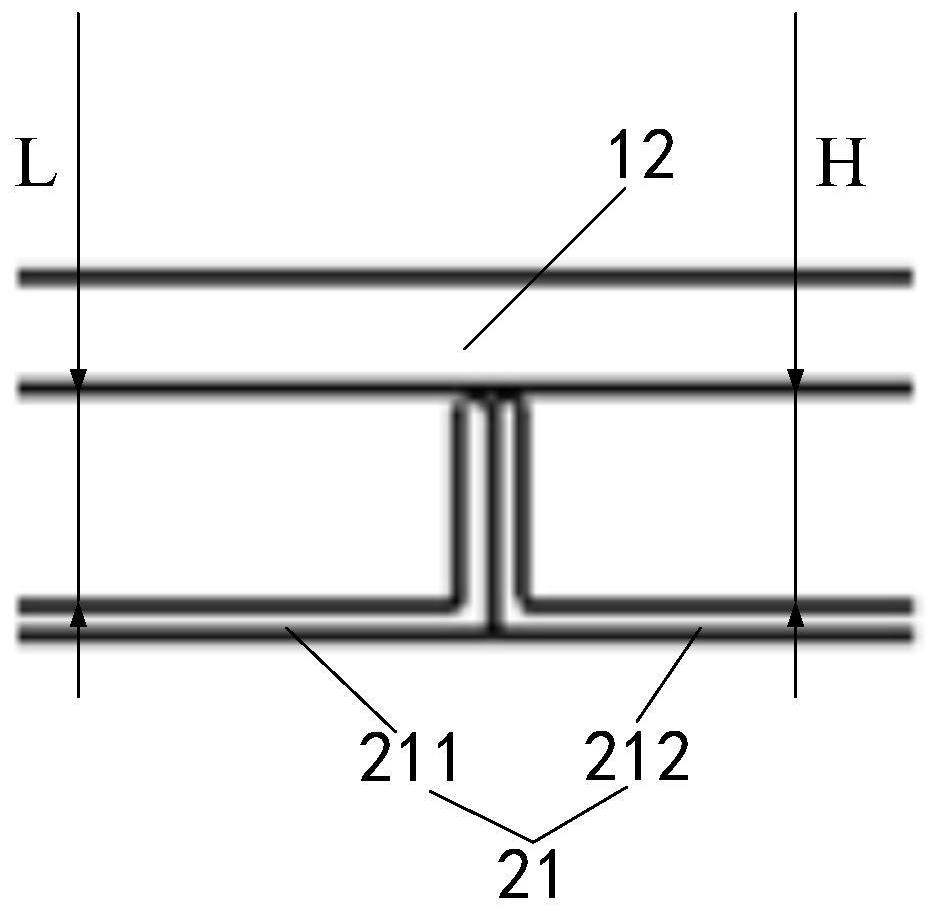

Logistics transportation system, unmanned aerial vehicle, landing platform and control method thereof

InactiveCN110398983ASimple connection structureImplement automatic expansionPosition/course control in three dimensionsPush pullElectric energy

The invention provides a logistics transportation system, an unmanned aerial vehicle, a landing platform and a control method thereof. The unmanned aerial vehicle is landed and stopped on the landingplatform, a first bracket in the unmanned aerial vehicle is in contact with the first side of a first push plate in the landing platform, and a second bracket in the unmanned aerial vehicle is in contact with the first side of a second push plate in the landing platform, wherein the first side is a landing surface where the unmanned aerial vehicle is landed and stopped; and a push-pull hook on thepush plate of the landing platform drives the movement of the first bracket and / or the second bracket. The unmanned aerial vehicle of the invention does not need to consume the own electric energy when unloading, and contributes to improving the endurance capability; and the brackets and the connection structure between the brackets and the main body of the unmanned aerial vehicle are relativelysimple, so that the self-weight and the manufacturing cost can be reduced.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

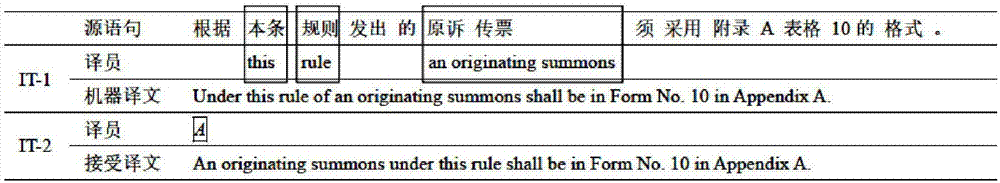

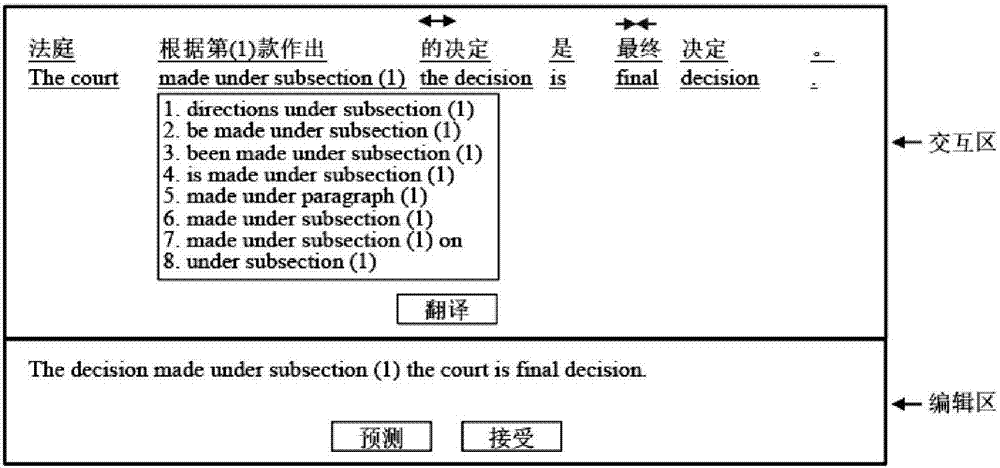

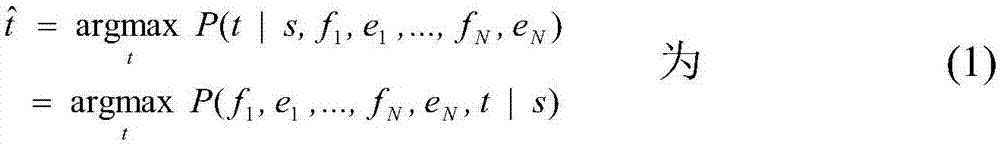

Interactive machine translation method based on bilingual segments

ActiveCN107885729AImprove translation efficiencyImprove translation qualityNatural language translationSpecial data processing applicationsMachine translationInteractive machine translation

The invention relates to an interactive machine translation method based on bilingual segments. The method includes the steps of establishing a mathematical model, wherein for each source language segment, a translator is provided with multiple translation options, and the optimal translation is obtained through the mathematical model; designing a translator interface, wherein the translator interface includes an interaction area and an editing area, the interaction area gives a source sentence and translation options after phrase segmentation, and the editing area gives a machine translationwhen the translator completes the confirmation and clicks a 'Translate' button; decoding, wherein after the translator confirms the bilingual segments in the interaction area, the translator's choiceof translation options for each segment fi and the current segmentation result of the source sentence are acquired, and a phrase-based statistical machine translation decoder is achieved by a multi-stack decoding algorithm. The method improves interactive protocols, allows the translator to confirm the bilingual segments, provides more clues to the translator, and gives the decoder more direct guidance, reduces the human labor in a human-computer interaction process, and promotes the improvement of interactive machine translation efficiency and translation quality.

Owner:SHENYANG AEROSPACE UNIVERSITY

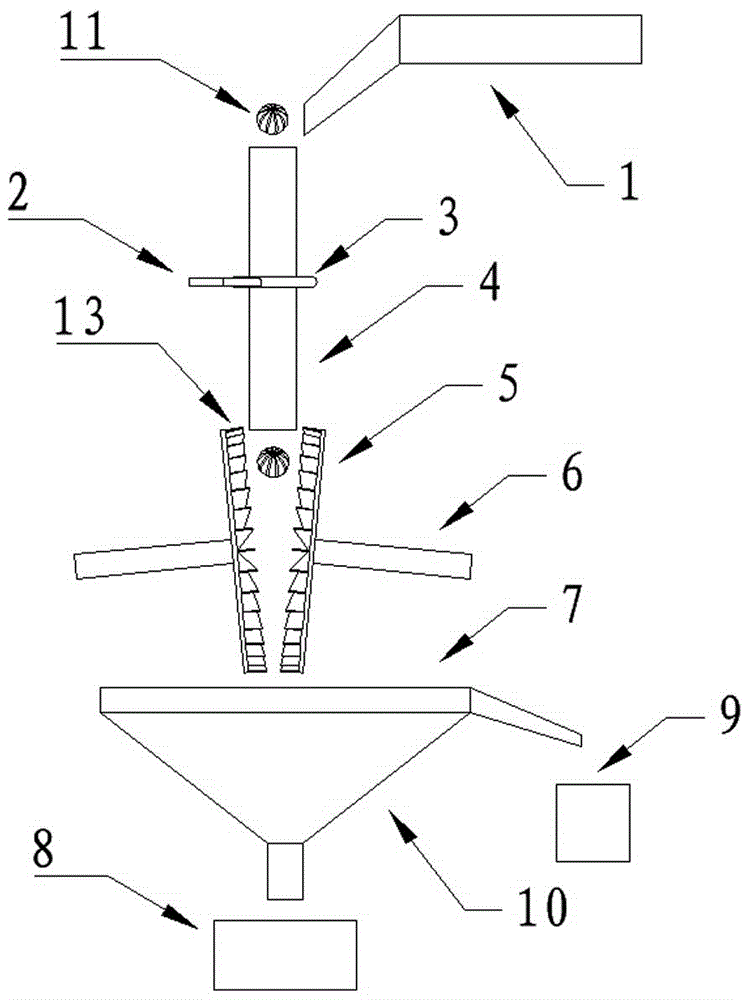

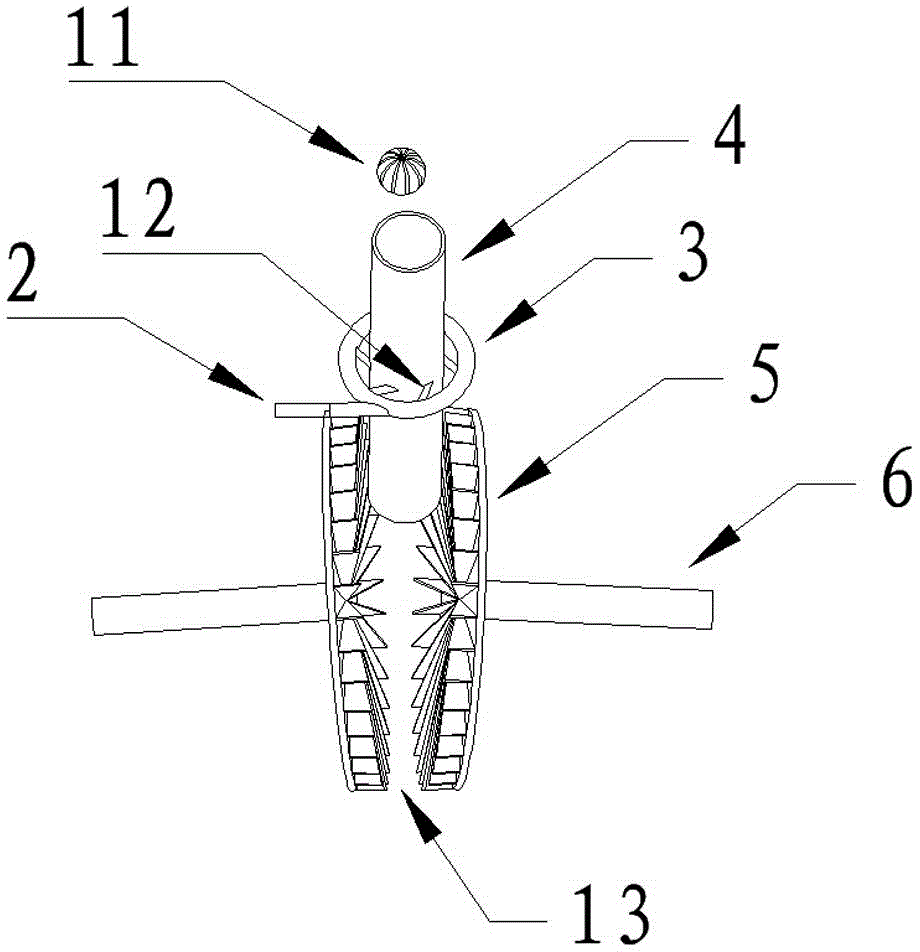

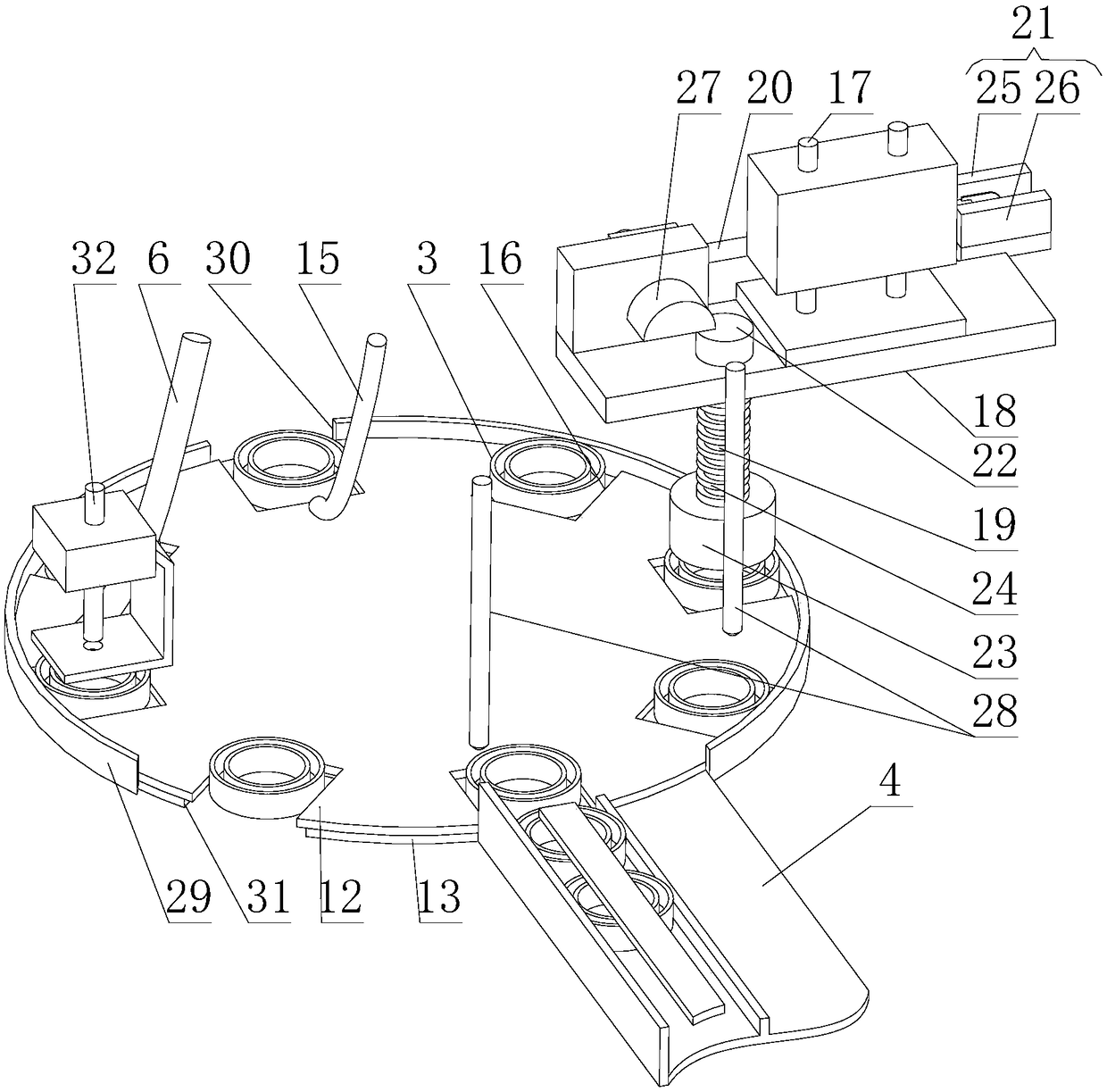

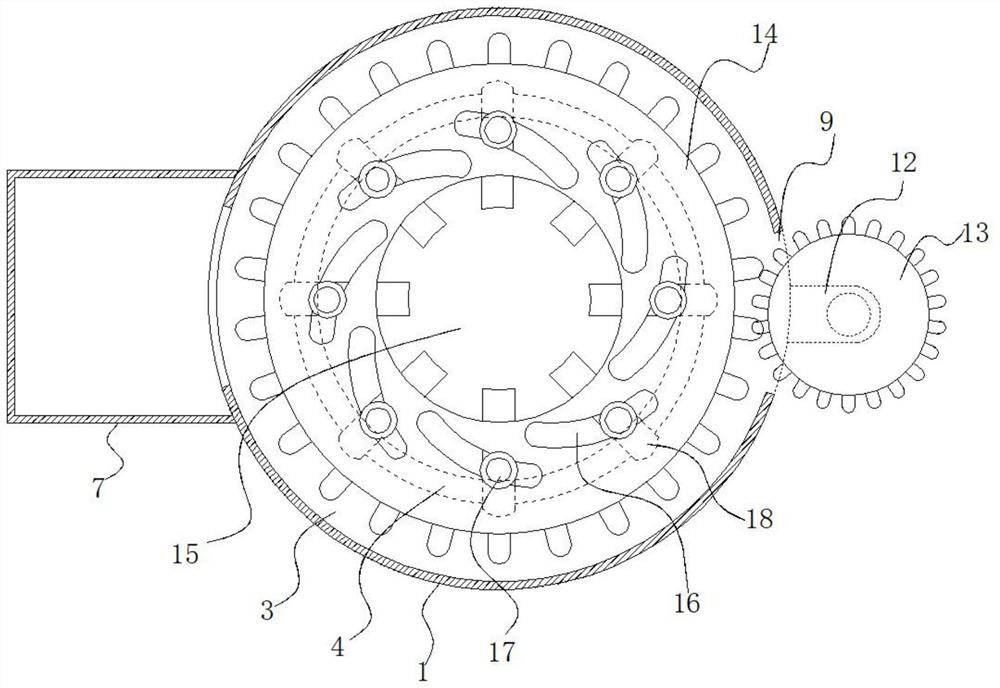

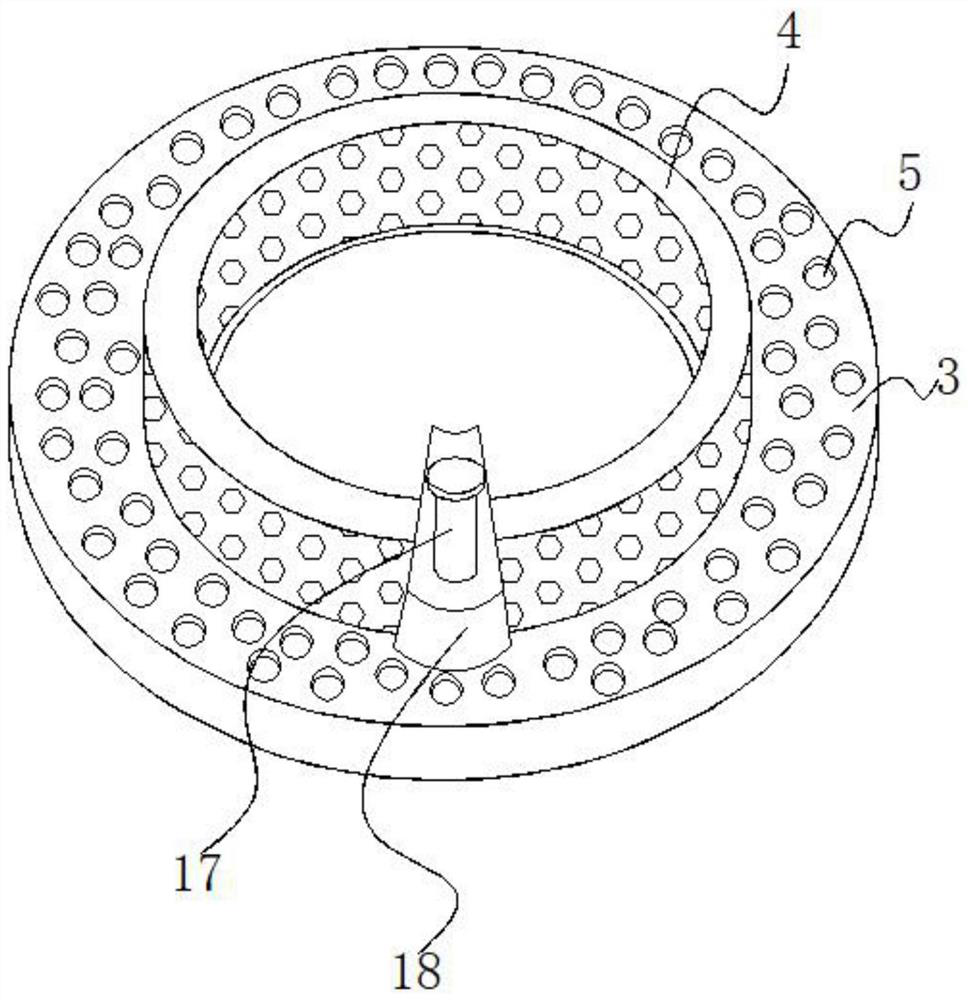

Rotary soft-blade lily bulb sectioning device

ActiveCN104351931AUniform and efficient feedingExact splitFood treatmentCycloneMechanical engineering

The invention discloses a rotary soft-blade lily bulb sectioning device. The rotary soft-blade lily bulb sectioning device comprises two soft turntables, wherein the two turntables are opposite to each other and rotate in opposite directions, each turntable is provided with soft blades for enhancing the attached drive to the lily bulb, and the distance between the two turntables is adjustable in the range of 1cm to 10cm; a cyclone pipe which is vertically arranged is arranged above each soft turntable, and an air spraying pipe which enters in the tangential direction is arranged no the cyclone pipe; a vibrating feeding machine is arranged above each soft turntable or the cyclone pipe; a vibrating sorting machine is arranged below each soft turntable. The soft turntables and the soft blades are ingeniously used for kneading the lily bulb, the centrifugal sectioning is promoted by the rotation acceleration, flexible extrusion and kneading also can be realized, not only can the sectioning be promoted, but also the lily bulb is not damaged, by combining the cyclone acceleration optimized application, high-efficient, reliable and nondestructive mechanical sectioning of the lily bulb can be realized, the labor intensity is alleviated, the working efficiency is greatly improved, a good foundation is set for the subsequent production of the lily bulb, and the prospect is wide.

Owner:OLSON FOOD JIANGMEN

Oil exploration equipment with drill bit cleaning and accurate detection functions

ActiveCN107654188APrecise and stable rotationImprove practicalityEarth drilling toolsDrilling machines and methodsPetroleumOil exploration

The invention relates to oil exploration equipment with drill bit cleaning and accurate detection functions. The oil exploration equipment with the drill bit cleaning and accurate detection functionscomprises a main body, a supporting frame, a drill bit, a detection mechanism, a cleaning mechanism and a central control mechanism. The cleaning mechanism comprises a lifting assembly and a cleaningassembly. The cleaning assembly comprises a driving unit and a reciprocating unit. The detection mechanism comprises a moving assembly, a swinging assembly and a telescopic assembly. The telescopic assembly comprises a shell, an air cylinder, a moving block, a telescopic frame and a magnetic prospector. According to the oil exploration equipment with the drill bit cleaning and accurate detection functions, through the detection mechanism, the prospection area of the magnetic prospector is wider, the magnetic prospector is kept at a relatively stable height from the ground, and the situation that the magnetic prospector is damaged when impacted by protrusions on the ground or detection data are inaccurate due to concaves in the ground is prevented. Through the cleaning mechanism, through automatic cleaning with a spraying head, manual work is reduced, higher convenience is achieved, and the practicality and reliability of the oil exploration equipment are improved.

Owner:SHENGLI OIL FIELD SHENGHUI OIL TECH DEV

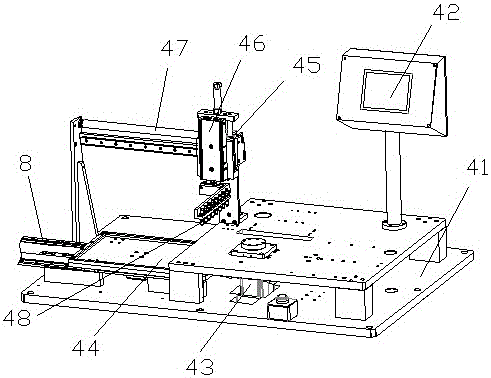

Full-automatic cutting machine

ActiveCN106563946AReduce energy consumptionImplement automatic croppingOther manufacturing equipments/toolsLarge fixed membersDistribution controlEngineering

The invention relates to a full-automatic cutting machine. The full-automatic cutting machine comprises a machine frame; the machine frame is provided with a power distribution control box and a touch operation screen which are matched with each other; the power distribution control box is provided with a workbench platen; the workbench platen is provided with a bracket and a rotary motor extending out of the bracket; the rotary motor is provided with a square rotary platform; a material loading mold is arranged on the rotary platform, and the rear side and the right side of the rotary platform are provided with a creasing device and a cutting device which are matched with the material loading mold correspondingly; the cutting device comprises a shearing frame arranged on the workbench platen; the shearing frame is connected with a propelling air cylinder arranged on the right side of the workbench platen and is provided with a shearing air cylinder, and a cutting knife is arranged below the shearing air cylinder. According to the full-automatic cutting machine, the square rotary platform is adopted, the four edges of the square rotary platform are provided with metal sheet material loading molds, and metal sheets are sequentially matched with the creasing device and the cutting device through the rotary platform, so that energy consumption is reduced, automatic cutting can also be achieved, the labor intensity is greatly relieved, and the cutting quality is improved.

Owner:DONGGUAN UNIV OF TECH

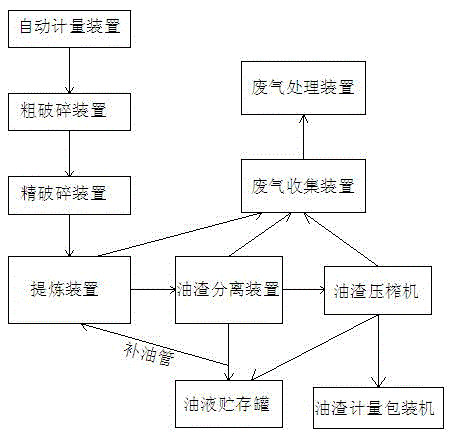

Non-intermittent industrial oil refining treatment technology and automatic refining system

ActiveCN105219514APrevent scorching etc.Batchless RefiningFatty-oils/fats productionOil and greaseAutomatic control

The invention relates to a non-intermittent industrial oil refining treatment technology. The technology comprises the steps of metering, crushing, refining, oil residue separation, squeezing, waste gas collection, waste gas treatment and the like. The invention further relates to an automatic refining system for non-intermittent industrial oil refining. The system is characterized by comprising an automatic metering device, a coarse crushing device, a fine crushing device, a refining device, an oil residue separating device, an oil residue squeezing machine, a waste gas collecting device, a waste gas treating device, an oil residue metering packaging machine, an oil liquid storage pot and an automatic control system. By the adoption of the non-intermittent industrial oil refining treatment technology and the automatic refining system, non-intermittent oil refining can be achieved, the temperature in different stages of the refining process is better controlled, the oil refining quality is improved, oil residues and waste gas are treated, environmental protection is achieved, and meanwhile oil residue utilization rate is improved.

Owner:HUNAN XIANGBO COMML GREASE CO LTD

Wet sander

ActiveCN111730473AImprove processing efficiencyReduce human laborDispersed particle filtrationTransportation and packagingSanderWater storage

The invention discloses a wet sander. The wet sander comprises a shell, wherein the upper end of the shell is fixedly provided with a handle, the inner top of the shell is fixedly provided with a motor, an output shaft of the motor is fixedly provided with a rotating shaft, the bottom of the rotating shaft is fixedly provided with a sanding plate, the circumferential side wall of the rotating shaft is rotationally connected with a water storage tank, the side wall of the rotating shaft is fixedly provided with a rotating plate which is slidably connected with the bottom of the water storage tank, and the upper end of the rotating plate is provided with a dislocation groove in a penetrating mode. The wet sander has the advantages that the rotating shaft drives the rotating plate to rotate in the rotary processing process of the sanding plate, so that the dislocation groove is superposed with a drainage hole, water drops and enters spraying holes under the action of centrifugal force, and then a spraying groove sprays water to the surface to be processed of a plate, so that the automatic sprinkling in the processing process is completed, the position is the position to be processed,the sprinkling is accurate without manual sprinkling and control over the sprinkling position, the processing efficiency is improved, and manual labor is reduced.

Owner:临沂新达五金工具有限公司

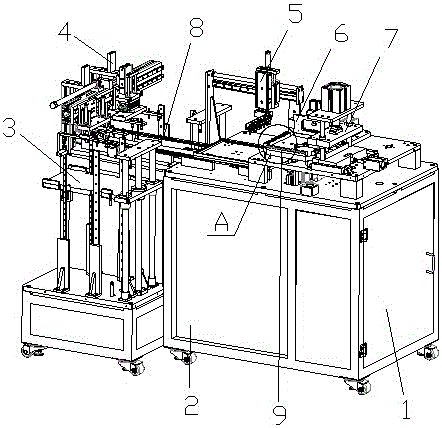

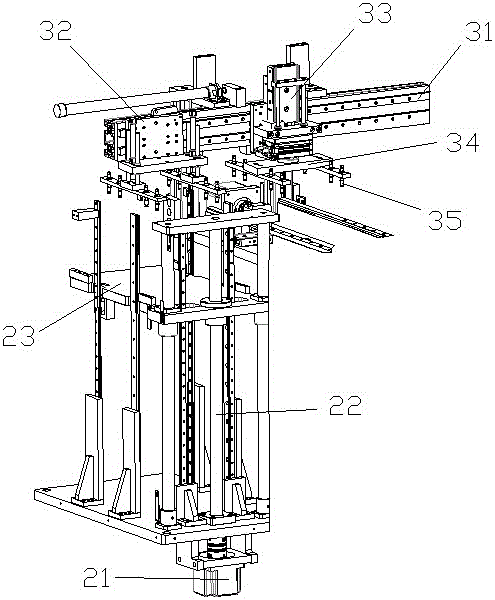

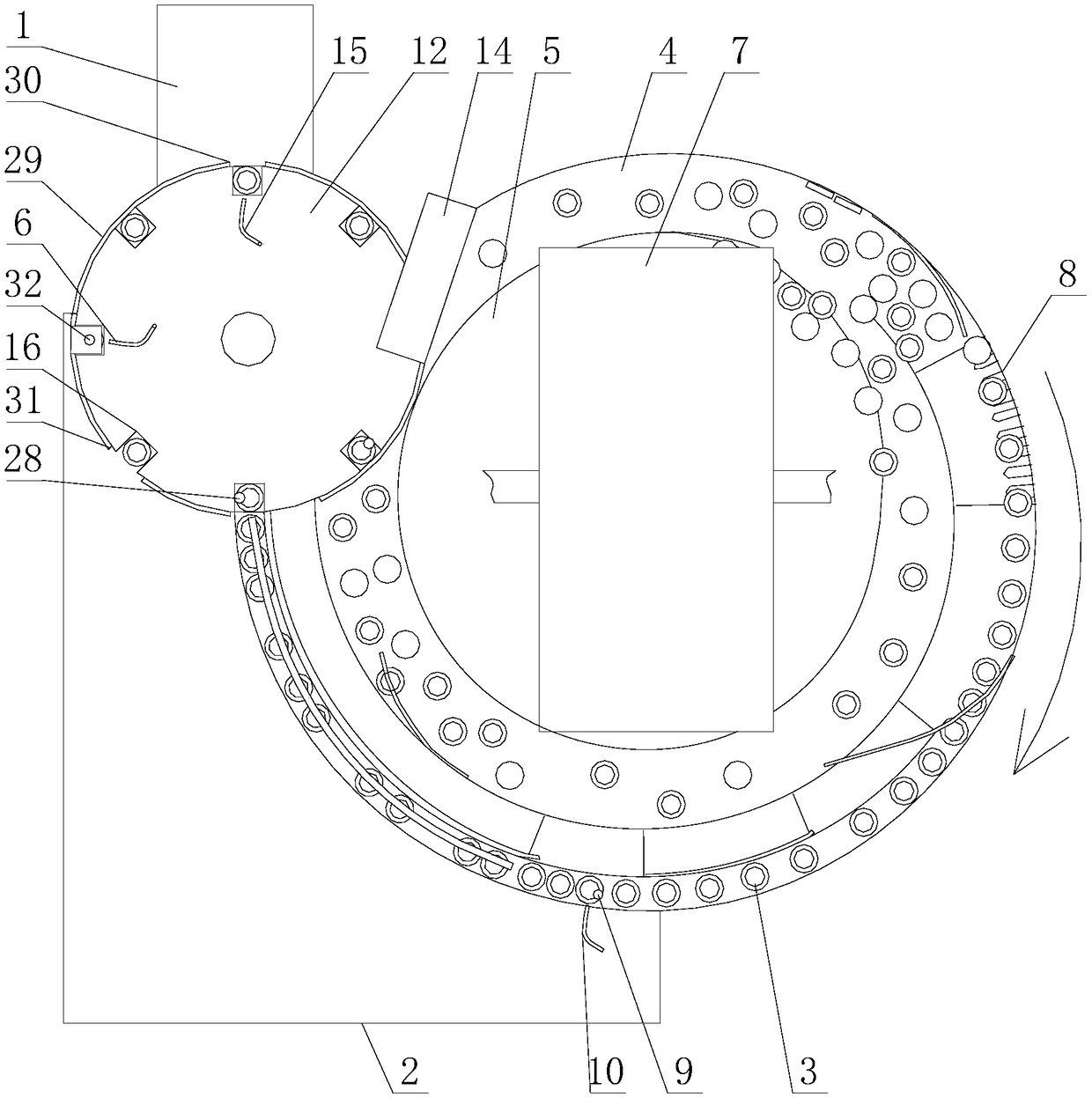

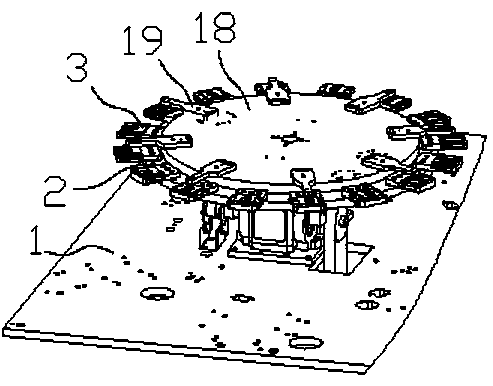

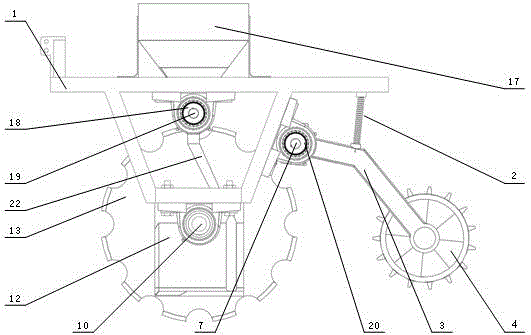

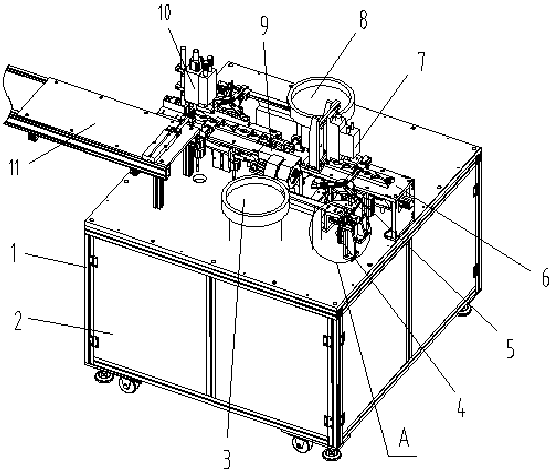

Automatic mounting system for mutual inductor magnetic ring shell cotton rings

The invention relates to an automatic mounting system for mutual inductor magnetic ring shell cotton rings, and belongs to the technical field of mutual inductor fittings. The system comprises a mounting roller, a vibration disc with a spiral guide plate and a screening mechanism connected with an output end of the spiral guide plate, which are arranged in a mutual inductor magnetic ring shell conveying direction in sequence; an output end of the screening mechanism is connected with a finished product storage box and a defective product recovery box; an output end of the mounting roller is positioned above an input end of the vibration disc, or the two are connected by dint of a conveying mechanism; a reverse eliminating section for mutual inductor magnetic ring shells, a shell removing mechanism and a color sensor cooperating with a control end thereof are arranged at the middle part of the spiral guide plate; a collecting end of the color sensor is towards the upper end surface of the spiral guide plate; and an output end of the shell removing mechanism is connected with the defective product recovery box. The system uses a mechanical production mode to replace manual production, prominently improves the production efficiency, and reduces the production cost.

Owner:河北申科电力股份有限公司 +5

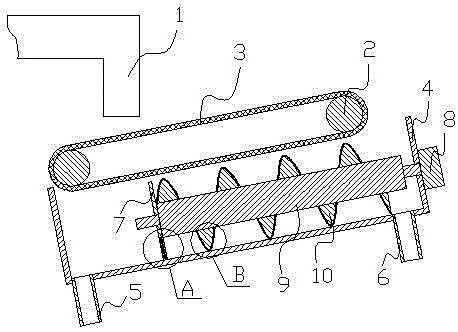

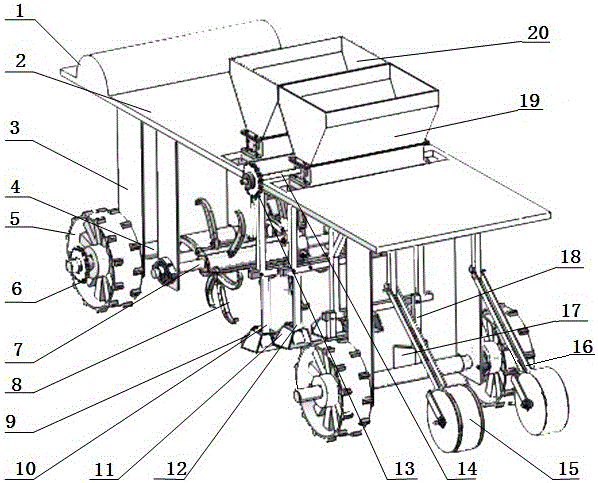

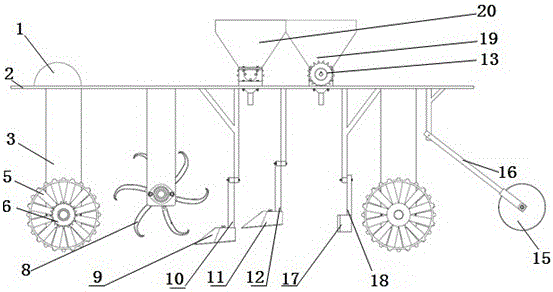

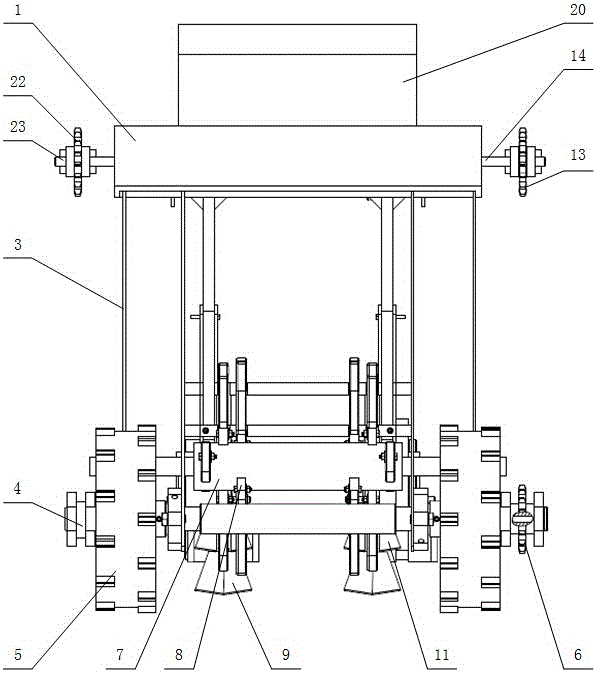

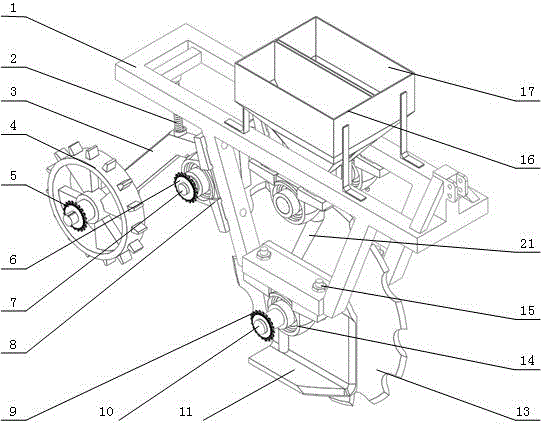

Fagopyrum tataricum no-tillage planter

InactiveCN106385814AReduce human laborMeet the sowing requirementsSpadesPloughsAgricultural engineeringProtection sex

The invention relates to a fagopyrum tataricum no-tillage planter, and belongs to the field of agricultural machinery design. The fagopyrum tataricum no-tillage planter comprises a rack assembly, an anti-blocking furrowing assembly, a fertilization and seeding assembly, a soil covering and pressing assembly and a transmission assembly, wherein the anti-blocking furrowing assembly, the fertilization and seeding assembly, the soil covering and pressing assembly and the transmission assembly are fixedly mounted on the rack assembly. By adopting the fagopyrum tataricum no-tillage planter, fagopyrum tataricum no-tillage planting in a corn stubble land can be achieved, procedures of furrowing, fertilization, seeding, soil covering and pressing can be completed at one time, the human labor can be reduced, seeding requirements can be met, and the operation efficiency can be improved; due to adoption of a straight blade rotary blade, an active anti-blocking technique is achieved, good anti-blocking properties can be achieved, the soil disturbance is small, and a small amount of power is consumed; the fagopyrum tataricum no-tillage planter is simple in structure and convenient to adjust, and has a great significance in popularizing protective cultivation in corn and coarse cereal planting areas.

Owner:KUNMING UNIV OF SCI & TECH

Road surface fallen leaf cleaning device

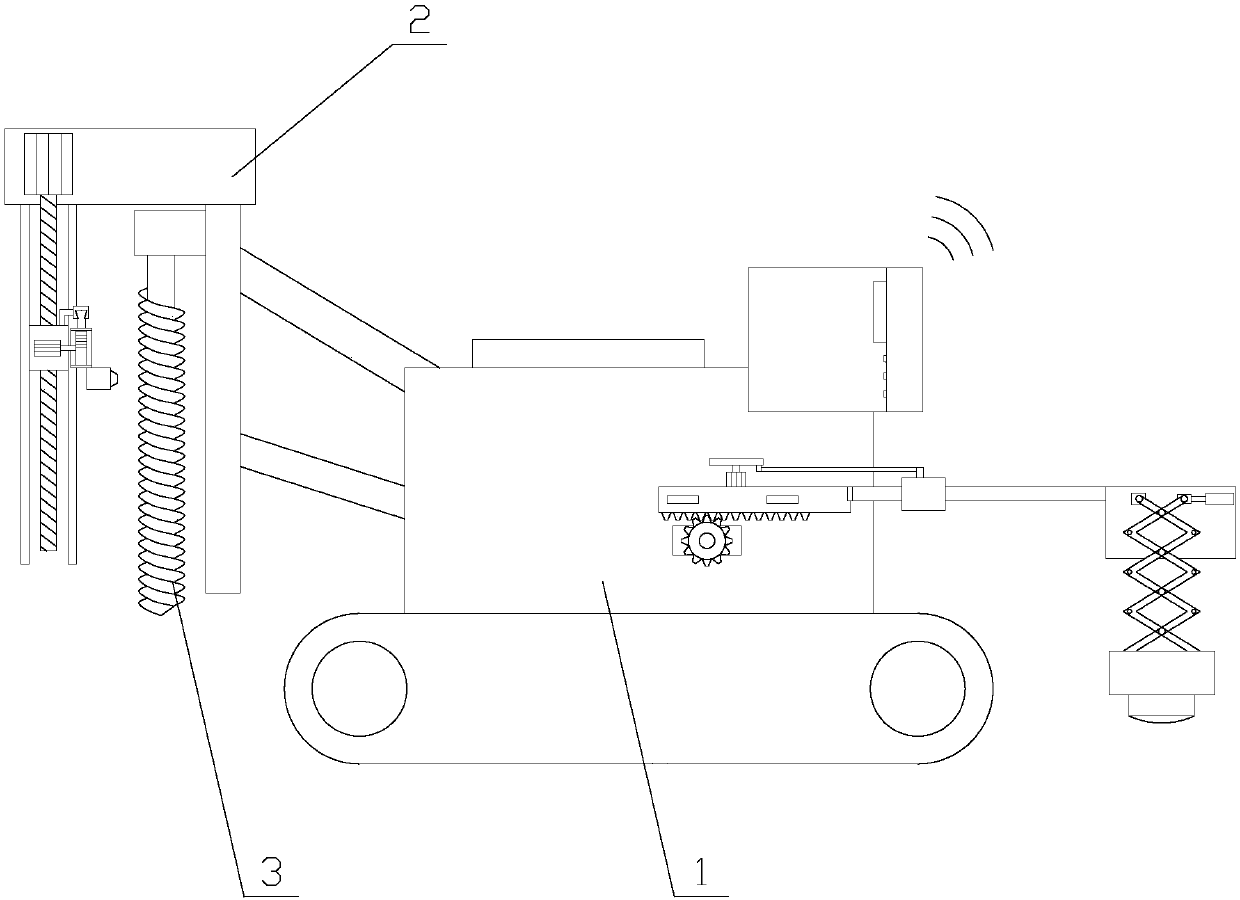

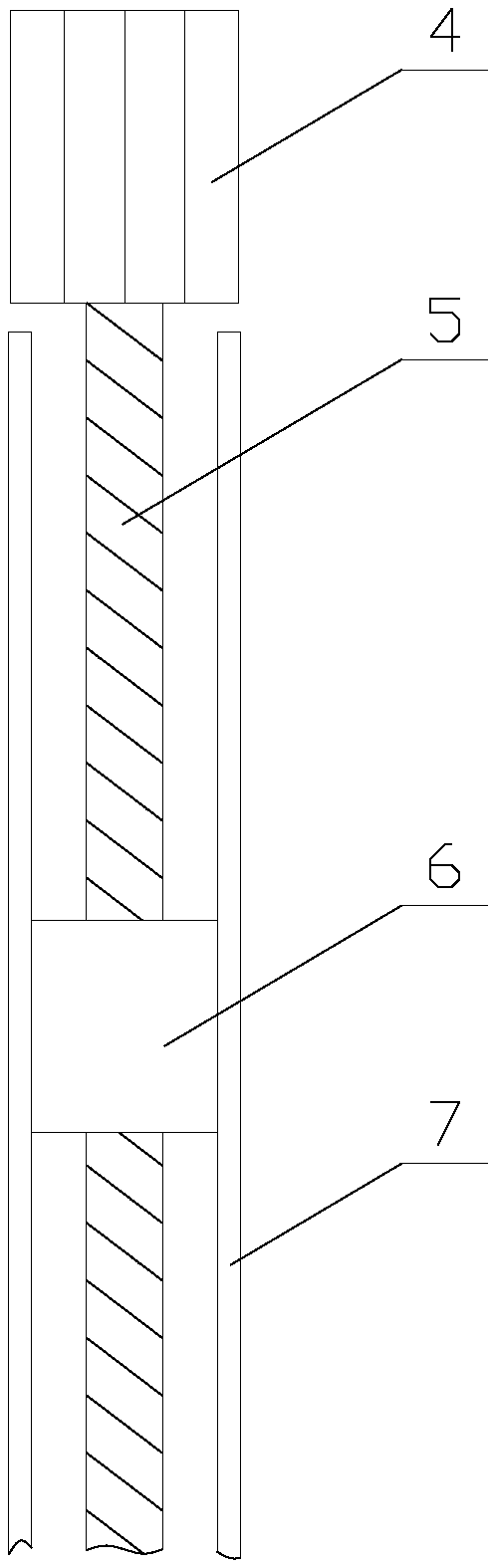

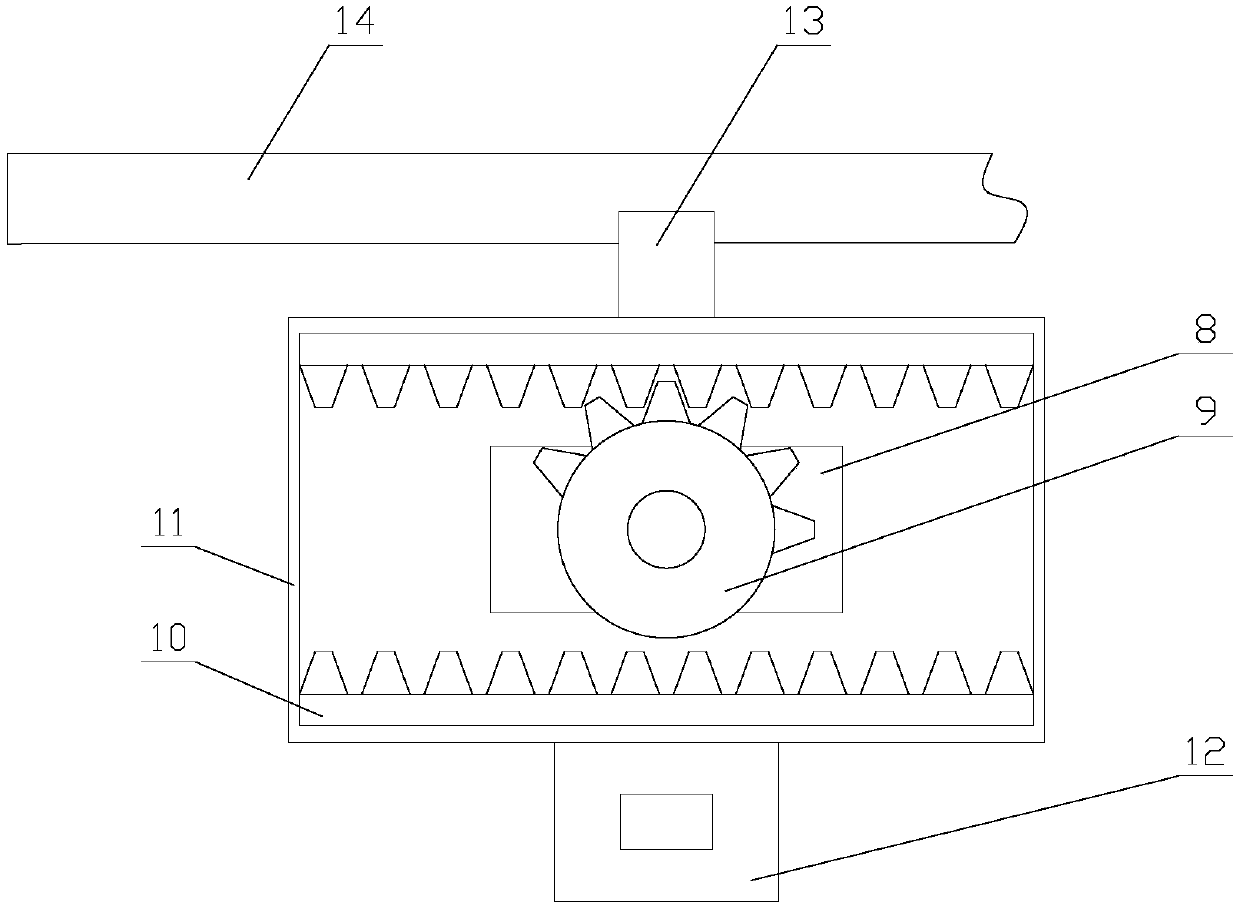

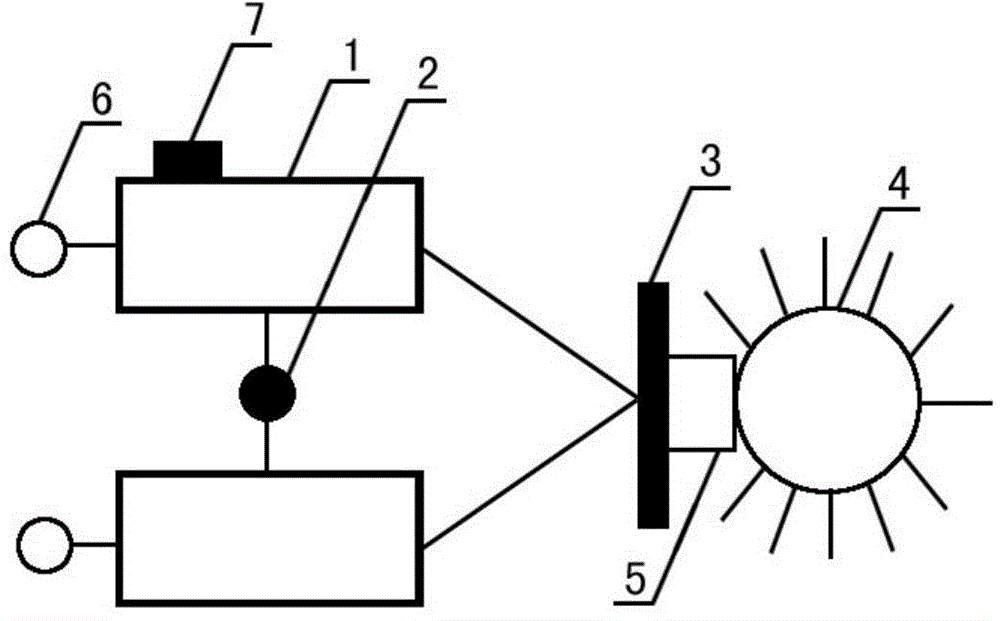

A road surface fallen leaf cleaning device comprises a rack (1); a power switch (2) is arranged on the rack, and a lifting device (3) is arranged at the front end of the rack and is linked with a broom device (4); the broom device (4) is connected with a refuse chute (5); when the device is used, the power switch (2) is started, and the broom device (4) descends to the proper position through the lifting device (3) to vertically swing, and leaves are swept into the refuse chute (5); stepping devices (6) are arranged so as to facilitate advancing motion; a prompt device (7) is arranged, and therefore prompt information is sent out when the cleaning process is started; a manner for reminding information is sounds or LED lamplight display; the lifting device (3) can properly perform ascending or descending motion and is suitable for cleaning different sites; a high-definition camera probe is arranged on the rack, and the cleaning process is remotely monitored; and the aim of intelligently cleaning leaves at urban street corners is achieved, the operation process is simple and convenient, the practicability is high, and human labor force is relieved.

Owner:ANQING DADONG ELECTRONICS SCI & TECH CO LTD

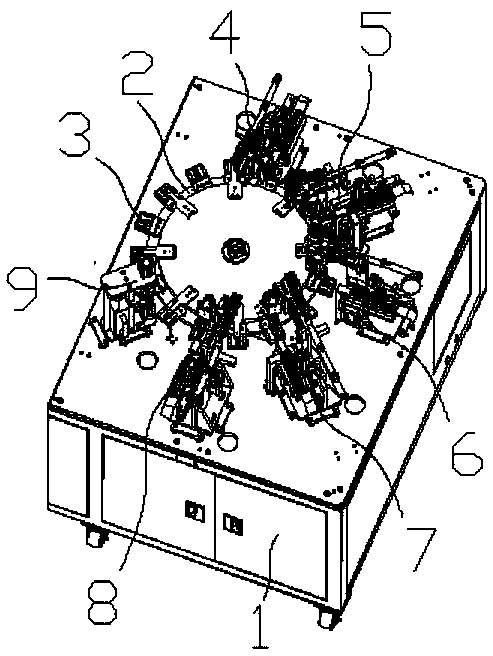

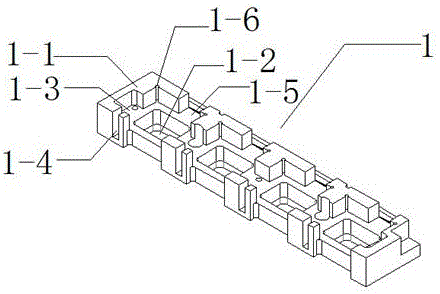

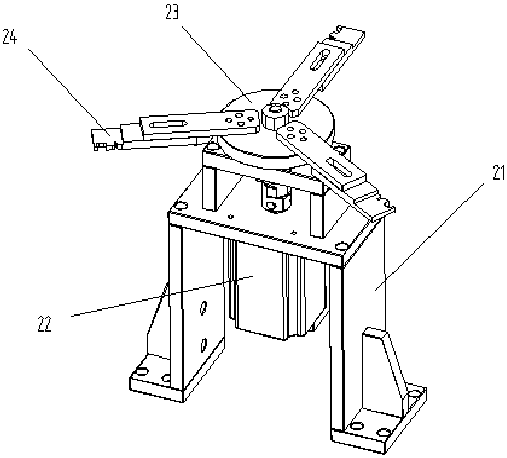

Interface chip assembling mechanism of electronic product

InactiveCN110587294ARealize continuous automatic assemblyPlace stableAssembly machinesEngineeringMechanical engineering

The invention relates to an interface chip assembling mechanism of an electronic product. The interface chip assembling mechanism of the electronic product comprises a machine frame. A rotating disk with a drive structure is arranged on the machine frame. The rotating disk is evenly provided with assembling carriers. Each assembling carrier comprises a carrier body. Each carrier body is provided with a material loading opening with the width equal to the length of a lower shell. The bottom face of each material loading opening is provided with an elastic sheet groove matched with an elastic sheet in position and a head matching groove matched with the head of the lower shell in position and shape. The two side faces of the innermost end of each material loading opening are provided with aninclined opening facilitating assembling and a terminal matching opening matched with a terminal correspondingly. The machine frame is sequentially provided with a lower shell feeding device, a lowerterminal feeding device, a clamping block feeding device, an upper terminal feeding device, an upper shell feeding device and a pressing device in the rotation direction of the rotating disk, and thelower shell feeding device, the lower terminal feeding device, the clamping block feeding device, the upper terminal feeding device, the upper shell feeding device and the pressing device are matchedwith the assembling carriers. By means of the structural design of the assembly carriers, the lower shell can be stably placed, the rotating disk cooperates with the feeding devices of all the parts,and then continuous automatic assembly of the interface chip is achieved; and in this way, the assembly efficiency is improved, and work intensity of workers is lowered.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Active no-tillage planter

InactiveCN106068820AReduce human laborMeet the sowing requirementsPlantingAgricultural rollersAgricultural engineeringSprocket

The invention relates to an active no-tillage planter, and belongs to the field of agricultural machines. The active no-tillage planter comprises a rack assembly, an anti-blocking furrowing assembly, a fertilizing and sowing assembly, an earthing and pressing assembly and a transmission assembly, wherein the anti-blocking furrowing assembly, the fertilizing and sowing assembly, the earthing and pressing assembly and the transmission assembly are fixedly installed on the rack assembly. The anti-blocking furrowing assembly comprises a driving chain wheel, a driving shaft, an L-type furrowing cutter I, an L-type furrowing cutter II and a disc stubble cutting cutter, wherein the driving chain wheel is installed at one end of the driving shaft, the disc stubble cutting cutter is installed on the driving shaft, and the L-type furrowing cutter I and the L-type furrowing cutter II are arranged at the two sides of the disc stubble cutting cutter respectively. No-tillage sowing operation in the hilly and mountain area can be achieved, the processes of anti-blocking furrowing, fertilizing, sowing and pressing are completed at a time, human labor is relieved, the sowing requirement is met, and operation efficiency is improved; the active anti-blocking technology is achieved, the anti-blocking performance is high, soil disturbance is small, and power consumption is low. The active no-tillage planter is simple in structure and convenient to adjust.

Owner:KUNMING UNIV OF SCI & TECH

Automatic skill test machine

PendingCN106154150AEfficiencyReduce human laborCircuit interrupters testingProduct recoveryEngineering

The invention discloses an automatic skill test machine, which comprises a tooling, a tooling feeding device, a tooling dust removal device, a product feeding table, a skill device, a defective product recovery device and a qualified product discharging opening, wherein the tooling comprises a tooling body and a product clamp groove formed inside the tooling body; the tooling is arranged on the tooling feeding device; the tooling feeding device is connected with the tooling dust removal device through a tooling advancing rail; the tooling dust removal device is connected with the product feeding table through a tooling return rail; the product feeding table is connected with the skill device through a product feeding rail; the skill device is connected with the defective product recovery device through a rail; the qualified product discharging opening is formed in one side of the unqualified product recovery device. The automatic skill test machine has the advantages that the operation is convenient; the work speed is high; the production efficiency is high; the product is more standard and integral; meanwhile, the fatigue of an operator can be effectively reduced.

Owner:MINGGUANG WANJIA LIANZHONG ELECTRONICS

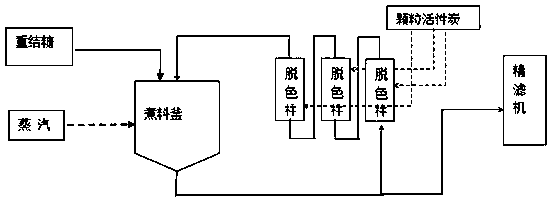

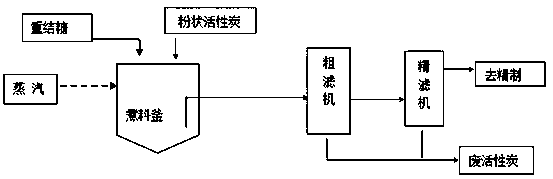

Decolorizing method of recrystallized sugar in acesulfame potassium production

InactiveCN110747296AReduce human laborLess impuritiesSaccharides productionProcess engineeringBiology

The invention relates to a decolorizing method of recrystallized sugar in acesulfame potassium production. The method comprises the following steps: (1) adding the recrystallized sugar and deionized water into a boiling kettle, controlling the mass ratio of recrystallized sugar to deionized water to be 1:(1-1.3), and performing stirring and heating to 85-95 DEG C; (2) adding 500 Kg of granular activated carbon into each decolorizing column tower in advance, feeding the obtained sugar solution into each decolorizing column tower at a speed of 30-40 M<3> / h, returning the decolorized sugar solution to the boiling kettle, and keeping the temperature at 85-95 DEG C all the time; and (3) controlling the water temperature of the jacket of a fine filter to be 95-100 DEG C, feeding the mixed solution of the sugar solution and the activated carbon into the fine filter at 1.2-1.6 M<3> / h, clarifying the obtained filtrate, feeding the clarified filtrate into a crystallization section, and crystallizing the clarified filtrate. The method has the advantages of simplicity in operation, reduction of the labor intensity, high utilization rate of raw materials, realization of cleanness and environmental protection due to pyrolysis regeneration of the activated carbon, shortening of the boiling time by at least half an hour through circular heating using a forced circulation pump, ensuring of continuous production of a workshop section, great increase of the production efficiency, realization of online operation, effectiveness in reduction of impurities, and quality improvement.

Owner:ANHUI JINGHE IND

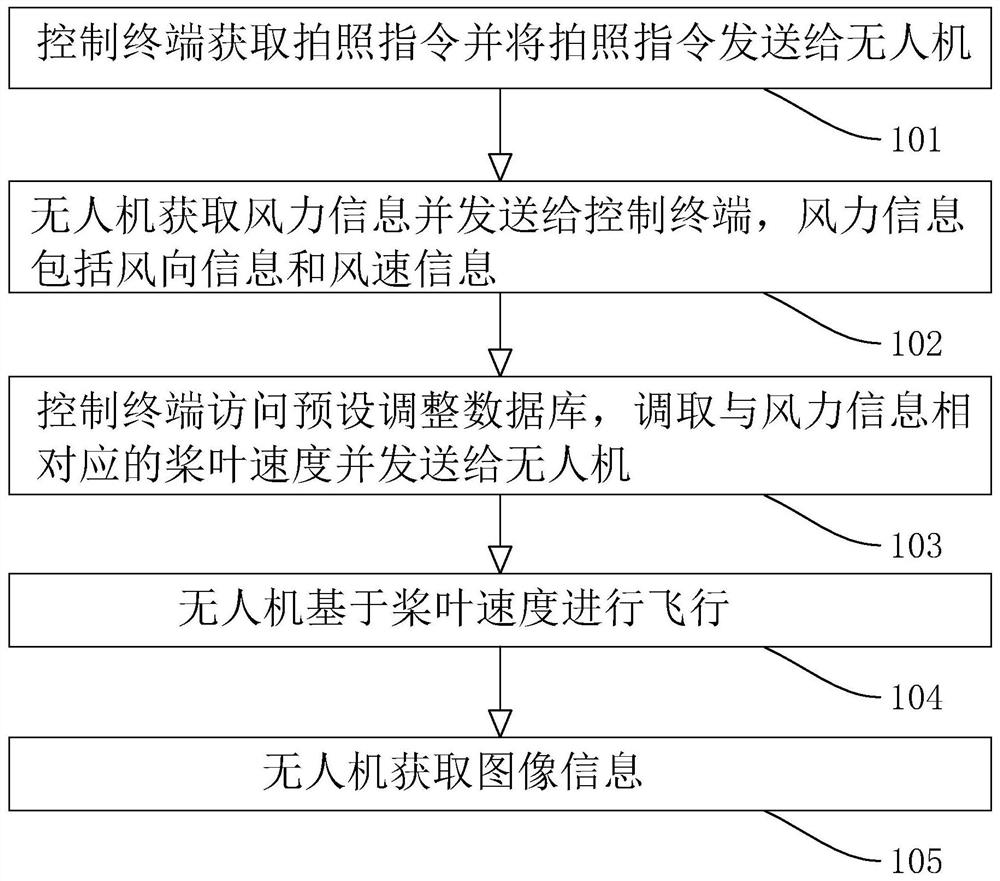

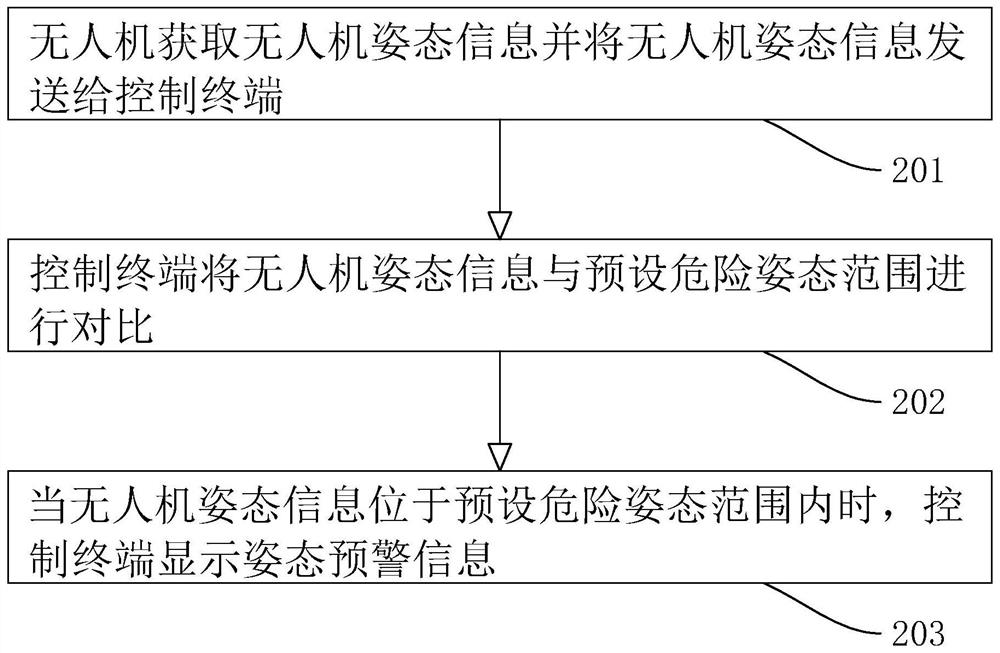

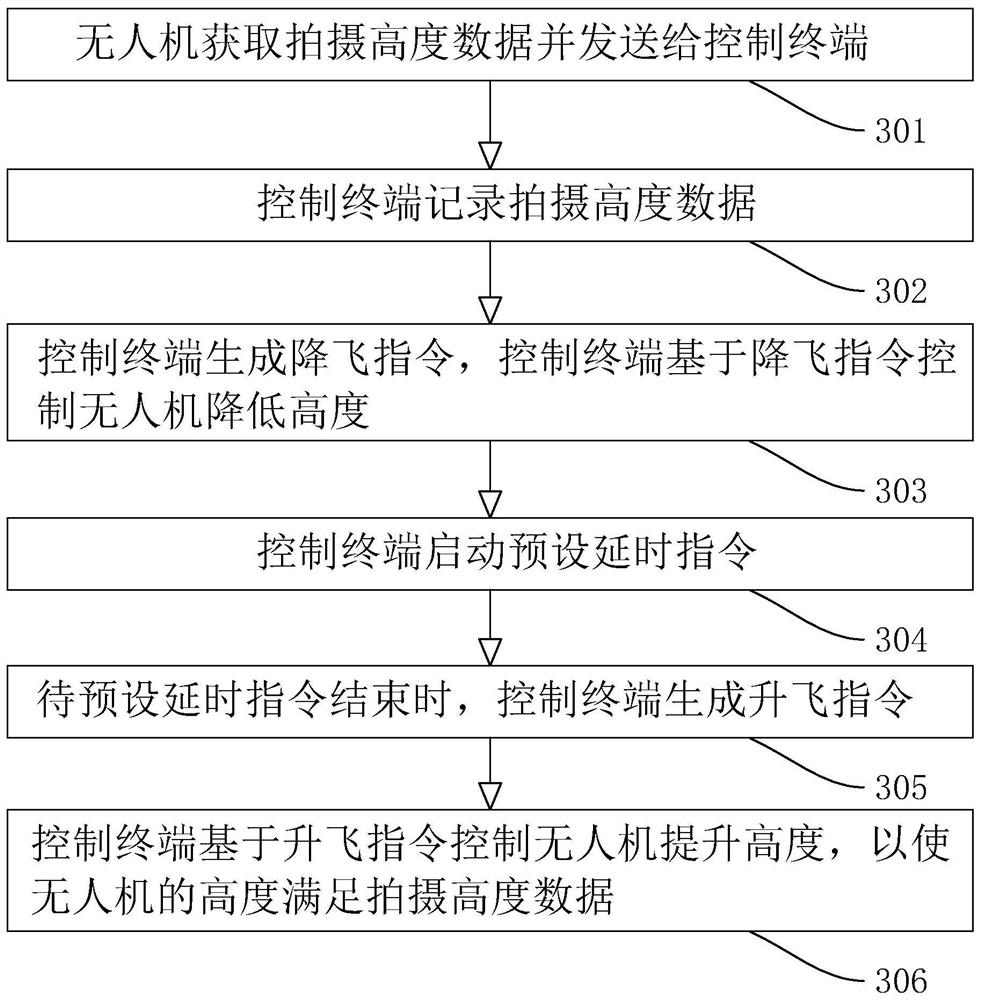

Method and system for oblique shooting measurement of unmanned aerial vehicle

PendingCN113759951ANot easy to shakeEasy to judgePhotogrammetry/videogrammetryAttitude controlWind runUncrewed vehicle

The invention relates to an unmanned aerial vehicle oblique shooting measurement method and system, and belongs to the technical field of unmanned aerial vehicle shooting; the method comprises the steps that a control terminal obtains a shooting instruction and sends the shooting instruction to an unmanned aerial vehicle; the unmanned aerial vehicle obtains wind power information, wherein the wind power information comprises wind direction information and wind speed information; the control terminal accesses a preset adjustment database, calls a paddle speed corresponding to the wind power information and sends the paddle speed to the unmanned aerial vehicle; the unmanned aerial vehicle flies based on the paddle speed; and the unmanned aerial vehicle acquires image information. The unmanned aerial vehicle has the advantages that the influence of wind power on shooting of the unmanned aerial vehicle is reduced, and unclear conditions during oblique image shooting are reduced.

Owner:深圳市中正测绘科技有限公司

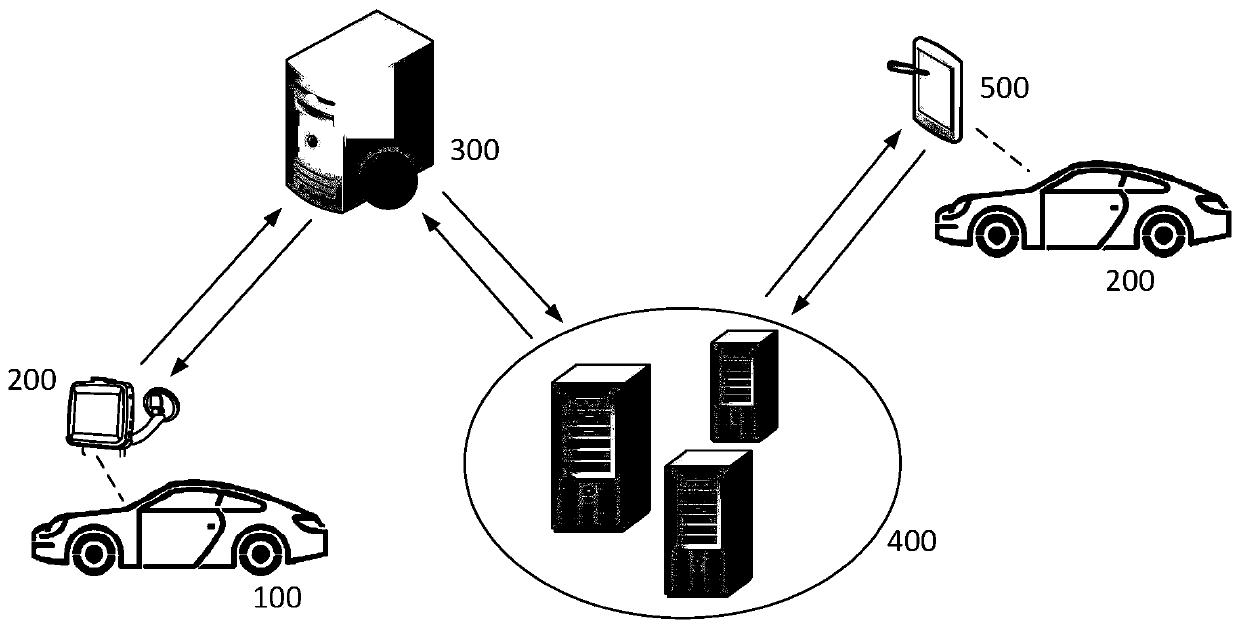

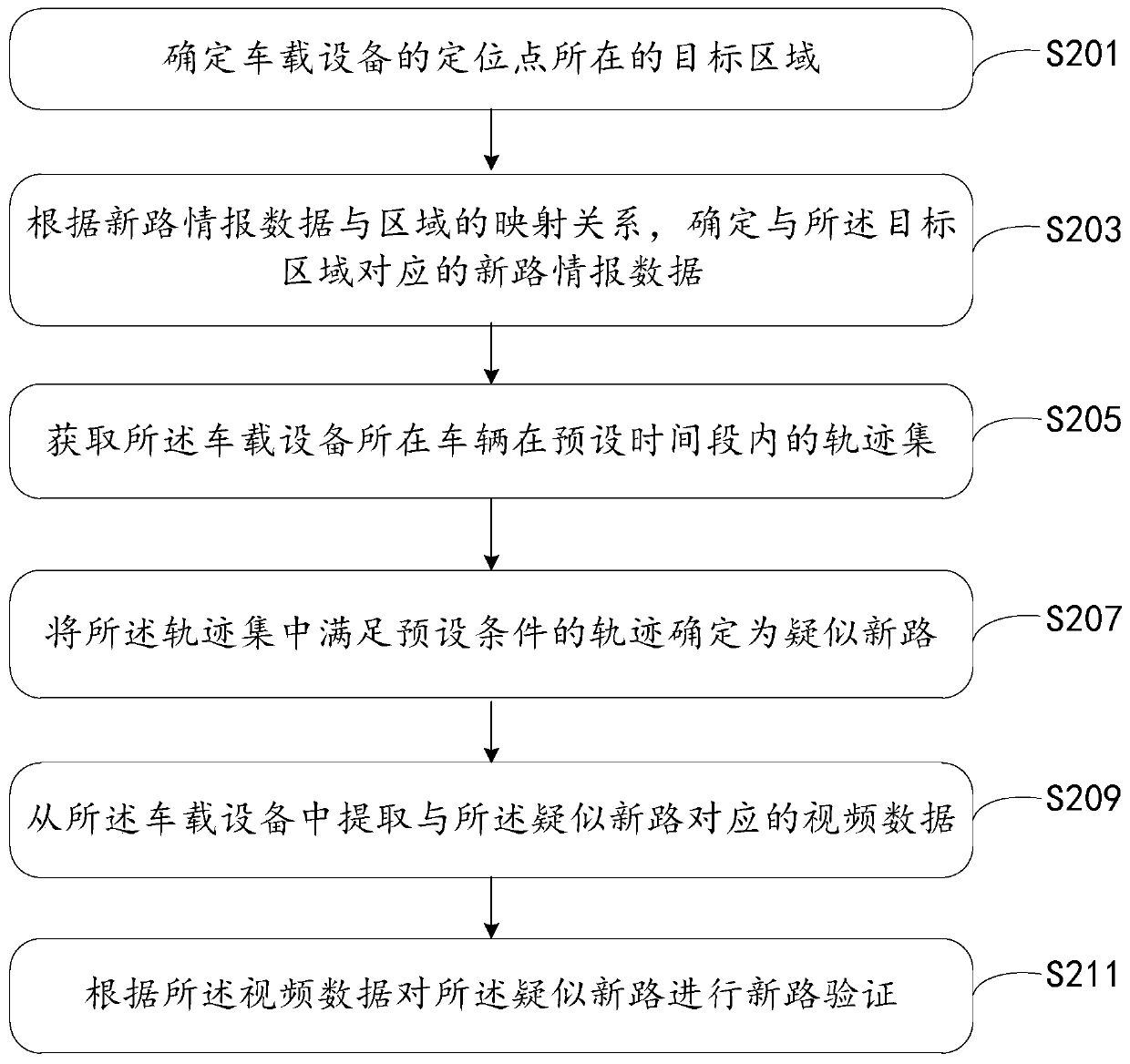

New road discovery method and device, equipment and storage medium

ActiveCN110516019AReduce collection costsImprove collection efficiencyCharacter and pattern recognitionGeographical information databasesRoad networksComputer science

The invention relates to the field of traffic information service, and provides a new road discovery method and device, equipment and a storage medium. The new road discovery method comprises the steps: collecting new information data in advance, judging whether a vehicle is near a new road information place by analyzing a positioning point of vehicle-mounted equipment carried on the vehicle; whenthe vehicle is near a new road information place, matching the recent track of the vehicle with the existing road network data; taking a part, which cannot be matched with the existing road network,in the track as a suspected new road; and further calling the video data of the vehicle-mounted equipment, and verifying whether the suspected new road is the new road through the road sign recognition and matching technology. Therefore, the new road discovery method can obviously improve the new road information collection and verification efficiency, can accelerate the map product updating progress, does not need collection team field investigation, and reduces the information collection cost.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Grain rapid dryer

InactiveCN106332964AQuick drying and dehumidificationEasy to storeSeed preservation by dryingSteering wheelEngineering

The invention discloses a grain rapid dryer, which comprises a feed inlet, a hot-air dryer, a discharge port, a water outlet, a condensation tank, a humidity measurement instrument, a chute, a conveyor belt, steering wheels, a brake, a dehumidifier and a dryer body. One side of the top of the dyer body is provided with the feed inlet. The top of the dyer body is provided with the hot-air dryer. The chute is installed at one side of the feed inlet. The bottom of the dyer body is provided with the condensation tank, the top of which is provided with the dehumidifier. The bottom of the condensation tank is equipped with the water outlet. The humidity measurement instrument is mounted inside the dyer body. The device is used for drying and dehumidifying grains. The device is convenient for storage and transportation of grains. As one side of the feed inlet is provided with the conveyor belt, human labor is reduced. The humidity measurement instrument inside the dryer body can be used for detecting temperature of grain entering the device. According to different humidity conditions, different feeding speeds are adopted so as to dry grain to the maximum. The drying air-heater provides wind power and heat source. The dehumidifier is used for pumping evaporated moisture into the condensation tank and discharging.

Owner:合肥朝霞机械科技有限公司

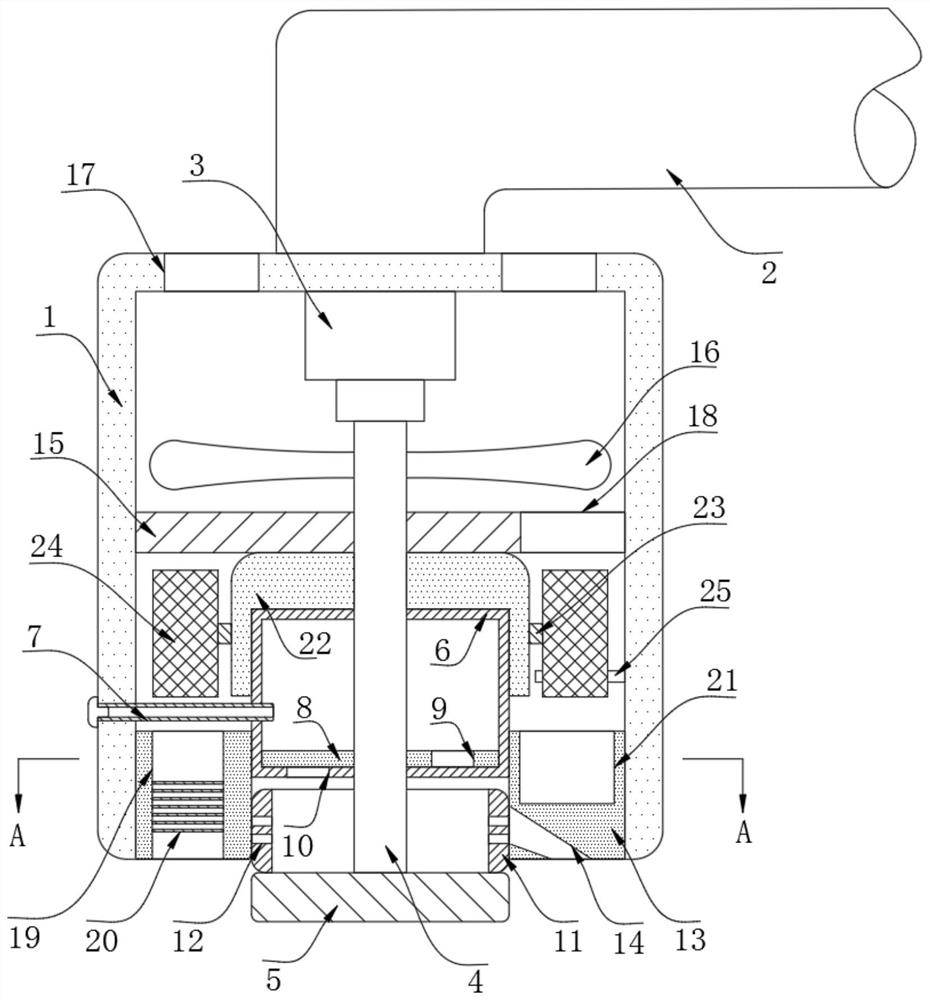

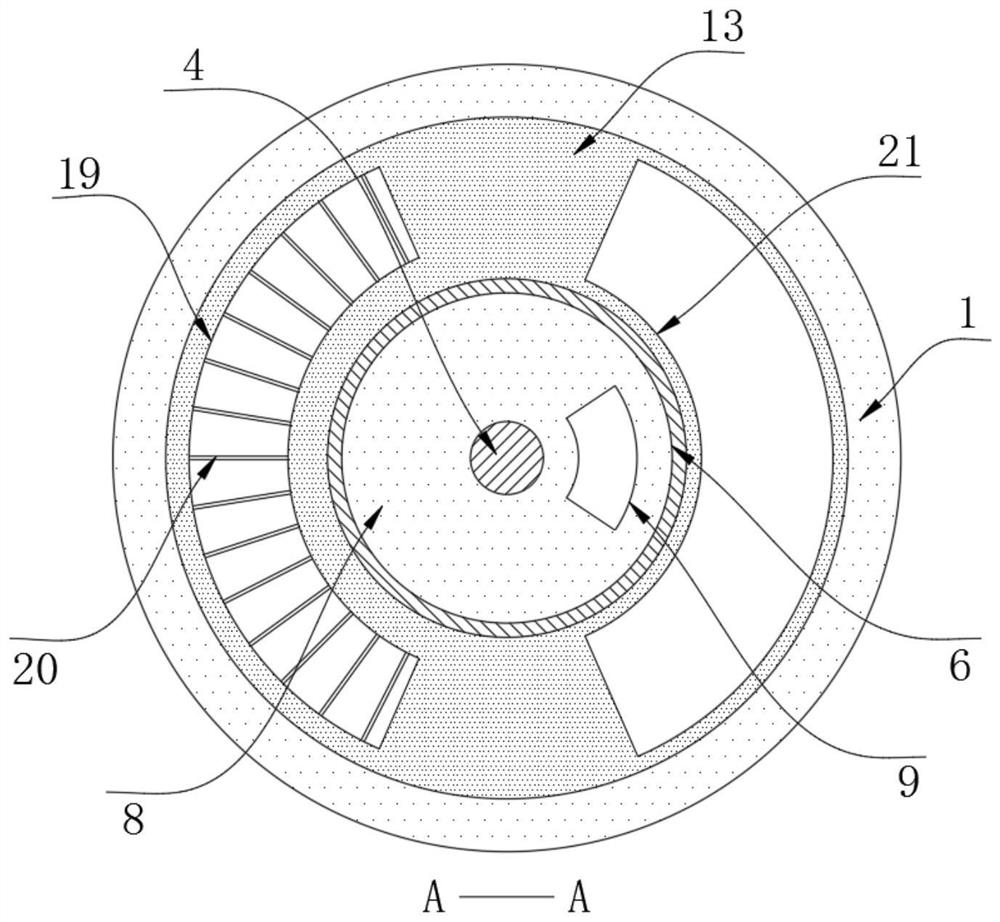

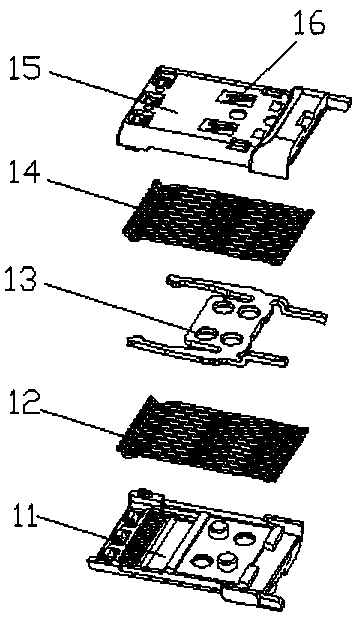

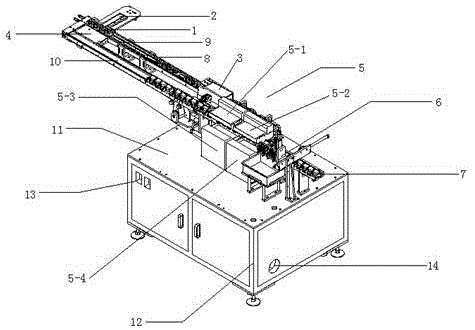

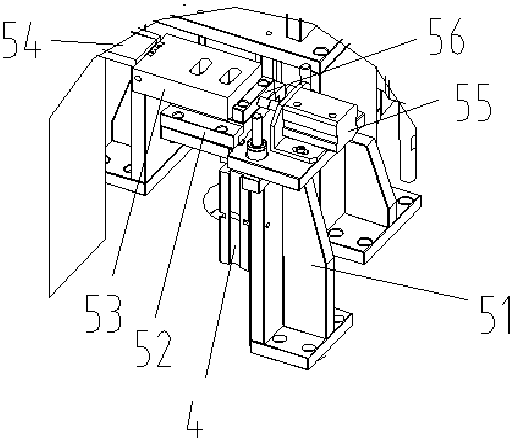

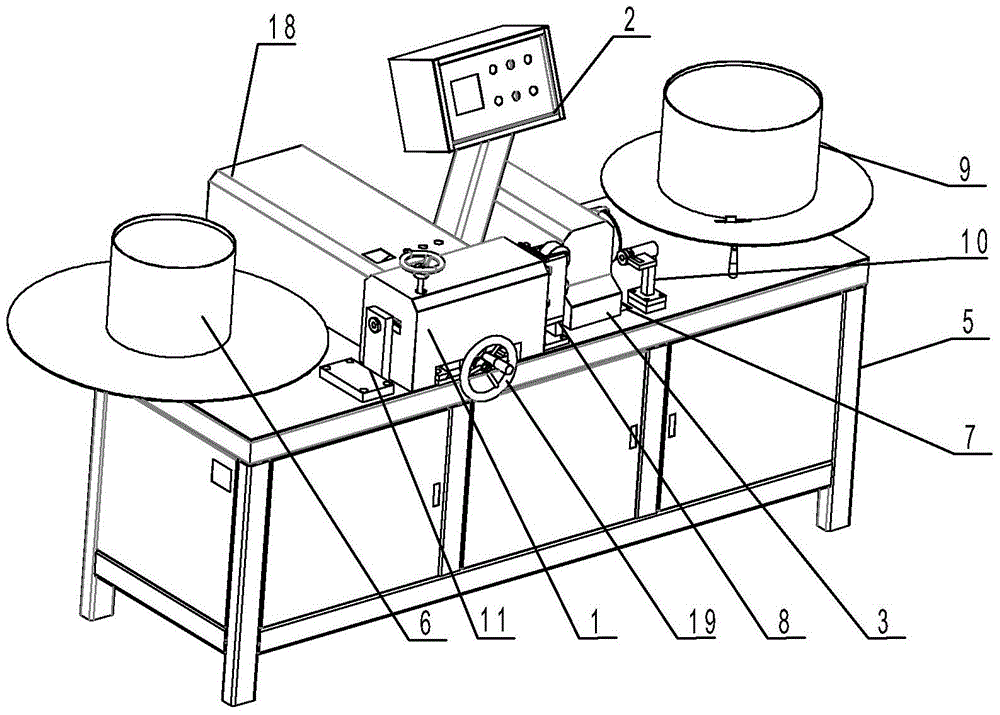

A button battery automatic butt welding device

ActiveCN106808075BRealize the welding effectReduce human laborWelding/cutting auxillary devicesAuxillary welding devicesDistribution controlButton battery

The invention relates to an automatic butt welding device for a button battery, which includes a frame and a power distribution control box. Sheet feeding device, there is an overturning device between the two groups of feeding devices, the overturning device includes a overturning bracket arranged on the power distribution control box, the overturning bracket is provided with a overturning shaft through the bearing seat, and the two ends of the overturning shaft are respectively sleeved with manipulators Gripper cylinder and gear, the jaw cylinder of the manipulator is provided with a gripper that cooperates with the button battery on the feeding device, the gear meshes with the brace provided on the brace mount, and the brace mount is connected to the overturning cylinder; the invention provides Two sets of feeding devices, respectively set negative contact welding and positive contact welding on the two sets of feeding devices, and combine the two sets of feeding devices by turning over the device, so as to realize the effect of continuous feeding welding, which greatly saves manpower and improves production efficiency.

Owner:江苏瑞鑫数控装备有限公司

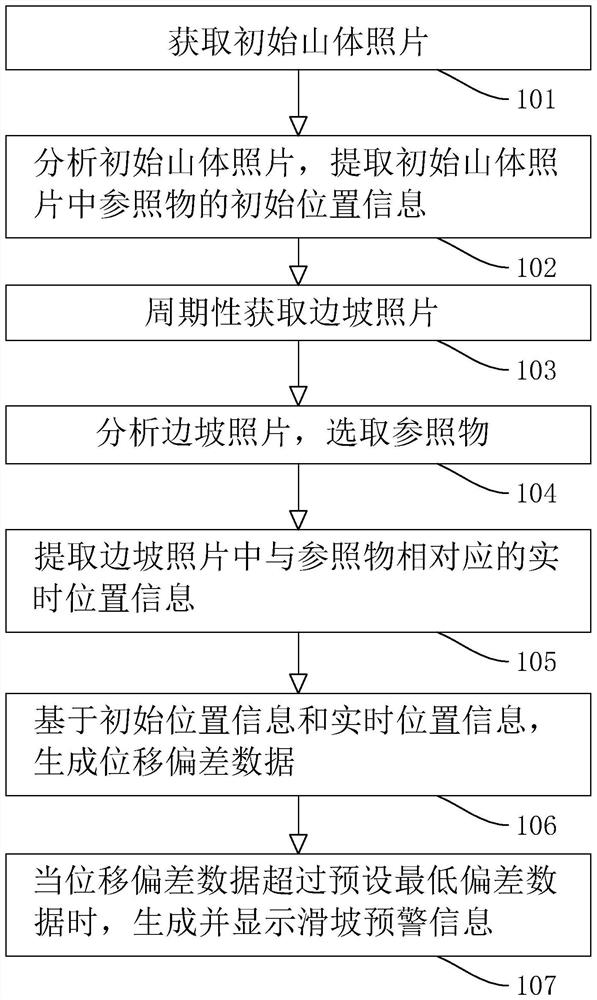

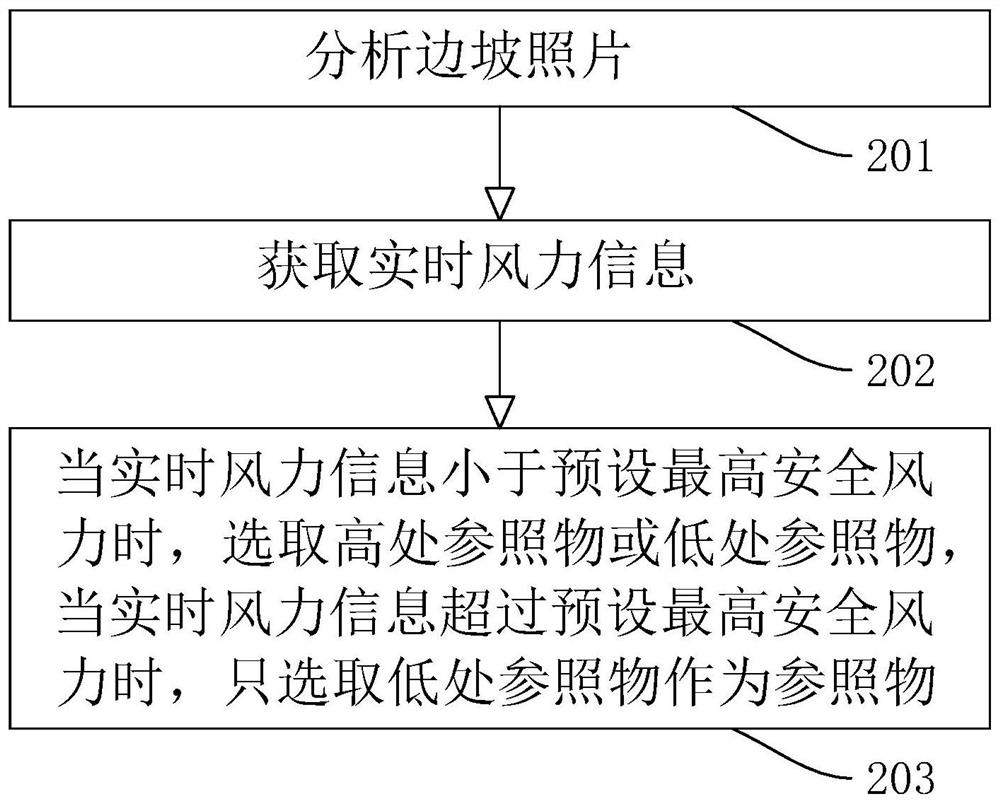

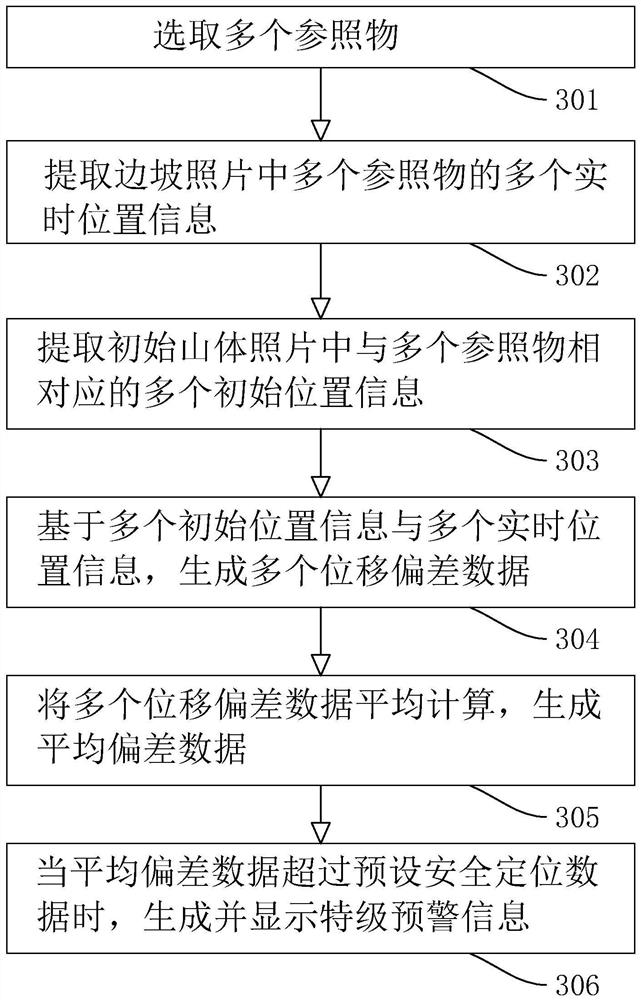

High and steep slope visual monitoring method and system

PendingCN114092879AImprove securityReduce human laborCharacter and pattern recognitionAlarmsVisual monitoringDisaster monitoring

The invention relates to a high and steep slope visual monitoring method and system, and belongs to the technical field of geological disaster monitoring, and the method comprises the following steps: obtaining an initial mountain picture; analyzing the initial mountain photograph, and extracting initial position information of a reference object in the initial mountain photograph; periodically obtaining side slope photos; analyzing the side slope picture, and selecting the reference object; extracting real-time position information corresponding to the reference object in the side slope picture; generating displacement deviation data based on the initial position information and the real-time position information; and when the displacement deviation data exceeds preset minimum deviation data, generating and displaying landslide early warning information. The method has the advantages that manual labor is reduced, and meanwhile the safety of landslide monitoring work is improved.

Owner:中煤浙江测绘地理信息有限公司

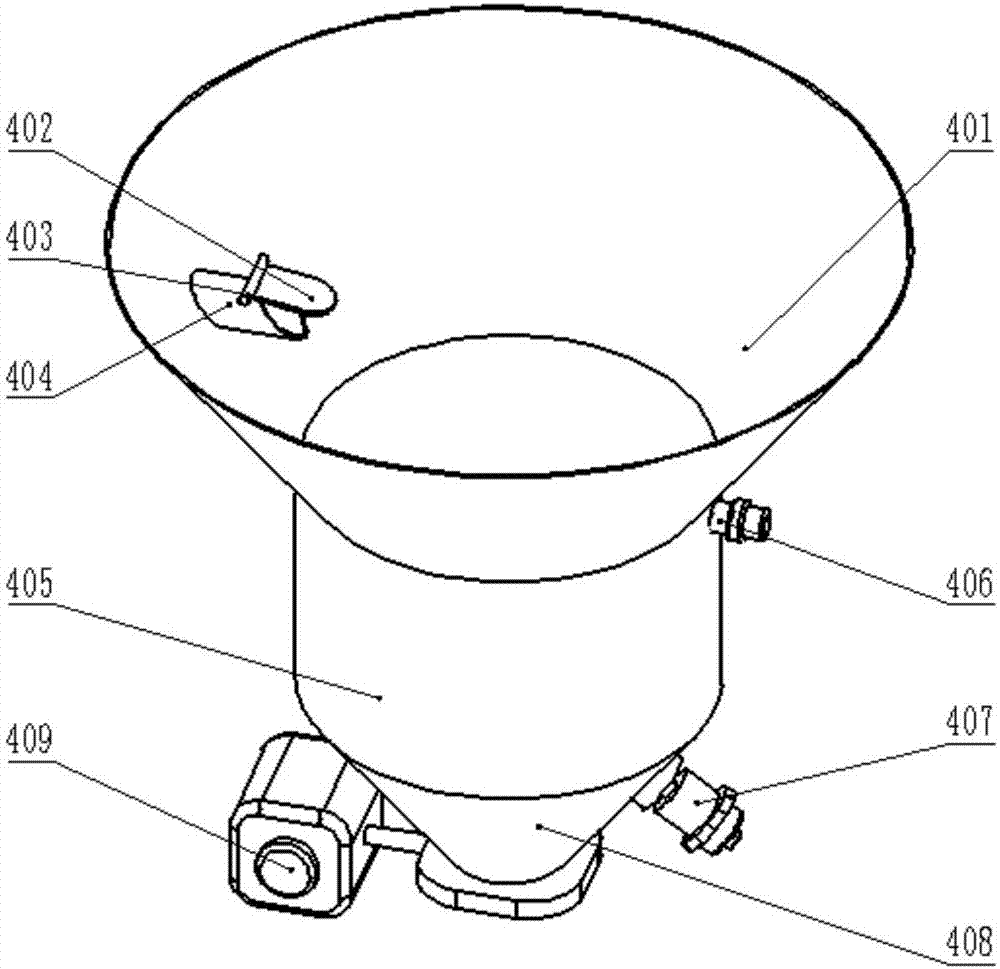

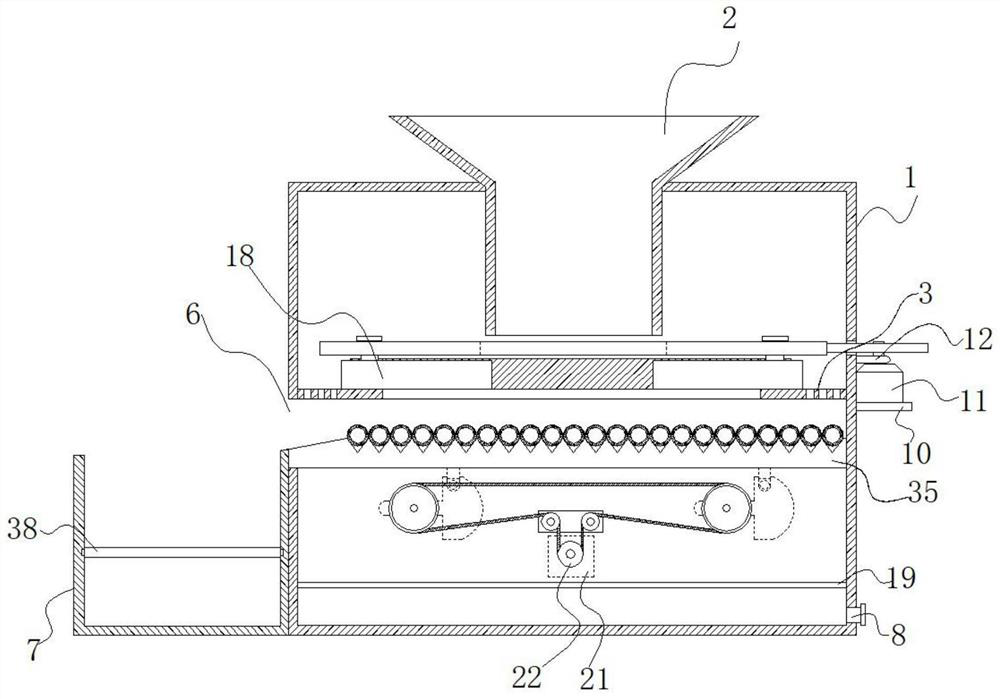

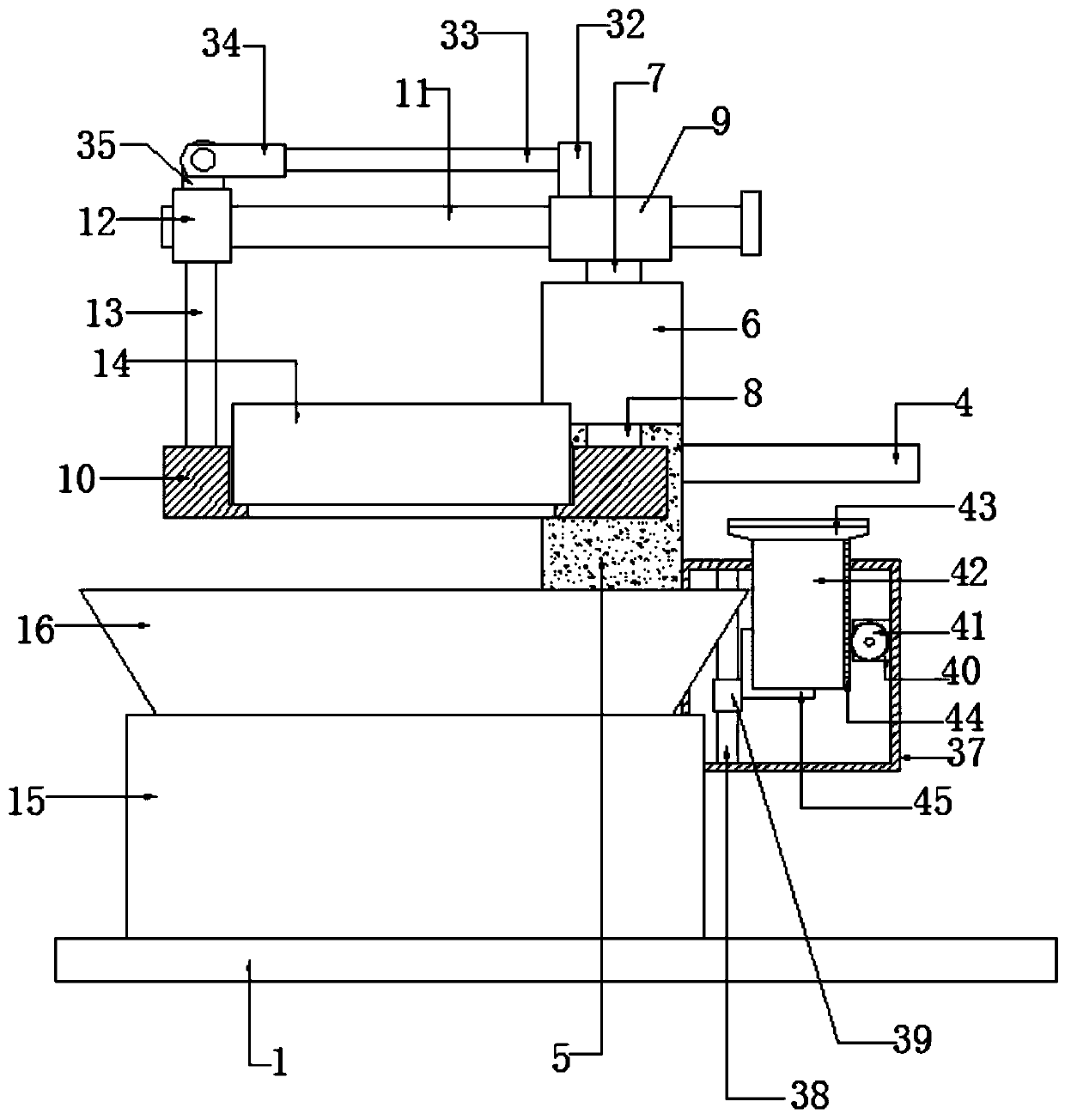

Jacking conveying type fermentation engineering solid-liquid separation device

ActiveCN113478885AReduce human laborImprove separation efficiencyClimate change adaptationPressesStructural engineeringFermentation

The invention discloses a jacking conveying type fermentation engineering solid-liquid separation device. The device comprises a box body, wherein a feeding hopper is arranged at the center of the top of the box body, an extrusion device is arranged below the feeding hopper, a supporting table is arranged at the bottom of the extrusion device, a boss is arranged at the center of the top of the supporting table, the middle of the boss and the middle of the supporting table are each provided with a channel, a discharging valve is installed on the channel formed in the middle of the supporting table, a plurality of water outlet holes are formed in the periphery of the top of the supporting table and the side edge of the boss, a discharging opening is formed in the position, located in the middle of the side edge of the box body, of one side of the lower portion of the supporting table, a solid collecting box is arranged on the side edge of the box body and located on one side below the discharging opening, a conveying device is arranged on the inner side of the discharging port, and a liquid discharging port is formed in the bottom of the side, away from the solid collecting box, of the box body. The device has the beneficial effects that manual labor is effectively reduced, and the separation efficiency is improved.

Owner:甘肃祁草元生物科技有限公司

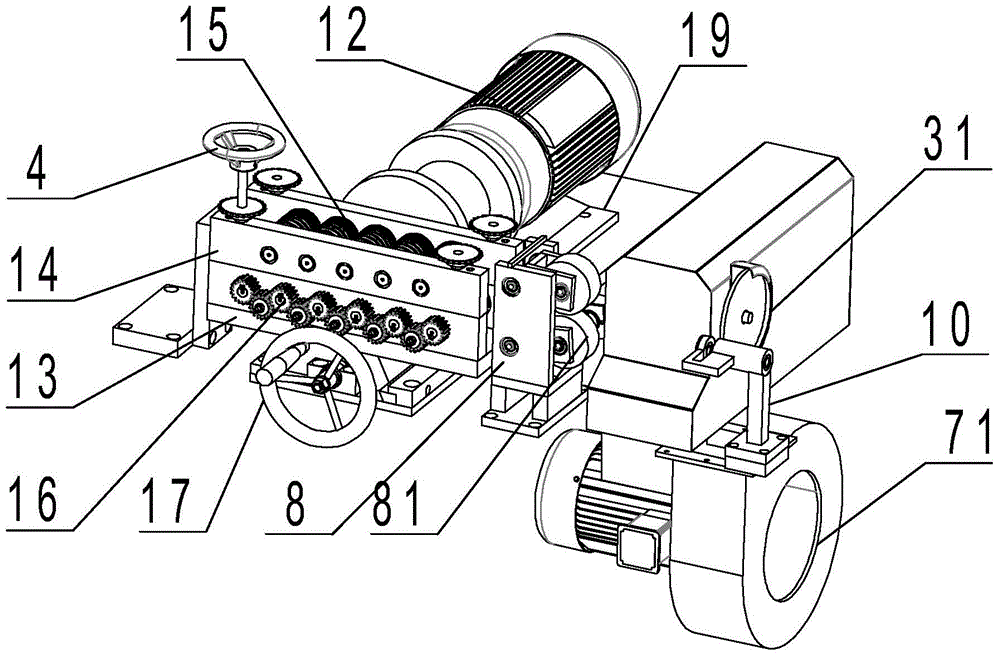

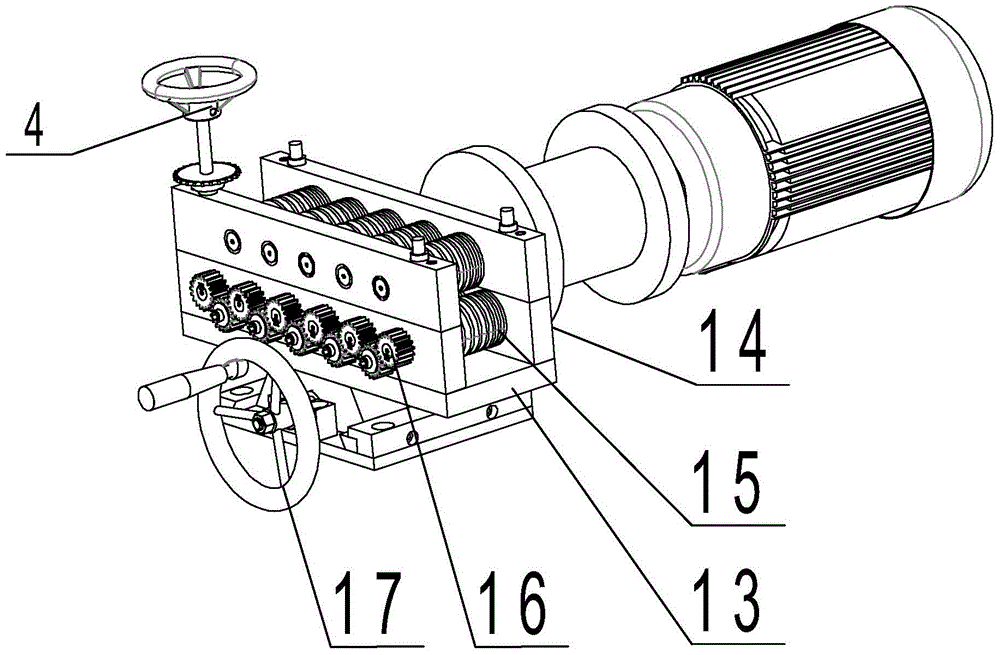

An armored cable automatic meter counting and unloading machine

The invention relates to an automatic meter-counting cutting machine for armored cables. It mainly solves the problem that the existing automatic wire rod cutting machine cannot automatically stop, cut and circle materials while counting meters. It is characterized in that: the driven tray, straightening driving device, meter counting device, cutting device, and active feeding tray are sequentially arranged on the frame, and the straightening driving device is controlled by a geared motor through a clutch with a brake pad The armored cable is stopped and then cut, a rotatable device is installed under the driven tray, a guiding mechanism is provided on the left side of the straightening drive device, a meter wheel is provided on the meter counting device, a positioning device is provided on the right side of the cutting device, and the driven The working stations of the feeding tray, guiding mechanism, straightening driving device, meter counting device, cutting device, positioning device and active feeding tray are on the same straight line. The armored cable automatic meter counting and cutting machine has high precision, which ensures the smooth completion of automatic straightening, meter counting, cutting and coiling, reduces manpower labor, and prevents damage to the wire due to human pulling.

Owner:HUADONG INSTR & METER FACTORY YUEQING CITY

Full-automatic flattening device for cartons

The invention discloses a full-automatic flattening device for cartons. The full-automatic flattening device for the cartons comprises a fixed frame [1], wherein an extrusion device [2] and a roller [3] are arranged on the fixed frame [1]; the extrusion device is connected with a motor [4]; during use, a carton is vertically placed on the fixed frame [1], and then the motor [4] is started; the extrusion device [2] makes the carton symmetric to push the carton from the middle part to the two sides of the carton; the roller [3] moves to flatten the carton, and is made of stainless steel; the diameter of the fixed frame [1] can be adjusted to meet the requirements of different cartons; a covering plate is arranged on the fixed frame [1] to keep out wind and rain; and stripes are set on the roller [3] to prevent rolling sliding. The full-automatic flattening device can mechanically flatten the cartons for recycling and storage, can narrow the storage space, is easy to stack up, and can save the labor intensity and solve the treatment process of carton flattening.

Owner:徐绍英

Soil recycling mechanism of flower transplanting machine

ActiveCN110352742AImprove survival rateAvoid churnCultivating equipmentsFlower-pot fillingElectric machineryEngineering

The invention discloses a soil recycling mechanism of a flower transplanting machine. The soil recycling mechanism comprises a bottom plate; racks are arranged on two sides of the top of the bottom plate. First and second conveyer belts arranged in parallel are arranged between the racks. A support post is arranged between the first conveyer belt and the second conveyer belt; a bidirectional motoris mounted at the top of one side of the front of the support post; two ends of the bidirectional motor are provided with a spindle I and a spindle II respectively; the end of the spindle I and the second of the spindle II are provided with a fixing block I and a holding plate respectively; a connection bar I penetrates the middle of the fixing block I; the end of the connection bar far away fromthe fixing block I is sleeved with a fixing block III; a support bar is arranged at the bottom of the fixing block III; the bottom of the support bar is fixed to one end of the top of the holding plate. The soil recycling mechanism has the advantages that loss of soil at flower roots during transplanting is avoided, working efficiency is improved effectively, and survival rate of flowering plantsafter planting is increased.

Owner:连云港人与人环保科技有限公司

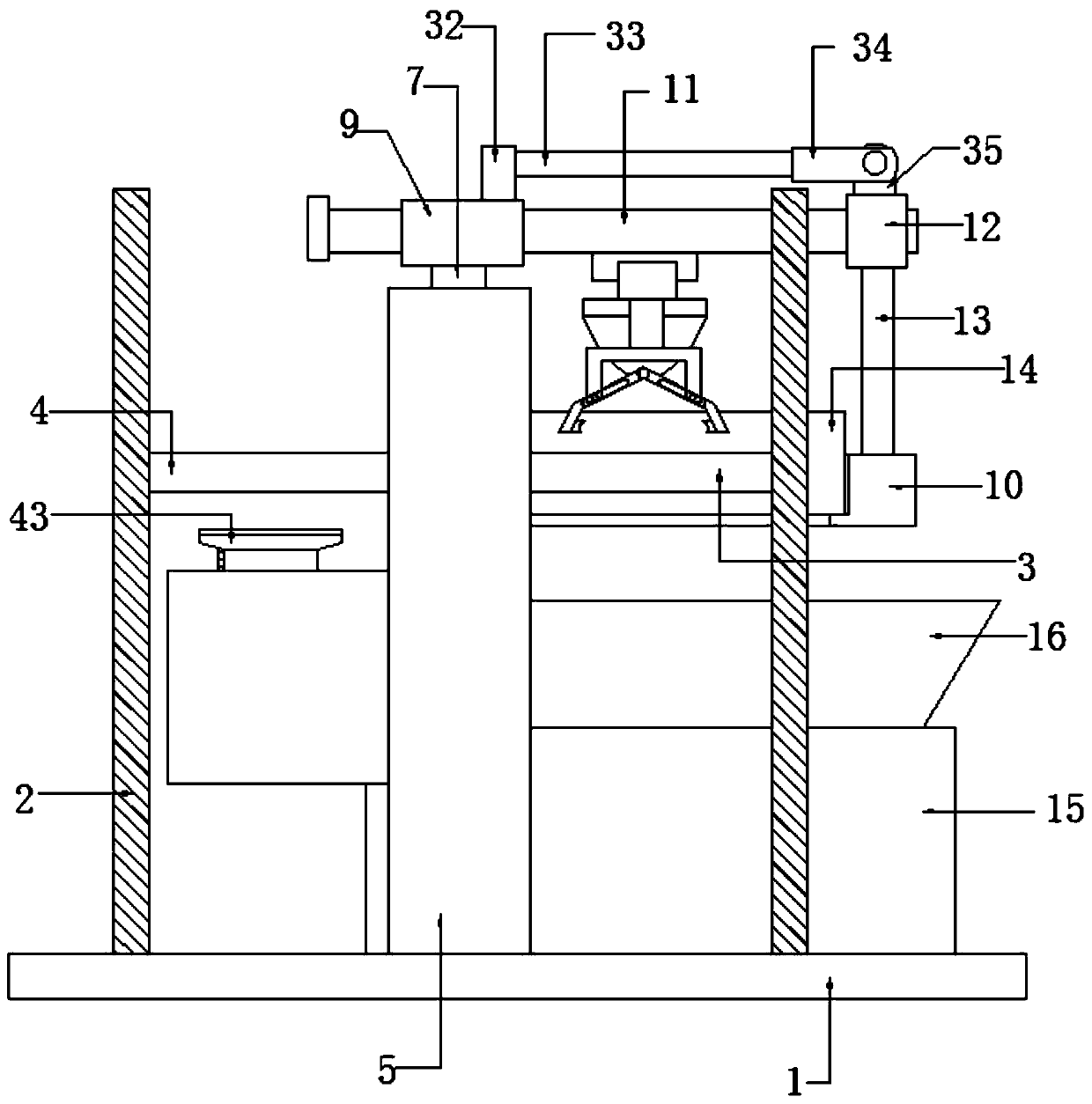

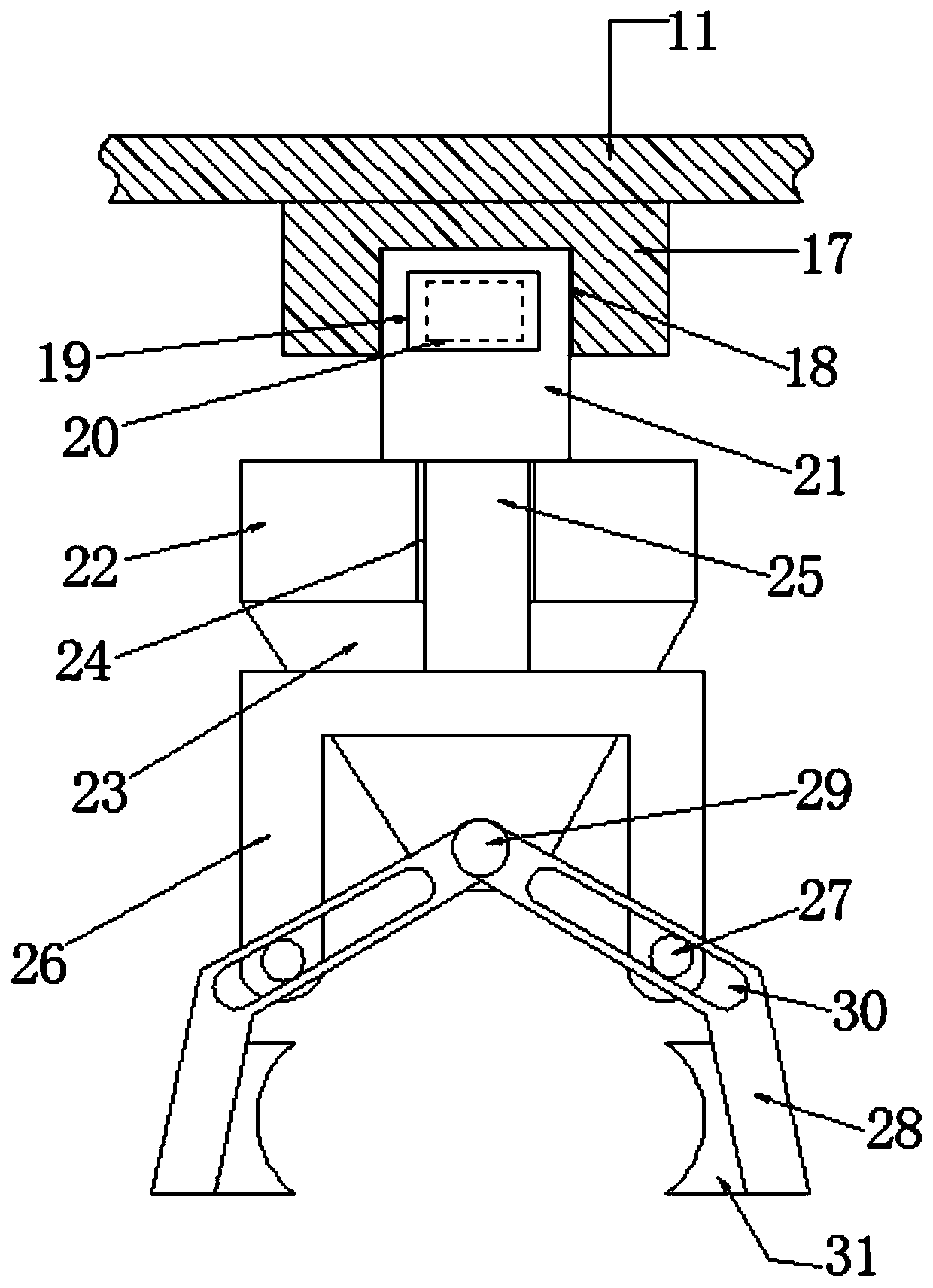

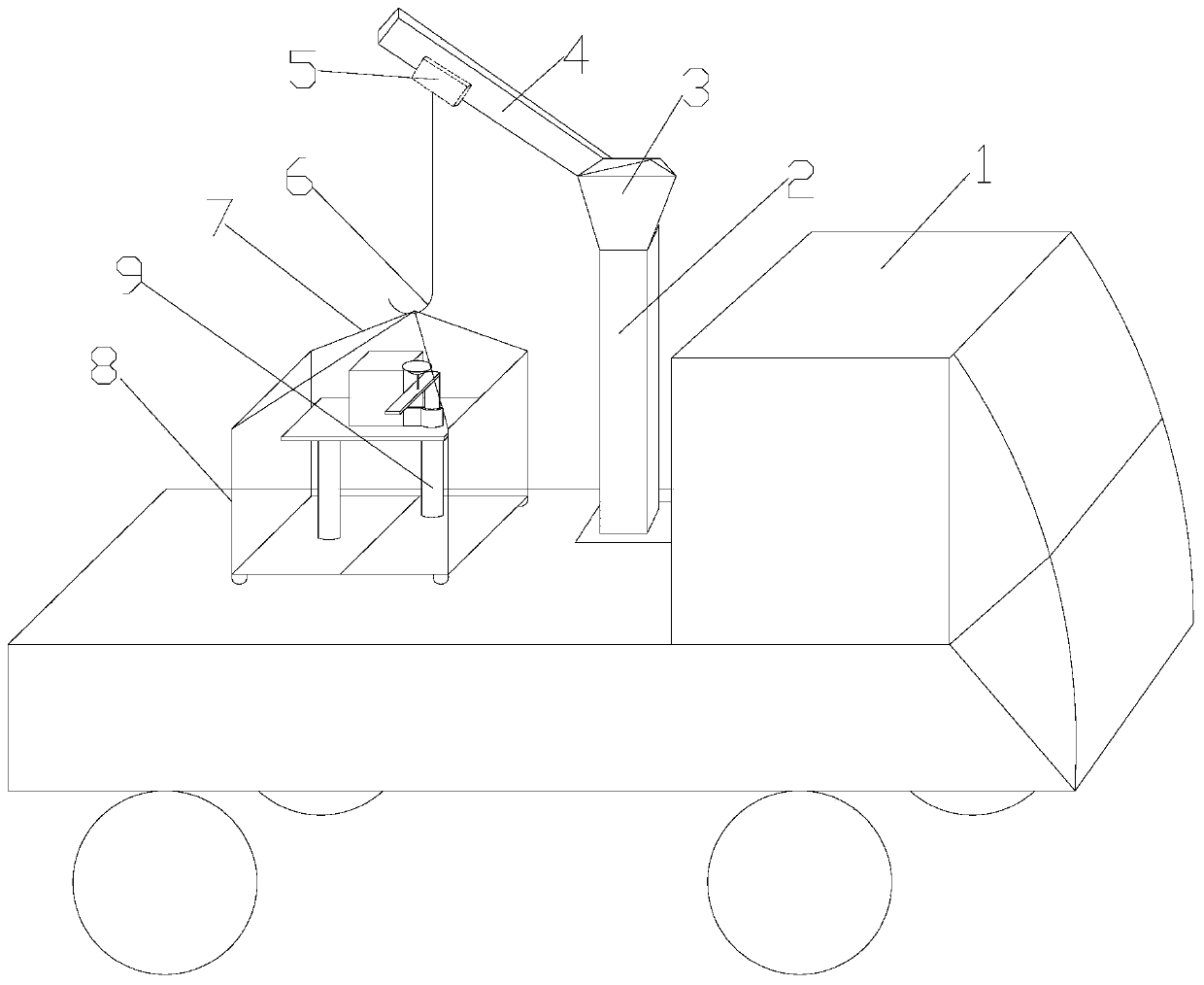

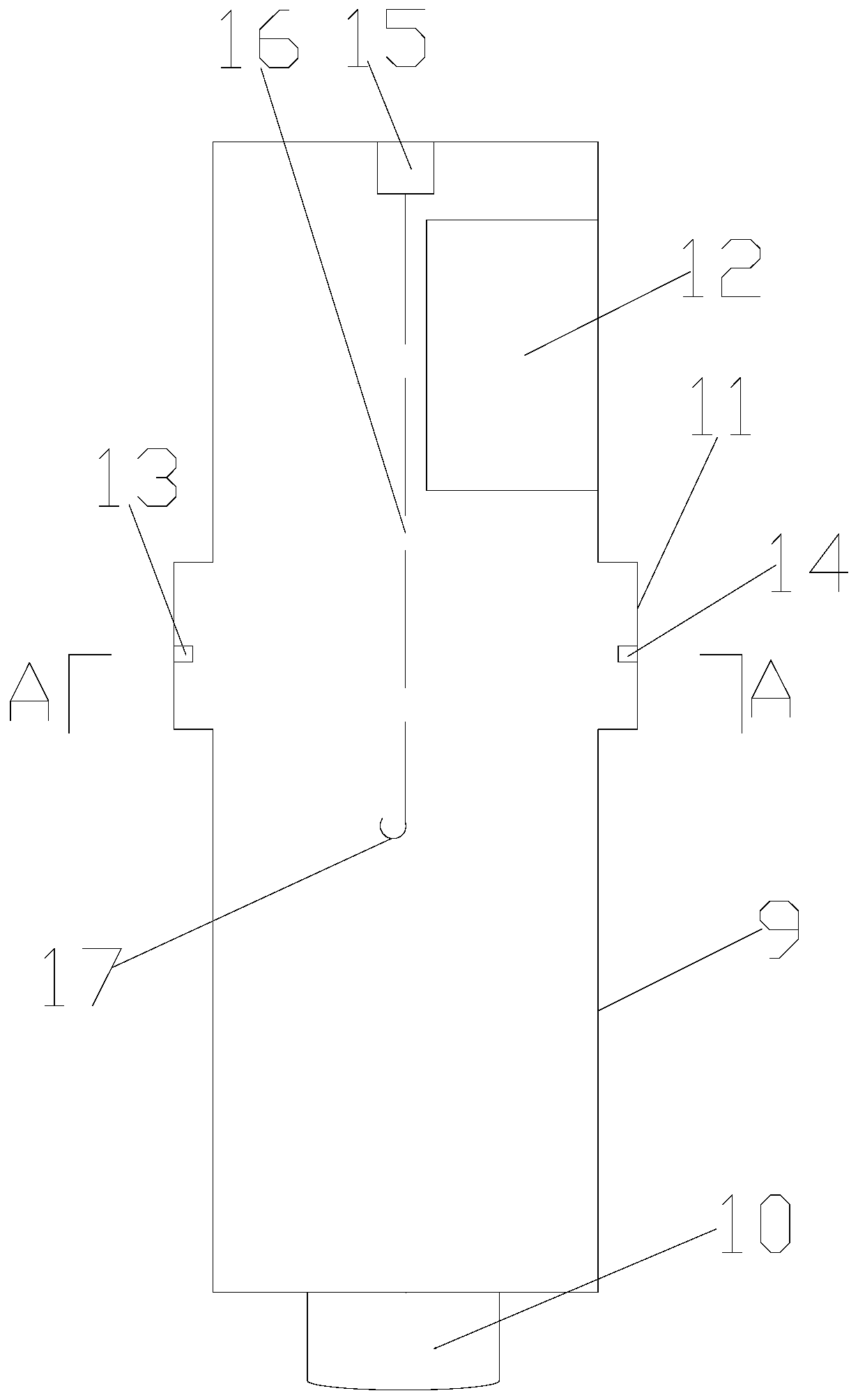

Highway engineering pavement automatic loading and unloading-type drilling core thickness measurement evaluation device and method

PendingCN111442732AEasy to promote and useReduce human laborSurveyUsing optical meansDrill holeCantilever

The invention discloses a highway engineering pavement automatic loading and unloading-type drilling core thickness measurement evaluation device and method. The device comprises a pull ring, a transport vehicle and a cantilever crane which is installed on the transport vehicle and used for automatically loading and unloading a core drilling machine. The method comprises the following steps: 1, setting highway engineering pavement sampling points, and installing the pull ring; 2, measuring the thickness of a pavement core sample; 3, completing drilling core sampling and thickness measurement on the pavement at all highway engineering pavement sampling point positions; 4, calculating the average thickness of all pavement core samples; 5, calculating a thickness representative value of the pavement core samples; 6, judging whether the thickness representative value of the pavement core samples meets the design requirement or not; and 7, judging whether the thickness of a jth pavement core sample is qualified or not, and calculating the percent of pass of highway engineering pavements. The cantilever crane is installed on the transport vehicle, automatic loading and unloading of the core drilling machine are achieved, the structure of a drilling barrel is modified, the thicknesses of the core samples are automatically calculated through the process of lifting the core samples, time is saved, and errors caused by manual measurement are avoided.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

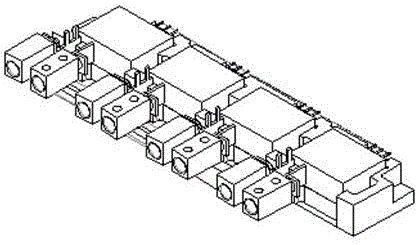

Logistics transportation system, unmanned aerial vehicle, landing platform and control method thereof

PendingCN112230672ASimple connection structureImplement automatic expansionPosition/course control in three dimensionsLogistics managementTransit system

The invention provides a logistics transportation system, an unmanned aerial vehicle, a landing platform and a control method thereof. The unmanned aerial vehicle lands and is parked on the landing platform, a first support in the unmanned aerial vehicle is in contact with a first surface of a first push plate in the landing platform, and a second support in the unmanned aerial vehicle is in contact with a first surface of a second push plate in the landing platform, wherein the first surface is a landing surface on which the unmanned aerial vehicle lands; and a push-pull hook on a push plateof the landing platform drives the first bracket and / or the second bracket to move. According to the unmanned aerial vehicle, electric energy does not need to be consumed when the unmanned aerial vehicle unloads, the cruising ability can be improved, the support and the connecting structure of the support and the unmanned aerial vehicle body are simple, and the dead weight and manufacturing cost can be reduced.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

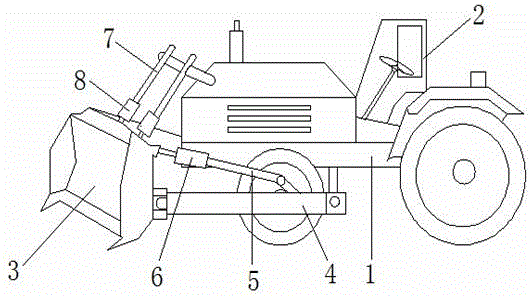

Automatic bulldozing apparatus of farm tractor

InactiveCN106576452AGuaranteed uptimeQuality assuranceSoil-working equipmentsEngineeringAgricultural machinery

The invention provides an automatic bulldozing apparatus of a farm tractor, and belongs to the field of agricultural machinery. The automatic bulldozing apparatus comprises a cab connected with a tractor body, a bulldozing shovel, a push rack the two ends of which are connected with the front end of the tractor body and the bulldozing shovel respectively, an inclined pull bar the two ends of which are connected with the push rack and the bulldozing shovel respectively, an inclined oil cylinder connected between the bulldozing shovel and the inclined pull bar, an upper pull bar the two ends of which are connected with the front end of the tractor body and the bulldozing shovel, and an elevating oil cylinder connected between the bulldozing shovel and the upper pull bar. The automatic bulldozing apparatus can clean farmlands while maintaining functions of an original farm tractor, flatten fields with pits and hollows, remove barriers in operating areas, backfill pits that are not quite deep, build ridges low in height and reduce labor force. In this way, the tractor can run steadily, and the work efficiency and the land plowing quality are ensured.

Owner:ZHEJIANG DIYE AGRI EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com