Wet sander

A sanding machine and wet technology, applied in the field of sanding machines, can solve problems such as low efficiency and trouble, and achieve the effects of reducing subsequent processing, avoiding waste and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

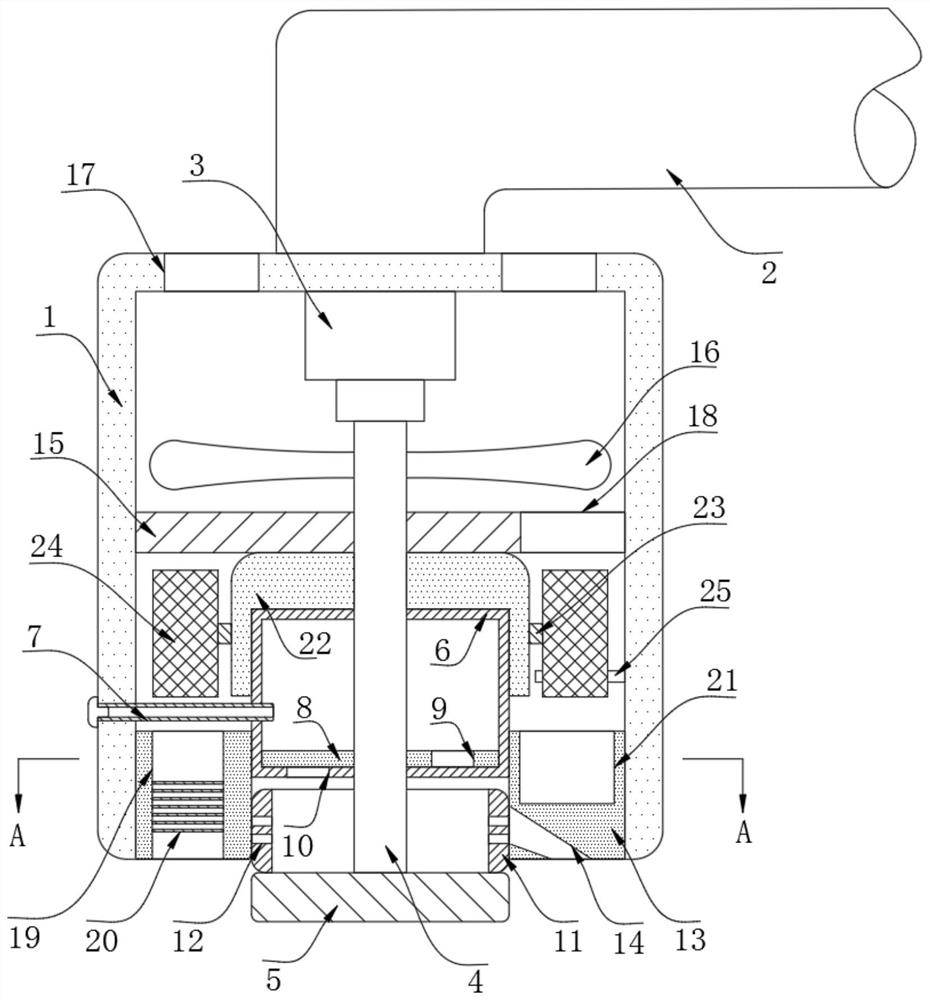

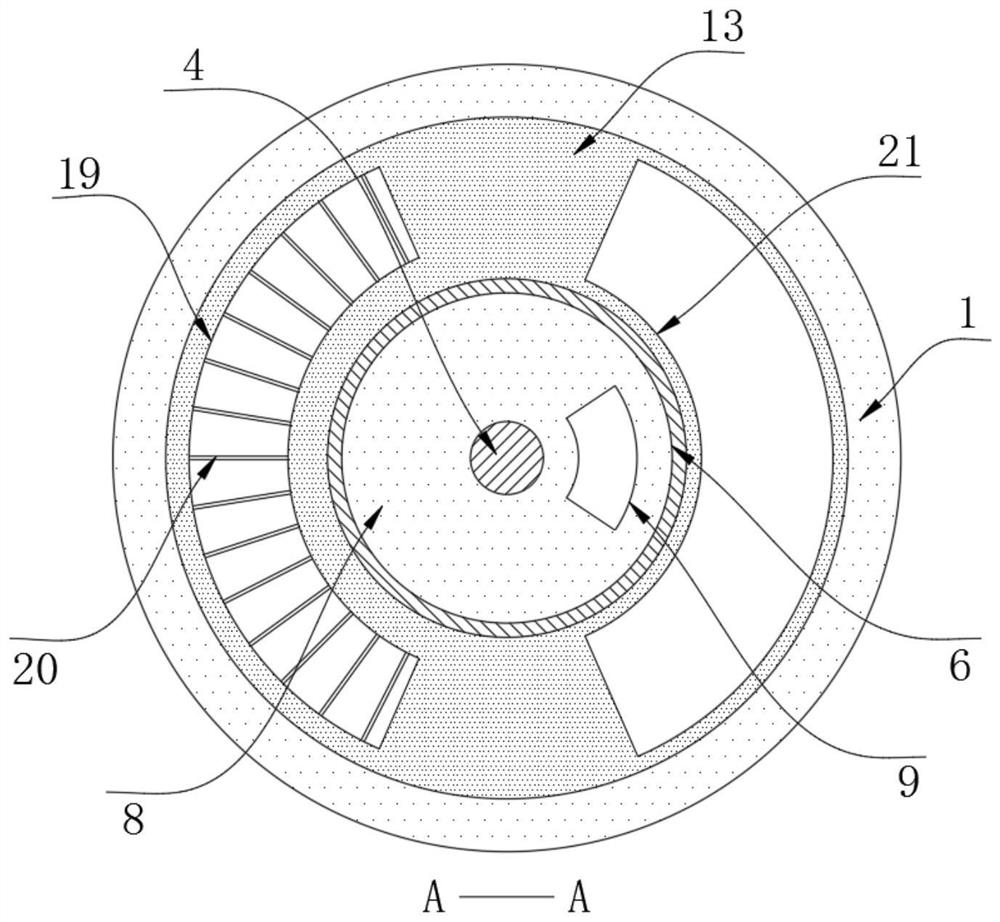

[0020] refer to Figure 1-2 , a wet sander, comprising a housing 1, a handle 2 is fixed on the upper end of the housing 1, a motor 3 is fixed on the inner top of the housing 1, a rotating shaft 4 is fixed on the output shaft of the motor, and a sanding disk 5 is fixed on the bottom of the rotating shaft 4 , the circumferential side wall of the rotating shaft 4 is rotatably connected with the water storage tank 6, and the side wall of the rotating shaft 4 is fixed with a rotating plate 8 slidingly connected with the inner bottom of the water storing tank 6, and the rotating plate 8 is in sealing sliding connection with the bottom of the water storing tank 6, and the rotating plate The upper end of 8 is provided with dislocation groove 9, the bottom of water storage tank 6 is provided with drainage hole 10, and the side wall of shell 1 is inserted with water supply pipe 7 connected with water storage tank 6. Water supply pipe 7 is a hard pipe to realize the The rotation limit of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com