Patents

Literature

57results about How to "Reduce subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamond/copper composite material with high heat-conducting property and preparation method thereof

The invention relates to a diamond / copper composite material with high heat-conducting property and a preparation method thereof and belongs to the field of metallic materials. The diamond / copper composite material is composed of copper or copper alloy, diamond particles and a transition layer, wherein volume fraction of the copper or copper alloy is 38-49%, the volume fraction of the diamond particles and the transition layer is 62-51%, and particle size range of diamond is 80-130Mu m. A preparation technological process comprises the following steps: carrying out pre-treatment on the diamond, plating by adopting a salt bath, preparing a performed blank, and preparing a composite material by carrying out non-pressure infiltration. The diamond / copper composite material has the advantages that a diamond / copper composite material with high volume fraction and high heat-conducting property can be directly moulded and prepared, the prepared composite material is high in density, uniform in tissue distribution, controllable in interface thickness and high in thermal conductivity, processing equipment is simple, operability is strong, energy consumption and cost are low, mass production can be realized, heat-conducting property is high, and the diamond / copper composite material can be applied to the field of thermal management or electronic packaging.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for preparing zirconium oxide ceramic

The invention relates to a method for preparing zirconium oxide ceramic, which comprises the following steps of: preparing high solid phase slurry by adopting low-toxicity gel and dispersant, then adding an initiator, performing vacuum deaeration, injecting the slurry into a mold, curing and stripping to obtain a green body, and drying and sintering the green body to obtain the ceramic. The method is used for preparing the green body which has good surface finishment, peeling resistance, cracking resistance, good uniformity and high strength, the strength of the green body is 20 to 40MPa, andthe green body can be directly machined so as to effectively reduce the subsequent processing cost; and the green body can be sintered into the ceramic at one time, the yield reaches 100 percent, theceramic has excellent performance and good stability, the strength is 800 to 1,200MPa, the fracture toughness is 10 to 20MPa.m1 / 2, the average strength is 550MPa compared with the strength of the drypressing molded ceramic, the average fracture toughness is 8MPa.m1 / 2, and the performance of the ceramic is greatly improved.

Owner:NANJING UNIV OF TECH

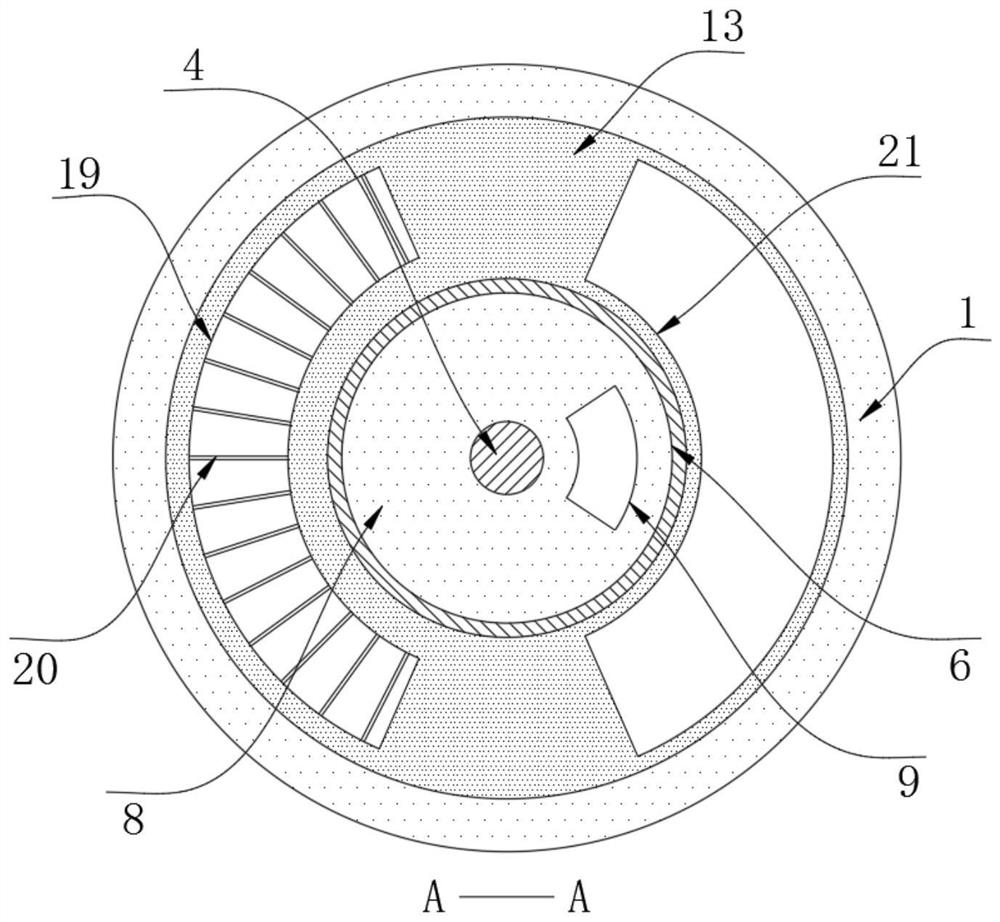

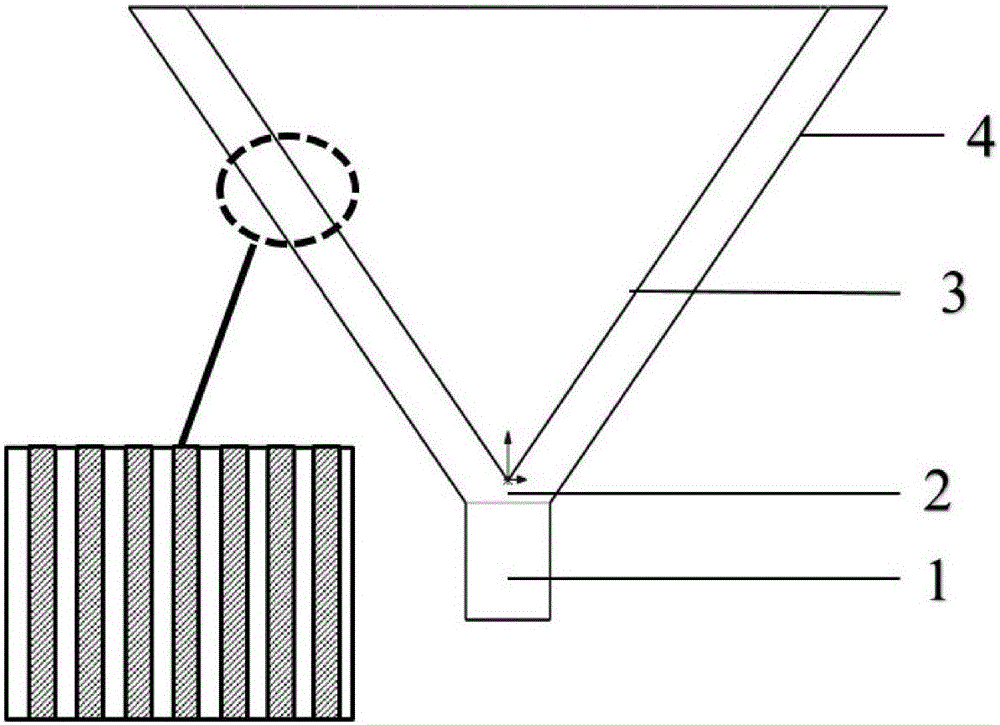

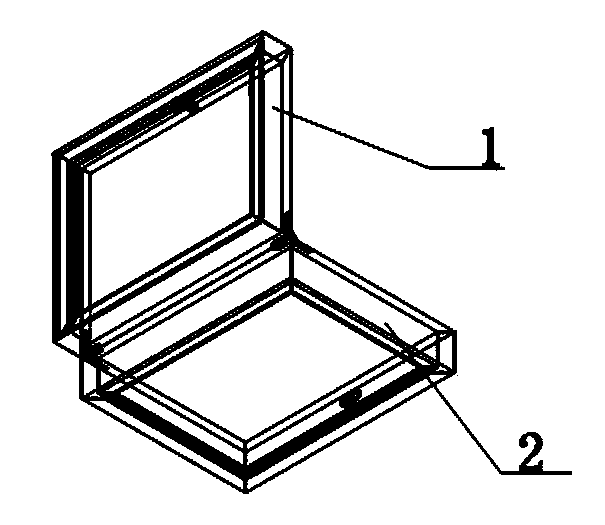

Method for casting and forming TiAl-based alloy vent valve

The invention provides a method for casting and forming a TiAl-based alloy vent valve, and relates to casting methods for the TiAl-based alloy vent valve. The technical problems that gravity casting of an existing TiAl-based alloy vent valve can not enable mold filling to be conducted smoothly, inner quality can not be guaranteed, a centrifugal casting method is complex in process, the material utilization rate is low, the casting process is too complex, and the surface quality is poor are solved. The method mainly comprises the steps that first, the prior art is used for manufacturing a metal mold of the vent valve; second, the metal valve of the vent valve in the first step is placed in a suction casting chamber of a smelting furnace, and the metal mold of the vent valve is mounted on a mold seat; third, a graphite suction port is mounted on a water cooling crucible; fourth, a TiAl-based alloy pig which is smelted in advance is placed in a suction casting crucible of a vacuum arc melting furnace, and overheating melt is obtained by smelting; fifth, a vacuum system of a suction casting chamber of the vacuum arc melting furnace is opened, a suction casting button is opened, suction casting, mold filling and cooling are conducted, and a casting is obtained. The method is used for preparing TiAl-based alloy vent valve castings.

Owner:HARBIN INST OF TECH

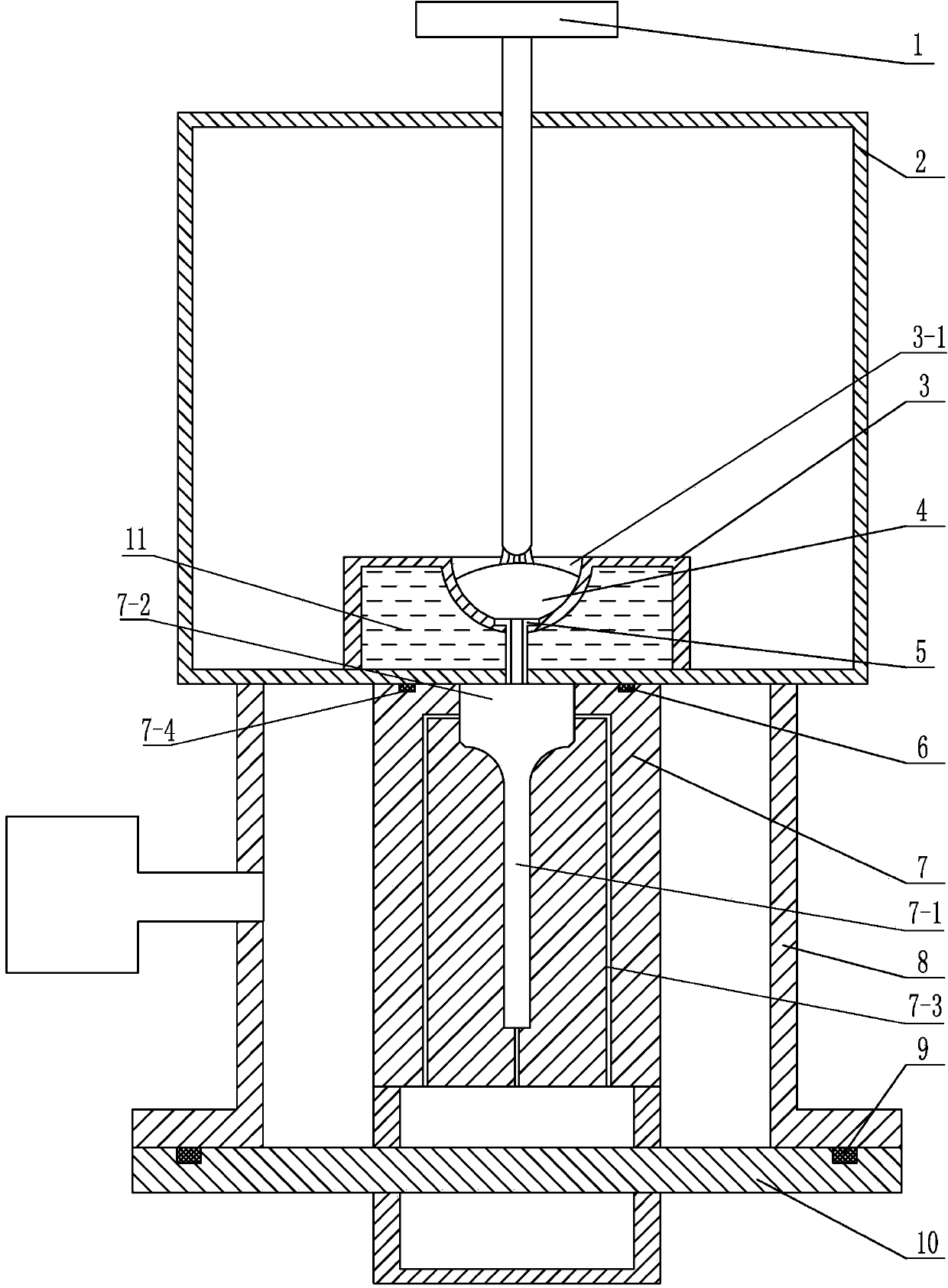

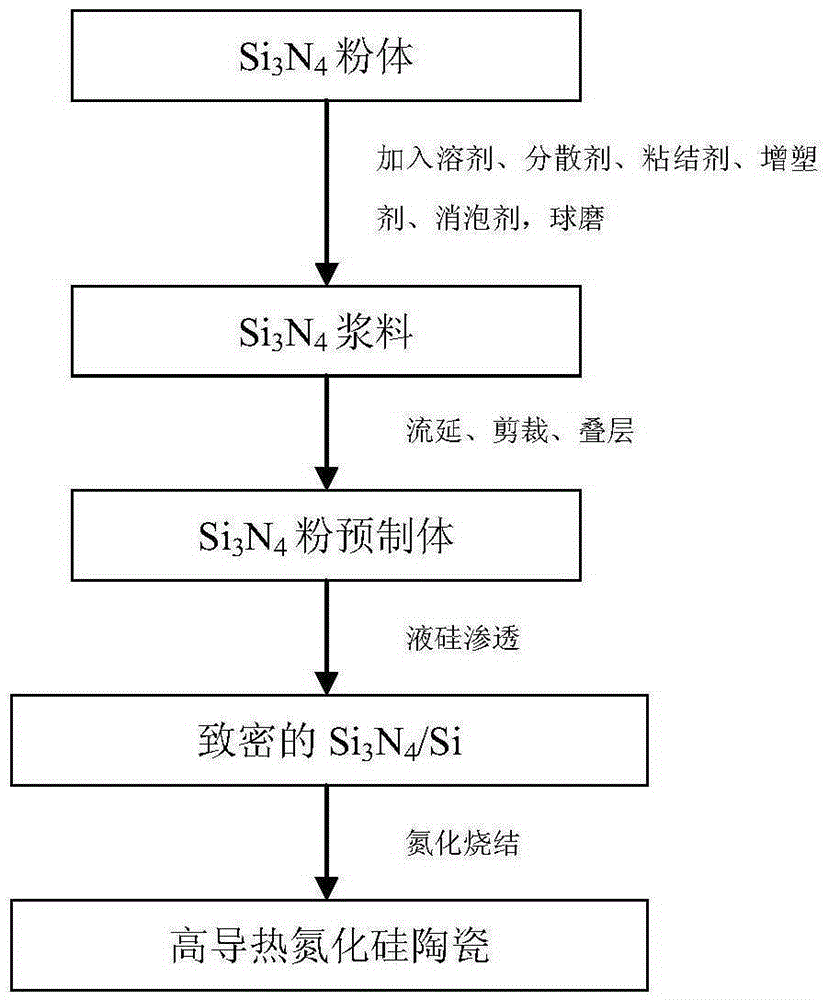

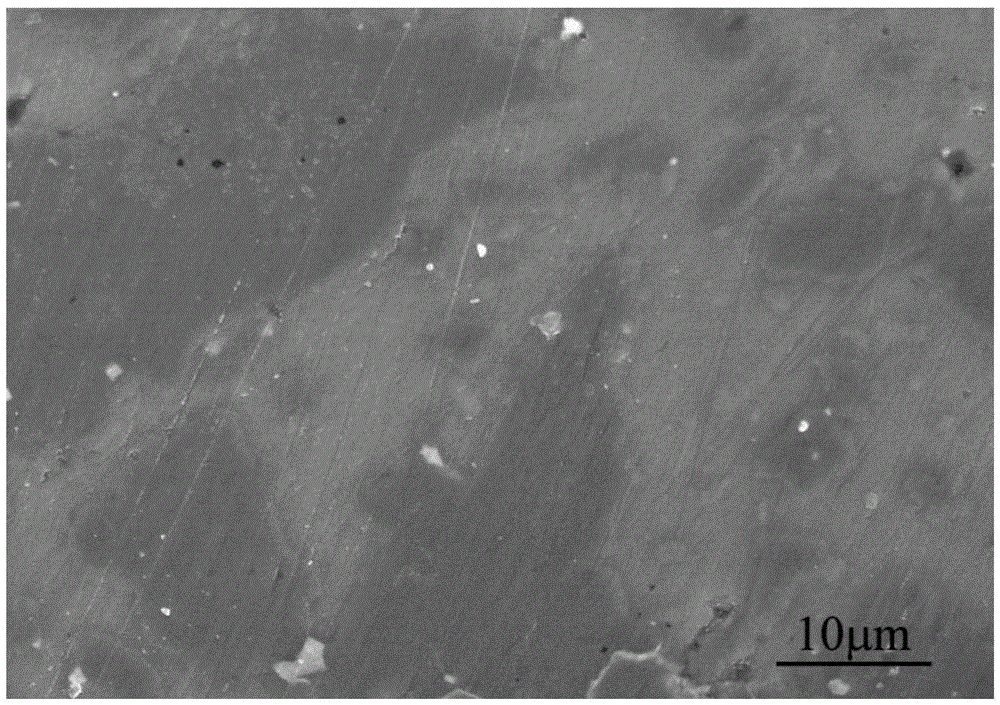

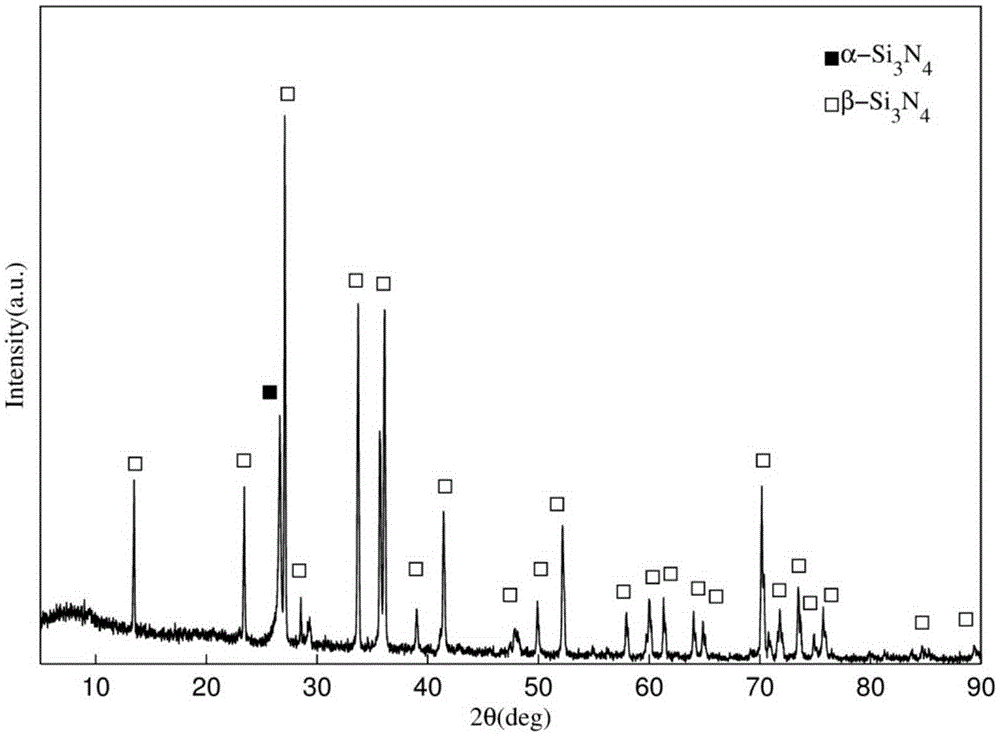

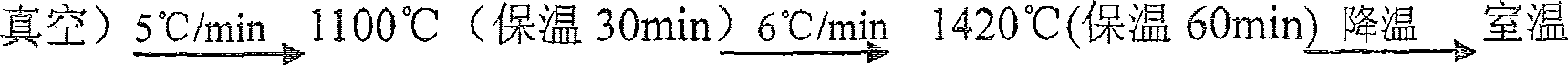

Method for preparing high-thermal-conductivity silicon nitride ceramics

InactiveCN105254306ALow preparation temperatureReduce subsequent processingThermal conductivityNitrogen treatment

The invention relates to a method for preparing high-thermal-conductivity silicon nitride ceramics. The method comprises the steps that firstly, thermal treatment and acid pickling treatment are carried out on Si3N4 powder, and then Si3N4 slurry is prepared; an Si3N4 thin layer is prepared through a casting process technology, and porous silicon nitride powder prefabricated bodies are obtained after the thin layer is cut and overlapped; the prefabricated bodies are subjected to liquid silicon penetration through high-purity silicon powder, and compact Si3N4 / Si is obtained; nitrogen treatment is carried out on Si3N4 / Si in a nitrogenation oven, so that Si in the material is subjected to a nitriding reaction to generate Si3N4. Compared with frequently-used processes for preparing the high-thermal-conductivity silicon nitride ceramics, such as isostatic pressing sintering and hot pressed sintering, a tape casting method is combined with liquid silicon penetration forming and nitriding sintering processes, no or little machining is needed, preparation temperature is low, no sintering additive needs to be added, and the influence of a grain boundary on the thermal conductivity of the material is avoided. The thermal conductivity of the prepared silicon nitride ceramics can reach 80-120 Wm<-1>K<-1>.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

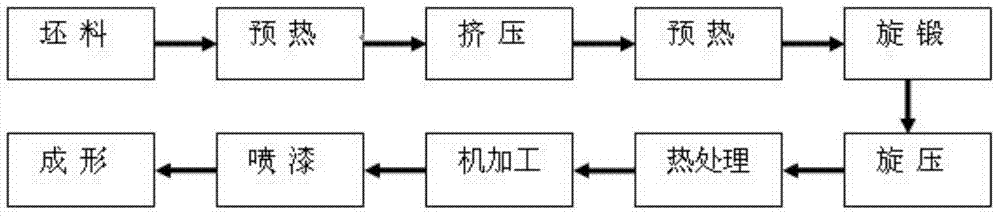

Truck and motor coach magnesium hub rotary-swaging forming method

InactiveCN104759839AReduce consumptionReduce subsequent processingMetal-working apparatusWheelsTruckMachining

The invention relates to a truck and motor coach magnesium hub rotary-swaging forming method. The method utilizes certain temperature and pressure and adopts rotary-swaging forming to enable magnesium alloy to be formed according to a predetermined die shape. The method comprises the technological steps of blank preparation, blank preheating, extrusion (pre-machining), blank pre-heating, rotary-swaging forming, heat treatment, machining, paint spraying and forming. Magnesium alloy automobile hubs produced by means of the method is high in finished product rate and stable in mechanical property, follow-up machining can be decreased, and machining amount and energy consumption can be reduced. By means of the method, large-sized hubs can be produced, and hub weight can be decreased.

Owner:山西晋隆发科技有限责任公司

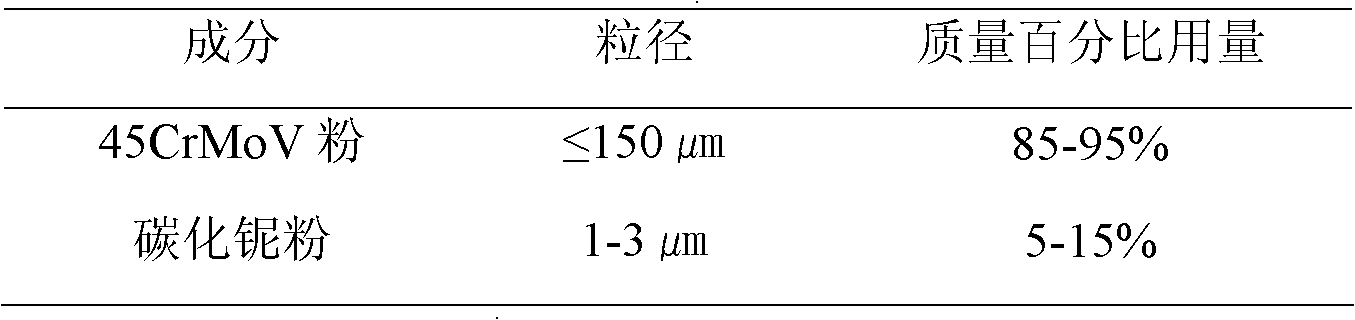

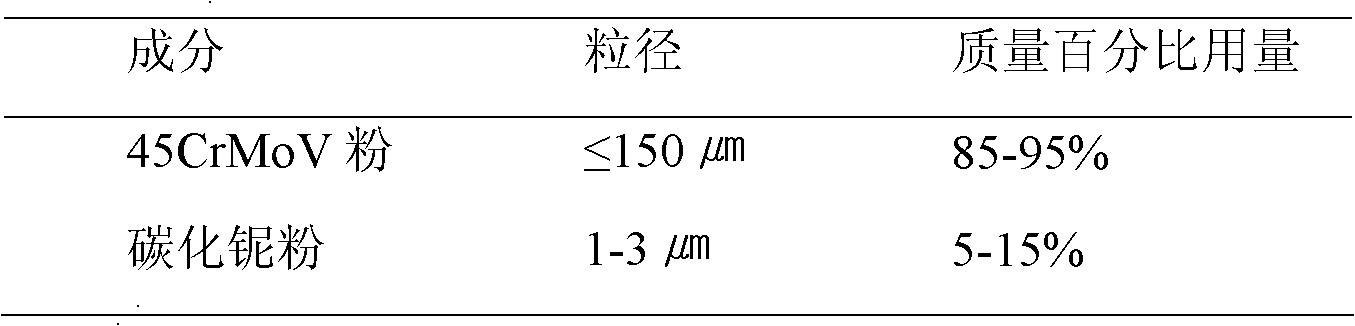

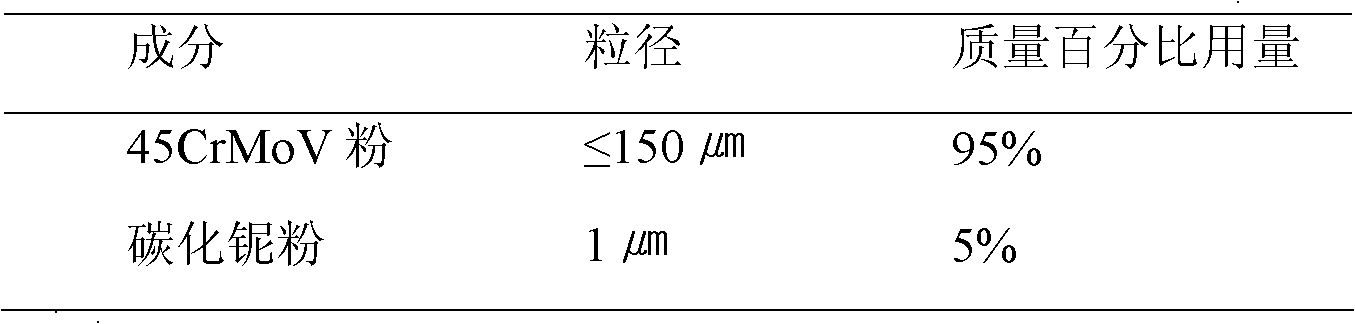

Powder metallurgy spring steel composite material and preparation method thereof

The invention discloses a powder metallurgy spring steel composite material and a preparation method thereof. The composite material comprises the components with the content by mass percent: 85-95% of 45CrMoV and 5-15% of carbonized niobium powder; and the powder metallurgy spring steel composite material is prepared by the method combining high-energy ball-milling and thermal isostatic pressing sintering. The invention adopts the high-energy ball-milling to lead NbC to be evenly dispersed on a 45CrMoV spring steel base body, and greatly improves the wear resistance of the material under the condition of ensuring the mechanical property of the material; and furthermore, by adopting the method combining the high-energy ball-milling and the thermal isostatic pressing sintering, the invention effectively solves the problem of enhancing the fusion and interface of particles and the base body, thus leading the enhanced particles and base body to be more closely combined with each other. The spring steel composite material is especially applicable for manufacturing an elastic element.

Owner:SOUTH CHINA UNIV OF TECH

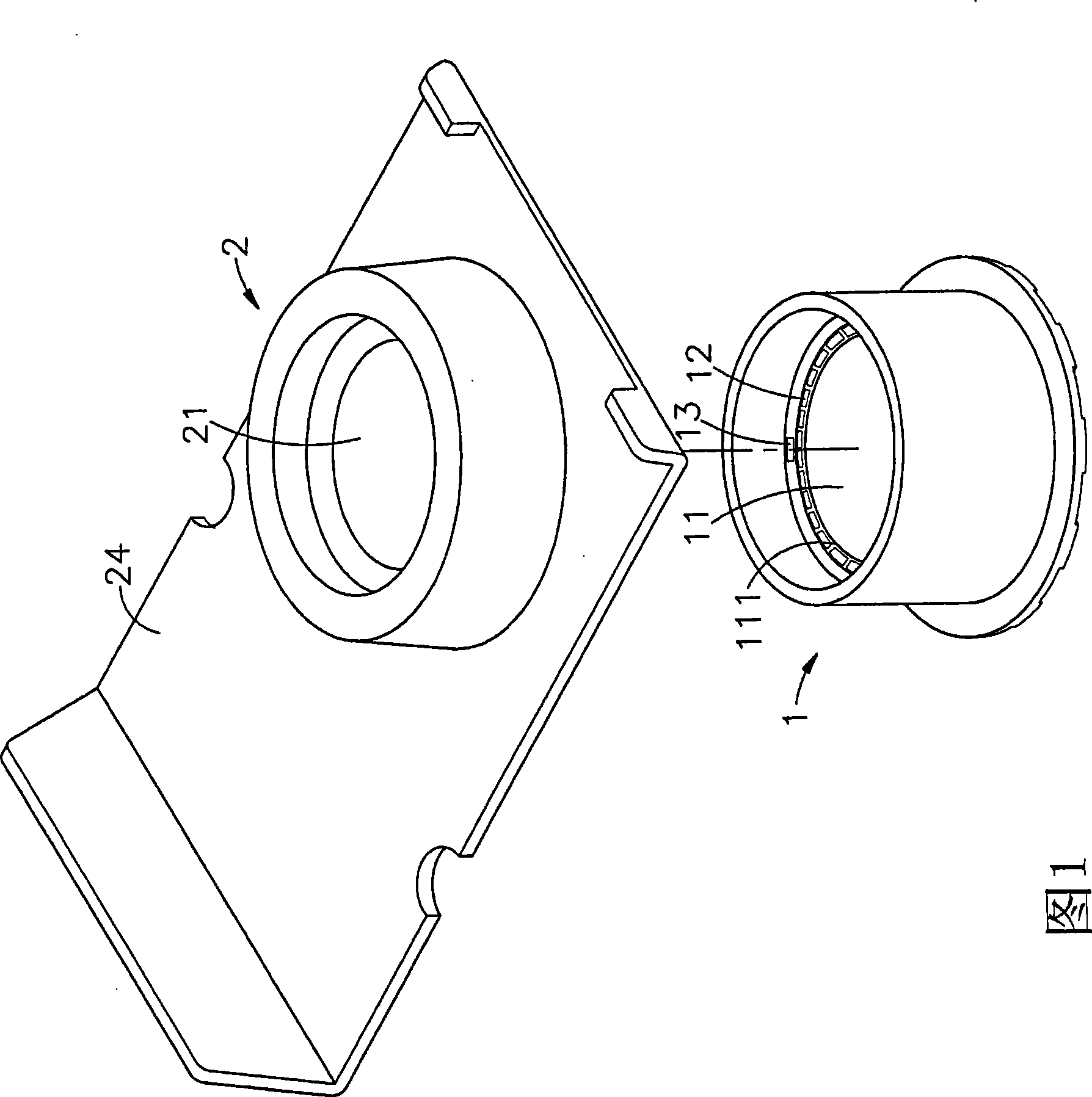

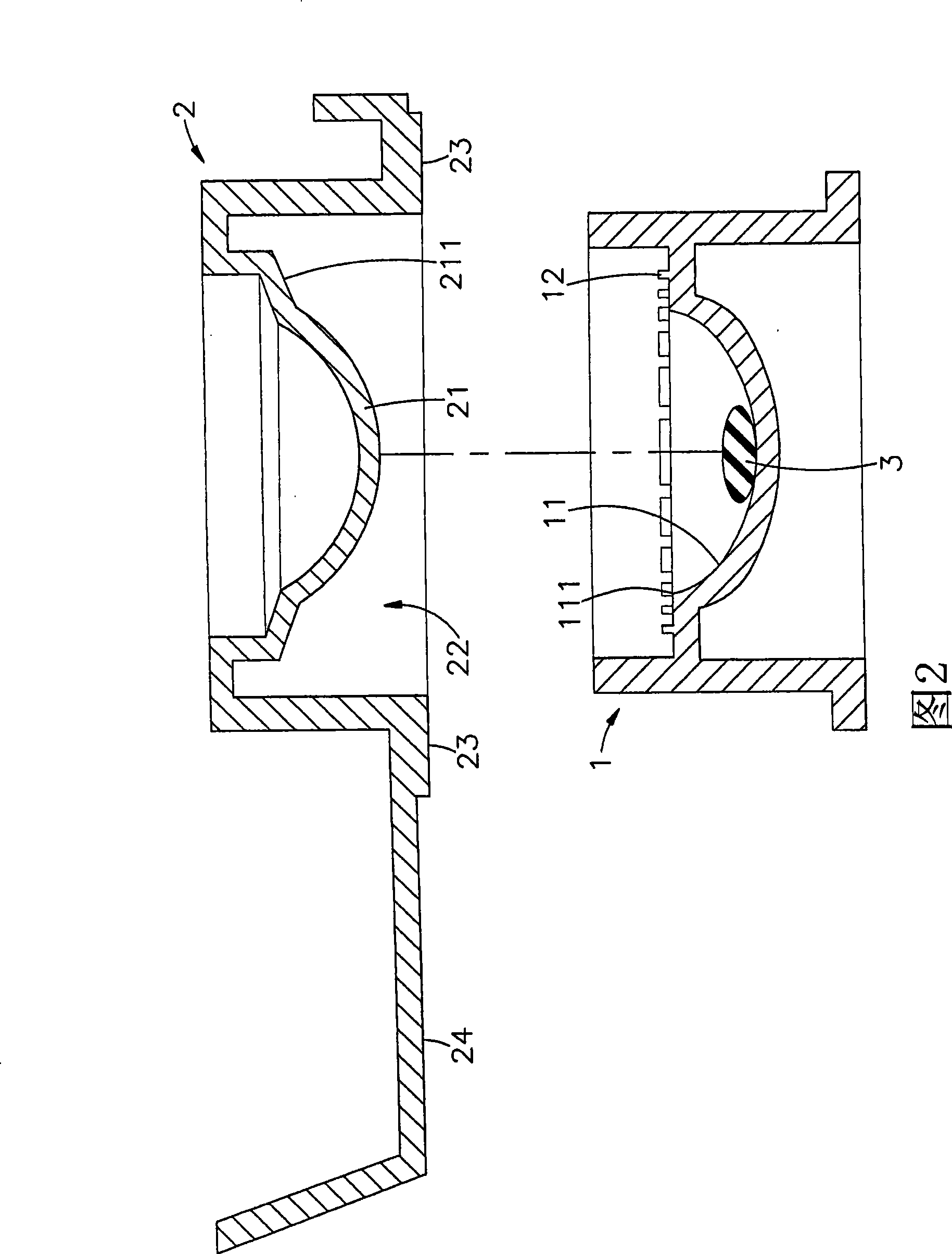

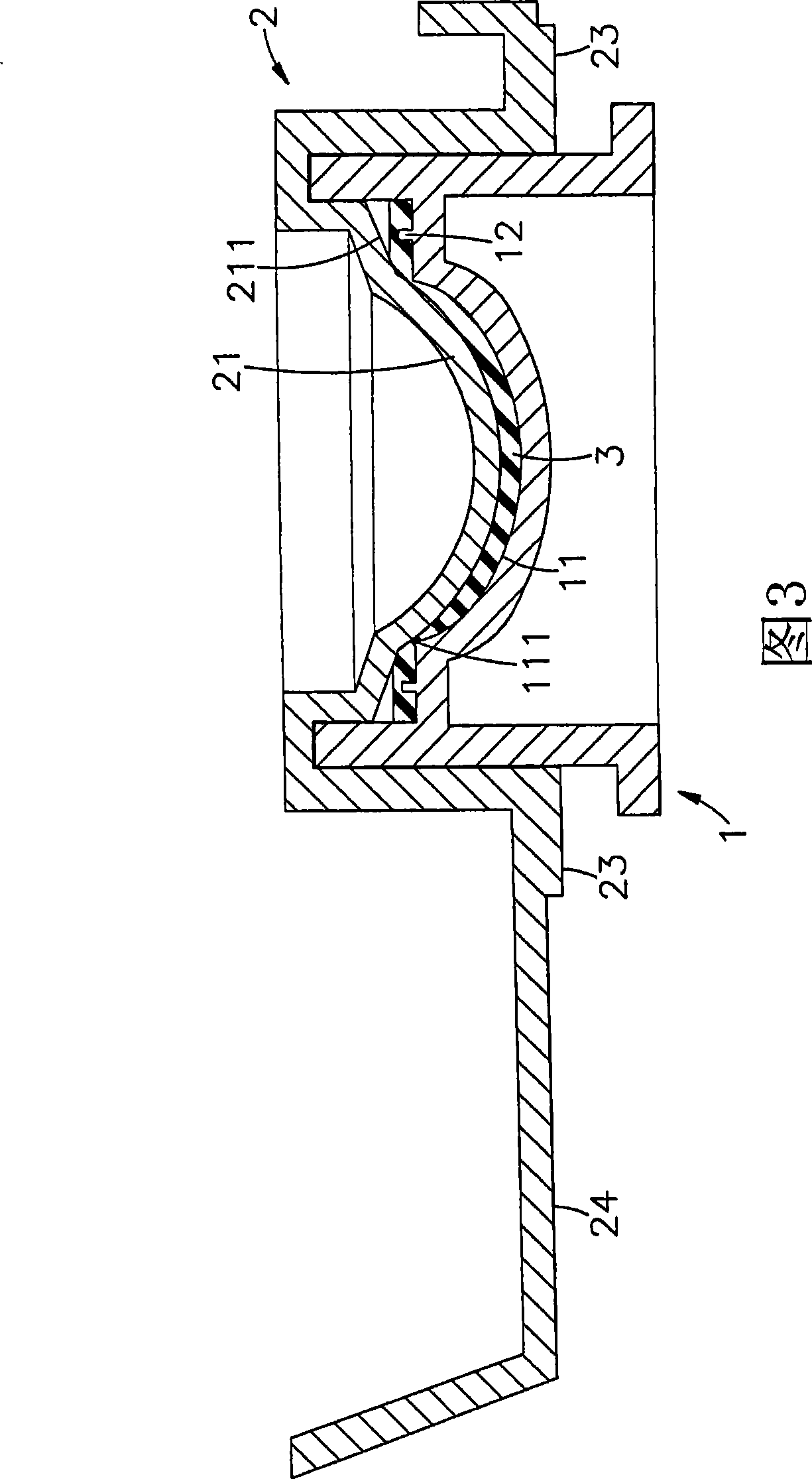

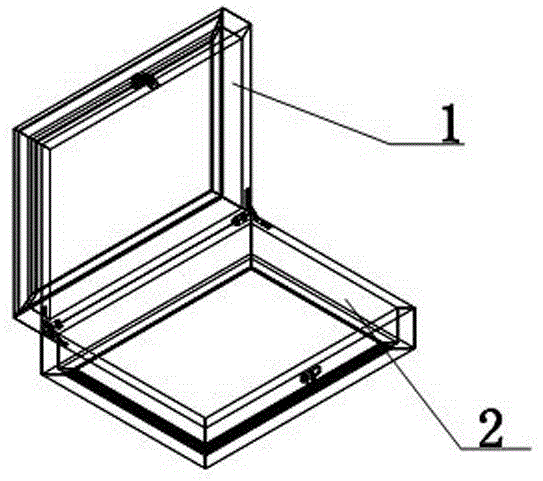

Contact lens molding method and mould

InactiveCN101428477ASimple processShort processOptical articlesUsing protective liquidsManufacturing cost reductionLens plate

The invention relates to a method for shaping contact lenses and a mould, particularly a method which can use simple moulds for forming the contact lenses. The method comprises the following steps: placing the contact lens material in a die cavity of a mould; then, using the mould of an auxiliary appliance to press the lens material in the die cavity; causing the lens material to spread and extend along an arc surface of a die cavity and a mould; pushing excessive materials and overflowing out of the corner cut edge; proving the retained surface at the outer part of the mould for jointing the corner cut edge; removing the excessive materials; solidifying and treating the lens material in the mould; jointing the lens material on the surface of the mould of the auxiliary appliance; shaping glasses of the contact lenses after testing; packaging after injecting buffer solution in the appliance space of the outer part of the mould of an auxiliary appliance; and manufacturing products for selling. The contact lens has the advantages that the manufacturing procedure is simple and fast; and the purposes for saving labor and time, reducing the manufacturing cost, and keeping with the economic effect can be achieved.

Owner:UNICON OPTICAL

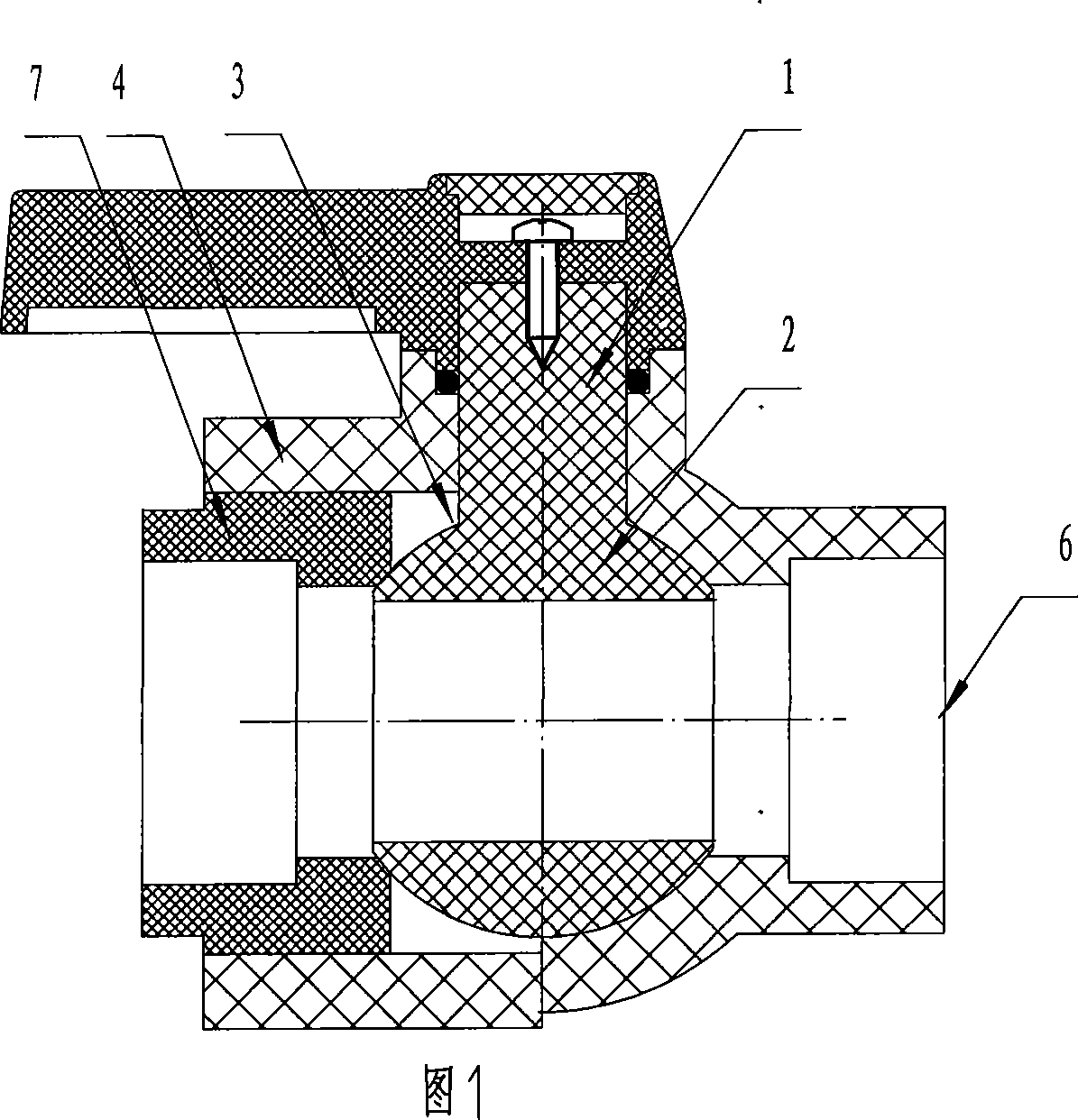

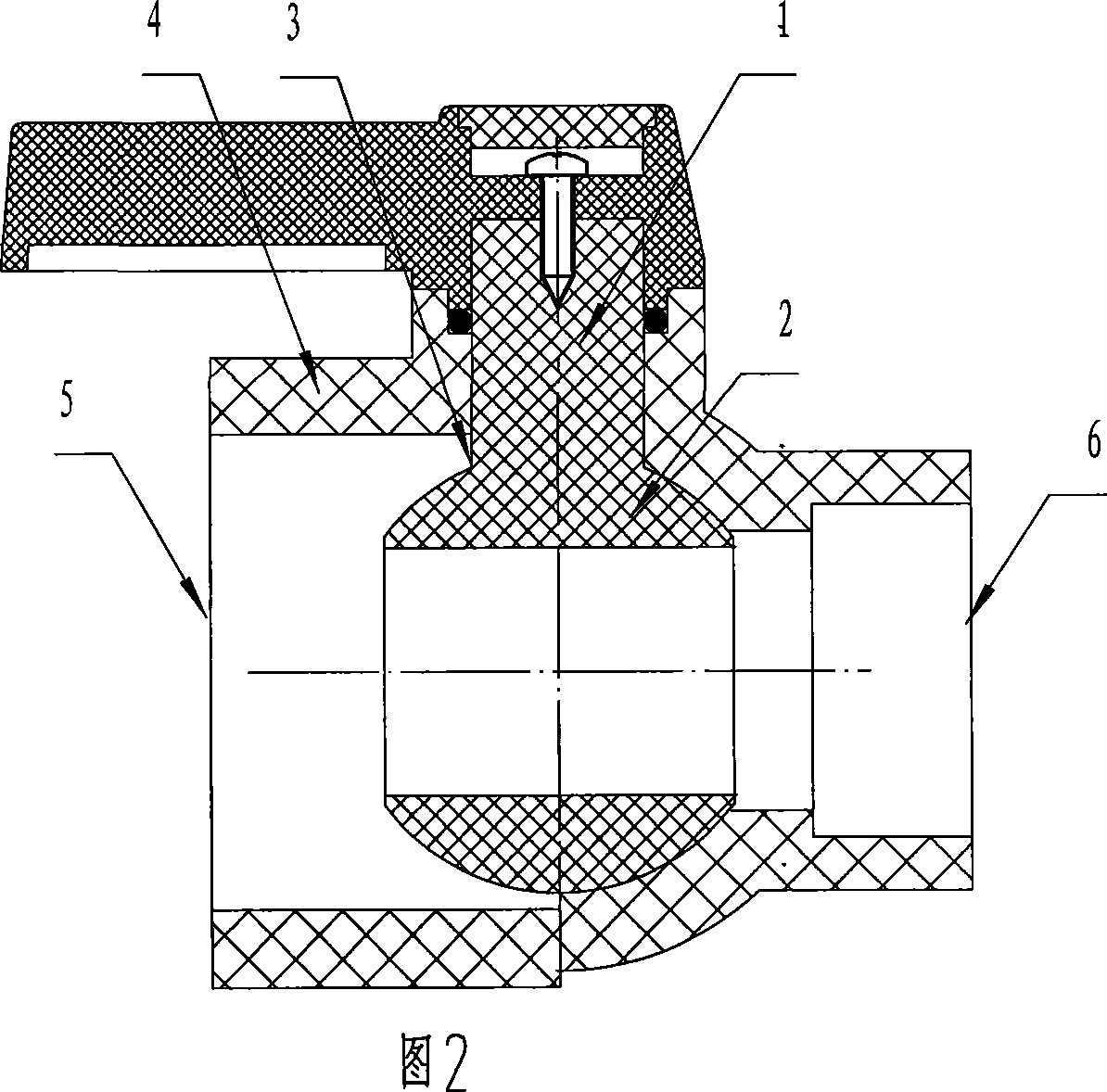

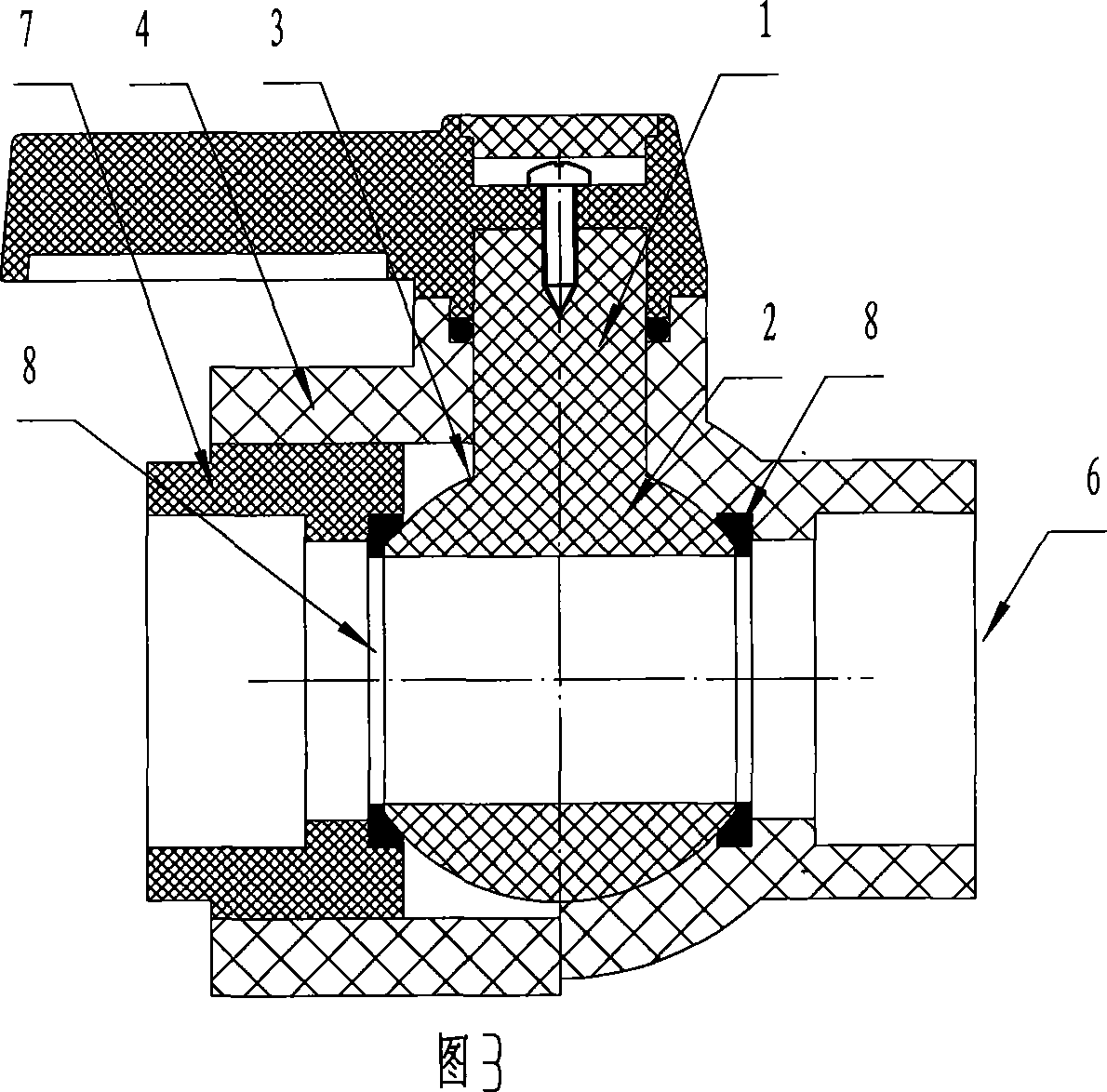

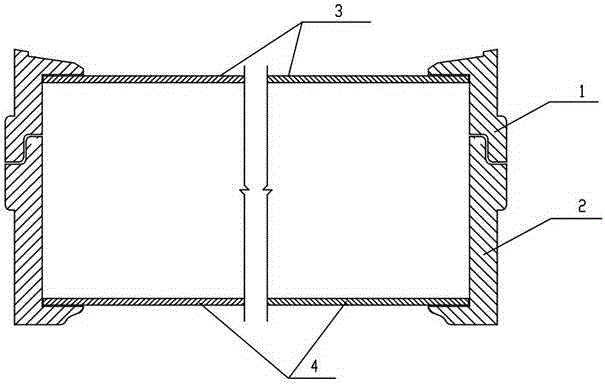

Method for producing plastic ball valve

InactiveCN101059177AAvoid the risk of sheddingReduce contact areaPlug valvesValve housingsPlastic materialsBall valve

The present invention relates to a manufacturing method of plastic ball valve, it is characterized by producing as the following steps: a. producing integrated spool which fixes and connects the valve bar and the valve ball into one unit; b, laying the valve ball of said integrated spool and the valve bar position connected with the valve ball in the die used for producing the plastic ball valve body; c. injecting the plastic material into the die used for producing the plastic ball valve body after the plastic material is heated and melted, cooling the plastic material in the die and modeling into plastic ball valve body, and the valve ball of integrated spool and the valve bar position connected with the valve ball is completely limited in the plastic ball valve body and can not be pulled out after the plastic ball valve body is cooled and shaped; d. connecting a plastic valve cover with through-hole on at least one open position of two side openings of plastic ball valve body, and linking the through-hole of plastic valve cover with the flow way in the plastic ball valve body. The invention is benefit for raising the products quality and extending the use life of products, and is facilitated the production of valve body.

Owner:罗荣森

Indirect extrusion casting method of wrought aluminum alloy castings

The invention discloses an indirect extrusion casting method of wrought aluminum alloy castings. The method comprises the steps of alloy preparation, alloy smelting, indirect extrusion casting and heat treatment, wherein all components are prepared by mass percentage; Si, Cu and Cr in alloys are respectively added by intermediate alloys of an aluminum silicon alloy, an aluminum copper alloy and an aluminum chrome alloy; Mg and Al are respectively added by pure magnesium and pure aluminum; firstly, the pure aluminum and the intermediate alloys of aluminum silicon, aluminum copper and aluminum chrome are added; a refining agent is added for refining; then, magnesium is added after the temperature reduction; and finally, the temperature is adjusted and then the indirect extrusion casting is performed. The method has the prominent advantages of no need of quantitative casting, easy control of casting size, realization of near-net forming, reduction of subsequent processing, realization of high material utilization rate above 90%, reduction of cost, and capabilities of producing castings with more complex shapes and larger wall thickness differences and enabling the castings to have high mechanical performance.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

Wet sander

ActiveCN111730473AImprove processing efficiencyReduce human laborDispersed particle filtrationTransportation and packagingSanderWater storage

The invention discloses a wet sander. The wet sander comprises a shell, wherein the upper end of the shell is fixedly provided with a handle, the inner top of the shell is fixedly provided with a motor, an output shaft of the motor is fixedly provided with a rotating shaft, the bottom of the rotating shaft is fixedly provided with a sanding plate, the circumferential side wall of the rotating shaft is rotationally connected with a water storage tank, the side wall of the rotating shaft is fixedly provided with a rotating plate which is slidably connected with the bottom of the water storage tank, and the upper end of the rotating plate is provided with a dislocation groove in a penetrating mode. The wet sander has the advantages that the rotating shaft drives the rotating plate to rotate in the rotary processing process of the sanding plate, so that the dislocation groove is superposed with a drainage hole, water drops and enters spraying holes under the action of centrifugal force, and then a spraying groove sprays water to the surface to be processed of a plate, so that the automatic sprinkling in the processing process is completed, the position is the position to be processed,the sprinkling is accurate without manual sprinkling and control over the sprinkling position, the processing efficiency is improved, and manual labor is reduced.

Owner:临沂新达五金工具有限公司

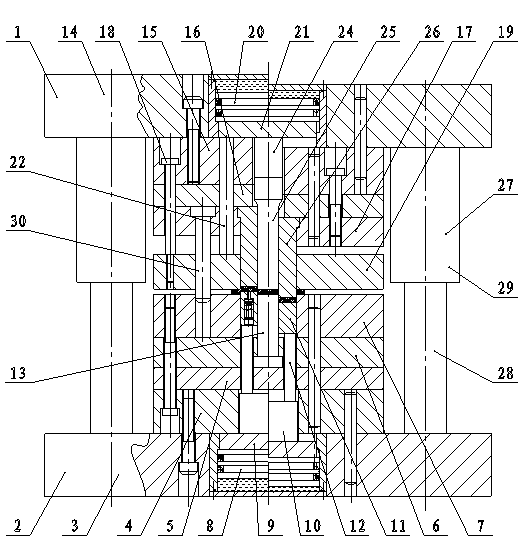

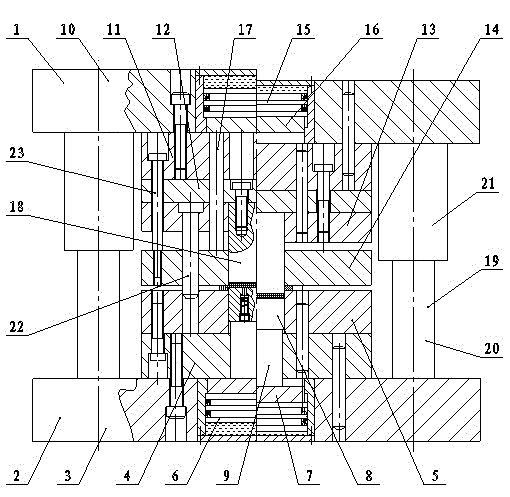

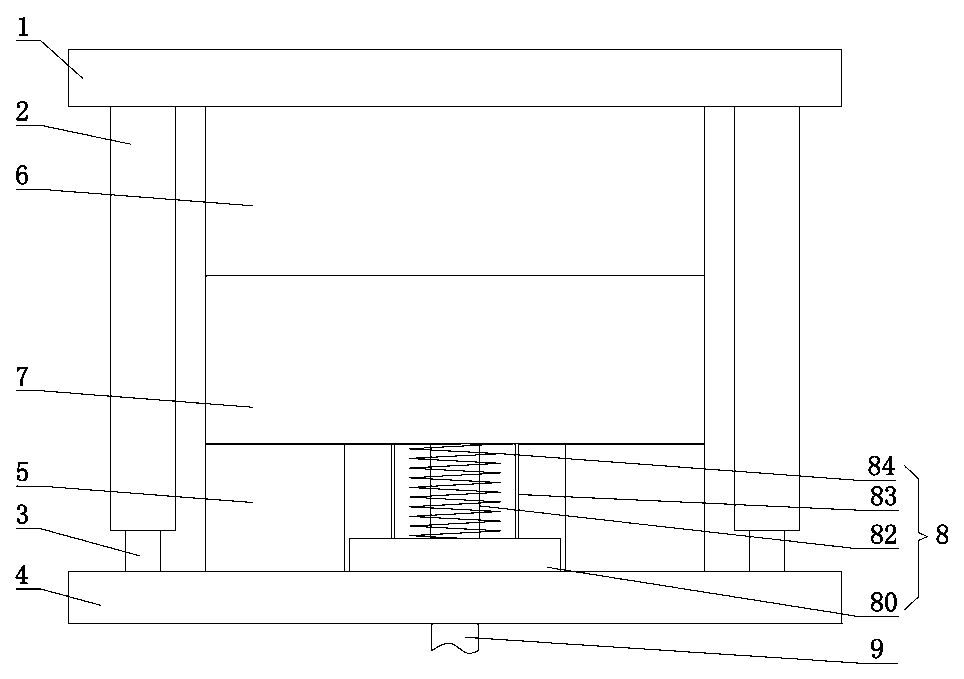

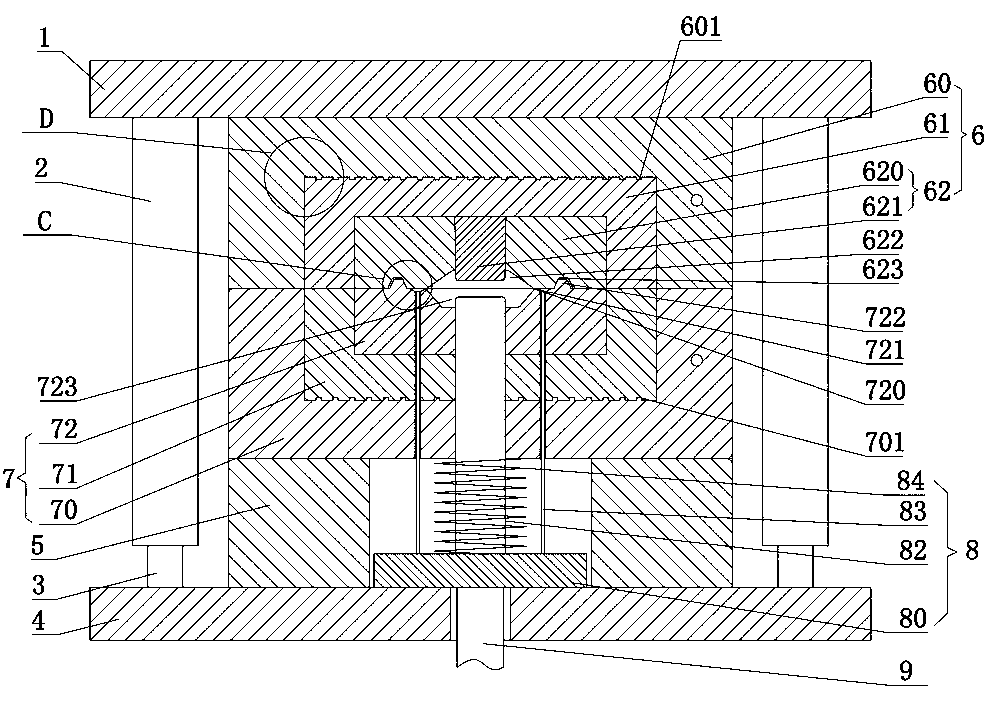

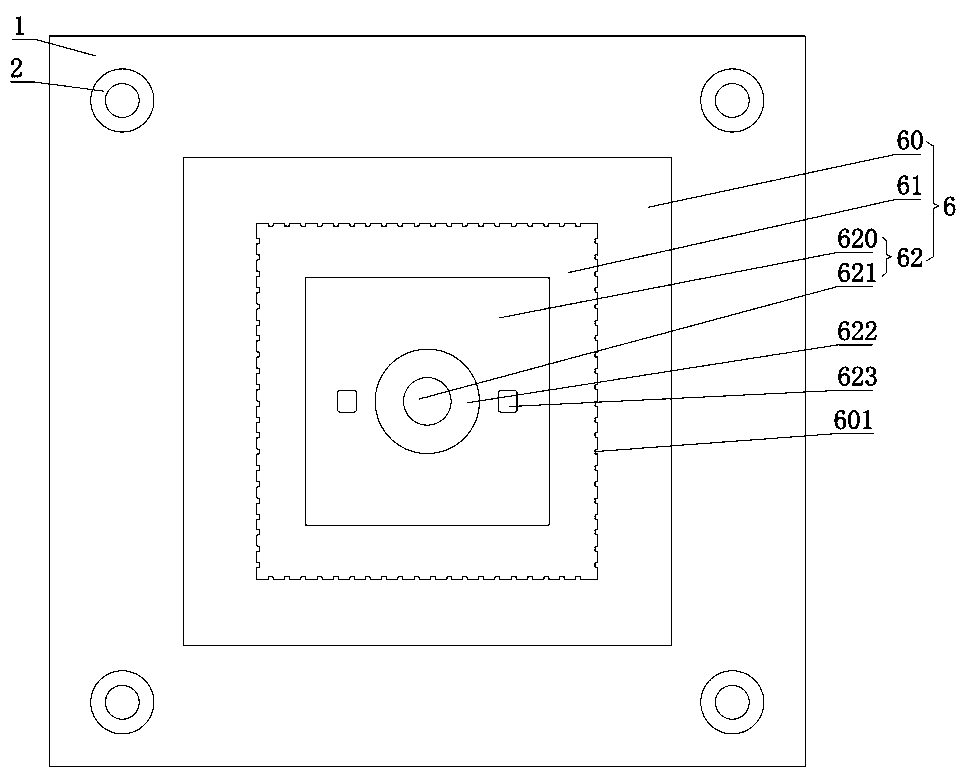

Reciprocating fine blanking compound die

InactiveCN103071722ARealize two-way compound punchingReduce glitchesMetal working apparatusPistonPetroleum engineering

The invention relates to a reciprocating fine blanking compound die, which belongs to the technical field of dies and aims to solve the technical problem to provide a fine blanking compound die which is capable of reducing blank burrs. The reciprocating fine blanking compound die has the technical scheme that the die comprises an upper die and a lower die, wherein the lower die has the structure that a lower die plate, a lower base plate, a lower fixing plate and a lower concave die are sequentially fixed on a lower die seat through bolts, and a lower oil cylinder is arranged in a central hole 6+5 of the lower die seat, a lower pressure bearing plate is fixed on a piston of the lower oil cylinder, and lower convex and concave die is sleeved in a central hole of the lower concave die; and the upper die has the structure that an upper die plate, an upper base plate and an upper fixing plate are sequentially fixed on the bottom of an upper die seat through bolts, bolts of an upper concave die are connected with the upper concave die after penetrating through the upper die plate, the upper base plate and the upper fixing plate, an upper oil cylinder is arranged in a central hole of the upper die seat, the upper part of an upper convex die is movably sleeved in a central hole of the upper base plate, and the lower part of the upper convex die is sleeved in a central through hole of an upper convex and concave die. According to the blanking die disclosed by the invention, raw materials are blanked bidirectionally to effectively reduce the burrs.

Owner:CHANGZHI HUIFENG ELECTROMECHANICAL INDAL TRADE

Foamed plastic packing box and preparation method thereof

InactiveCN102617945AFeel goodReduce pollutionBio-packagingRigid containersPolymer sciencePlastic packaging

The invention relates to a foamed plastic packing box and a preparation method thereof. Aim at solving problems produced in packing box production thereby satisfying increasing requirements from people on packing boxes, the invention provides the foamed plastic packing box and the preparation method thereof. The foamed plastic packing box comprises: by weight, 90 to 110 parts of polystyrene resin, 0.8 to 0.9 parts of sodium bicarbonate NaHCO3, 0.046 to 0.078 parts of silicone oil, 11 to 14 parts of modified polystyrene resin and 2.5 to 5 parts of industrial starch. Compared with the prior art, the foamed plastic packing box reduces environmental pollution, has good environmental benefits, reduces follow-up processes, and has a low cost and a good cost-performance ratio.

Owner:陈嘉荣

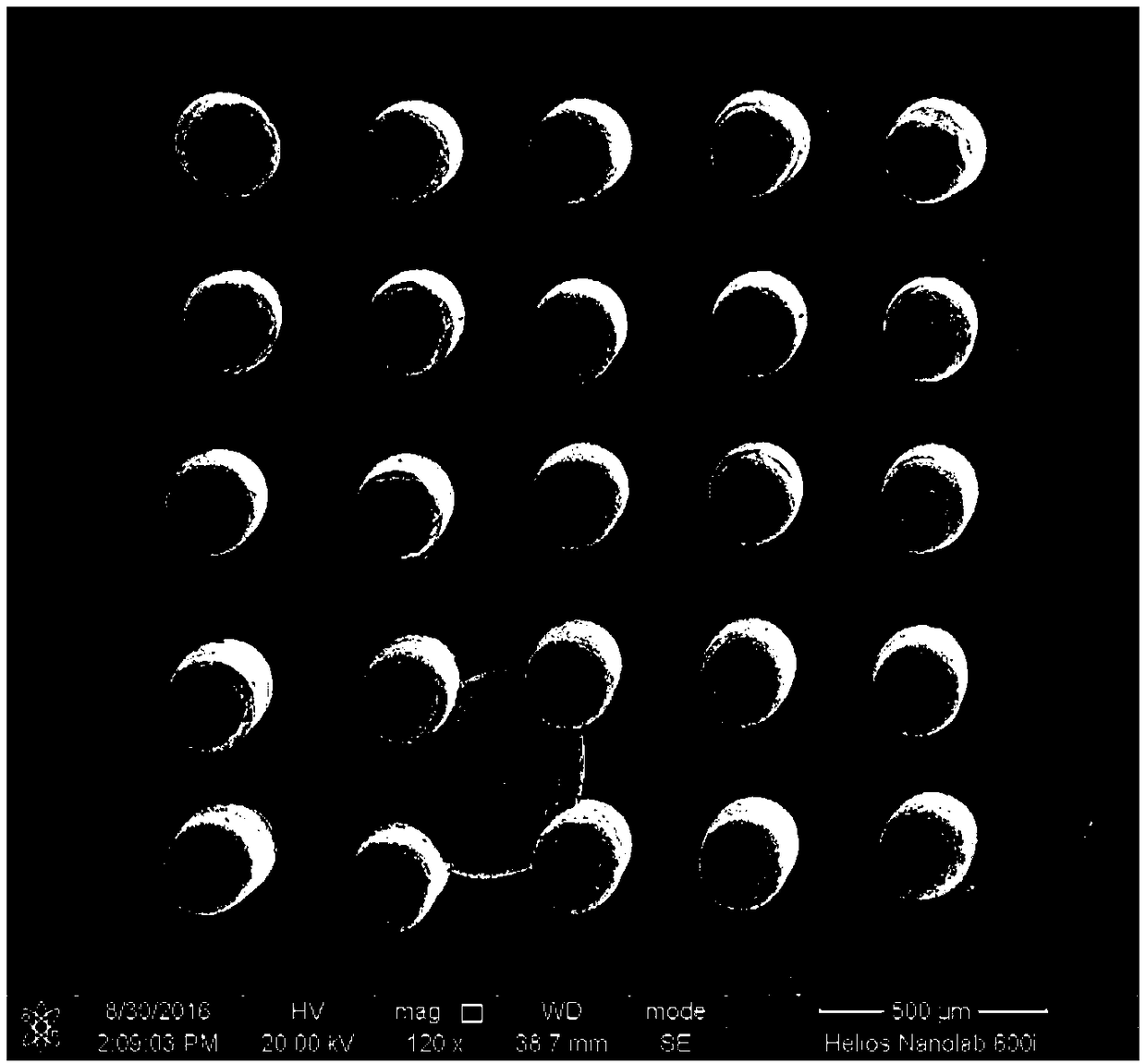

Boron carbide ceramic ball and preparation method thereof

The invention relates to a boron carbide ceramic ball and a preparation method thereof. The preparation method comprises the following steps: (1) performing spray granulation on boron carbide powder,carbon black powder, a surfactant A, a sintering aid and a binder to obtain boron carbide granulating powder; (2) heating and stirring the boron carbide granulating powder obtained in the step (1), asurfactant B and a high polymer binder, mixing and crushing to obtain injected granules; (3) performing injection molding on the injected granules obtained in the step (2) to obtain a spherical greenbody, degreasing and sintering the obtained spherical green body to obtain the boron carbide ceramic ball. Compared with the prior art, the preparation method has the advantages that the boron carbideceramic ball with relatively high degree of sphericity can be prepared, a prepared material used in the grinding process is small, the efficiency is high, and the production cost can be better saved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Copper conic liner and preparation method thereof

ActiveCN106694877ASame orientationImprove plasticityAmmunition projectilesFluid removalMelting tankStructure property

The invention discloses a copper conic liner and a preparation method thereof. The copper conic liner comprises a supporting column body, a liner top, an inner wall surface and an outer wall surface, wherein the supporting column body is connected with the liner top. The preparation method is characterized in that a laser fusion covering type rapid forming method is adopted; the temperature gradient of a bath formed by laser beams is utilized, and the hot flow dispersing direction is controlled through a water cooling system, on that basis, small columnar dendrite grains in a fusion covering layer can directionally grow in the axis direction of the liner, and thus the liner of which each part has the directional solidifying structure property can be prepared. The copper conic liner prepared by the method is outstanding in stretching performance in the axis direction, so that the metal jet extending performance can be effectively improved, the jet breakup time can be prolonged, and as a result, the penetration performance can be improved; in addition, the preparation method has the advantages of being short in formation time, high in size accuracy, and high in material utilization rate.

Owner:NANJING UNIV OF SCI & TECH

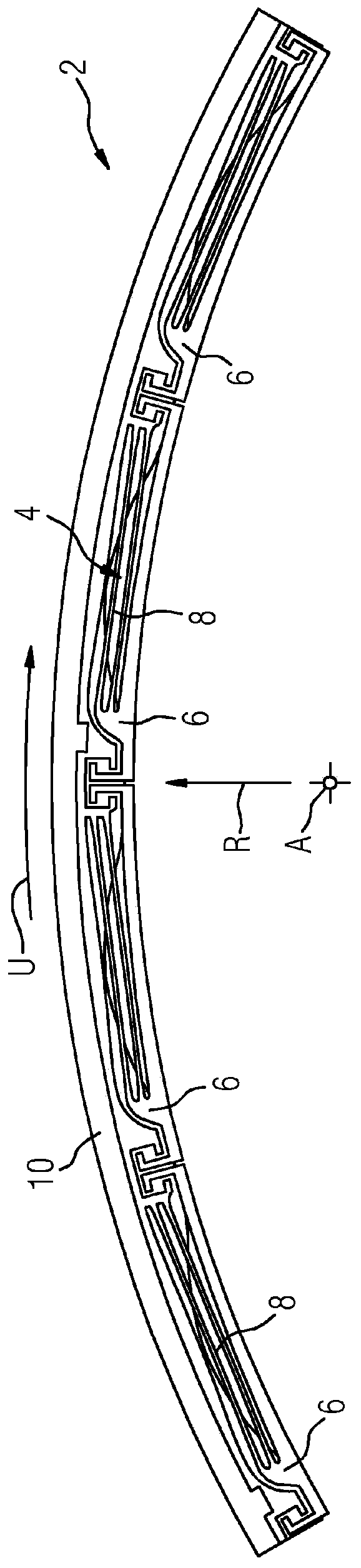

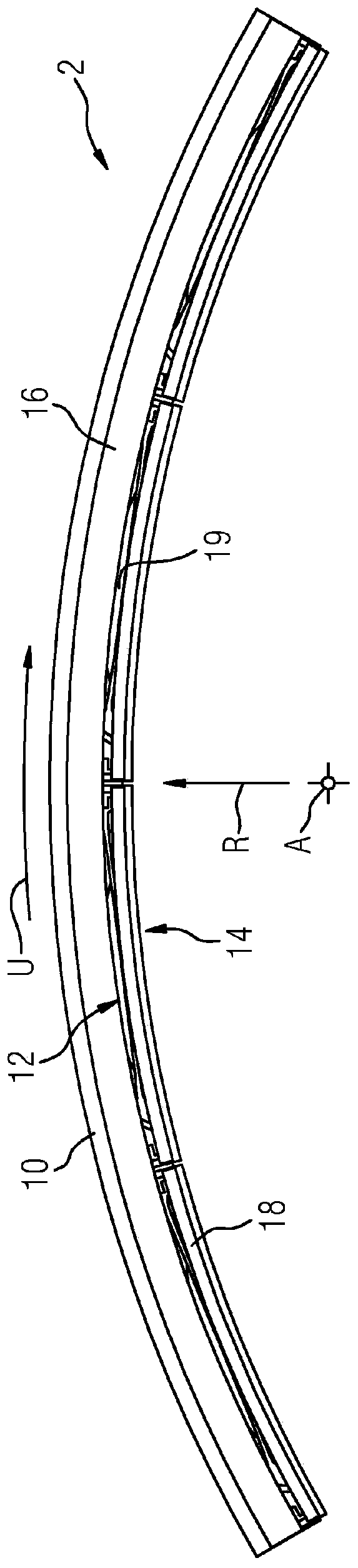

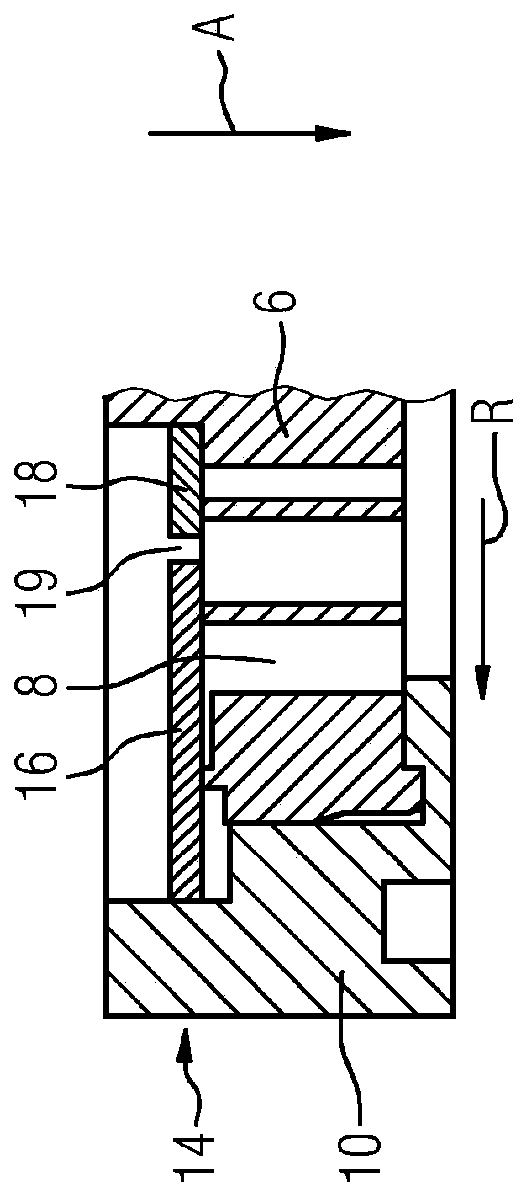

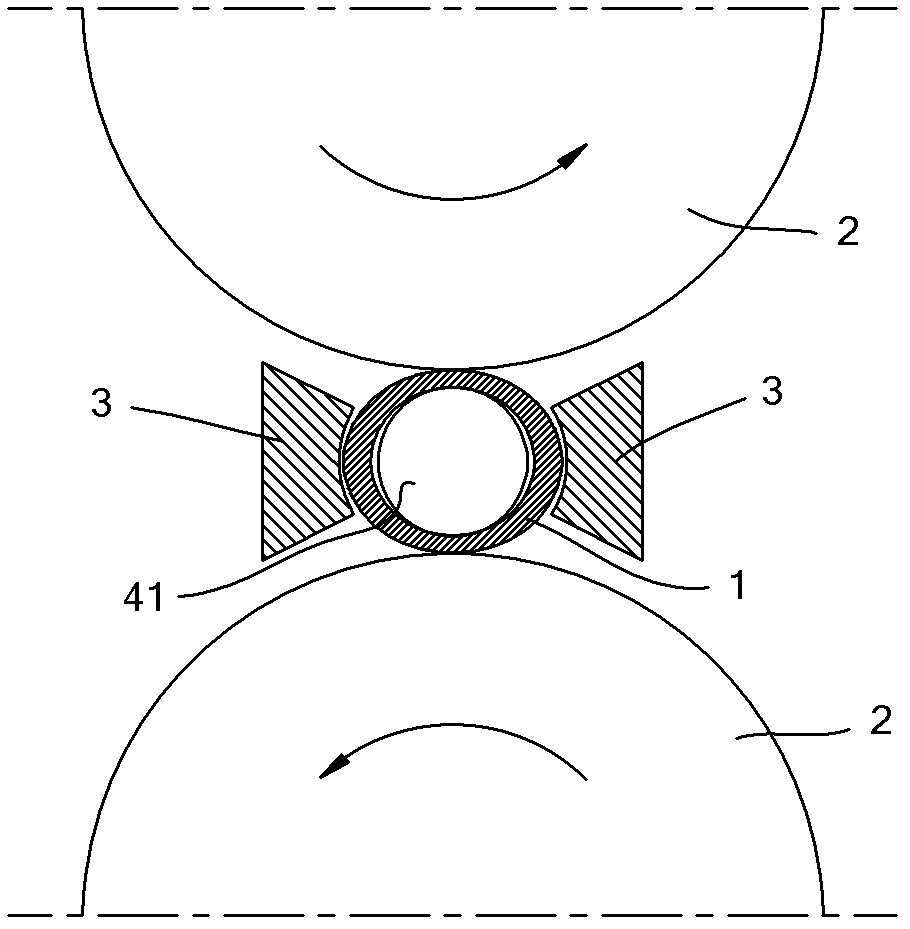

Seal for sealing a peripheral gap between two machine components

The invention relates to a seal comprising: a main seal having a shoe establishing a contactless seal between machine components and a spring element supporting the shoe on the machine components suchthat a radial movement of the shoe acts as a reaction to a fluid pressure applied to the shoe; and an auxiliary seal sealing the spring element in the axial direction, the auxiliary seal having at least two layers adjacent to each other in the axial direction. In order to improve the functional reliability, the layers each comprise at least two sheets which are positioned radially next to each other; for each layer, one sheet is fixed and the other sheet is movable by being fixed on the shoe; seen from the radial direction, the two moving sheets of every two directly adjacent layers have different widths, the wider one of the two moving sheets is combined with the narrower fixed sheet to form a layer, and the narrower one of the two moving sheets is combined with the wider fixed sheet toform a layer; and the wider moving sheet in one layer is overlapped with the wider fixed sheet in the corresponding other layer in the radial direction.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

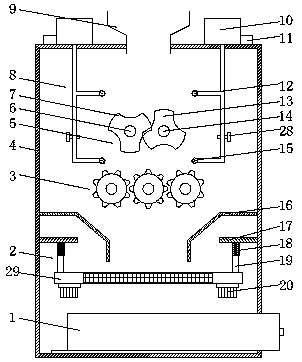

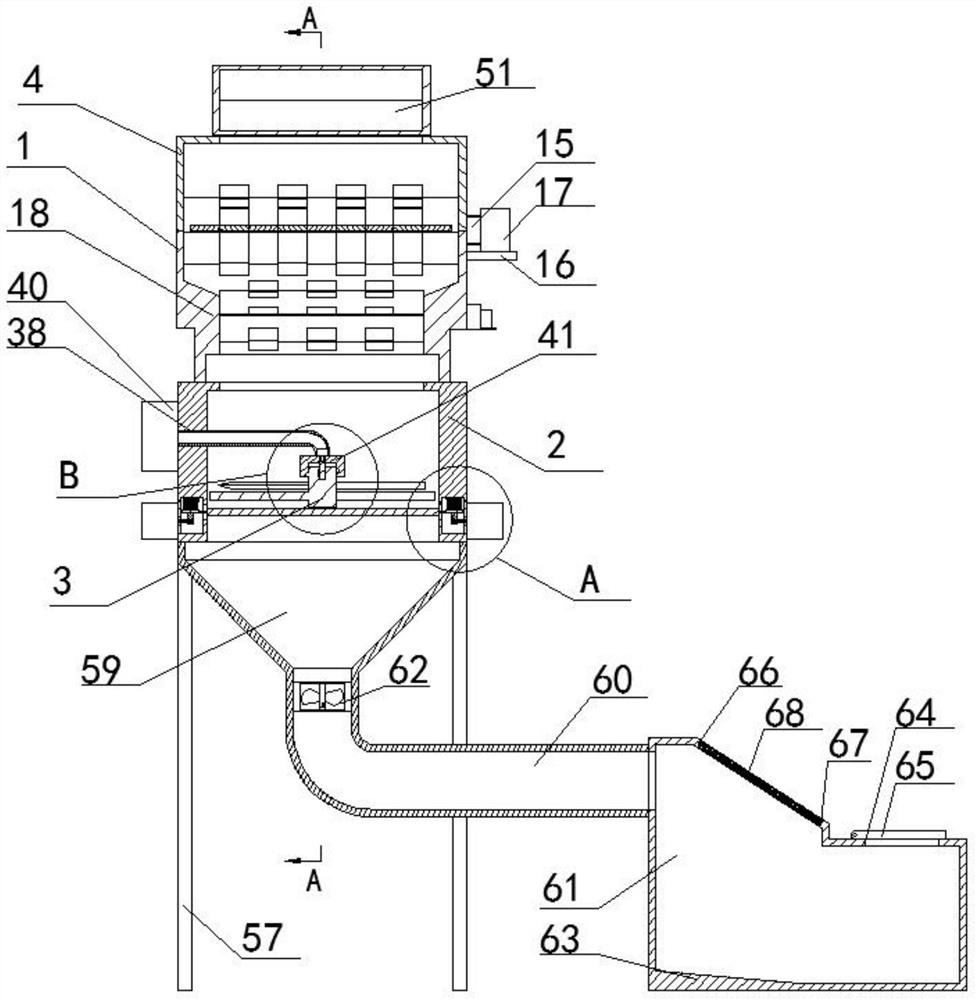

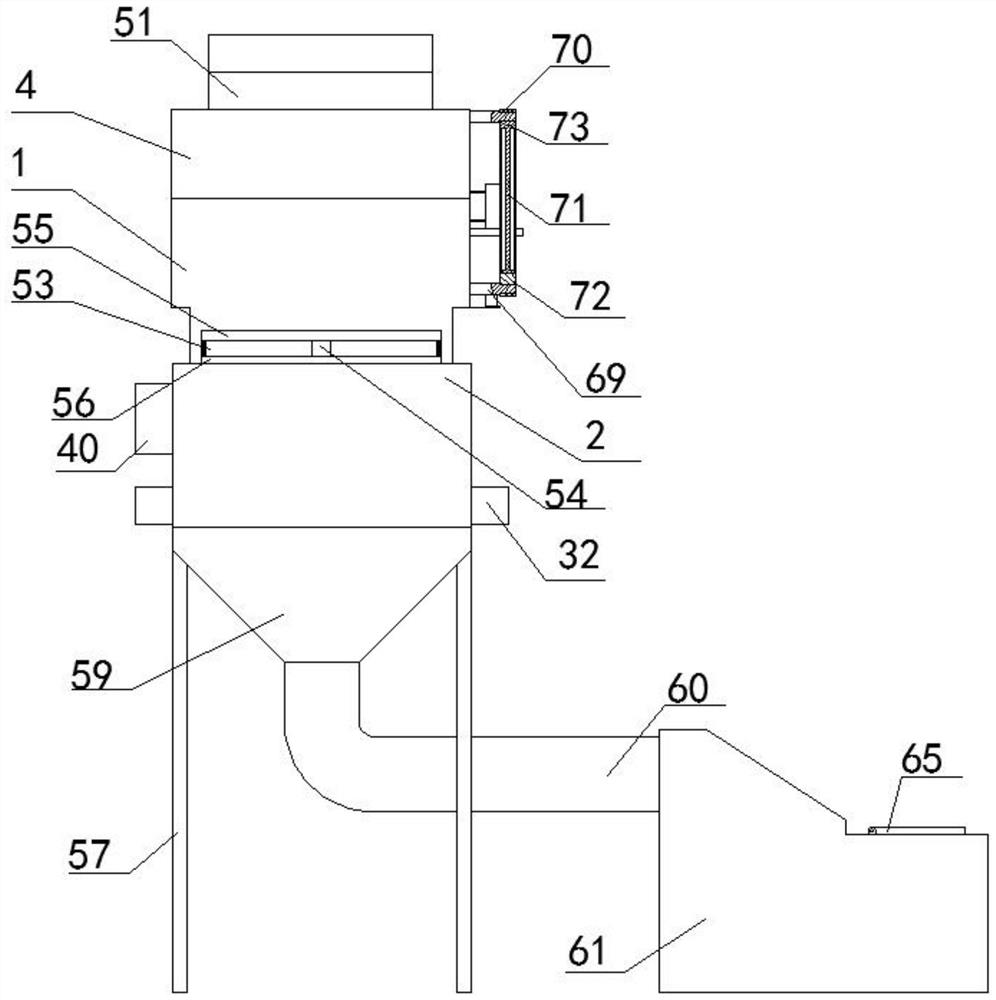

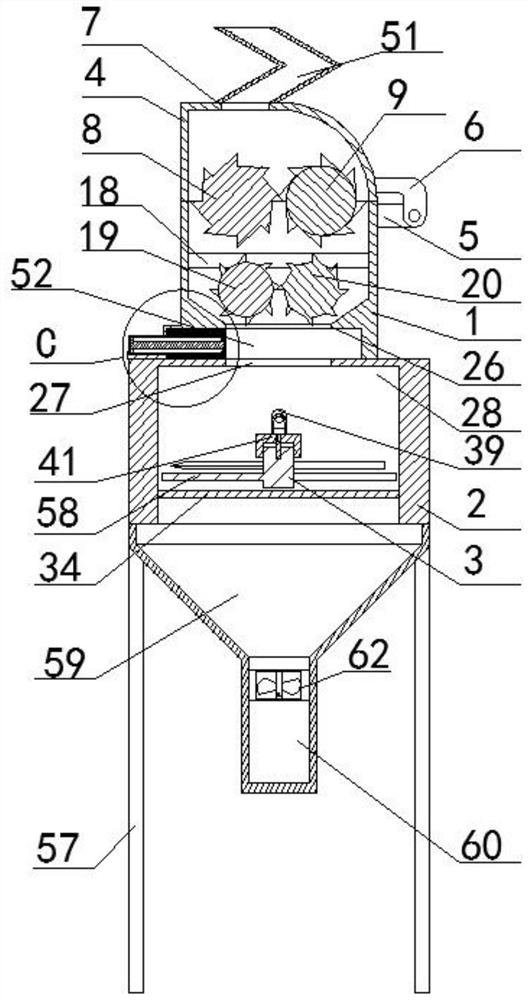

Self-cleaning pulverizing device for pueraria lobata

InactiveCN109331958AReduce the difficulty of crushingIncrease productivityCleaning using liquidsGrain treatmentsLobataWater storage tank

The invention discloses a self-cleaning crushing device for pueraria lobata. The self-cleaning crushing device comprises a machine case, a cutting mechanism, a crushing mechanism, a spraying mechanism, a screen mechanism and a storage box. The cutting mechanism comprises a driving motor I, a rotating shaft I, a rotating shaft II, a blade group I and a blade group II, wherein the blade group I andthe blade group II are welded to the rotating shaft I and the rotating shaft II and are composed of blades, and the blades are welded to the rotating shaft I and rotating shaft II correspondingly. Fixed gaps are arranged between adjacent blades. The outer circumferences of the blades are provided with equally divided notches. The crushing mechanism comprises a plurality of driving motors II, rolling shafts and rolling rollers, wherein the rolling rollers are fixedly connected to the rolling shafts. The spraying mechanism comprises a water storage tank, a water outlet pipe and a spray head arranged on the end portion of the water outlet pipe. The screen mechanism comprises an installation plate, a spring, a connecting column, a metal screen and vibration motors symmetrically arranged at twosides of the bottom of the metal screen, wherein the metal screen is welded to the bottom of the connecting column. By means of the self-cleaning crushing device, the powder yield of the pueraria lobata can be improved, and the equipment service life can be ensured as well.

Owner:霍山县宝康食品厂

Burr-free punching mold system

InactiveCN103658314AReduce manufacturing costIncrease productivityPerforating toolsPunchingEngineering

The invention relates to a burr-free punching mold system. The burr-free punching mold system comprises a main punching mold, a back-punching mold, an upper template and a lower template, wherein the main punching mold comprises a first convex die and a first concave die; the back-punching mold comprises a second convex die and a second concave die; the first concave die is fixed on the upper template, and the second concave die is fixed on the lower template; during punching, a punched piece is firmly pressed by both the first concave die and the second concave die; the first convex die penetrates through the second concave die to complete primary punching, and then the second convex die penetrates through the first concave die to finish secondary punching. Compared with the prior art, the burr-free punching mold system has advantages of being wide in application range, low in production cost, high in producing efficiency and the like.

Owner:SHANGHAI QIANGJING METAL PROD

Reciprocating Fine Blanking Die

InactiveCN103071721BRealize two-way punchingReduce glitchesMetal working apparatusMechanical engineeringEngineering

The invention relates to a reciprocating fine blanking die, which belongs to the technical field of dies and aims to provide a fine blanking die which is capable of reducing blank burrs. The reciprocating fine blanking die has the technical scheme that the blanking die comprises an upper die and a lower die, wherein the lower die has the structure that a lower die plate and a lower concave die are sequentially fixed in a superposition mode from bottom to top on a lower die seat through bolts, and a lower oil cylinder is arranged in a central hole of the lower die seat, and a lower pressure bearing plate on a piston of the lower oil cylinder is fixedly connected with a lower convex die through a lower compression bar; and the upper die has the structure that an upper die plate, a base plate and a convex die fixing plate are sequentially fixed in a superposition mode from top to bottom on the bottom of an upper die seat through bolts, bolts of an upper concave die are connected with the upper concave die after penetrating through the upper die plate, the base plate and the convex die fixing plate, an upper oil cylinder is arranged in a central hole of the upper die seat, an upper compression bar penetrates through the upper die plate, the base plate and the convex die fixing plate, and the upper convex die is sleeved in the central holes of the convex die fixing plate and the upper concave die. According to the blanking die disclosed by the invention, raw materials are blanked bidirectionally to effectively reduce the burrs.

Owner:CHANGZHI HUIFENG ELECTROMECHANICAL INDAL TRADE

Micro component liquid forming method conducted under composite action of multiple physical fields

ActiveCN109351918AIntegrity guaranteedThe effect of surface tension is reducedFoundry mouldsFoundry coresPhysical fieldCasting mold

The invention relates to the field of a micro component liquid forming method, in particular to a micro component liquid forming method conducted under the composite action of multiple physical fields, and aims at solving the technical problems that in the existing single force field forming process, micro component forming is incomplete, and mechanical performance is not stable. The method comprises the steps that a micro model is made, and model assembling is conducted; a gypsum casting mold is prepared through assisting of the multiple physical fields; dewaxing and casting mold roasting areconducted; metal fusion is conducted through assisting of an electric field; pouring forming is assisted through the multiple physical fields; and demoulding and cleaning are conducted, and a metal micro component is obtained. According to the method, subsequent machining is not needed, one-time forming can be achieved, the micro component is integrally formed, and the surface quality is excellent. The method is used in the field of metal micro component forming.

Owner:HARBIN INST OF TECH

Forging and pressing die

ActiveCN111112532ASmall size deviationHigh precisionForging/hammering/pressing machinesEngineeringMechanical engineering

The invention relates to a forging and pressing die. The forging and pressing die comprises an upper die base, a fixing plate, an upper combination die, a lower combination die and an ejection device,wherein a guide sleeve is arranged on the bottom surface of the upper die base; a guide column is arranged in the guide sleeve in a penetrating mode; the guide column is fixed on a lower die base; athrough hole is formed in the center of the lower die base; an ejector rod movably penetrates into the through hole; the fixing plate is arranged on the top surface of the lower die base; the upper combination die comprises an upper outer die, an upper inner die and an upper die core; the upper die core is a combination body composed of an upper plate body and a round rod; the combination body isarranged in a second upper groove of the upper inner die; a frustum-shaped hole is formed in the bottom surface of the upper plate body; the lower end of the round rod extends out of a first through hole and is arranged in the frustum-shaped hole; the lower combination die comprises a lower outer die, a lower inner die and a lower die core; and an inverted frustum-shaped hole and a residual material groove are formed in the top surface of the lower die core. The forging and pressing die aims to solve the problems that in the prior art, according to a forging and pressing die, the size deviation of a forge piece is prone to being too large, a die cavity is prone to generating plastic deformation, the sudden change position of the inner wall of the die cavity is prone to cracking, and the forge piece is prone to deformation during discharging.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

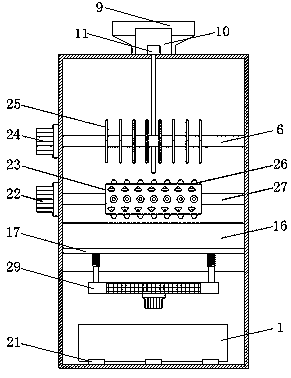

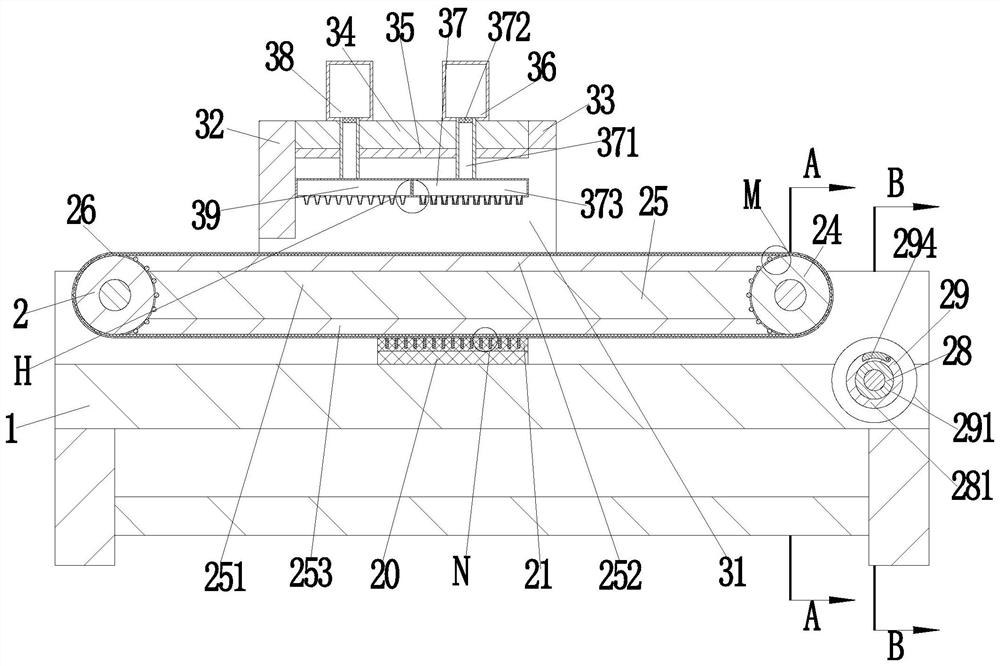

Intelligent textile spray printing machine

ActiveCN112248660AAvoid wastingReduce subsequent processingTypewritersOther printing apparatusTextile fiberRubber sheet

The invention relates to an intelligent textile spray printing machine which comprises a workbench, a conveying device and a spray printing device, the conveying device is arranged in the middle of the workbench, the spray printing device is arranged at the upper end of the middle of the workbench, and the conveying device comprises a rubber plate, a sponge block, a first motor, a large gear, a round roller, a supporting plate, a supporting belt, a small gear, a sleeve and a positioning cylinder. According to the machine, textile fabrics are conveyed through the conveying device, the surface of the supporting belt is cleaned, the fabrics obtained after the completion of spray printing are rolled, textile chippings attached to the textile fabrics are cleaned and collected through the sprayprinting device, the textile fabrics are sensed, and when the fabrics are hollow or made of cotton and linen materials, materials sprayed by a first spray head and a second spray head only make contact with the portions where textile fibers exist so that waste of the materials is prevented, subsequent processing is reduced, and the aesthetic degree of spray printing of the textile fabrics is improved.

Owner:江苏汉印机电科技股份有限公司

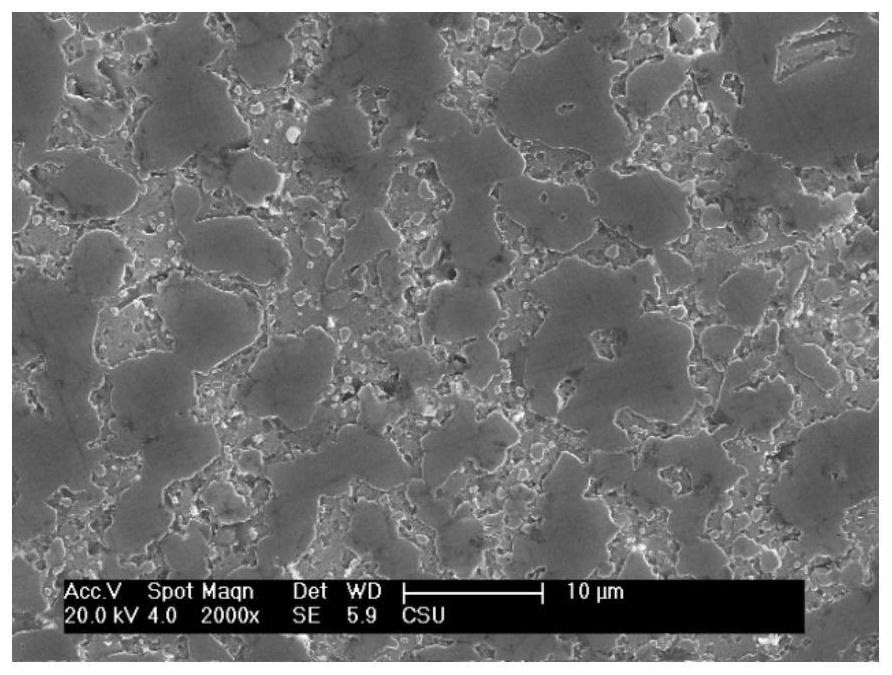

Method of producing hard alloy rotatable special-shaped blade

InactiveCN100519010CSolve the technical problem that it is impossible to directly prepare special-shaped bladesReduce subsequent processingWaxCoupling

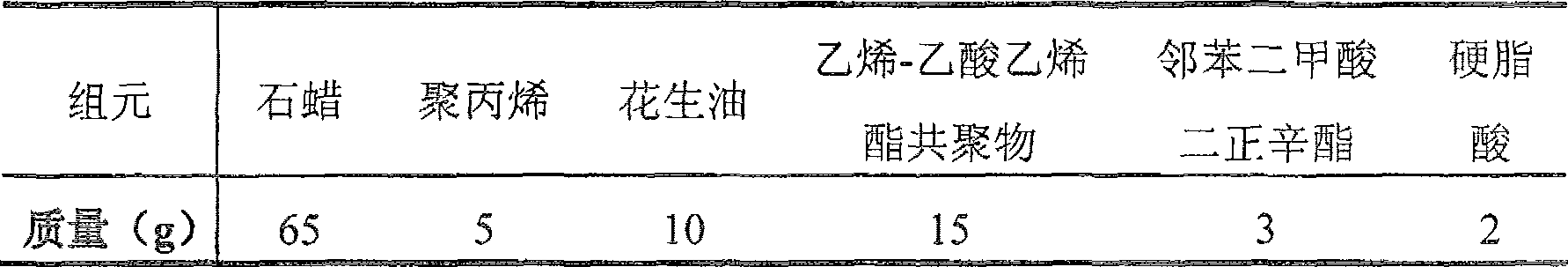

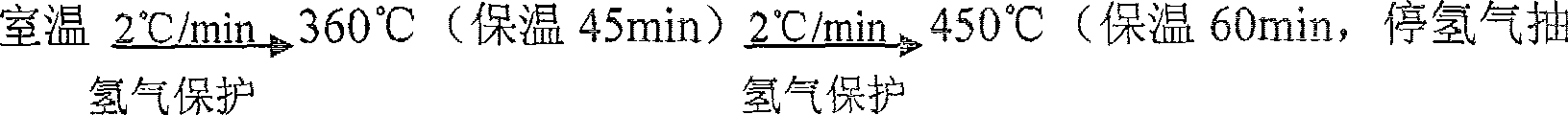

The invention relates to a WC-Co cemented carbide indexable special-shaped blade prepared by powder injection molding, which is characterized in that WC-Co mixed powder and a wax-oil-low molecular coupling agent-high molecular polymer composition The multi-component binder is mixed to prepare a uniform feed, and the feed is injected on the injection machine to produce an indexable special-shaped blade injection blank, and the injection blank is solvent-degreased in a solvent to control the solvent degreasing rate in the range of 45% to 65%. In the end, the solvent degreasing billet is finally subjected to a one-step thermal degreasing + sintering process. The prepared indexable special-shaped insert has high mechanical properties, and its bending strength is higher than that of the alloy prepared by the ordinary molding method, which can meet the production requirements. At the same time, the size deviation of the product is within Within ±0.5%.

Owner:CENT SOUTH UNIV

Foamed plastic packing box and preparation method thereof

InactiveCN102617945BReduce pollutionReduce subsequent processingBio-packagingRigid containersPolymer sciencePlastic packaging

The invention relates to a foamed plastic packing box and a preparation method thereof. Aim at solving problems produced in packing box production thereby satisfying increasing requirements from people on packing boxes, the invention provides the foamed plastic packing box and the preparation method thereof. The foamed plastic packing box comprises: by weight, 90 to 110 parts of polystyrene resin, 0.8 to 0.9 parts of sodium bicarbonate NaHCO3, 0.046 to 0.078 parts of silicone oil, 11 to 14 parts of modified polystyrene resin and 2.5 to 5 parts of industrial starch. Compared with the prior art, the foamed plastic packing box reduces environmental pollution, has good environmental benefits, reduces follow-up processes, and has a low cost and a good cost-performance ratio.

Owner:陈嘉荣

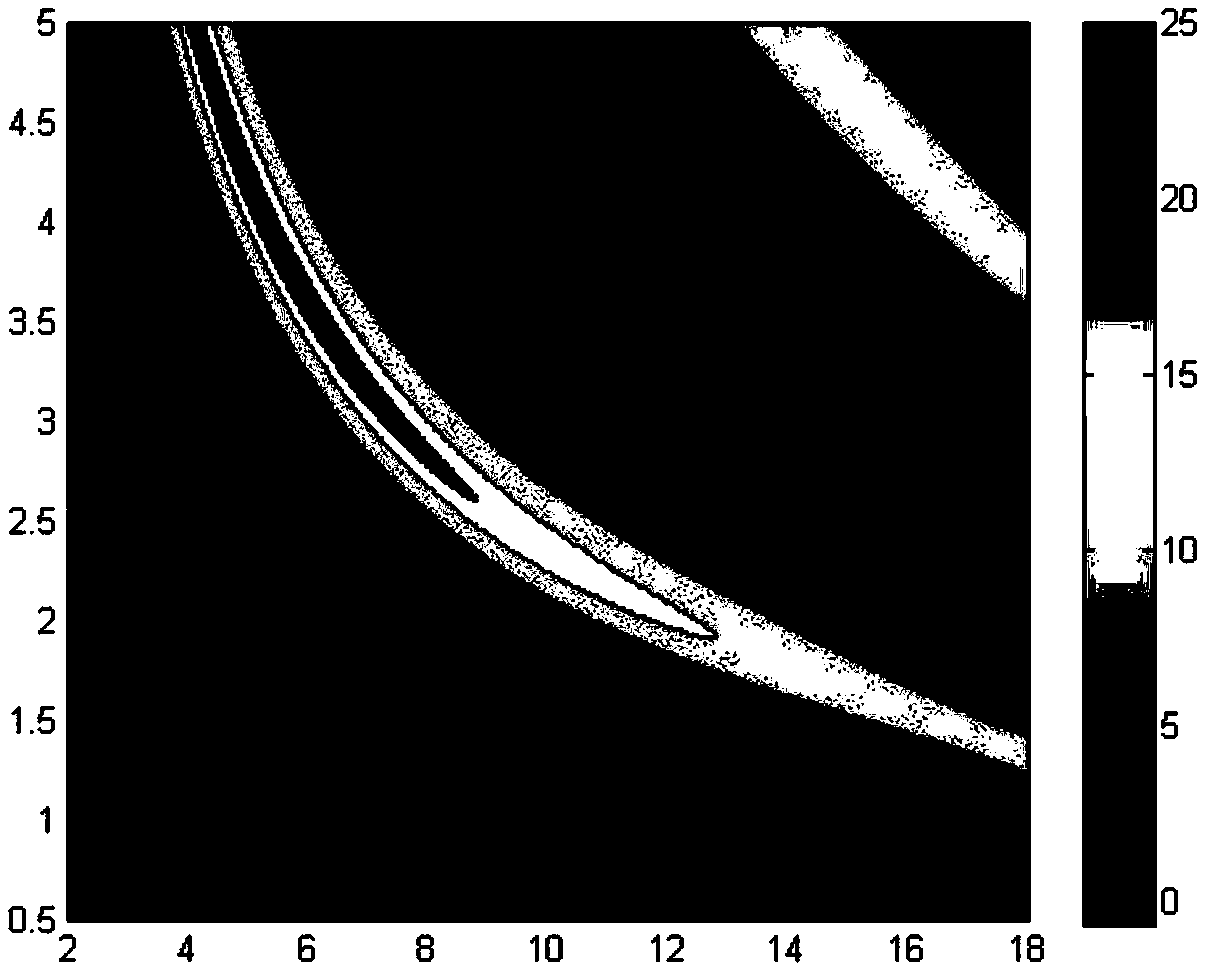

A kind of preparation method of carbon-based wave-absorbing material prepared by aluminosilicate polymer

The invention discloses a carbon-based wave absorbing material prepared from aluminosilicate polymer and a preparation method of the carbon-based wave absorbing material. The carbon-based wave absorbing material is formed by using metakaolin, a carbon material and an alkali activating solution to synthesize the aluminosilicate polymer and curing, wherein a mole ratio of metakaolin and the carbon material is 1:(3-24), and a mole ratio of silicon and aluminum in the aluminosilicate polymer is (1-2):1. The preparation method includes: activating kaolin; preparing mixed powder; preparing the alkali activating solution; preparing the aluminosilicate polymer; curing for forming. The preparation method is simple in process, capable of realizing direct forming of complex or large parts at low temperature and wide in application range. The carbon-based wave absorbing material is low in cost and high in unit thickness absorptivity and meets requirements on thinness, lightness, width and strength.

Owner:智合(深圳)新材科技有限公司

Shiitake mushroom crushing device and use method thereof

InactiveCN113304810ANot easy to pile upImprove efficiencyGrain treatmentsShiitake mushroomsAgricultural engineering

The invention discloses a shiitake mushroom crushing device. The shiitake mushroom crushing device comprises a breaking box, a crushing box and a rotary cutter. Shiitake mushroom crushing is divided into a coarse crushing process and a fine crushing process through the breaking box and the crushing box, and firstly, two sets of breaking wheels in the breaking box are used for performing coarse crushing on shiitake mushrooms falling into the breaking box, so that the shiitake mushrooms are changed into smaller shiitake mushroom blocks, so as to reduce subsequent processing, the crushed shiitake mushroom blocks fall into the crushing box, a micro motor drives a rotating shaft to rotate, the rotary cutter rotates to start to cut the shiitake mushroom blocks into powder, and meanwhile, an arc inclined groove is formed in an annular boss, a semi-spherical block is arranged at the upper end of the rotary cutter, and the semi-spherical block moves inside the arc inclined groove, so that the rotary cutter moves up and down in a small range, the crushing efficiency is accelerated, a filter screen is arranged below the rotary cutter, a cam motor in a spring cavity drives a cam to rotate, the filter screen vibrates, the shiitake mushroom powder can be conveniently shaken out of the device, the shiitake mushroom powder is prevented from being accumulated in the device, and it is guaranteed that no large mushroom blocks exist in the shiitake mushroom powder falling into a material receiving box.

Owner:浙江机电职业技术学院

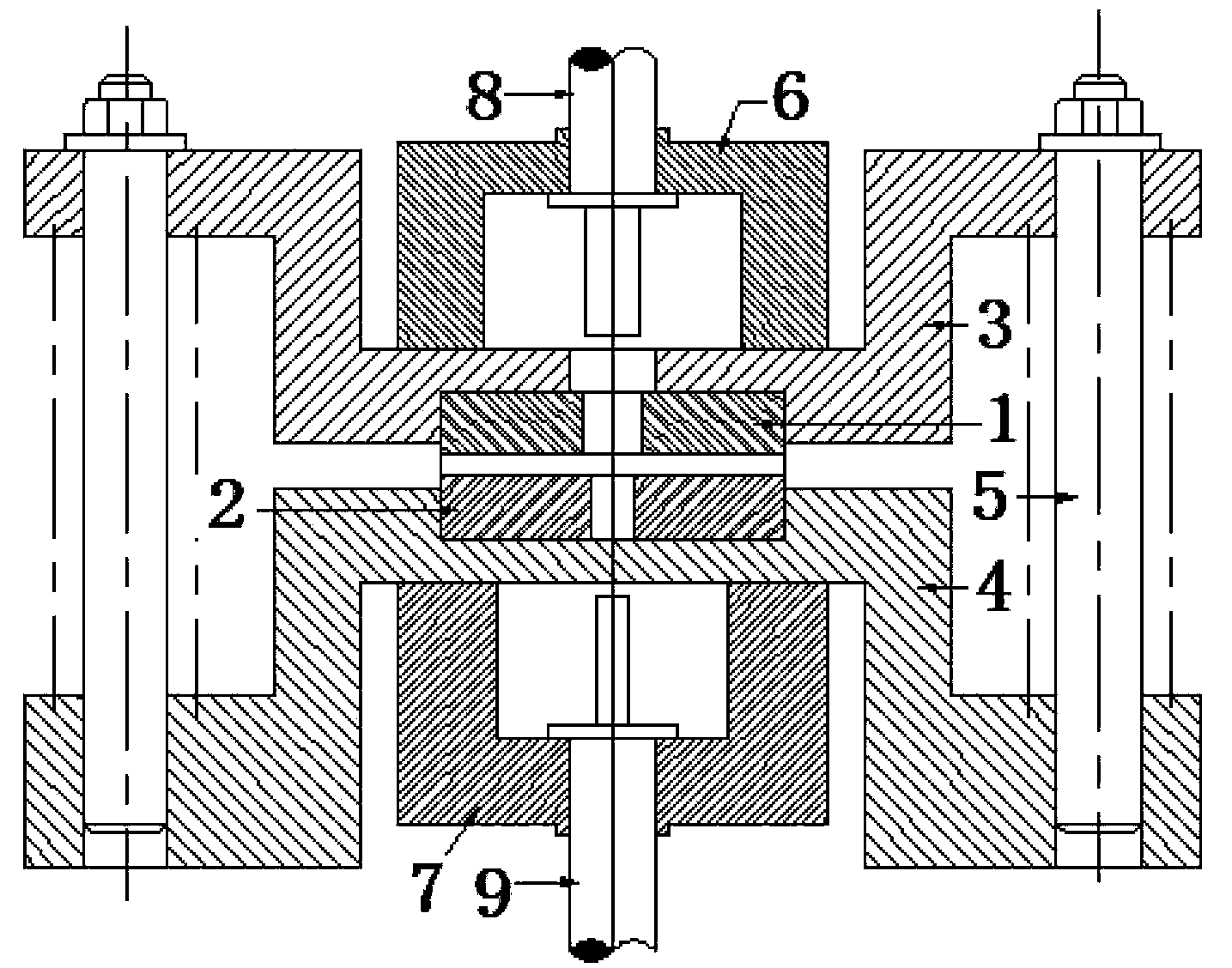

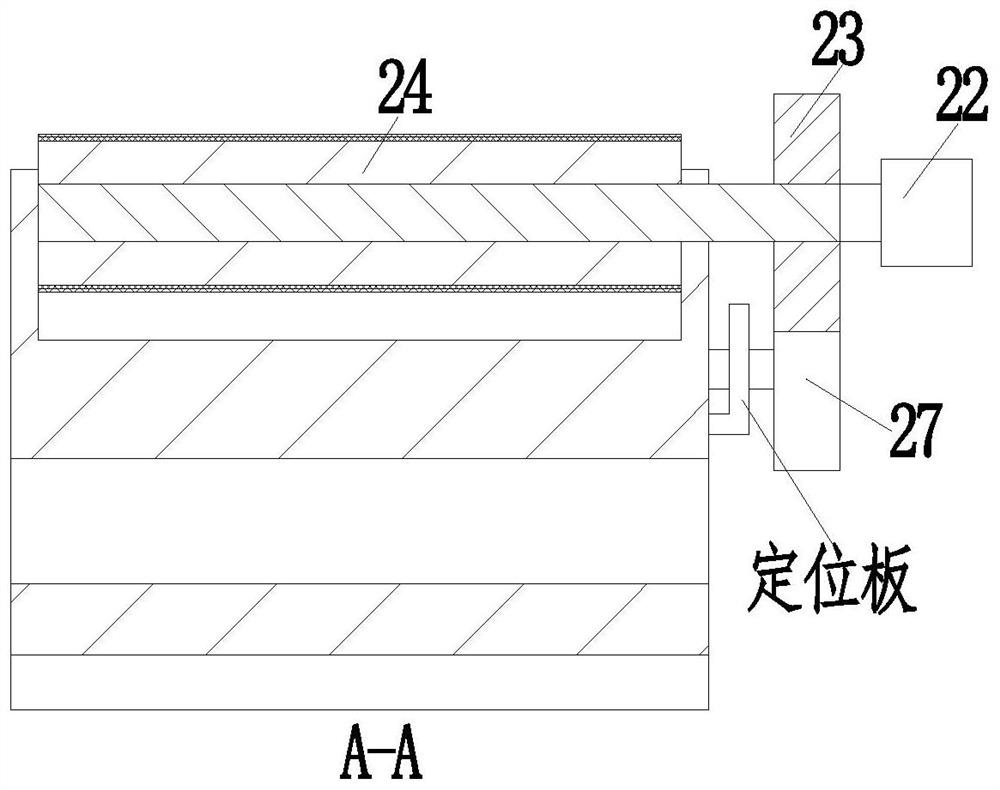

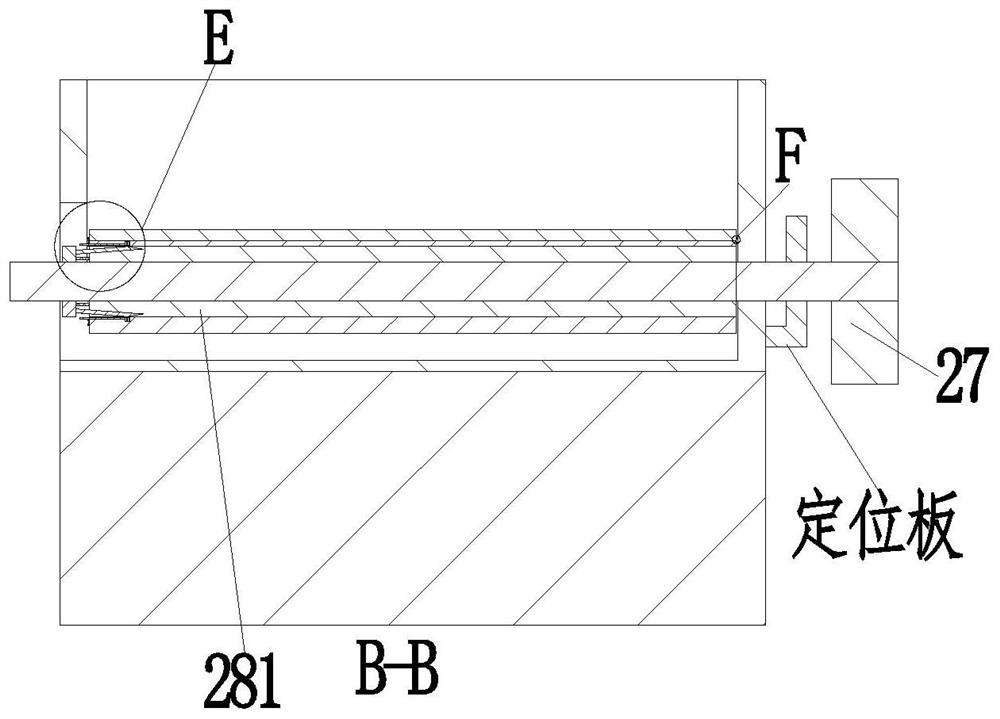

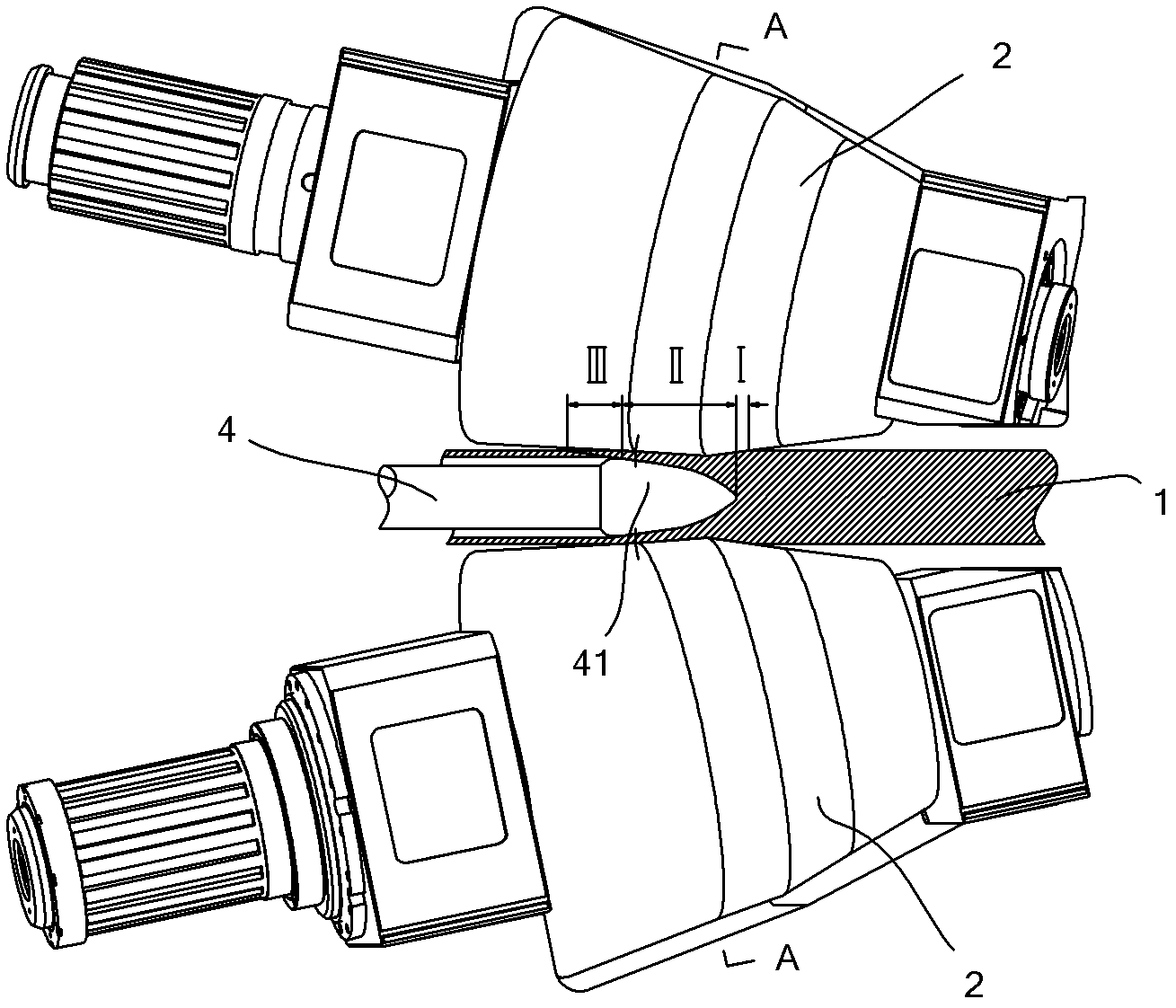

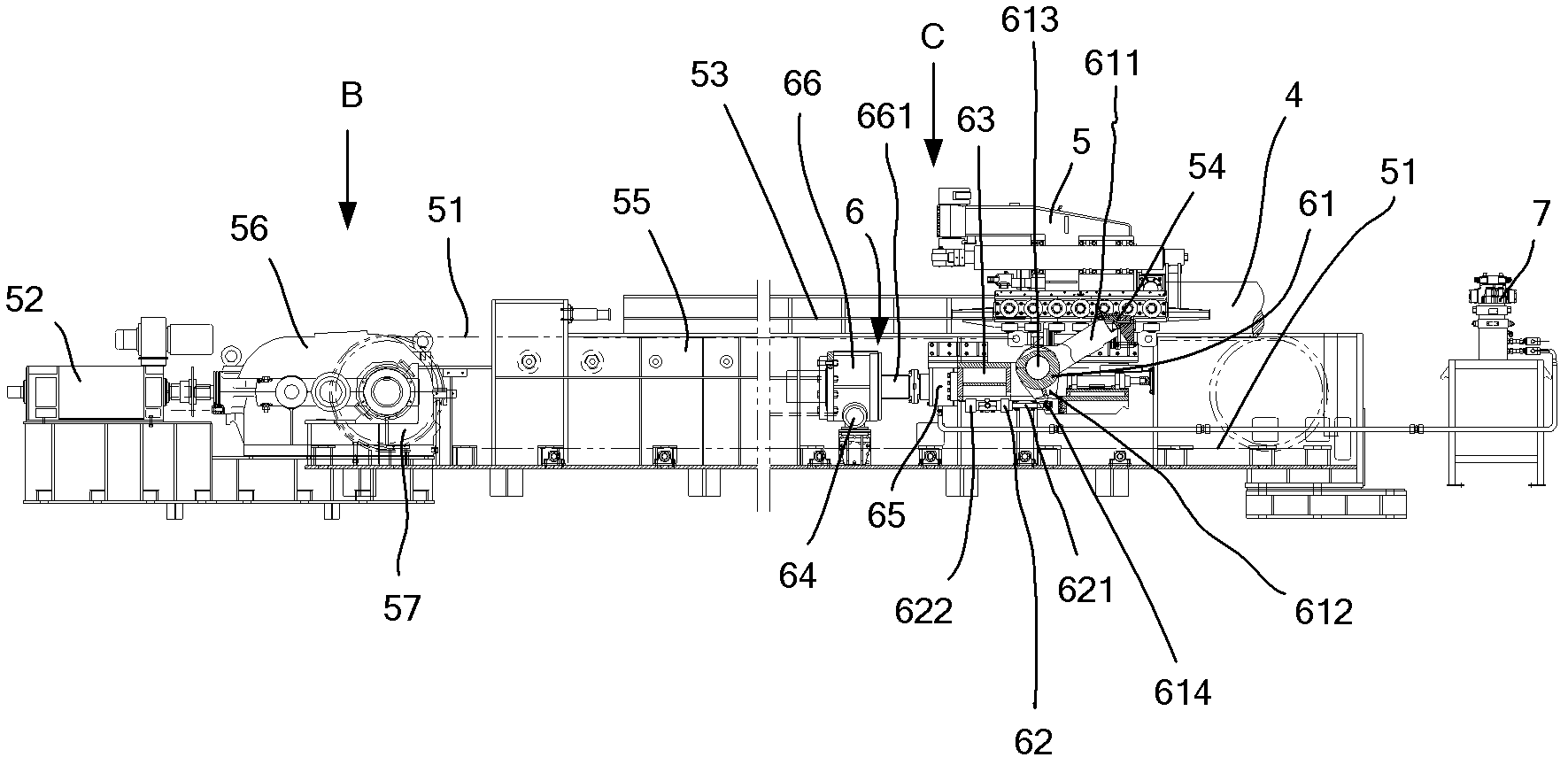

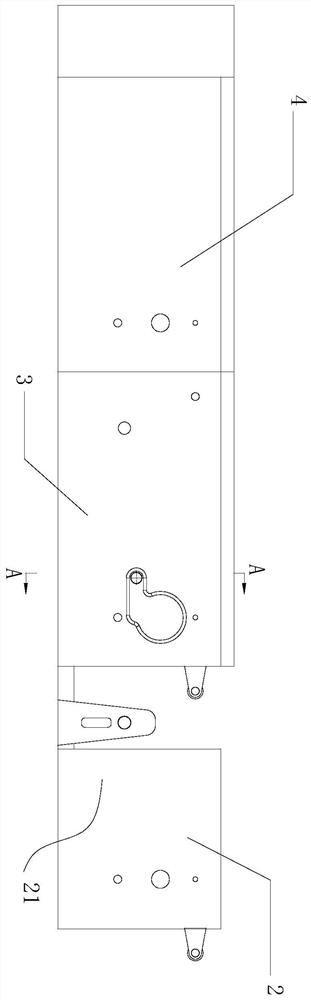

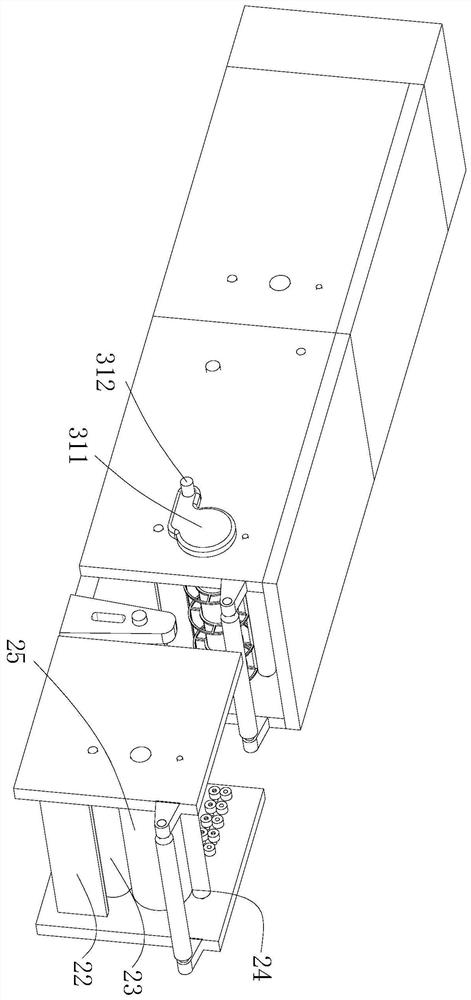

Seamless steel tube perforator piercing point on-line regulating device

ActiveCN102513359BStable inner diameterConstant inner diameterMetal rolling arrangementsPiercing pointEngineering

The invention discloses a seamless steel tube perforator piercing point on-line regulating device, which comprises a piercing rod and a piercing rod trolley, wherein the piercing point is at one end of the piercing rod and is a cone; the terminal line of the cone is a straight line with transitional curves at two ends; and the other end of the piercing rod is arranged on the piercing rod trolley. The seamless steel tube perforator piercing point on-line regulating device is characterized by also comprising a locking device, wherein the position of the piercing rod trolley is locked by the locking device; when the piercing point presses a tube blank of a seamless steel tube, the locking device can move the locked position of the piercing rod trolley along the moving direction of the tube blank, so that the piercing rod can move together with the piercing rod trolley by means of a rolling force. According to the device, the piercing point can move along the moving direction of the tube blank in a tube blank perforation process, so that the outside diameter of the piercing point in a tube blank perforating forming region can be reduced to compensate for the increase of the outside diameter of the piercing point with heat expansion in the tube blank perforation process; and thus, the outside diameter of the piercing point in the tube blank perforating forming region can keep stable and constant, and the inside diameter of a tubular billet formed by tube blank perforation is not changed.

Owner:TAIYUAN HEAVY IND

Simulation printing method of nonlinear thin film material

InactiveCN112140759AAvoid wastingAvoid pollutionRotary pressesOther printing apparatusEngineeringPrinting press

The invention discloses a simulation printing method of a nonlinear thin film material. The method comprises the following steps: (1) transfer printing activation: adding an activating agent to enablea transfer printing PVA thin film to enter an activated state; (2) simulation calculation: performing modeling and simulation according to a transfer printing model of a three-dimensional object, andsimulating stretching and deformation processes; (3) acquiring of a pre-deformation pattern: acquiring the transfer printing pre-deformation image according to an analogue simulation result; (4) layer planning: dividing the image into a PVA film carrier layer, a protective layer and a pattern layer according to the requirement of the thin film material; and (5) image-text transfer printing and rolling storage: printing the pre-deformation image and other image layers on the PVA thin film through intaglio printing. Intaglio printing equipment comprises a base, a protective layer printing mechanism, a boundary layer printing mechanism, an image printing mechanism and a winding mechanism. Multi-layer printing is set, one-time coating forming of the image and the protective layer is realized,independent brushing of the protective layer is avoided, boundary layer printing is set, and deformation of the image in the transfer printing process is greatly reduced.

Owner:明德新材料科技(浙江)股份有限公司

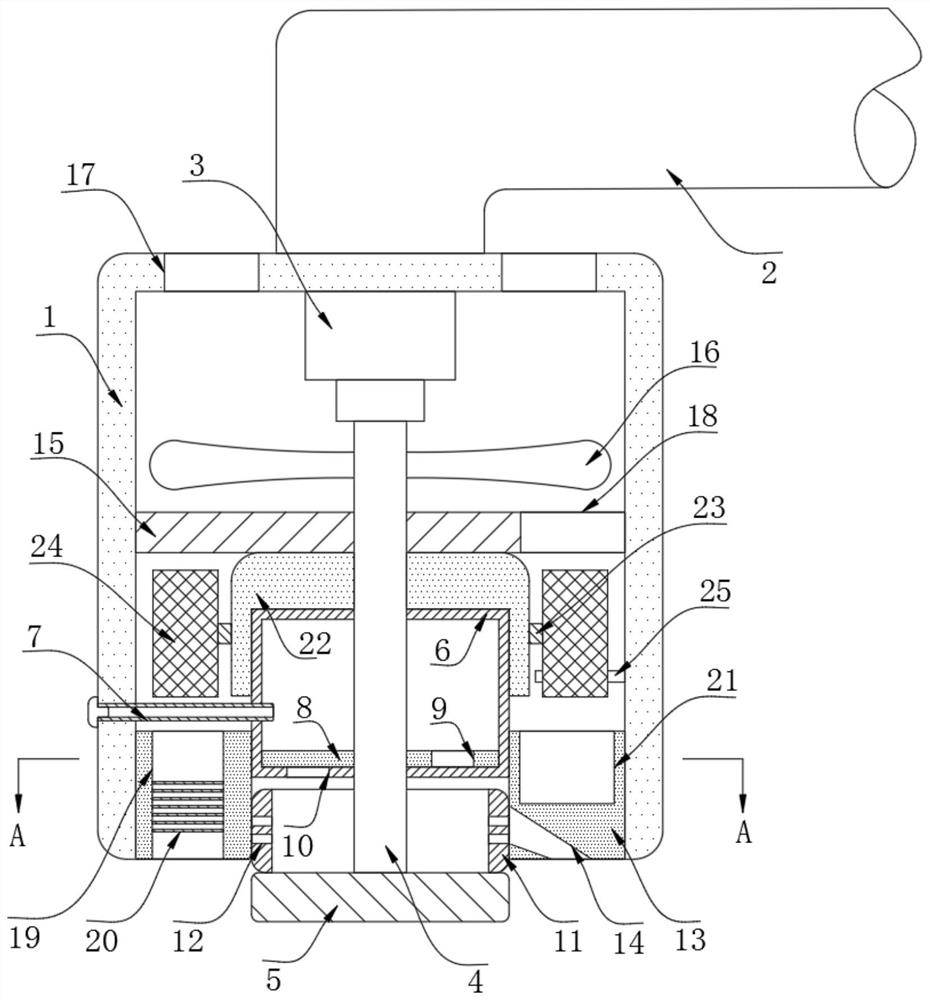

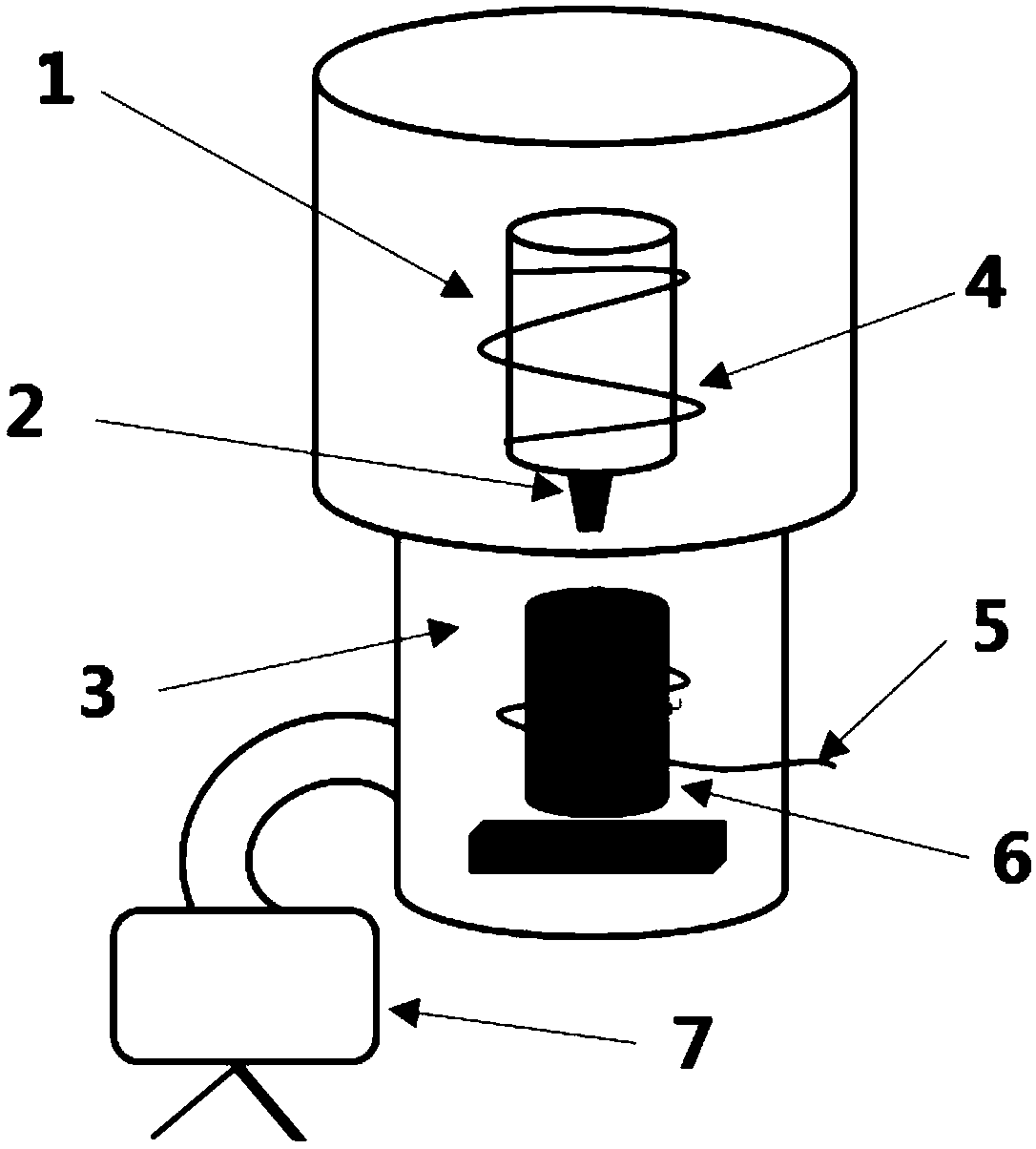

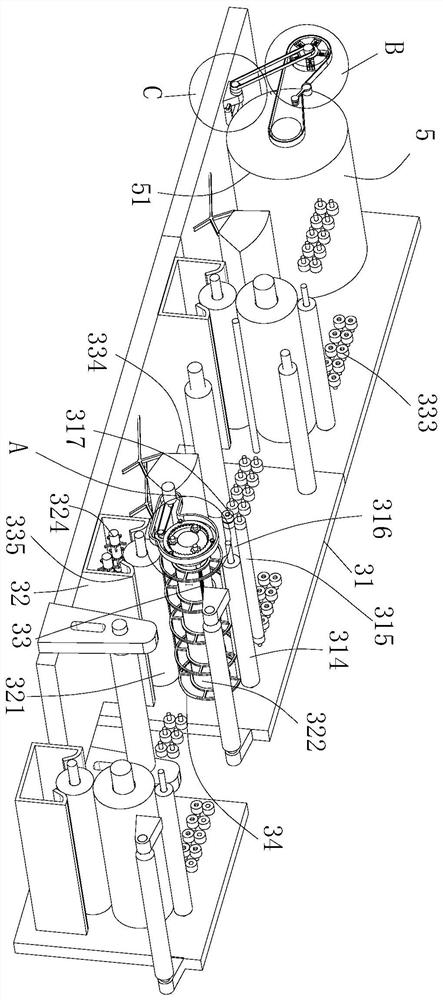

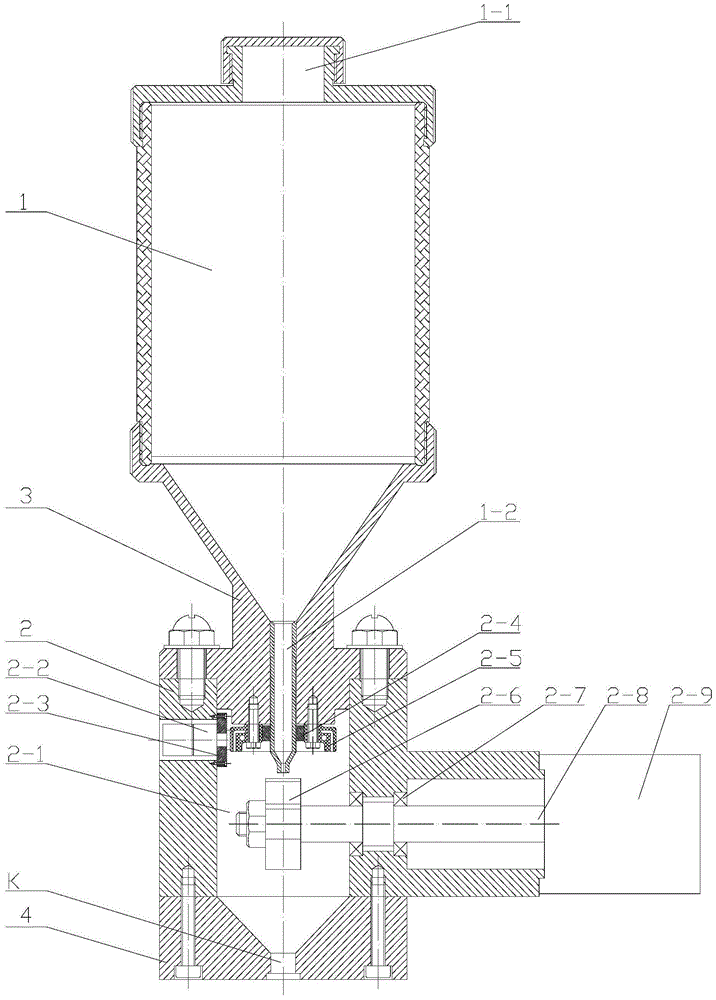

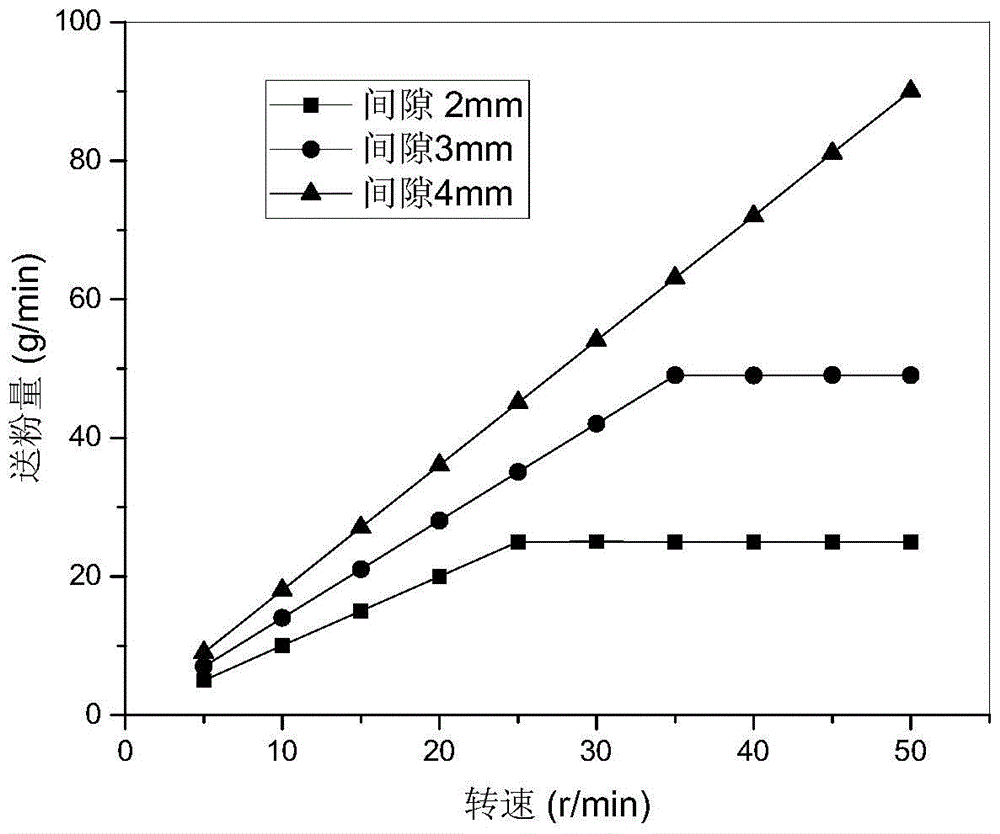

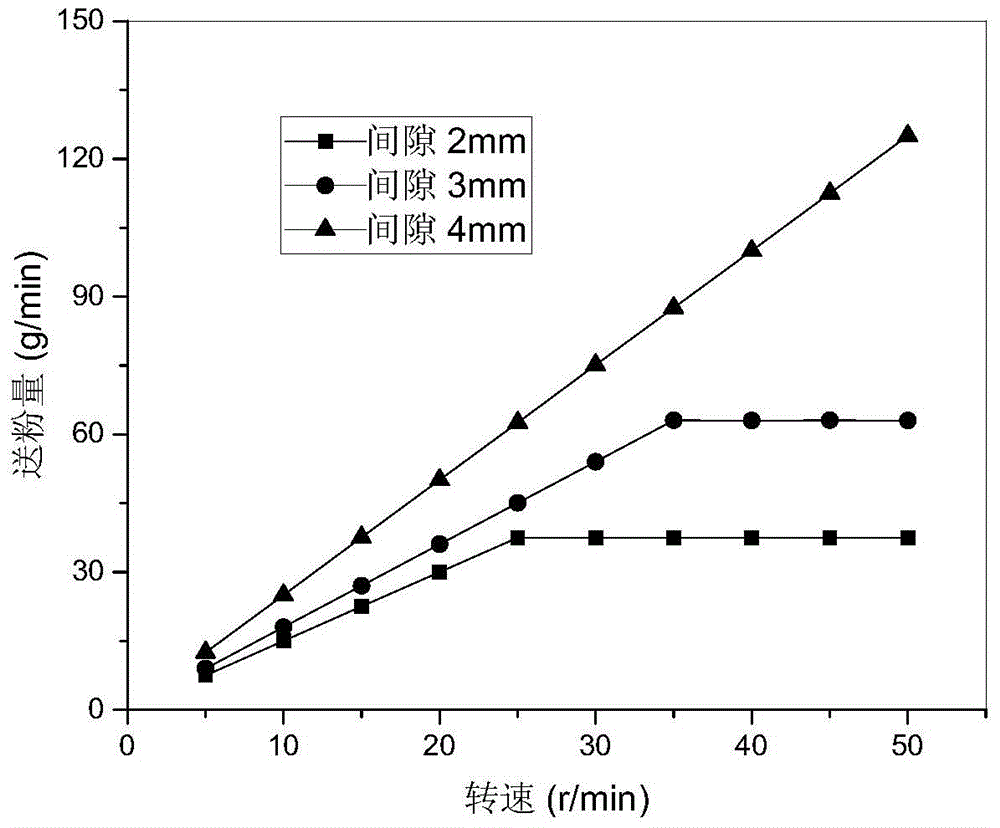

A controllable flow powder feeder for plasma spray gun

ActiveCN105436679BReduce subsequent processingImprove uniformityPlasma welding apparatusControl systemEngineering

The invention relates to a flow-controllable powder feeder for a plasma spraying welding gun, and belongs to the field of plasma spraying welding tool equipment. The flow-controllable powder feeder comprises a powder bin, conveying barrels, a connecting base, a base and a control system; a discharging nozzle at the lower end of the powder bin vertically penetrates the connecting base to enter inner cavities of the conveying barrels, and each conveying barrel is composed of a feeding adjustor and a drum conveyor; and the conveying barrels are correspondingly arranged in an inner cavity of a barrel up and down. On one hand, the feeding adjustor drives the discharging nozzle to spirally and vertically move so as to adjust a gap between a nozzle opening of the discharging nozzle and a drum of the drum conveyor under the discharging nozzle; and on the other hand, the drum conveyor controls the rotating speed of the drum so as to control the conveying speed of powder falling to the drum face from the discharging nozzle, falling off in a rotating manner and passing through a discharging opening, so that powder flow control is achieved. The flow-controllable powder feeder is accurate in control, the powder feeding continuity is good, the spraying welding layers are even, follow-up machining of the spraying welding layers is reduced to the maximum degree, waste of dusty materials is effectively avoided, and equipment guarantees are provided for the uniformity and the grade of the spraying welding layers.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

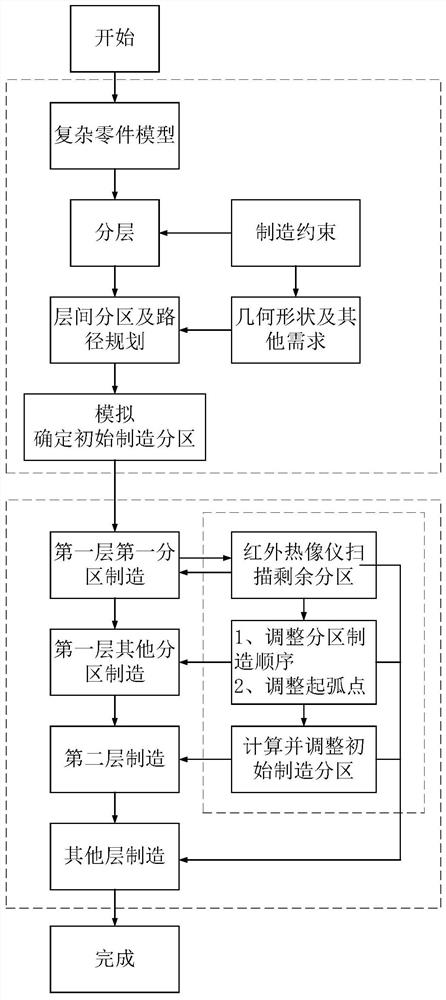

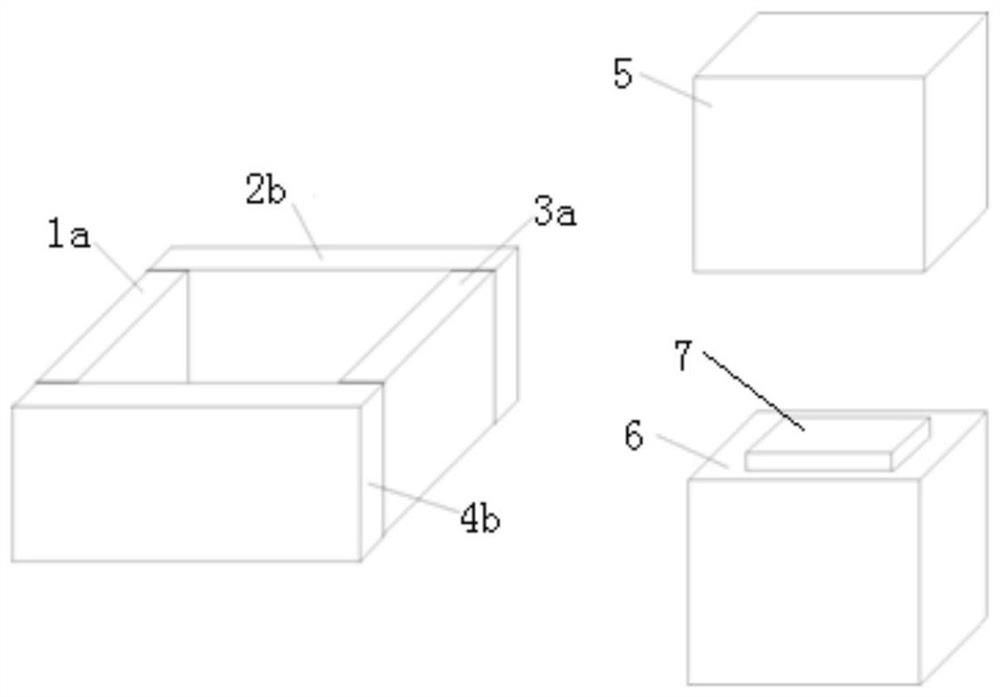

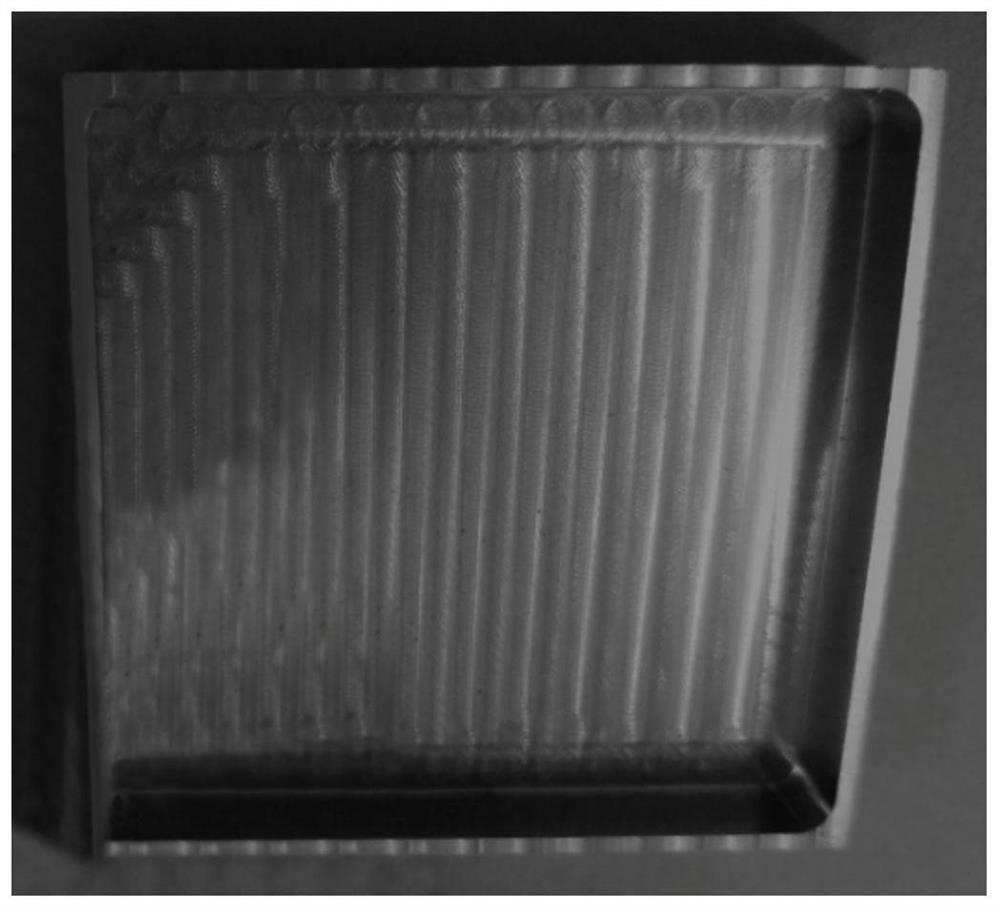

A Complicated Part Partition Manufacturing Method Based on Temperature Distribution

ActiveCN110695492BAvoid deformationQuality improvementWelding accessoriesProcess engineeringMachining

The invention belongs to the related technical field of arc additive manufacturing, and discloses a complex part partition manufacturing method based on temperature distribution. The manufacturing method comprises the following steps that firstly, based on manufacturing constraints, parts to be manufactured are layered, and each layer is subjected to area division; secondly, according to the partition shape, a filling path is planned, the filling path type and the direction of each partition are determined, and meanwhile the partition, with the minimum deforming amount, in the partitions serves as an initial manufacturing partition; thirdly, the initial manufacturing partition of the current layer is subjected to deposition filling, before one partition is manufactured through deposition,the remaining partitions of the current layer are subjected to thermal imaging scanning, temperature distribution of the remaining partitions is calculated, the partition, with the minimum partition average temperature, in the non-filled area is selected as the next manufacturing partition, and deposition filling continues until machining of the current layer is finished; and fourthly, the third step is repeated, and layer-by-layer machining is carried out until the pars to be manufactured are manufactured. Part quality and performance are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Near-net forming die and near-net forming method for high-silicon aluminum alloy shell

The invention provides a near-net-shape forming mold and near-net-shape forming method of a high-silicon aluminum alloy shell. The mold comprises long side pressing plates, short side pressing plates,an upper pressing block, a lower pressing block and a steel sleeve, wherein the long side pressing plates and the short side pressing plates are assembled into a mold frame, and the mold frame is provided with a mold cavity with an upper opening and a lower opening; and the upper pressing block and the lower pressing block can move in a reciprocating mode in the mold cavity, the top surface of the lower pressing block is provided with a boss, and the combined mold is fixed by the steel sleeve. The near-net-shape forming method of the high-silicon aluminum alloy shell comprises the following steps that gas atomization is conducted to prepare powder to obtain an aluminum-silicon raw material, a graphite mold is subjected to surface coating, drying and combination, then the raw material is flatly laid in the mold for pressure sintering, and mold stripping is conducted to obtain an aluminum-silicon shell material. According to the near-net-shape forming mold and near-net-shape forming method of the high-silicon aluminum alloy shell, the mold design is combined with the pressure sintering to directly manufacture the high-silicon aluminum alloy electronic packaging shell, the productionefficiency and the raw material utilization rate are improved, the preparation process is controllable, and is good in stability, and the method has extremely high industrial application value, and can be popularized to the manufacturing of other metal materials.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com