A controllable flow powder feeder for plasma spray gun

A technology of plasma and powder feeder, which is applied in the direction of plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that the plasma spray welding layer cannot be formed, the quality dilution rate of the spray welding layer is affected, and the plasma spray welding torch is damaged. The structure is simple, the service life is long, and the effect of improving the uniformity and grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

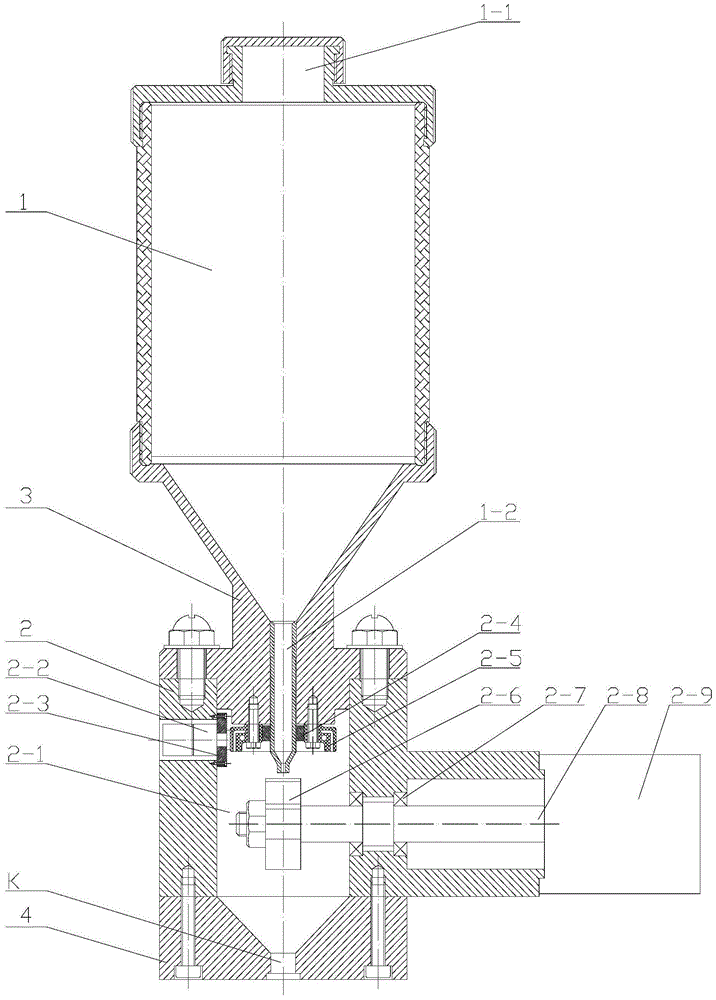

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: It is required to spray an iron-based spray welding layer with a thickness of 2 mm on a workpiece surface of 200 mm × 300 mm,

[0031] Spray welding operation:

[0032] 1. Fix the workpiece to be welded;

[0033] 2. Inject an appropriate amount of spray welding powder through the feed port;

[0034] 3. Select the inner diameter of the blanking nozzle as 1mm

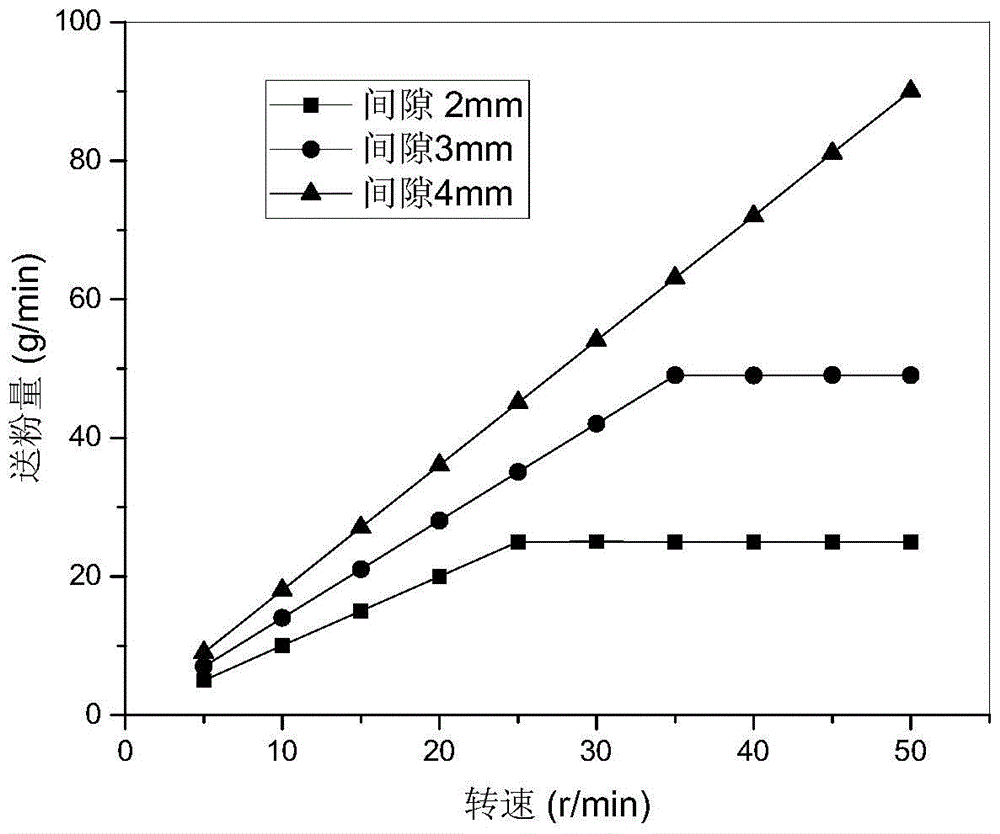

[0035] 4. Choose to set the powder feeding flow rate of the powder feeder of this design:

[0036] According to Table 1, select the gap between the mouth of the blanking nozzle and the drum to be 3mm, and the drum speed to be 20r / min;

[0037] 5. Connect the controllable flow powder feeder to the welding gun;

[0038] 6. Set relevant plasma spray welding process parameters;

[0039] 7. Start the plasma spray welding equipment. According to the above parameter selection, the plasma spray welding can be carried out according to the powder feeding rate of 28.06g / min. The operator can obtain a spray we...

Embodiment 2

[0040] Embodiment 2: require on the workpiece surface of 400 millimeters * 600 millimeters, the nickel-based spray-welding layer of 3 millimeters of thickness is spray-welded,

[0041] Spray welding operation:

[0042] 1. Fix the workpiece to be welded;

[0043] 2. Inject an appropriate amount of spray welding powder through the feed port;

[0044] 3. Select the inner diameter of the blanking nozzle as 3mm

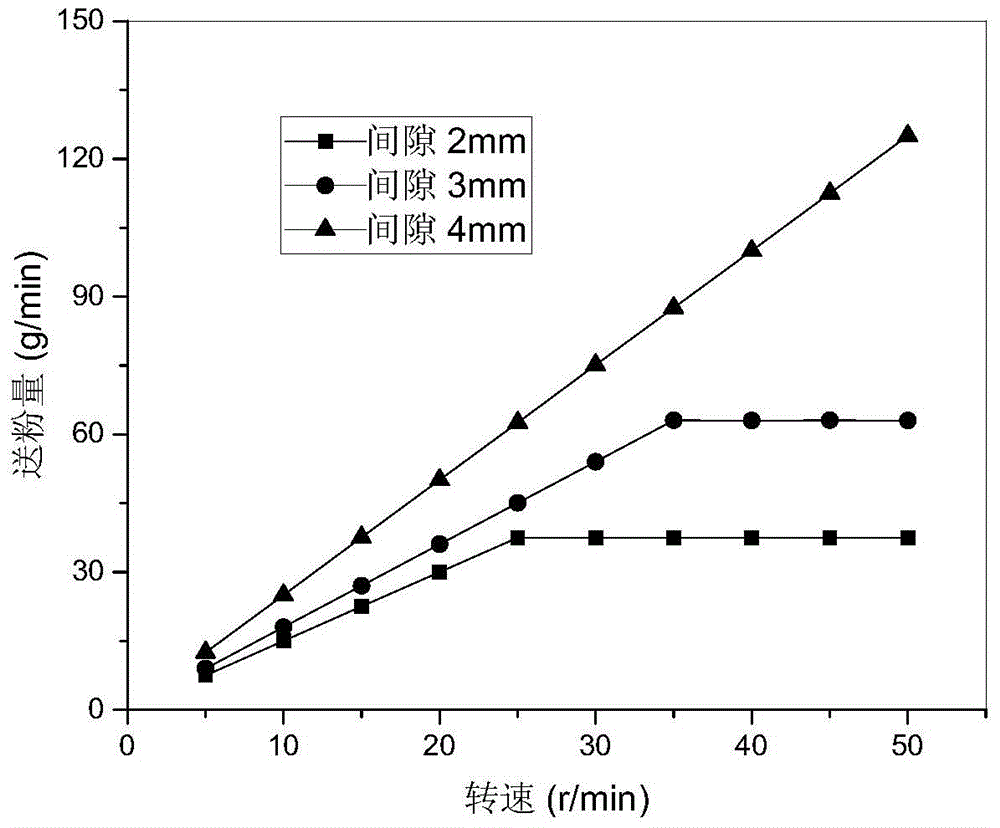

[0045] 4. Choose to set the powder feeding flow rate of the powder feeder of this design:

[0046] According to Table 2, select the gap between the mouth of the blanking nozzle and the drum to be 4mm, and the drum speed to be 40r / min;

[0047] 5. Connect the controllable flow powder feeder to the spray gun.

[0048] 6. Set relevant plasma spray welding process parameters;

[0049] 7. Start the plasma spray welding equipment. According to the above parameter selection, the plasma spray welding can be carried out at a powder feeding rate of 100.01g / min. The operator can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com