Near-net forming die and near-net forming method for high-silicon aluminum alloy shell

A high-silicon aluminum alloy, near-net forming technology, applied in the field of near-net forming of high-silicon aluminum alloy shells, can solve the problems of strict parameter requirements, low product efficiency, and many processing steps, so as to reduce subsequent processing, Small dimensional deviation and the effect of reducing the amount of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The present invention will be further described below by taking the preparation of an Al-50Si alloy shell for electronic packaging as an example.

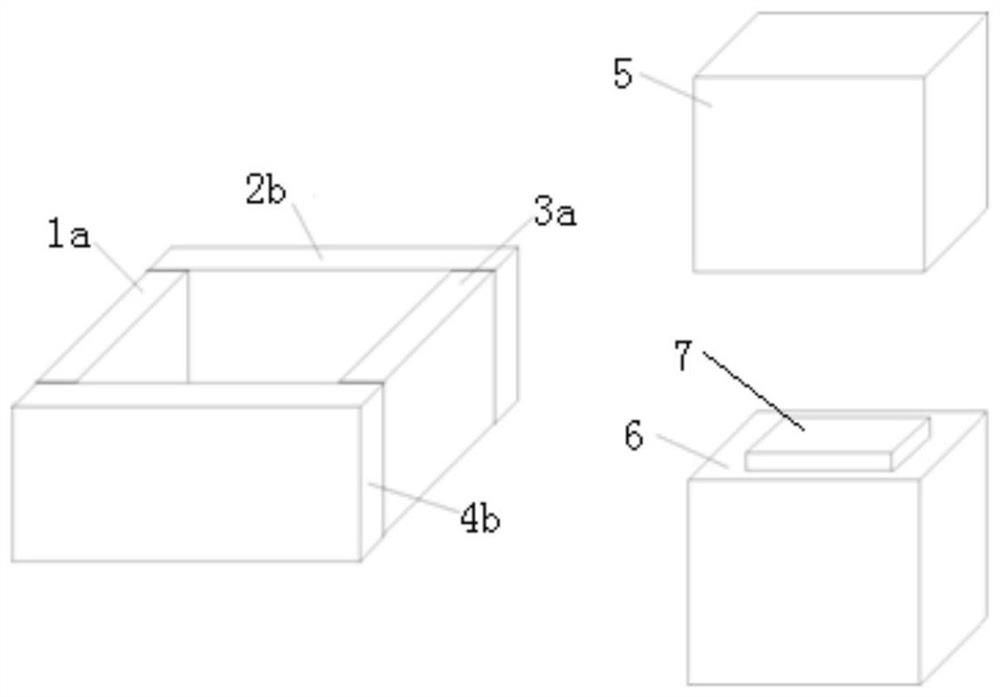

[0053] The mold used in this embodiment uses high-strength, high-density, and high-purity graphite as a raw material, and is processed by ordinary turning. The long and short side pressure plates and the upper and lower pressure blocks are not allowed to be chamfered. like figure 1 As shown, the length, height and thickness of the short side pressure plates (1a) and (3a) are respectively 50mm×50mm×12mm. The length, height and thickness of long side pressing plate (2b) and (4b) are respectively 74mm * 50mm * 12mm. The length, width and height of the upper pressing block 5 are respectively 50mm * 50mm * 30mm. The length, width and height of the lower pressing block 6 are respectively 50mm×50mm×30mm, and the boss 7 is located in the middle, and the size is 40mm×40mm×5mm.

[0054] Adopt this mould, the forming method of Al-50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com