Simulation printing method of nonlinear thin film material

A film material and printing method technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of poor rub resistance, cumbersome process, and high surface hardness of the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

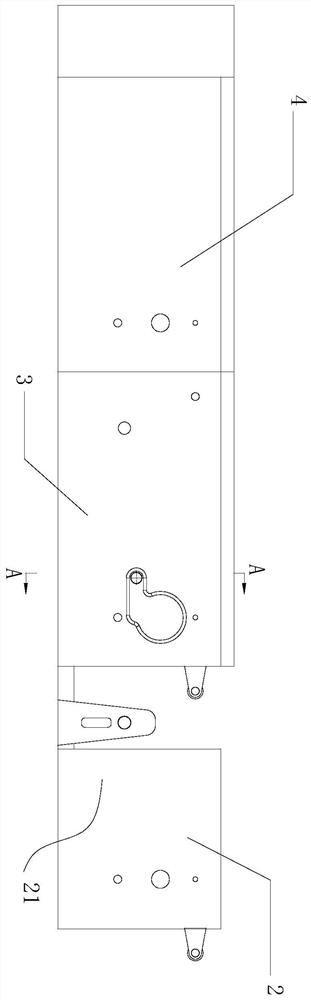

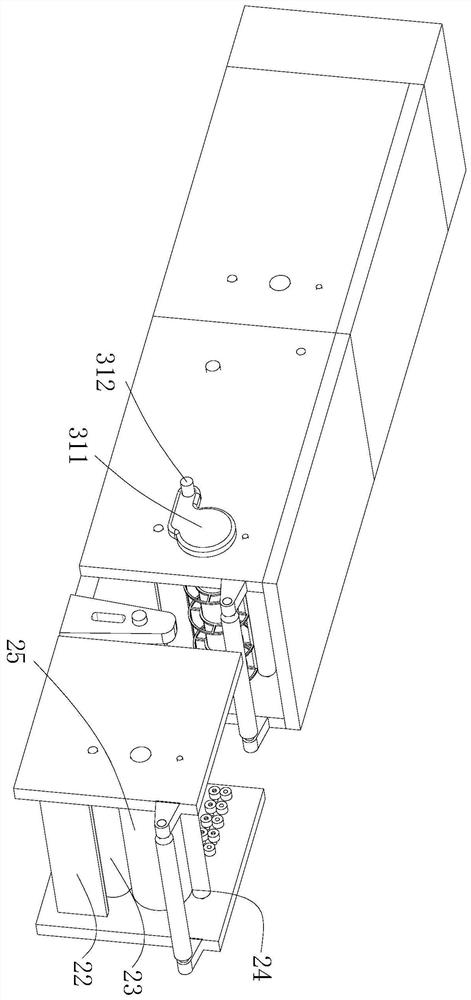

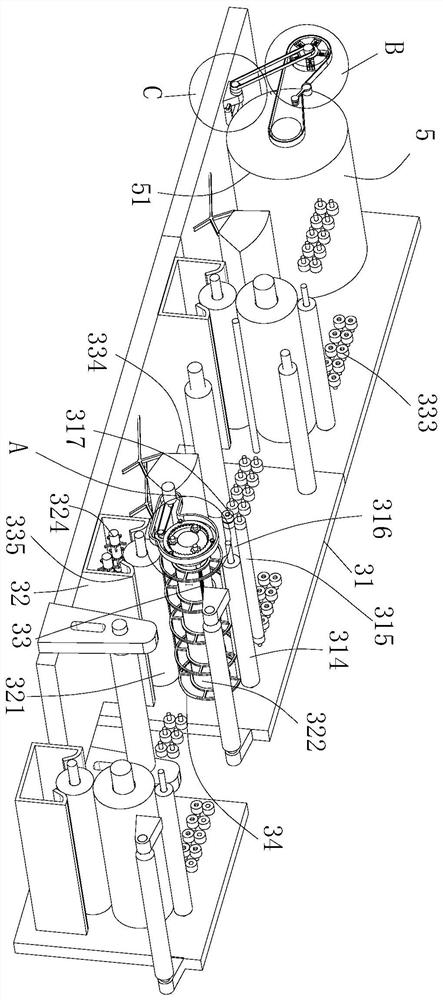

[0028]A simulation printing method for non-linear thin film materials is characterized in that it comprises the following steps:

[0029](1) Transfer activation: place the PVA film in a constant-temperature water tank to prepare samples, add an activator to make the transfer PVA film into an activated state;

[0030](2) Simulation calculation: According to the shape of the transfer model of the three-dimensional object and the water inlet angle of the PVA film in step 1, use the Stokes flow model to model and simulate the PVA film that entered the activated state in step 1, and simulate the PVA stretching and Deformation process

[0031](3) Pre-deformed pattern acquisition: According to the simulation results of step 2, establish the coordinates of the mapping relationship between the PVA film and the three-dimensional object transfer model, and calculate the transfer pre-deformed image according to the mapping relationship;

[0032](4) Layer planning: Divided into four layers according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com