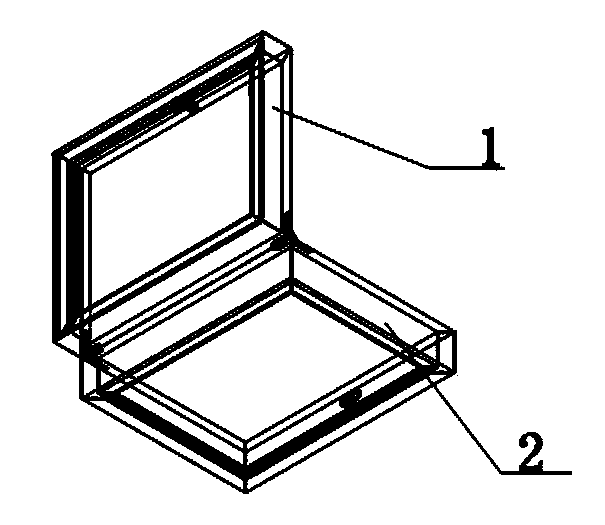

Foamed plastic packing box and preparation method thereof

A foamed plastic, packaging box technology, applied in packaging, biological packaging, transportation and packaging, etc., can solve the problems of low density of foamed materials, white pollution, waste of resources, etc., and achieve low cost, pollution reduction, and easy cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The quality of raw material components is: polystyrene resin 100kg; sodium bicarbonate 850g; silicone oil 65g; SECCO 825 modified polystyrene resin 12.5kg; industrial starch 4kg;

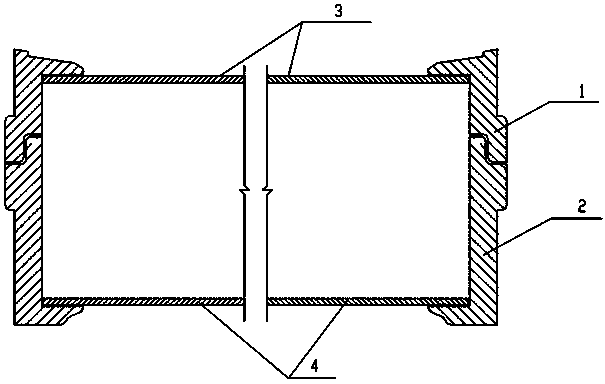

[0039] First, make two pairs of molds placed on the extrusion port. The longitudinal section of the mold is "L" shaped, the width of the box cover mold is about 35mm, and the width of the box bottom mold is 60mm.

[0040] Then add the above-mentioned components into the material box, and heat and stir in the material box until the material melts. The foaming agent sodium bicarbonate generally starts to foam above 120°C. The foaming agent sodium bicarbonate is fully foamed. When the temperature reaches 250 degrees Celsius, the molten material is extruded from the screw extruder into the port die, and the foam strip passes through the port die for initial molding. The surface is compounded with a PVC film layer printed with the required texture, the processing temperature is 220°C, and then coo...

Embodiment 2

[0047] The quality of raw material components is: polystyrene resin 90kg; sodium bicarbonate 800g; silicone oil 46g; Panjin 304 modified polystyrene resin 11kg; industrial starch 2.5kg;

[0048] First, make two pairs of molds placed on the extrusion port. The longitudinal section of the mold is "L" shaped, the width of the box cover mold is about 40mm, and the width of the box bottom mold is 65mm.

[0049] Then add the above-mentioned components into the material box, and heat and stir in the material box until the material melts. The foaming agent sodium bicarbonate generally starts to foam above 120°C. The foaming agent sodium bicarbonate is fully foamed. When the temperature reaches 250 degrees Celsius, the molten material is extruded from the screw extruder into the port die, and the foam strip passes through the port die for initial molding. The surface is compounded with a PVC film layer printed with the required texture. The processing temperature is 220°C, and then it ...

Embodiment 3

[0056] The quality of raw material components is: polystyrene resin 110kg; sodium bicarbonate 900g; silicone oil 78g; Panjin 304 modified polystyrene resin 14kg; industrial starch 5kg;

[0057] First, make two pairs of molds placed on the extrusion port. The longitudinal section of the mold is "L" shaped, the width of the box cover mold is about 50mm, and the width of the box bottom mold is 50mm.

[0058] Then add the above-mentioned components into the material box, and heat and stir in the material box until the material melts. The foaming agent sodium bicarbonate generally starts to foam above 120°C. The foaming agent sodium bicarbonate is fully foamed. When the temperature reaches 250 degrees Celsius, the molten material is extruded from the screw extruder into the port die, and the foam strip passes through the port die for initial molding. The surface is compounded with a PVC film layer printed with the required texture, the processing temperature is 220°C, and then cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com