Reciprocating Fine Blanking Die

A precision blanking and die technology, which is applied in the fields of die and reciprocating precision blanking die involved in blanking process, can solve the problems of aggravating edge wear, reducing die service life, and increasing production costs, so as to reduce subsequent processing and improve The effect of working efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

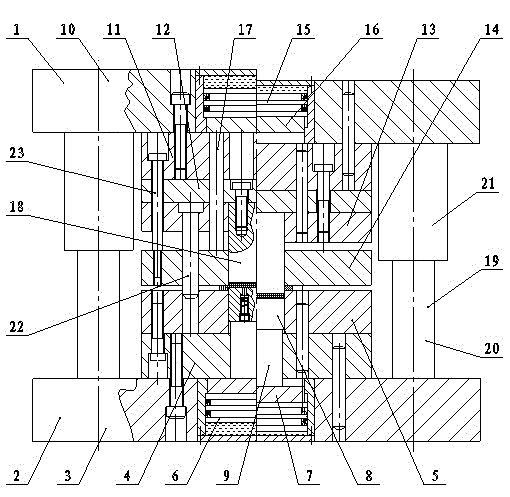

[0015] like figure 1 As shown, the reciprocating precision blanking die of the present invention includes an upper die 1 and a lower die 2. The structure of the lower die 2 is: the lower die base 3 is sequentially superimposed and fixed with a lower template 4 and a lower concave by bolts from bottom to top. Die 5, the centers of the lower mold base 3, the lower template 4 and the lower die 5 are all provided with through holes, and the lower oil cylinder 6 is installed in the hole in the center of the lower mold base 3, and the piston of the lower oil cylinder 6 is fixed with a lower The pressure bearing plate 7, the lower pressure bearing plate 7 and the lower punch 8 are connected and fixed by the lower pressing rod 9, the lower punch 8 is movably fitted in the hole in the center of the lower die 5, and the lower pressing rod 9 is movably fitted In the hole in the center of the lower template 4;

[0016] The structure of the upper mold 1 is as follows: the bottom of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com