Ceramic proppant and preparation method thereof

A technology of proppant and ceramsite, which is used in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of difficult process control, many raw material components, and increased product density, and achieves high strength and simple formula. , the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

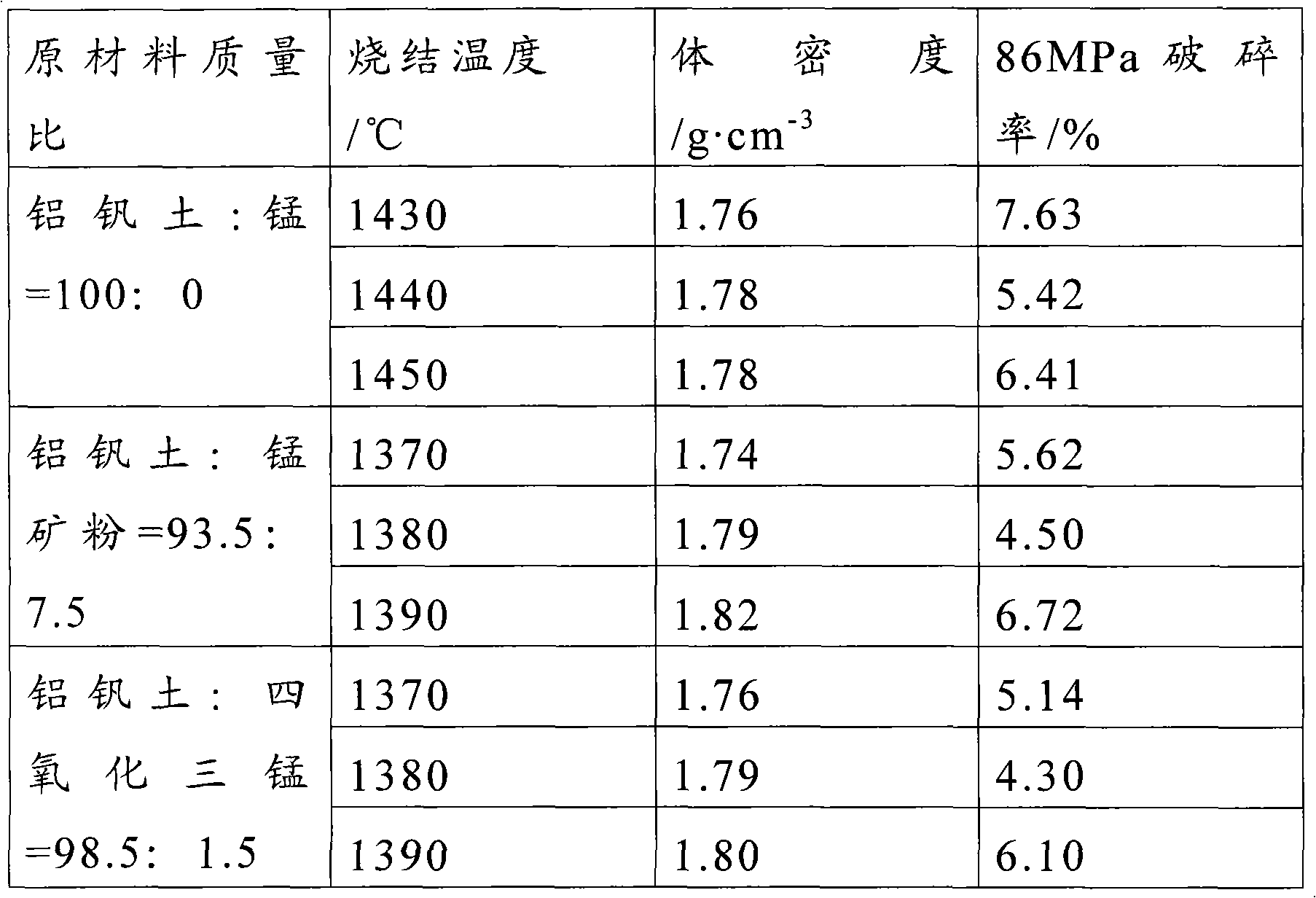

[0021] With a concentration of 0.5% polyvinyl alcohol aqueous solution as a binder, Yangquan bauxite (Al 2 o 3 content 75%), manganese ore powder (MnO 2 Purity 60%) and Norwegian Elkemn manganese tetroxide (purity 95%) made into raw pellets with a particle size of 0.425-0.85 cm for sintering experiments (see Table 1).

[0022] Table 1

[0023]

[0024] It can be seen from Table 1 that after adding Mn element, the sintering temperature decreases by 60°C (from 1440°C to 1380°C); adding 1.5% Mn 3 o 4 Reduced temperature with addition of 7.5% MnO 2 (60% purity) has the same effect; adding 1.5% Mn 3 o 4 with 7.5% MnO 2 In comparison, the breakage rate will be greatly reduced. Due to Mn 3 o 4 There are very few impurities, and there is more space to increase the content of bauxite, so that the strength of ceramsite sand has a wider space to improve.

[0025]After mixing 98.4 parts of bauxite and 1.6 parts of trimanganese tetraoxide, granulate with water and binder in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com