Non-cutting variable cross-section steel plate spring and end forming manufacturing technology and device thereof

A technology of leaf spring and manufacturing process, which is applied in the direction of spring/shock absorber, leaf spring, mechanical equipment, etc., to reduce wear, reduce the generation of early fatigue sources, and improve fatigue and service life.

Inactive Publication Date: 2009-10-21

QINGDAO SHUAICHAO IND

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004]Aiming at the problems existing in the prior art, the present invention aims to provide a non-cutting variable-section leaf spring and its end forming manufacturing process and device to solve the problem of automobile steel plate Defects in spring and its processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

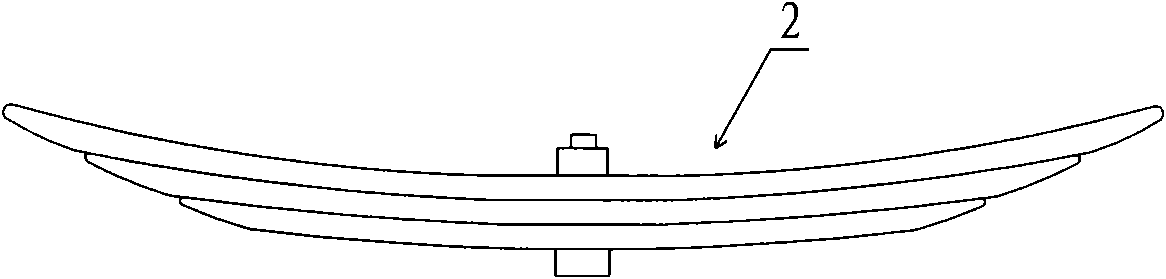

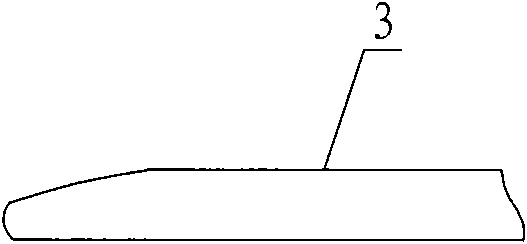

The invention discloses a non-cutting variable cross-section steel plate spring, which is an arc-shaped plate spring and consists of a plurality of variable cross-section steel plate spring strips overlapped mutually. The radian of each steel plate spring strip takes a steel plate center as a symmetric point and the arcs of both ends are completely same. A straight section is arranged in the middle part of each steel plate spring strip, the exterior at the end of the steel plate spring strip presents a convex arc and both sides thereof present a concave arc. The invention further discloses a manufacturing technology and a manufacturing device of the steel plate spring. The steel plate spring and the technology thereof, on the basis of keeping the property of an original variable cross-section steel plate, can effectively reduce the generation of early fatigue sources at ends among steel plate spring strips due to corner cut burr, increase the anti-fatigue life of the plate spring, improve the utilization rate of materials, reduce mold consumption during the plate manufacturing process, reduce the labor quantity of operators and effectively reduce the production cost of the plate spring.

Description

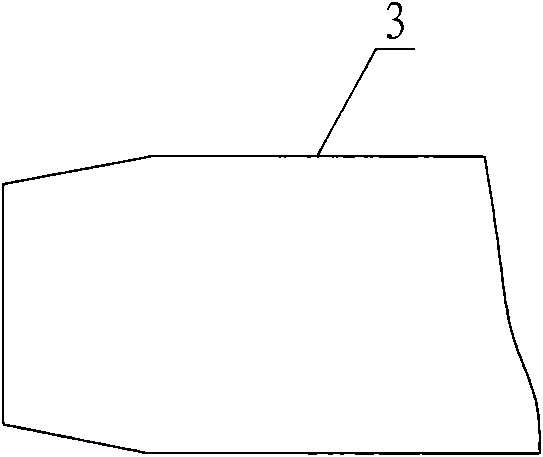

technical field [0001] The invention relates to an automobile leaf spring and its manufacturing process and device. Background technique [0002] Automobile steel plate is the main elastic component of automobile suspension system at home and abroad. During the operation of the automobile, it transmits the force and moment acting between the frame and the body, relieves the impact load transmitted to the body through the tire due to uneven road surface, and relieves the The vibration of the vehicle body plays a positive role in ensuring the ride comfort of the vehicle, the comfort of the passengers, the stability of the cargo being carried, and improving the service life of the relevant components of the vehicle. [0003] At present, the leaf springs used in various types of heavy-duty vehicles are generally end-rolled, but the width of the end after rolling is often not up to the size required for loading, so the end corners must be cut after rolling. Figure 4 , 5 The sho...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16F1/18B21C23/06B21C23/20B21C23/21

Inventor 廉喜国陈伟

Owner QINGDAO SHUAICHAO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com