Spring steel used for automobile suspension as well as preparation method and application thereof

A technology of automobile suspension and spring steel, which is applied in the field of spring steel for automobile suspension and its preparation, and can solve the problems that the quality, variety and specification of spring steel wire cannot meet user requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

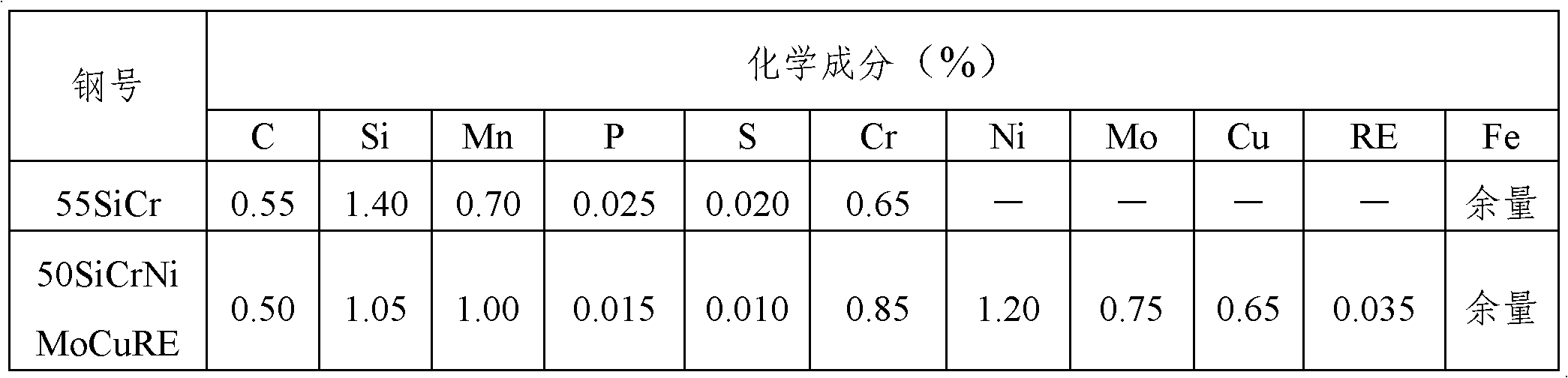

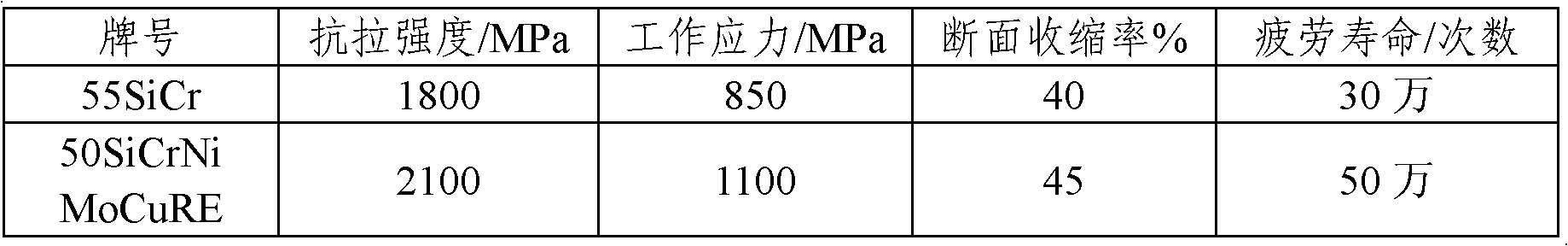

Method used

Image

Examples

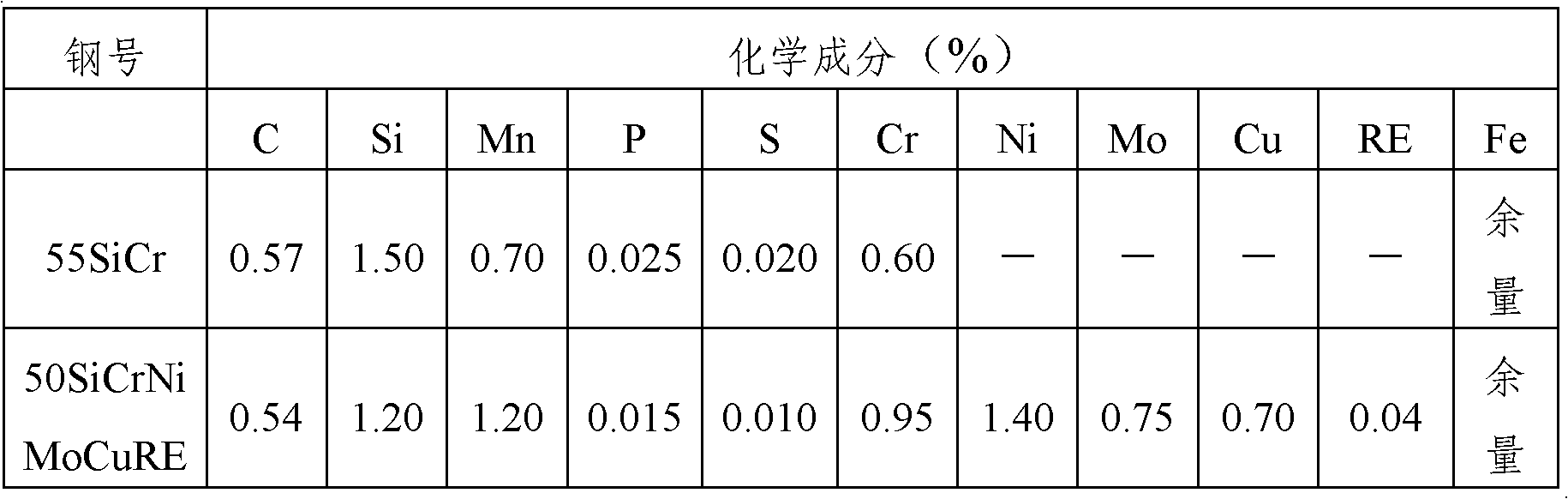

Embodiment 1

[0086] Embodiment 1: the preparation of spring steel (method A)

[0087] 1. Production process:

[0088] Hot metal pretreatment-converter-furnace refining-continuous casting to 300mm×400mm blooms-flame cleaning the surface of blooms-begin rolling to 160mm×160mm billets-flaw detection-skinning-heating-continuous rolling with controlled cooling 12mm disk Strip-Take-up-Check-Packing.

[0089] 2. Preparation steps

[0090] (1) Adopt conventional method to carry out molten iron pretreatment, pour into converter steelmaking after sloughing part P, S, Si molten iron;

[0091] (2) Molten iron accounts for 90%, clean steel scrap accounts for 10%, metal Ni, Cu and Mo-Fe alloy, lime (CaO) and fluorite are added at the same time, when the C content in molten steel reaches about 0.80%, and the alkalinity is above 2.0, [P]≤0.010%, [S]≤0.010%, when the molten steel temperature is 1550~1570℃, the molten steel is poured into the ladle. Enter the LF refining furnace for refining.

[0092] ...

Embodiment 2

[0103] Embodiment 2: the preparation of spring steel (method A)

[0104] The production process is the same as in Example 1.

[0105] Preparation steps:

[0106] (1) Adopt conventional method to carry out molten iron pretreatment, pour into converter steelmaking after sloughing part P, S, Si molten iron;

[0107] (2) Molten iron accounts for 90%, clean steel scrap accounts for 10%, metal Ni, Cu and Mo-Fe alloy, lime (CaO) and fluorite are added at the same time, when the C content in molten steel reaches about 0.80%, and the alkalinity is above 2.0, [P]≤0.010%, [S]≤0.010%, when the molten steel temperature is 1570~1590℃, the molten steel is poured into the ladle. Enter the LF refining furnace for refining.

[0108] (3) The main task in the oxidation period of the LF refining furnace is to reduce C and adjust the temperature of molten steel; the main task in the reduction period is to deoxidize and alloy, when [C], [Ni], [Cu], [Mo], [P ], [S] and other components reach the ...

Embodiment 3

[0118] Embodiment 3: the preparation of spring steel wire

[0119] Production process: Φ12mm wire rod pay-off-shot peening-flaw detection-grinding-drawing to Φ11mm-pay-off-intermediate frequency+high frequency induction heating-water quenching-intermediate frequency induction tempering-flaw detection-wire take-up-inspection-packaging-in library.

[0120] Concrete preparation steps are as follows:

[0121] (1) After the Φ12mm wire rod is unwound, it enters the straight wire shot peening machine for shot peening. The line speed is 40-50m / min. Oxidized iron scale on the surface of the wire.

[0122] (2) After shot peening, the wire rod is drawn into a Φ11mm steel wire by an inverted drawing machine with a diameter of 1200mm, and the area reduction rate of each pass is 16%.

[0123] (3) The 11.0mm steel wire is paid off, and the temperature of the heated steel wire reaches 950-970°C through medium frequency + high frequency two-stage induction heating. 20n / min, and then the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com