Patents

Literature

33results about How to "Excellent cold forming performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

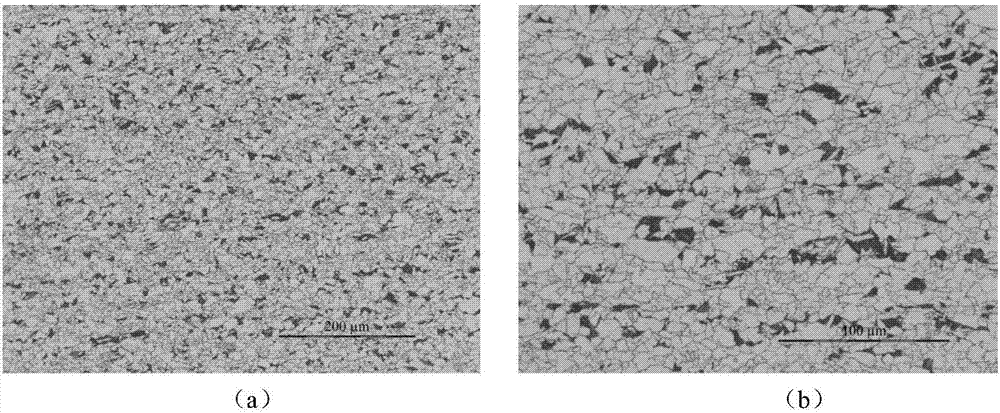

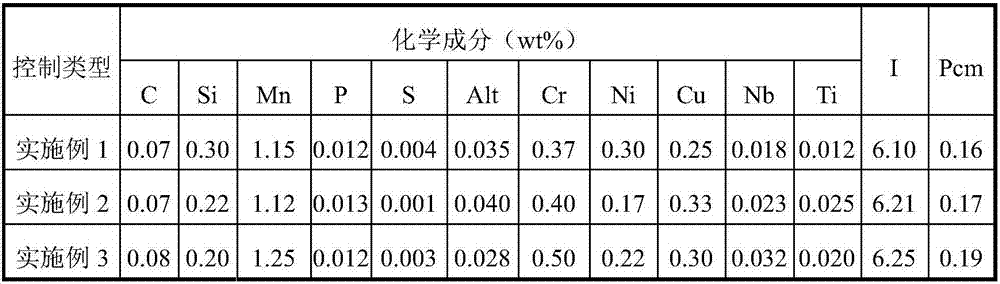

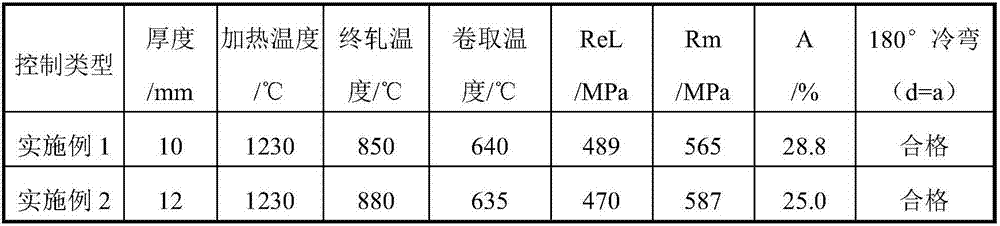

High-strength and high-toughness weather-proof hot-rolled steel plate and preparation method thereof

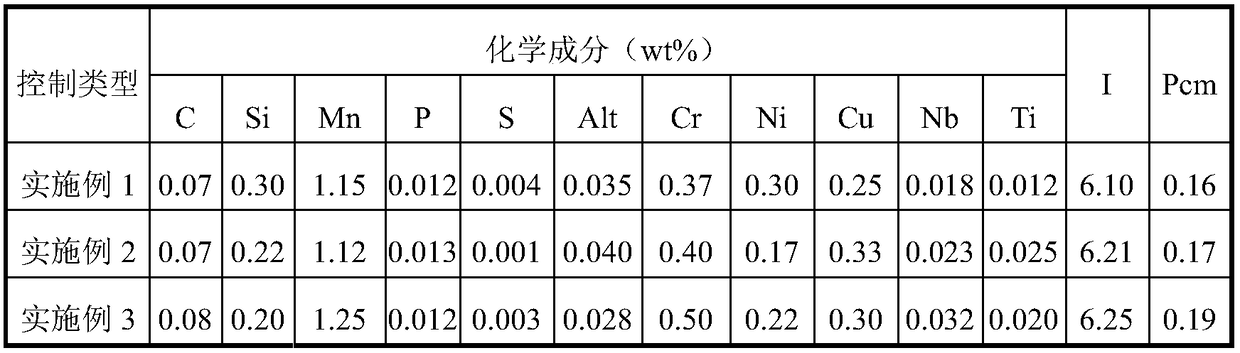

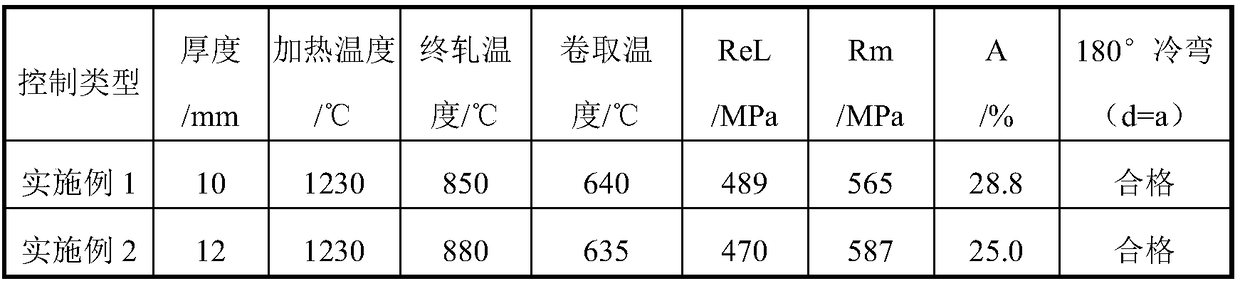

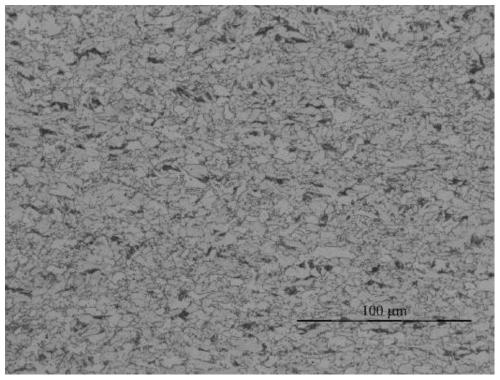

The invention relates to a high-strength and high-toughness weather-proof hot-rolled steel plate comprising the chemical components in percentage by weight: (wt,%): 0.05%-0.10% of C, 0.10%-0.50% of Si, 1.00%-1.30% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-0.70% of Cr, 0.10%-0.40% of Ni, 0.25%-0.50% of Cu, 0.020%-0.050% of Al, 0.010%-0.040% of Nb, 0.010%-0.030% of Ti and the balance Fe and unavoidable impurity elements. Meanwhile, the traditional hot strip rolling process is adopted, and a preparation method specifically comprises the steps: deep desulphurization of molten iron until S is less than or equal to 0.0050%, converter top and bottom combined blowing, alloy fine adjustment, LF secondary refining, slab continuous casting, heating, two-rack rough rolling and seven-rack finish rolling, laminar cooling and reeling. The steel plate disclosed by the invention has the mechanical properties that ReL is 450-500MPa, the Rm is greater than or equal to 550MPa, A is 25.0%-30.0%, the -60 DEG C longitudinal Charpy V-shaped gap impact power is greater than 300J, the high-strength and high-toughness weather-proof hot-rolled steel plate has good matching of strength and toughness, good cold bending forming and welding properties and favorable atmosphere corrosion resistance, and the corrosion resistance of the high-strength and high-toughness weather-proof hot-rolled steel plate is twice as high as that of Q345B steel.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

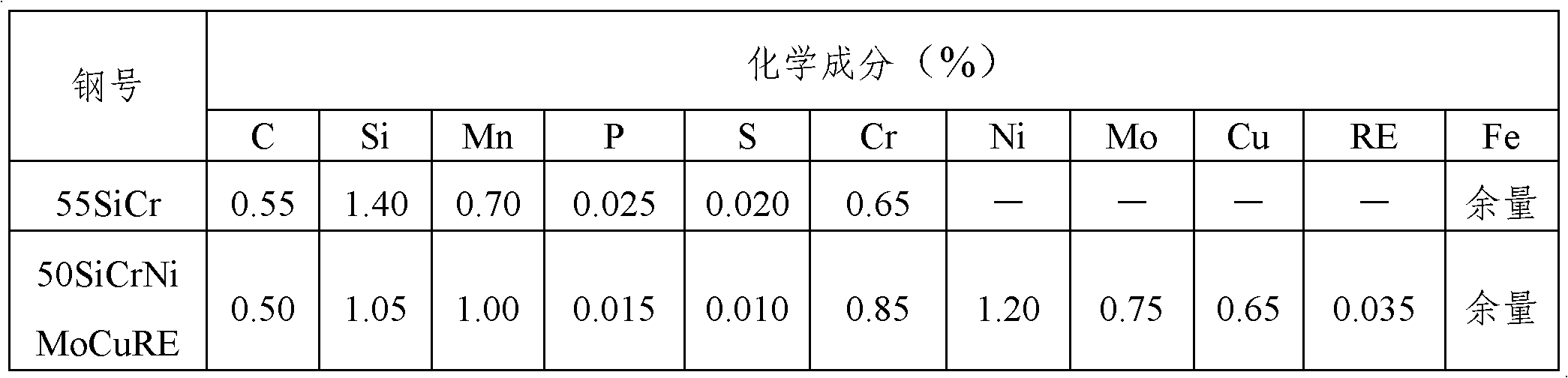

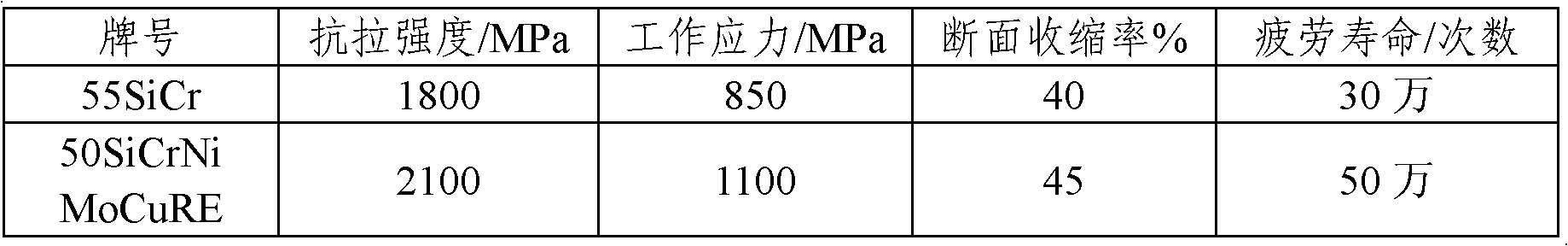

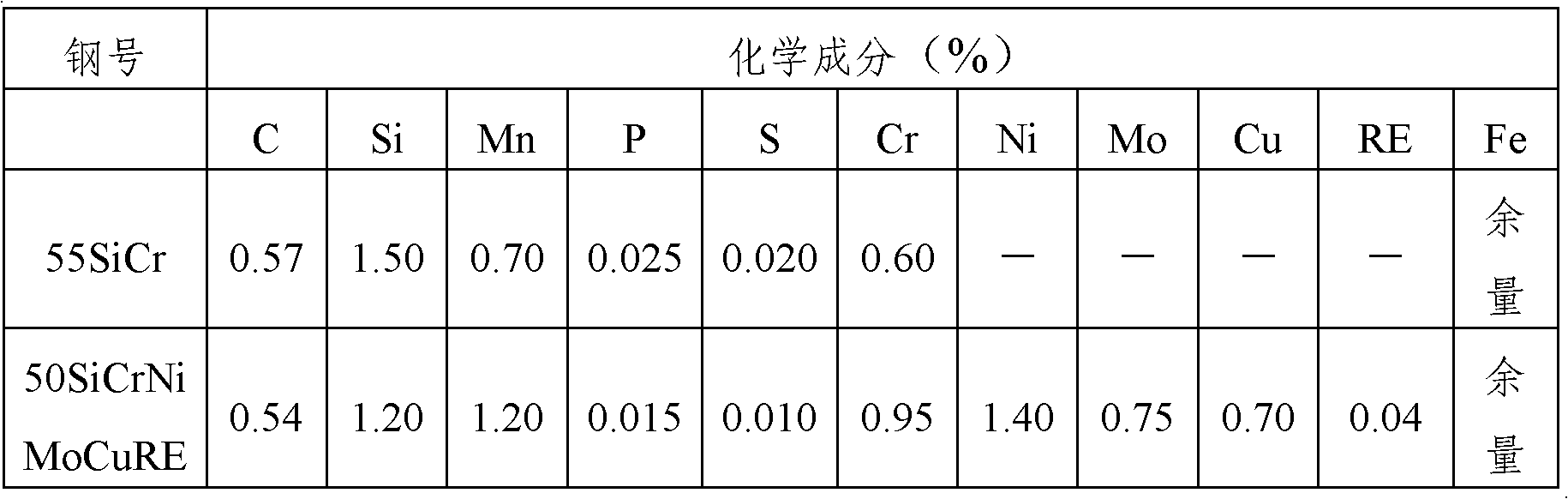

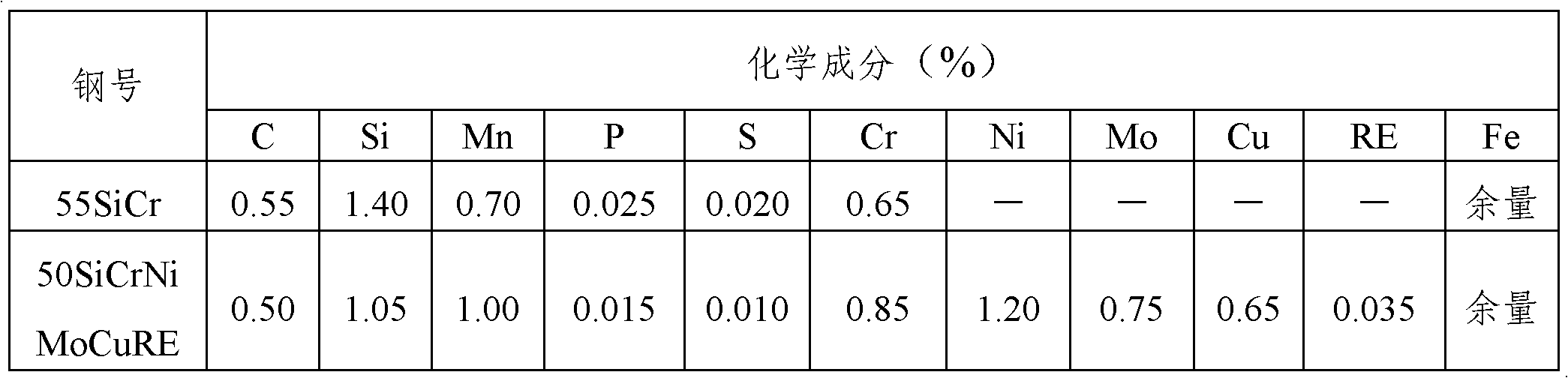

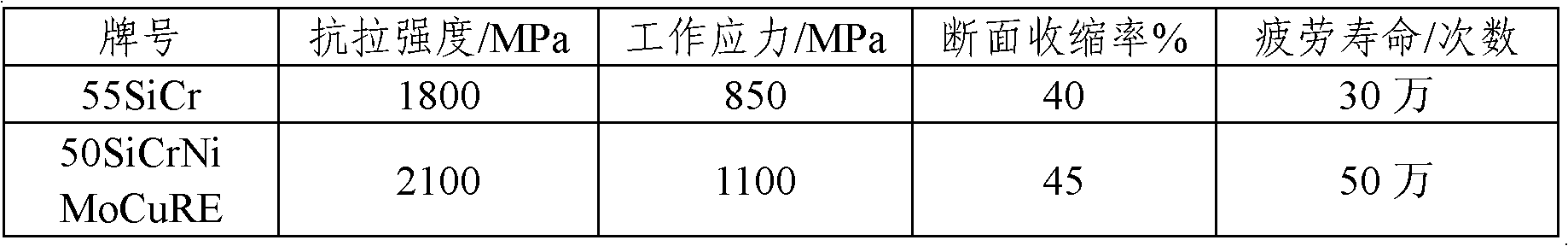

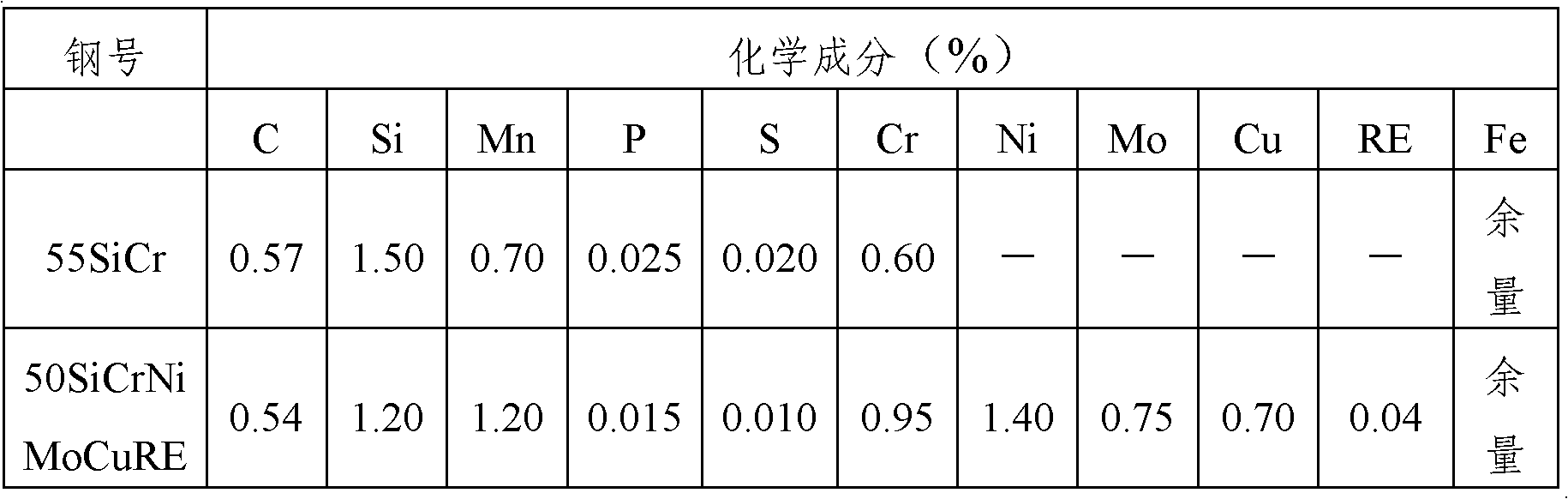

Spring steel used for automobile suspension as well as preparation method and application thereof

ActiveCN102634735AHigh tensile strengthIncrease work stressProcess efficiency improvementChemical compositionSpring steel

The invention provides a spring steel used for an automobile suspension. the spring steel comprises the following ingredients in percentage by weight: 0.46-0.56% of C, 0.90-1.20% of Si, 0.80-1.20% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.70-1.0% of Cr, 0.90-1.50% of Ni, 0.60-0.90% of Mo, 0.50-0.80% of Cu, 0.02-0.07% of RE and the balance of Fe and inevitable impurities. The invention also provides a preparation method for the spring steel and a method for preparing a spring steel wire by using the spring steel. According to the invention, the chemical components of the spring steel are reasonably designed, and the smelting rolling and steel wire preparation method and the auxiliary material adding method and proportion are improved. Compared with the existing 55SiCr steel, the tensile strength of the spring steel disclosed by the invention is improved by 400MPa, the working stress is improved by 200MPa, and the fatigue life is improved by 200 thousand times.

Owner:GUANGZHOU ORSA WIRE SCI & TECH

Thick specification hot-rolled steel sheet for roll forming high intensity metal sheet pile and manufacturing technology

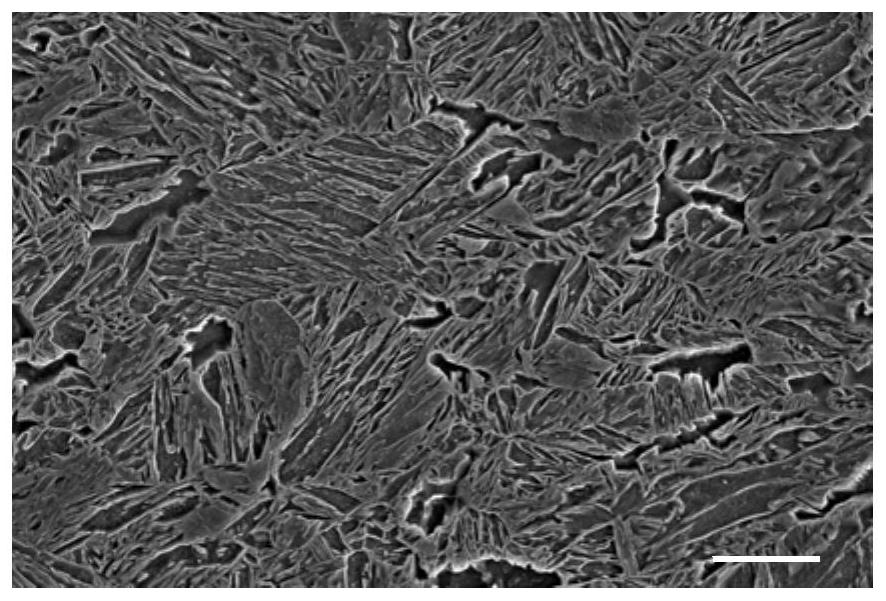

ActiveCN101451216AAvoid formingMeet demanding requirementsTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention relates to a high strength hot rolled plate and a production process thereof, in particular to a heavy gauge hot rolled steel plate for a roll bending forming high strength steel plate pile and a production process thereof. The invention mainly solves the technical problems of inadequate thickness, and lowcold bending performance and absorbed-in-fracture energy in the prior high strength heavy gauge steel plate. The technical proposal comprises: the heavy gauge hot rolled steel plate for the roll bending forming high strength steel plate pile comprises the following chemical components by weight percentage: 0.08 to 0.15 percent of C, 0.10 to 0.40 percent of Si, 0.30 to 0.90 percent of Mn, 0.020 to 0.040 percent of Nb, 0.010 to 0.030 percent of Ti, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S, and the balance being Fe. The microscopic structures can be fine grain ferrites, and pearlitic structures plus a small amount of bainite structures which are dispersed; the grain size level is 11 to 14; and the banded structure level is less than 0.5. The high strength hot rolled plate is mainly used for producing the steel plate pile.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

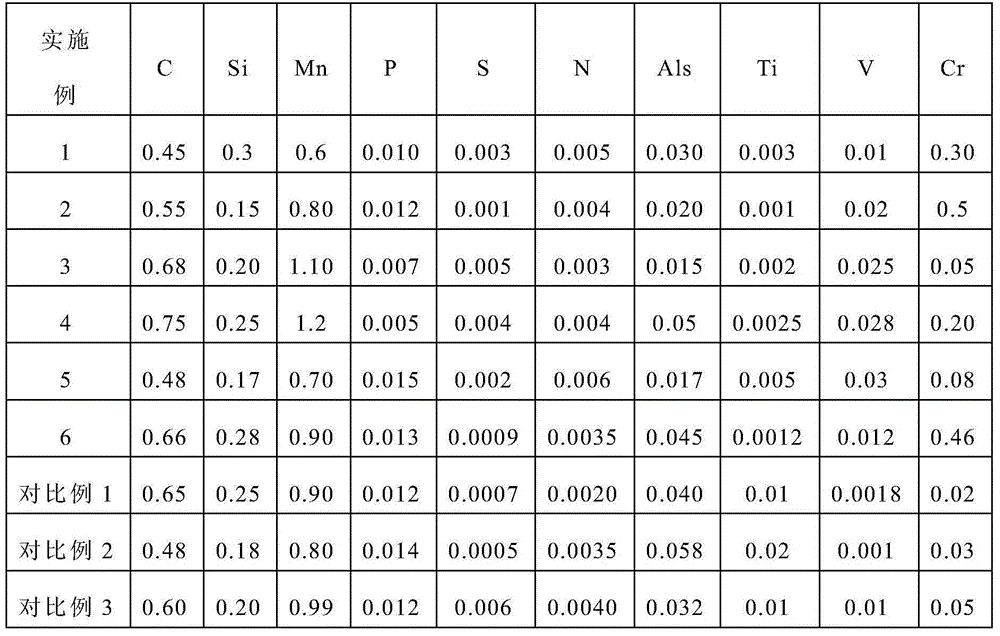

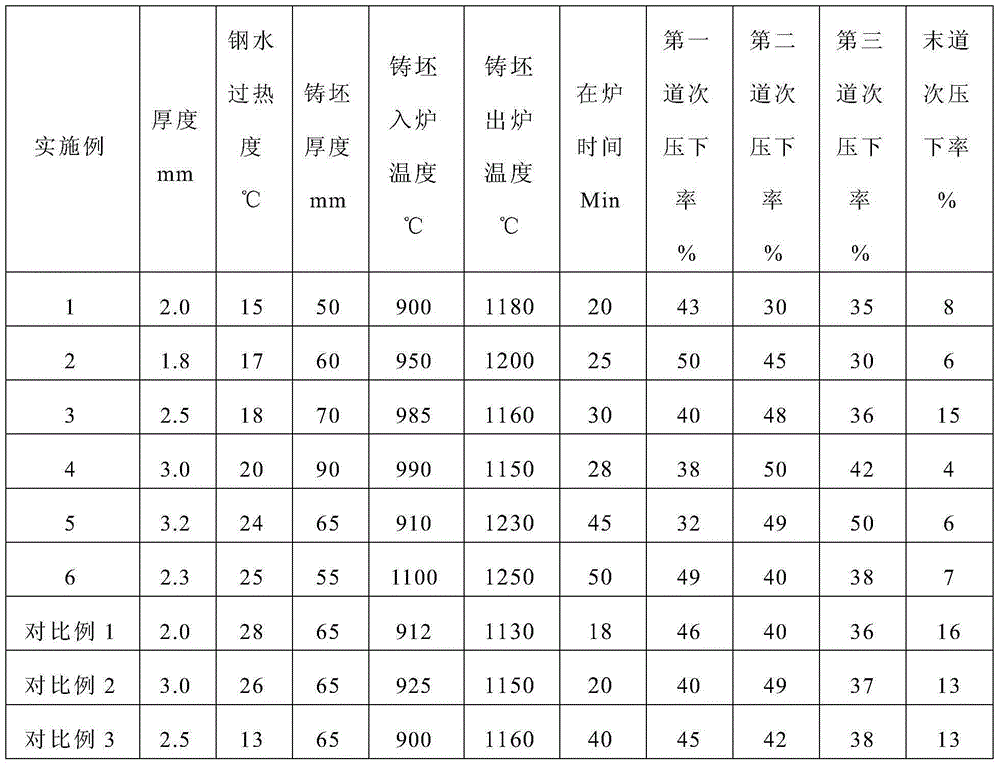

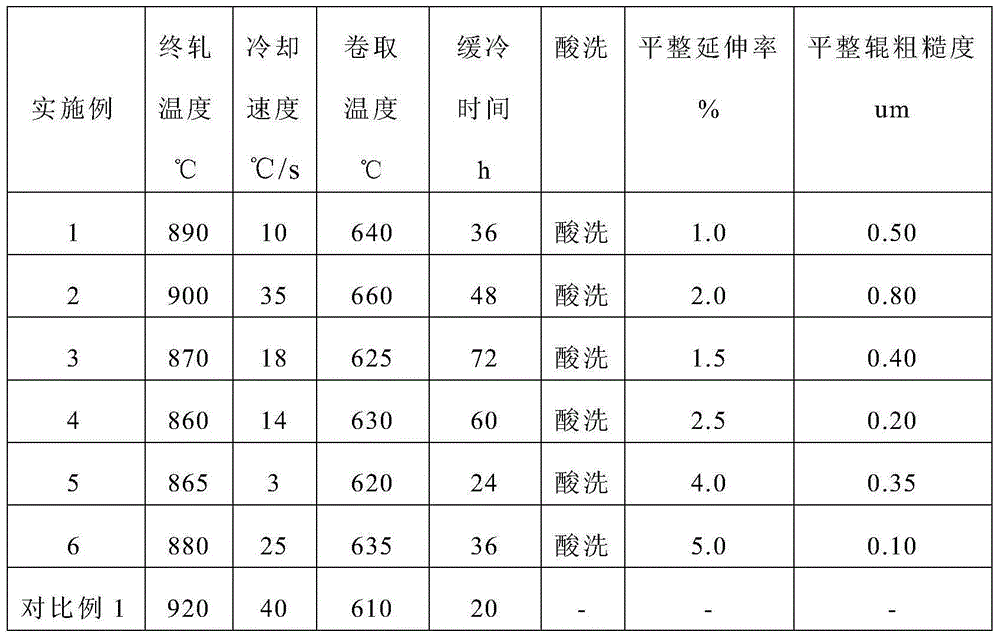

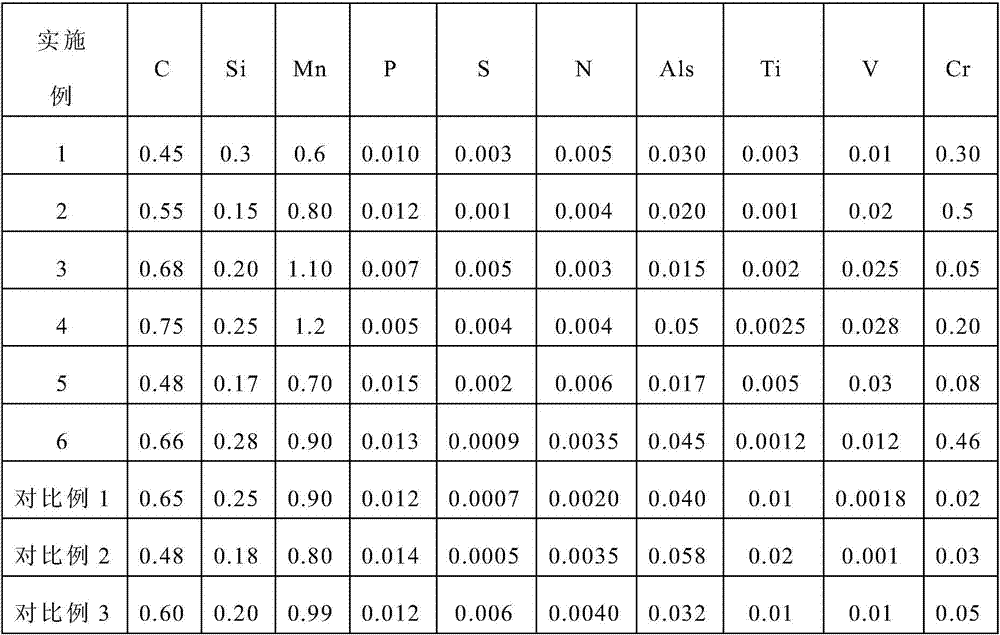

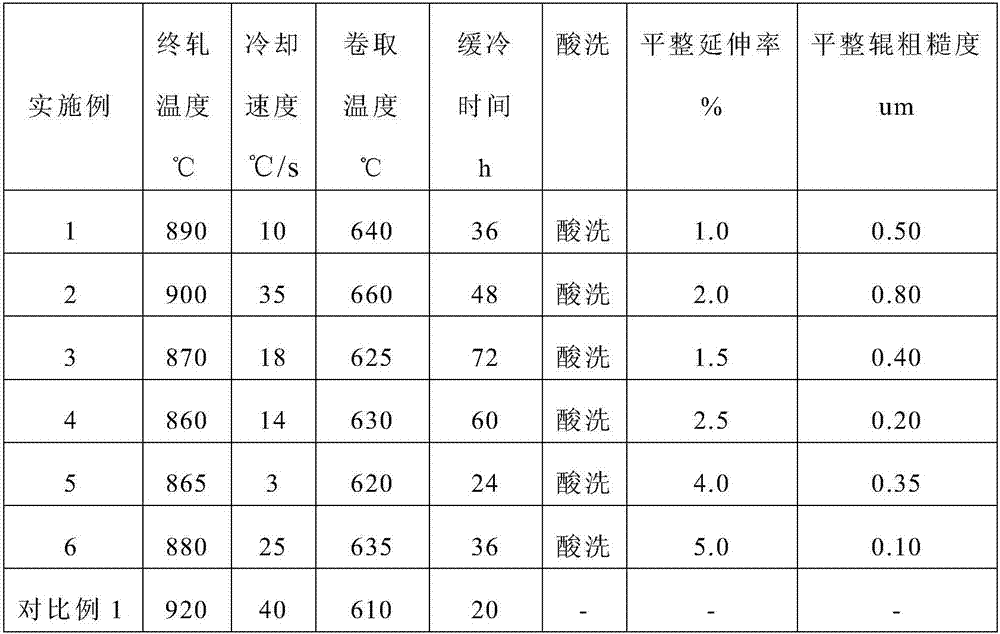

Hot-rolled steel for car friction plate and preparation method of hot-rolled steel

ActiveCN105063492AMeet the manufacturing process conditionsExcellent cold forming performanceChemical compositionHardness

The invention discloses hot-rolled steel for a car friction plate. The hot-rolled steel comprises the following chemical compositions by mass percent: 0.45-0.75 percent of C, 0.10-0.30 percent of Si, 0.60-1.20 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.006 percent of N, 0.05-0.50 percent of Cr, 0.015-0.050 percent of Als, less than or equal to 0.005 percent of Ti, 0.01-0.03 percent of V and the balance of Fe and inevitable impurities. The invention further discloses a preparation method of the hot-rolled steel for the car friction plate. The hardness of the hot-rolled steel is controlled within 18-25 HRC, the hardness of the steel annealed at 600-850 DEG C is still kept at 14-18 HRC, and the hot-rolled steel has favorable cold working forming performance and does not crack in the blanking and forming process.

Owner:武汉钢铁有限公司

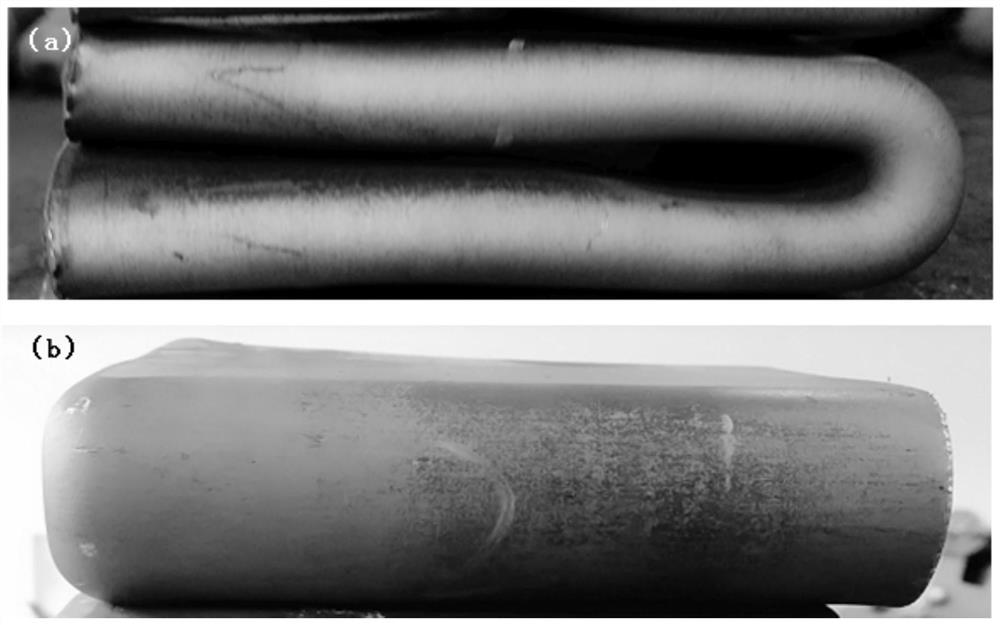

Large-diameter thin-wall cupronickel tube short process production method

The invention discloses a large-diameter thin-wall cupronickel tube short process production method and belongs to the technical field of metal materials. Specific to the problems that large-scale extrusion equipment up to 5000 tons is needed to produce large-diameter thin-wall cupronickel tubes through a traditional technique of semi-continuous casting solid ingot casting, punching, extruding, acid pickling, drawing and annealing, the finished product rate is low and the cost is high, the invention provides a method for producing the large-diameter thin-wall cupronickel tubes. Hot and cold combination casting horizontal continuous casting is adopted to producing large-size cupronickel tube blanks, and then a hole enlargement or / and hole shrinkage drawing is adopted to machining and forming the large-diameter thin-wall cupronickel tubes. The method has the advantages of being small in equipment investment, short in technical process, free of acid pickling and the like. The outer diameter of horizontal continuous casting tube blanks is 110-350 mm, the wall thickness is 5-30 mm, the elongation coefficient of hole enlargement drawing pass is 0.80-1.0, and the elongation coefficient of hole shrinkage drawing pass is 1.1-1.5; the outer diameter of machined products is 100-320 mm, and the wall thickness is 3-20 mm.

Owner:UNIV OF SCI & TECH BEIJING

Process for producing V-N micro alloy high strength steel band using thin plate blank continuously casting and continuously rolling technology

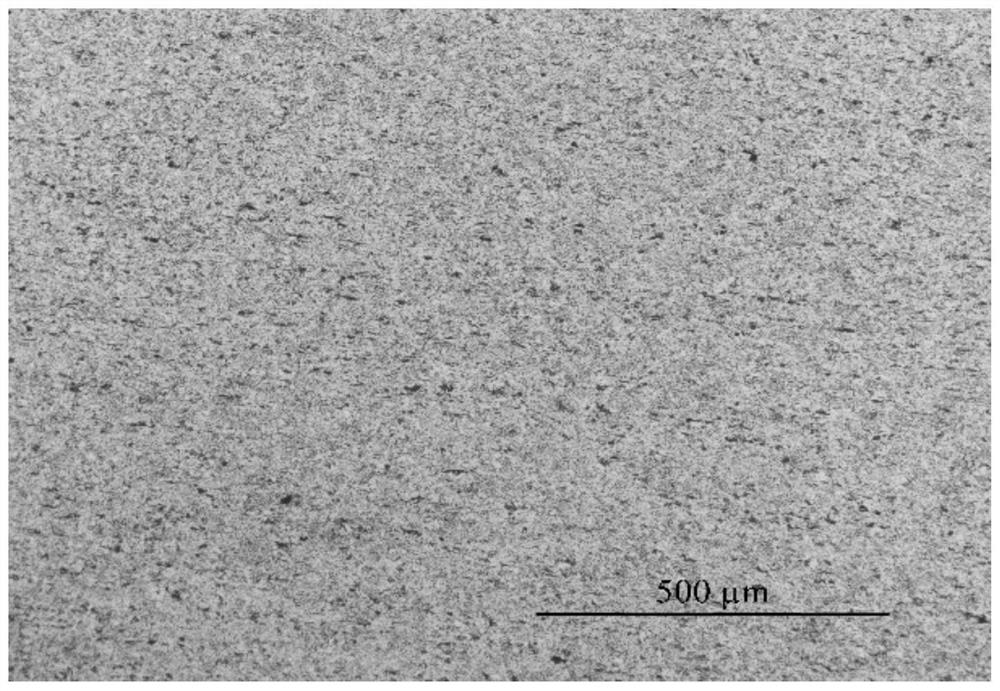

InactiveCN1748883ASpeed up coolingInhibit growthMetal rolling arrangementsMaterials scienceSteel plates

The continuous thin plate blank casting and rolling process for producing high strength V-N micro alloy steel belt includes smelting and refining in electric furnace or converter, continuous casting, heating after solidification inside bottom heating furnace, hot rolling, laminated flow cooling and winding. The continuous thin plate blank casting and rolling process has the technological parameters of: furnace entering temperature of cast blank 900-1050 deg c, homogeneous heating temperature 1050-1250 deg c, initially rolling temperature 1000-1170 deg c, finally rolling temperature 840-950 deg c and winding temperature 530-670 deg c. The molten steel contains: C 0.03-0.08 wt%, Si 0.01-0.8 wt%, Mn 0.1-2.0 wt%, V 0.01-0.20 wt%, Al 0.01-0.06 wt% and N 0.002-0.03 wt%. The produced high strength and fine grain steel belt and plate has ferrite grain size smaller than 6.0 micron, yield strength of 420-700 MPa, and excellent toughness, welding performance and forming performance.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Steel for card clothing

The invention provides steel for card clothing. The steel is prepared from the following components in percentage by mass: 0.75 to 0.85 percent of C, 0.10 to 0.50 percent of Si, 0.30 to 0.90 percent of Mn, 0.20 to 0.50 percent of Cr, smaller than 0.02 percent of P, smaller than 0.01 percent of S, 0.04 to 0.20 percent of V, 0.015 to 0.060 percent of Nb, 0 to 0.50 percent of Ni, 0 to 0.50 percent of Mo, 0 to 0.40 percent of Cu, and the balance being inevitable impurities. According to the steel disclosed by the invention, by adopting a mode of reasonably adding Nb and V, produced card clothing undergoing quenching-tempering heat treatment has crystal particle size of over 12 grades and hardness of over 800HV0.2 can be guaranteed while the steel has good cold processing forming performance, the wear resistance of products is remarkably improved, and the service life is also greatly prolonged.

Owner:金轮针布(江苏)有限公司

Short-process production method for high-strength and high-conductivity copper alloy strips

ActiveCN107716885AThe overall thickness is thinFlat surfaceMetal rolling arrangementsIngot castingHigh conductivity

The invention discloses a short-process production method for high-strength and high-conductivity copper alloy strips, and belongs to the technical field of metal materials. In order to solve the problem that large hot rolling equipment is needed when a traditional 'semi-continuous ingot casting-hot rolling-face milling-cold rolling-solid dissolving-cold rolling-aging' process is adopted for producing high-strength and high-conductivity copper alloy strips, meanwhile, the yield is low, energy consumption is large and the cost is high, hot-cold combined casting type horizontal continues castingis adopted for preparing copper alloy plate blanks, then the cold-rolling-solid dissolving-cold rolling-aging process is carried out, the high-strength and high-conductivity copper alloy strips are produced, blank reheating, hot rolling and face milling treatment can be omitted, and the method has the advantages that equipment investment is low, the technological process is short, the yield is high, energy consumption is low, and the production cost is low. The horizontal continuous casting plate blanks are 200-800 mm wide and 5-50 mm thick, the rolling pass deformation is 20-50%, the rollingspeed is 60-600 m / min, and the processed product is 200-800 mm wide and 0.05-2 mm thick.

Owner:UNIV OF SCI & TECH BEIJING

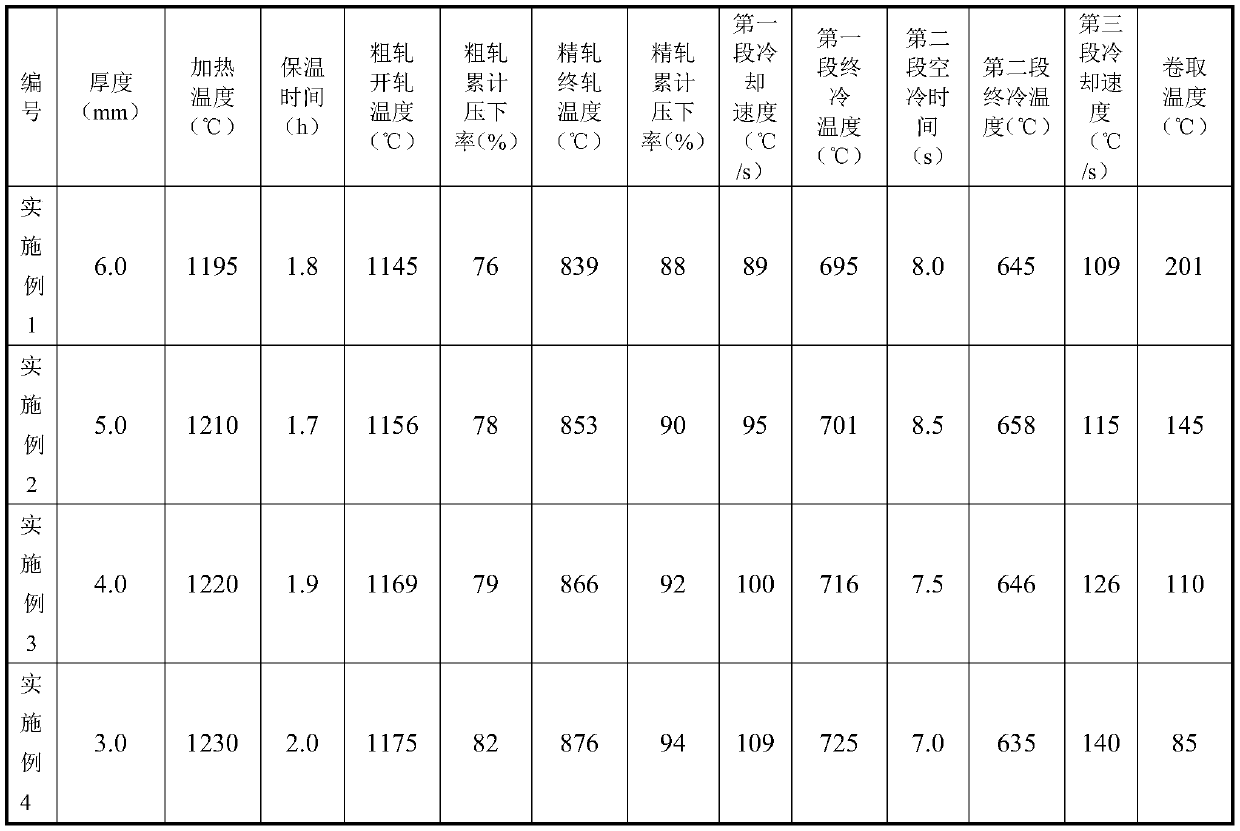

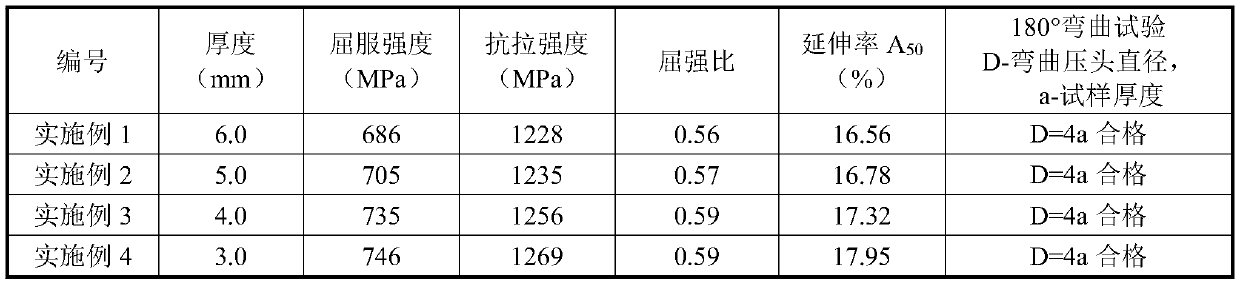

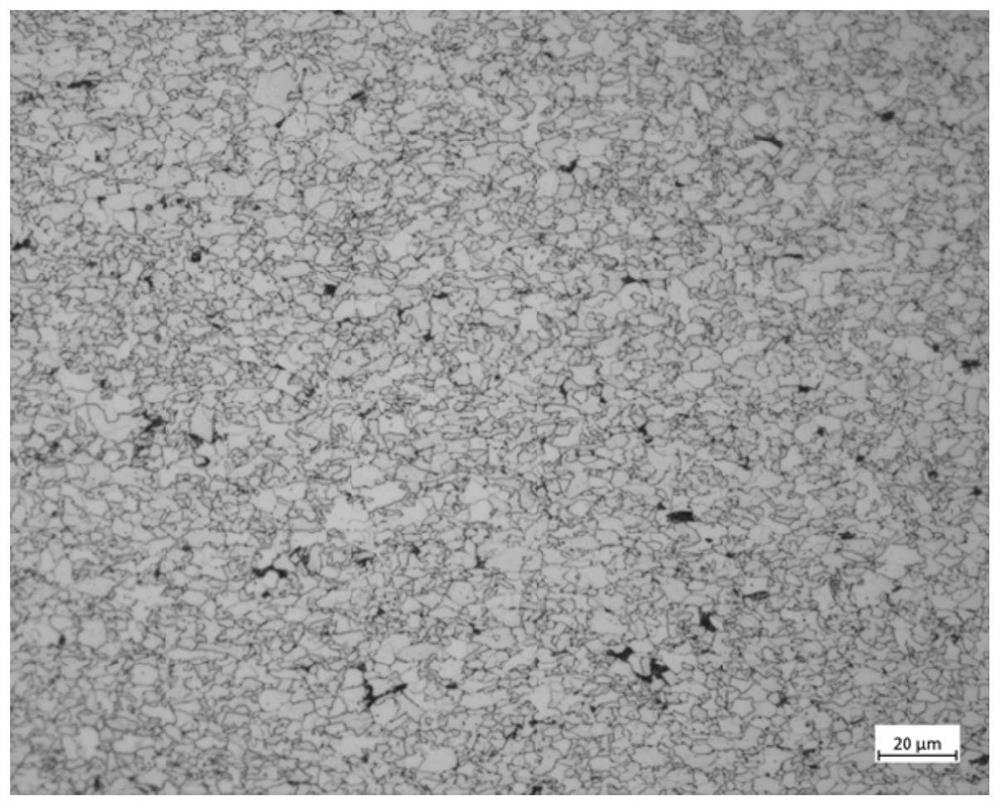

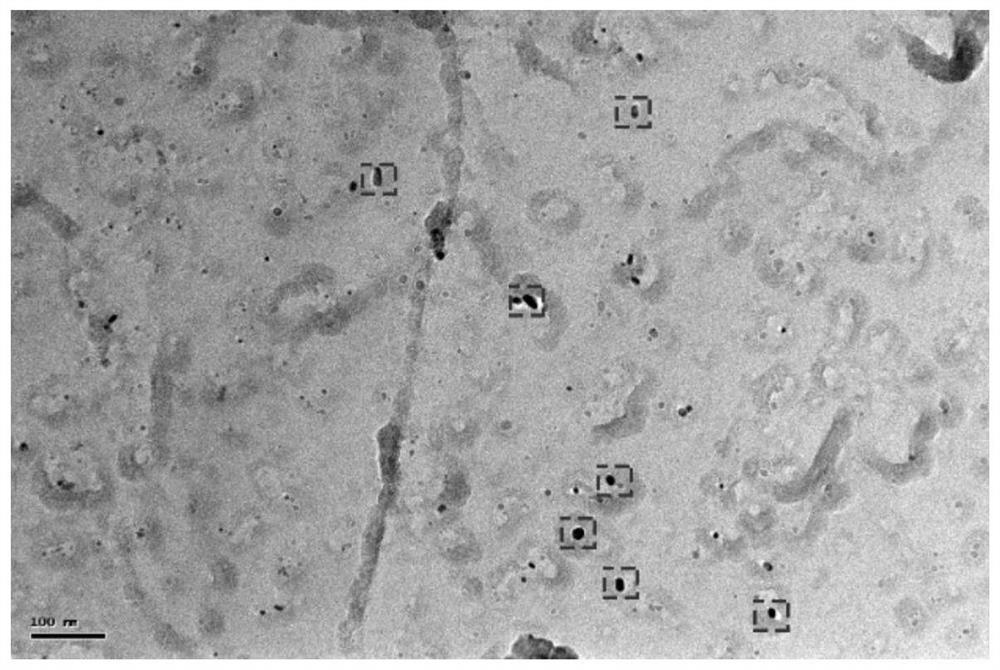

1200MPa-grade hot-rolled high-strength dual-phase steel plate and manufacturing method thereof

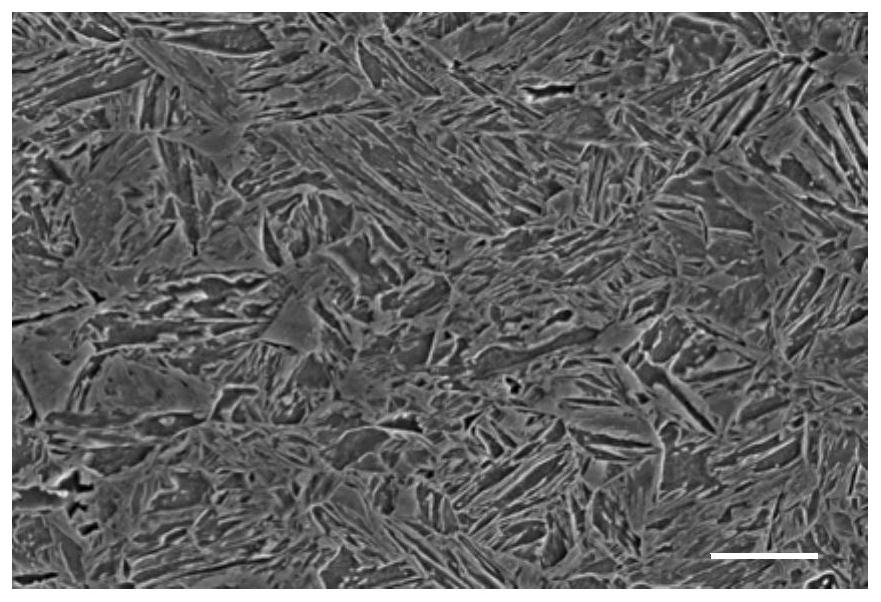

InactiveCN110643800AHigh strengthReduce intensityTemperature control deviceFurnace typesUltimate tensile strengthDual-phase steel

The invention discloses a 1200MPa-grade hot-rolled high-strength dual-phase steel plate which is prepared from the following chemical components in percentage by weight: 0.10-0.18 percent of C, 0.80 -1.50 percent of Si, 1.50-2.20 percent of Mn, smaller than or equal to 0.015 percent of P, smaller than or equal to 0.008 percent of S, 0.40-0.80 percent of Cr, 0.010 -0.050 percent of Nb, 0.010-0.040percent of Ti, 0.020-0.060 percent of Als and the balance of Fe and inevitable impurities. The microstructure of the 1200MPa-grade hot-rolled high-strength dual-phase steel plate is a dual-phase tissue with ferrite plus martensite, wherein the volume fraction of the ferrite is 20-30 percent, the volume fraction of the martensite is 70-80 percent, the yield strength of a product is larger than or equal to 650MPa, the tensile strength is larger than or equal to 1200MPa, the elongation A50 is larger than or equal to 16 percent, the yield ratio is smaller than or equal to 0.65, the cold bending performance is 180 DEG C, the product is qualified if D is equal to 4a, and the 1200MPa-grade hot-rolled high-strength dual-phase steel plate has relatively high strength, relatively low yield ratio andrelatively good forming performance.

Owner:MAANSHAN IRON & STEEL CO LTD

700MPa-grade high-strength weather-resistant steel plate resistant to atmospheric corrosion and production method thereof

The invention discloses a 700MPa-grade high-strength weather-resistant steel plate resistant to atmospheric corrosion and a production method thereof, and belongs to the field of high-strength weather-resistant steel. The steel plate comprises the following main chemical components in percentage by mass: 0.06 percent to 0.09 percent of C, 0.30 percent to 0.50 percent of Si, 1.10 percent to 1.50 percent of Mn, 0.010 percent to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.60 percent to 1.00 percent of Cr, 0.03 percent to 0.07 percent of Ni, 0.25 percent to 0.40 percent of Cu, 0.020 percent to 0.045 percent of Als, 0.100 percent to 0.140 percent of Ti, less than or equal to 0.0040 percent of N, less than or equal to 0.0035 percent of O, and the balance of Fe and inevitable impurity elements; and a microscopic structure of the steel plate is quasi-polygonal ferrite and pearlite, and the pearlite content is 2 percent to 4 percent. The high-strength weather-resistant steel has good atmospheric corrosion resistance and high plasticity, and the thickness range of the plate is 1.6 to 6.0 mm.

Owner:MAANSHAN IRON & STEEL CO LTD

Method of producing high undercooling control rolling fine grain high-strength C-Mn steel plate

InactiveCN101109037AAlloy composition is simpleLow priceHeat treatment process controlSteel beltHigh intensity

The invention is an undercooling controlled rolling fine grained high strength C-Mn steel plate production method, which relates to a steel plate rolling production process technology. The production technology comprises the steps that the C-Mn steel continuous casting steel billet with 50mm thickness is rolled for 6-pass in CSP production line under the temperature of 1150 DEG C. to 1000 DEG C., and the coarse microstructure of the casting billet is distorted and the microstructure generates recrystallization in deformation Austenite; The invention is capable of getting the higher strength; then, the C-Mn steel tape is cooled by the strong wind of the fan, and the big Austenite deformation is carried out; finally, the C-Mn steel tape is coiled on a roller machine as the finished product. The invention can get the higher strength through the crystallization of the steel with low C-Mn content; the alloy composite is simple and the price is lower; the invention is of good low temperature toughness and good cold bending forming; based on the composite regulation and base principle of application the technology, the invention is capable of getting the steel grade of good formablity of 400MPa level, 500MPa leve and 600MPa level from the C-Mn steel; the invention has the prevalent meaning of guidance to the fine grain high strength board's production.

Owner:CHINA AUTOMOTIVE ENG RES INST

A short-process production method for large-diameter thin-walled copper-nickel pipes

The invention discloses a short-process production method of a large-diameter thin-walled white copper pipe, which belongs to the technical field of metal materials. Aiming at the traditional "semi-continuous casting solid ingot-piercing extrusion-pickling-drawing-annealing" process to produce large-diameter thin-walled copper-nickel pipes requires more than 5,000 tons of large-scale extrusion equipment, and the yield is low and the cost is high. The present invention proposes a method of horizontal continuous casting of large-sized white copper pipe blanks using hot and cold combined molds, and then adopts diameter expansion or / and diameter reduction drawing to process and form large-diameter thin-walled white copper pipes, which has the advantages of small equipment investment, short process flow, No pickling and other advantages. The outer diameter of the horizontal continuous casting tube blank is 110~350mm, the wall thickness is 5~30mm, the extension coefficient of the drawing pass for expanding diameter is 0.80~1.0, the extension coefficient for drawing pass for reducing diameter is 1.1~1.5, and the outer diameter of the processed product is 100~ 320mm, wall thickness 3~20mm.

Owner:UNIV OF SCI & TECH BEIJING

1300MPa-grade hot continuous rolling ultrahigh-strength steel plate and manufacturing method thereof

The invention provides a 1300MPa-grade hot continuous rolling ultrahigh-strength steel plate and a manufacturing method thereof. The 1300MPa-grade hot continuous rolling ultrahigh-strength steel plate comprises the following components: 0.15-0.30% of C, 0.20-1.20% of Si, 1.5-2.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 0.020-0.050% of Nb, 0.020-0.050% of Ti, 0.10-0.50% of Als, 0.0010-0.0020% of B, less than or equal to 0.00015% of H, less than or equal to 0.0030% of N, less than or equal to 0.0030% of O and the balance of Fe and inevitable impurities. By adopting a TMCP and direct quenching process technology, a quenching and tempering or tempering heat treatment process is not needed, industrial production of the 1300MPa-grade hot continuous rolling ultrahigh-strength steel plate is achieved on a hot continuous rolling strip production line, and the 1300MPa-grade hot continuous rolling ultrahigh-strength steel plate has the characteristics of being short in process flow, low in production cost, high in product strength and hardness, good in wear resistance, good in cold bending forming property, good in plate shape and the like.

Owner:MAANSHAN IRON & STEEL CO LTD

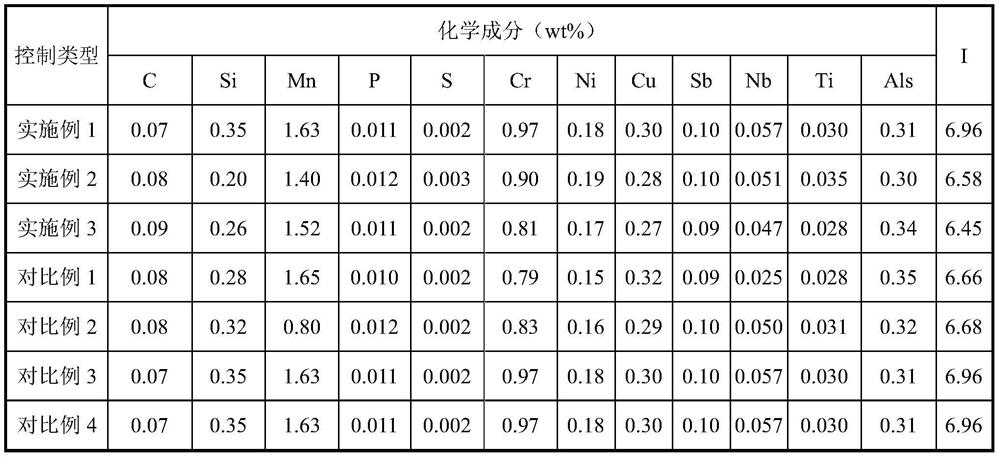

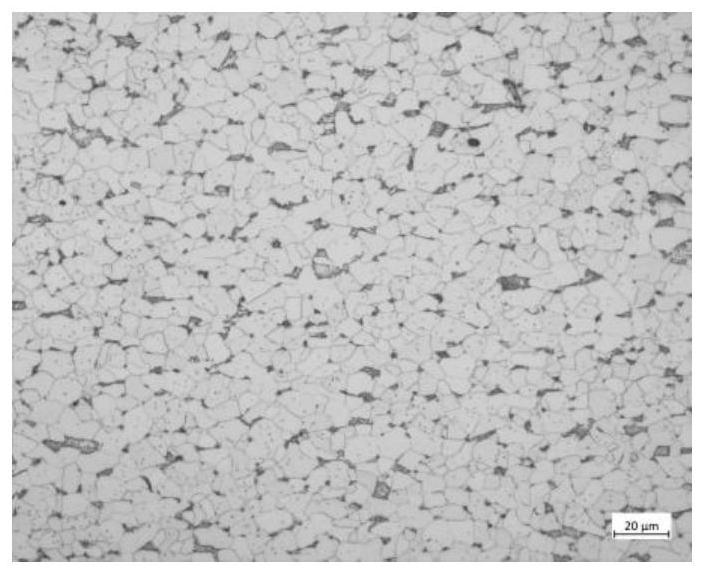

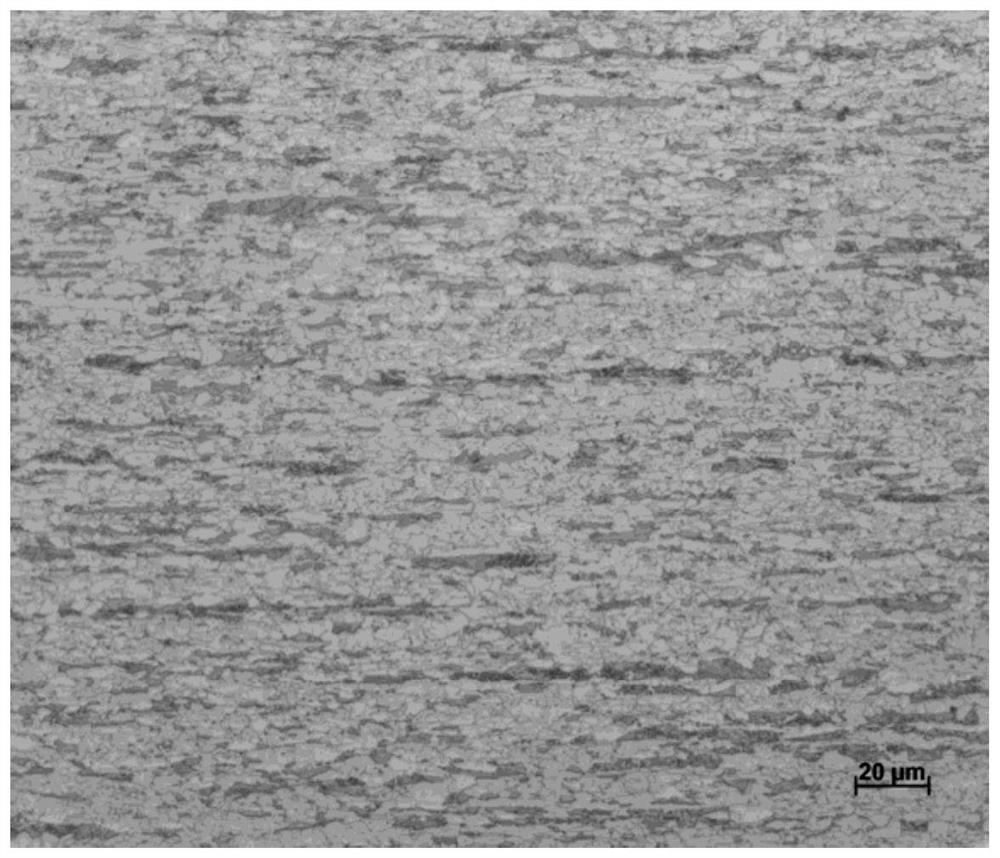

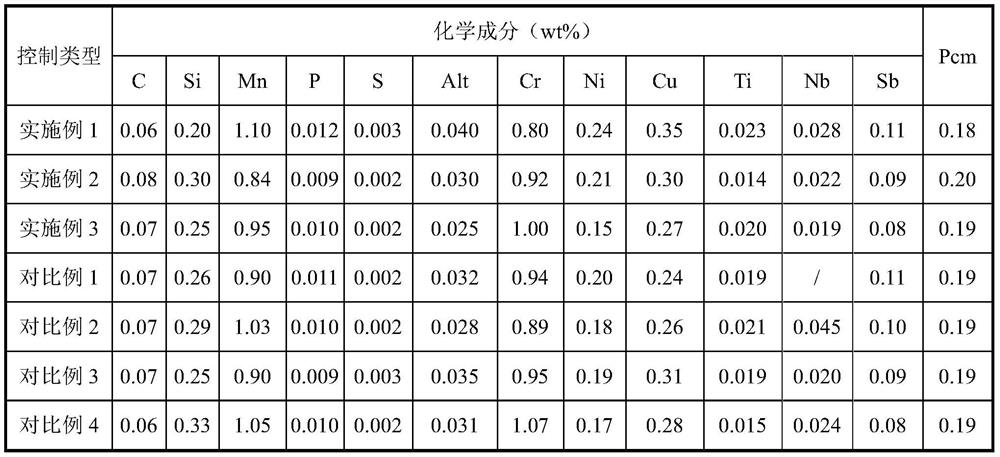

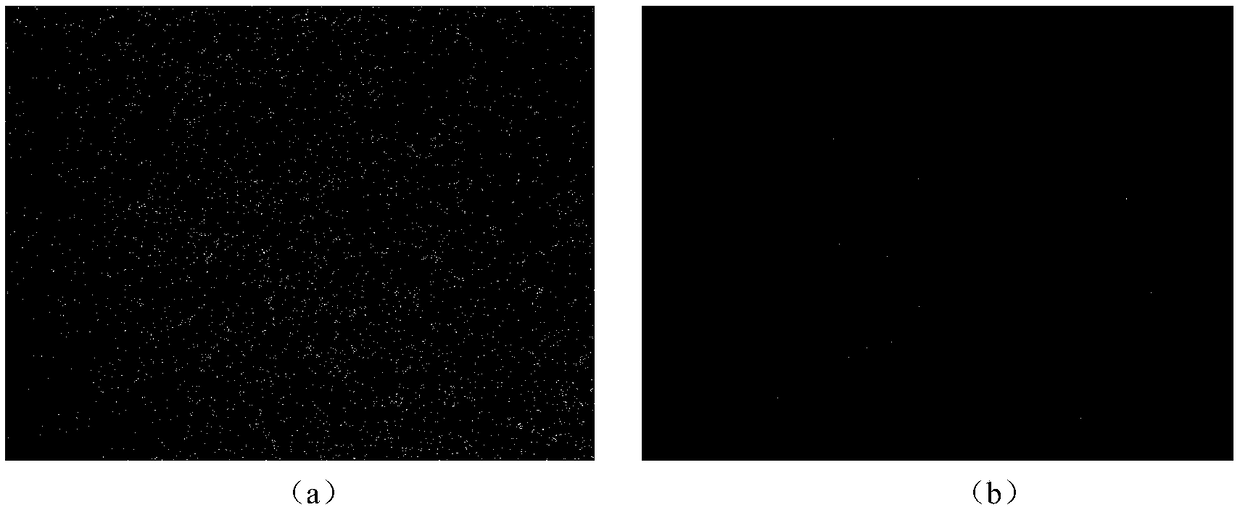

Niobium-titanium microalloyed acid medium corrosion-resistant steel plate with yield strength of 600MPa and production method thereof

The invention discloses a niobium-titanium microalloyed acid medium corrosion-resistant steel plate with the yield strength of 600 MPa and a production method thereof. The steel plate comprises the following chemical components of, in percentage by weight, 0.06% to 0.10% of C, 0.20% to 0.40% of Si, 1.30% to 1.70% of Mn, P less than or equal to 0.015%, S less than or equal to 0.005%, 0.70% to 1.00%of Cr, 0.10% to 0.20% of Ni, 0.25% to 0.30% of Cu, 0.045% to 0.060% of Nb, 0.025% to 0.045% of Ti, 0.08% to 0.10% of Sb, 0.020% to 0.040% of Als and the balance Fe and inevitable impurities, the weather resistance index I of the steel plate is greater than 6.0; and the steel plate is obtained by adopting the technological processes of molten iron pretreatment deep desulfurization, converter smelting, LF furnace refining, continuous casting, plate blank heating, rough rolling, finish rolling, laminar cooling and coiling. According to the niobium-titanium microalloyed acid medium corrosion-resistant steel plate with the yield strength of 600 MPa, the yield strength reaches 600 MPa, the cost is low, and the steel plate has good acid medium resistance and atmospheric corrosion resistance andmeanwhile has excellent strength and toughness matching and cold bending forming performance.

Owner:MAANSHAN IRON & STEEL CO LTD

Thin-gauge Ni-free weathering steel produced based on CSP process and production method of thin-gauge Ni-free weathering steel

The invention provides thin-gauge Ni-free weathering steel produced based on a CSP process and a production method of the thin-gauge Ni-free weathering steel. The thin-gauge Ni-free weathering steel comprises the following components: 0.04%-0.06% of C, 0.30%-0.55% of Si, 0.30%-0.80% of Mn, 0.020%-0.150% of P, less than or equal to 0.005% of S, 0.30%-0.80% of Cr, 0.25%-0.40% of Cu, 0.015%-0.040% of Als, 0.010%-0.040% of Ti and the balance of Fe and inevitable impurity elements. A proper amount of P and Si are added, through matching design and interaction of Si-P-Cu-Cr elements, the problems of continuous casting bleed-out and product surface crack defects caused by copper brittleness are solved, the manufacturing cost is reduced, and meanwhile good atmospheric corrosion resistance and strong plasticity matching are achieved.

Owner:MAANSHAN IRON & STEEL CO LTD

A hot-rolled low-yield ratio high-strength acid corrosion-resistant steel plate and its production method

ActiveCN112159921BLow yield ratioHigh strengthProcess efficiency improvementRefining (metallurgy)Slow cooling

The invention discloses a hot-rolled low-yield-ratio high-strength acid corrosion-resistant steel plate and a production method thereof. The main chemical composition and weight percentage content thereof are: C 0.06-0.08%; Si 0.20%-0.40%; Mn 0.80-0.00% 1.20%; P≤0.012%; S≤0.005%; Cr 0.70~1.20%; Ni 0.10~0.30%; Cu 0.20~0.40%; Alt 0.020~0.045%; 0.06~0.12%; the balance is Fe and unavoidable inclusions; the present invention adopts microalloying control technology combined with controlled rolling and controlled cooling principles, based on microstructure type control, deep desulfurization in molten iron pretreatment→converter smelting→furnace External refining→continuous casting→stacking and slow cooling→slab heating→controlled rolling→controlled cooling→coiling Hot continuous rolling strip production line develops high-strength acid-resistant steel products with low yield ratio, excellent formability and acid corrosion resistance , can be used in the manufacture of steel structures serving in acidic corrosive medium environments in transportation, tobacco, electric power, chemical energy, metallurgy and other industries.

Owner:MAANSHAN IRON & STEEL CO LTD

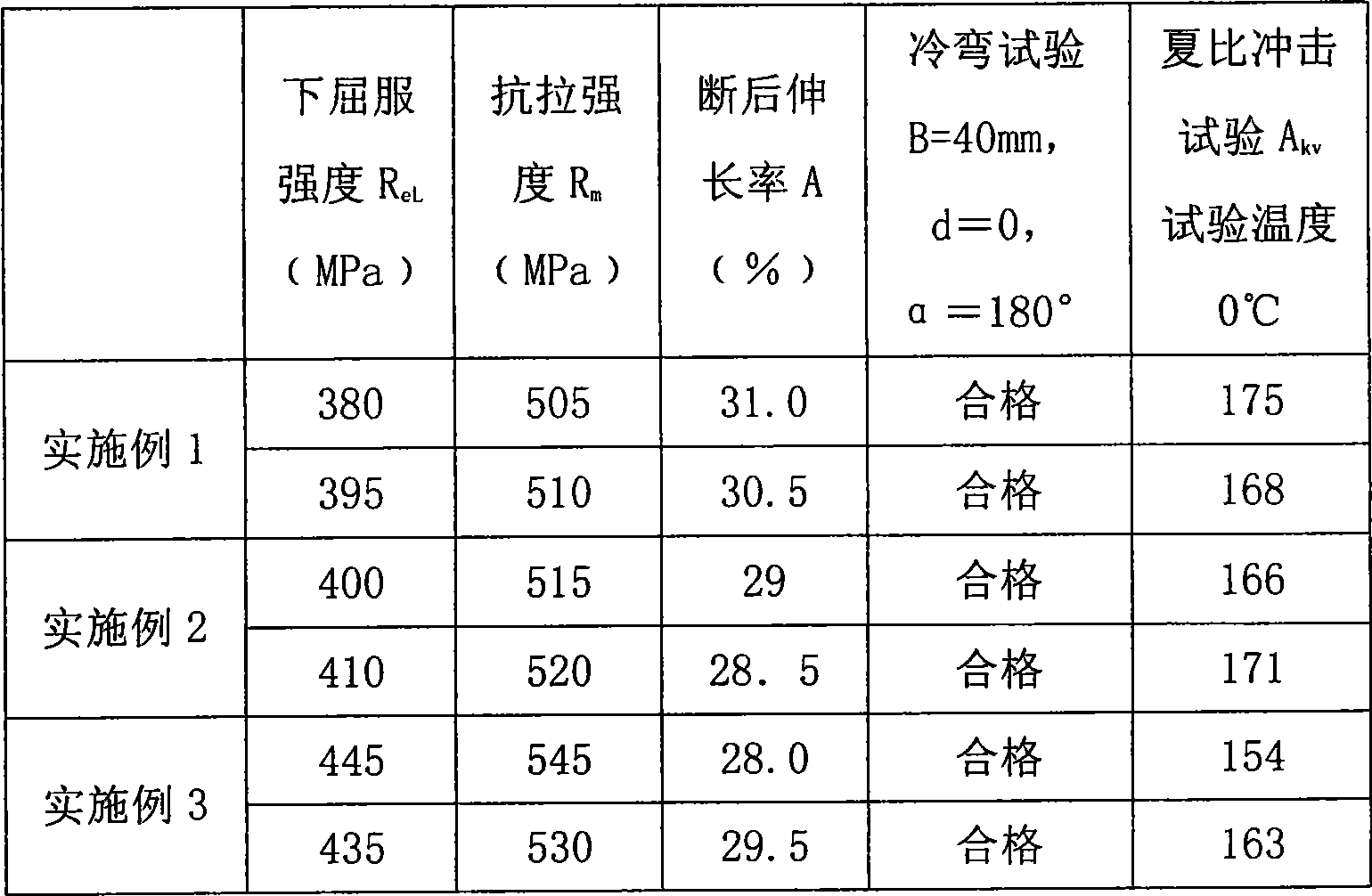

A high-strength and high-toughness hot-rolled weather-resistant steel plate and its preparation method

ActiveCN106947913BExcellent cold forming performanceGood welding performanceChemical compositionSheet steel

The invention relates to a high-strength and high-toughness weather-proof hot-rolled steel plate comprising the chemical components in percentage by weight: (wt,%): 0.05%-0.10% of C, 0.10%-0.50% of Si, 1.00%-1.30% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-0.70% of Cr, 0.10%-0.40% of Ni, 0.25%-0.50% of Cu, 0.020%-0.050% of Al, 0.010%-0.040% of Nb, 0.010%-0.030% of Ti and the balance Fe and unavoidable impurity elements. Meanwhile, the traditional hot strip rolling process is adopted, and a preparation method specifically comprises the steps: deep desulphurization of molten iron until S is less than or equal to 0.0050%, converter top and bottom combined blowing, alloy fine adjustment, LF secondary refining, slab continuous casting, heating, two-rack rough rolling and seven-rack finish rolling, laminar cooling and reeling. The steel plate disclosed by the invention has the mechanical properties that ReL is 450-500MPa, the Rm is greater than or equal to 550MPa, A is 25.0%-30.0%, the -60 DEG C longitudinal Charpy V-shaped gap impact power is greater than 300J, the high-strength and high-toughness weather-proof hot-rolled steel plate has good matching of strength and toughness, good cold bending forming and welding properties and favorable atmosphere corrosion resistance, and the corrosion resistance of the high-strength and high-toughness weather-proof hot-rolled steel plate is twice as high as that of Q345B steel.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

A kind of short-process production method of high-strength and high-conductivity copper alloy strip

ActiveCN107716885BThe overall thickness is thinFlat surfaceMetal rolling arrangementsIngot castingMetallic materials

Owner:UNIV OF SCI & TECH BEIJING

Blue 18K gold for hydrogen sulfide corrosion-resisting jewelry and process thereof

The invention discloses blue 18K gold for hydrogen sulfide corrosion-resisting jewelry and a process thereof. The blue 18K gold is prepared from the following alloy components in percentage by weight:0.1-0.2wt.% of Be, 1.2-1.5wt.% of Mo, 0.4-0.6wt.% of V, 1.5-1.8wt.% of In, 0.4-0.5wt.% of Sc, 0.1-0.2wt.% of Sm, 74.0-76.0wt.% of Au and the balance aluminum. The blue 18K gold overcomes the currentsituation that existing blue K gold is insufficient in performance, and breaks through the development bottleneck in the field of jewelry effectively. It can be expected that plenteous economical fruits and social benefits can be obtained by implementation and industrialization of the material.

Owner:GUANGZHOU YUZHI TECH CO LTD

Novel hot dipping aluminum alloy with hydrogen sulfide and sodium chloride corrosion resistance

InactiveCN108588507AImprove corrosion resistanceUniform compositionHot-dipping/immersion processesCorrosionChloride sodium

The invention discloses a novel hot dipping aluminum alloy with hydrogen sulfide and sodium chloride corrosion resistance. The aluminum alloy comprises the following components in percentage by weight: 0.1-0.2 wt.% of Ba, 0.3-0.5 wt.% of Hf, 0.4-0.6 wt.% of Ca, 1.2-1.5 wt.% of Bi, 0.2-0.4 wt.% of Sc, 0.1-0.2 wt.% of Eu, 0.2-0.3 wt.% of S, and the balance aluminum. The aluminum alloy solves the current situation of backward technologies in the national hot dipping aluminum alloy field at present, and breaks through the bottleneck of restricting the development of hot dipping aluminum steel plate production technologies and equipment in the national high-end field through technology innovation and optimal design. In the near future, the material can be widely applied to more fields.

Owner:GUANGZHOU YUZHI TECH CO LTD

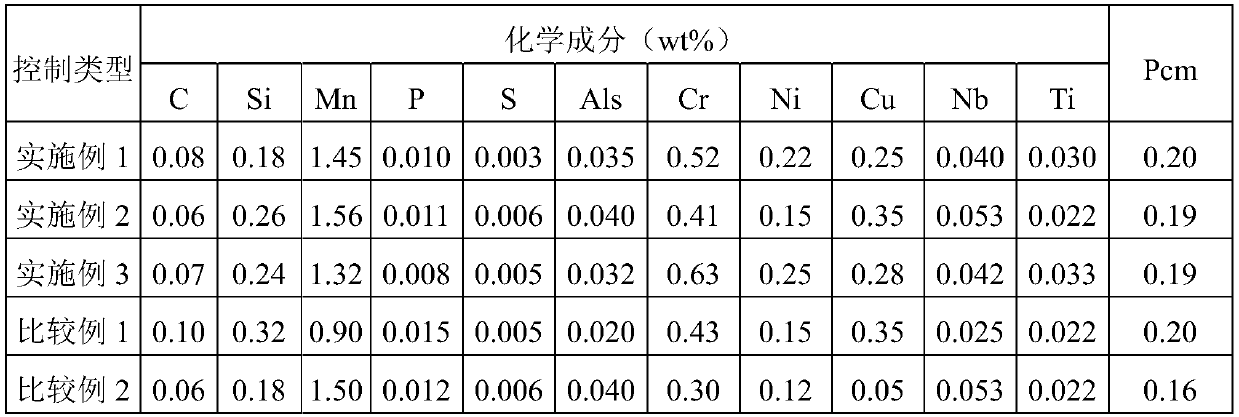

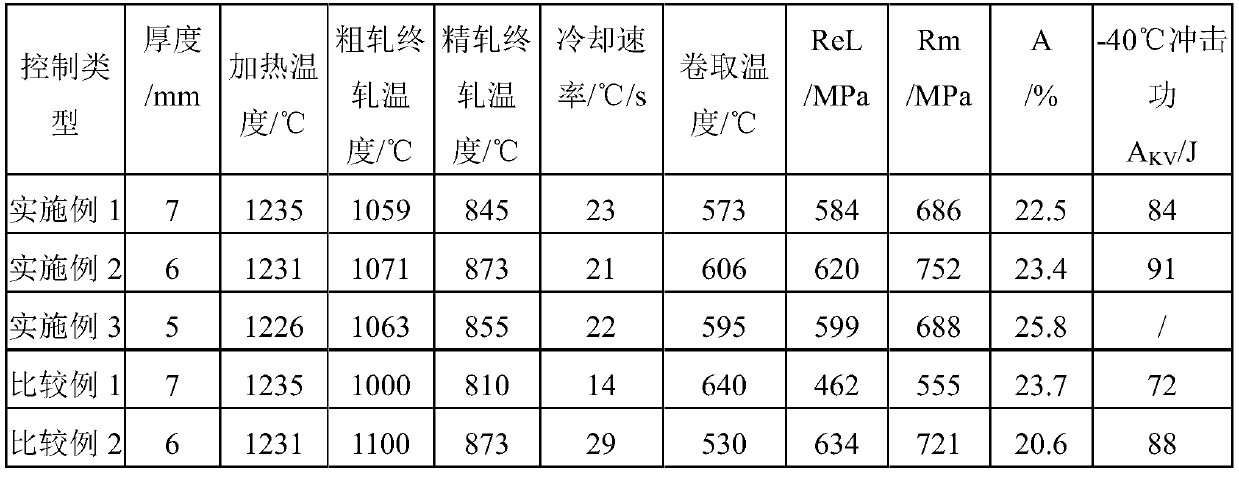

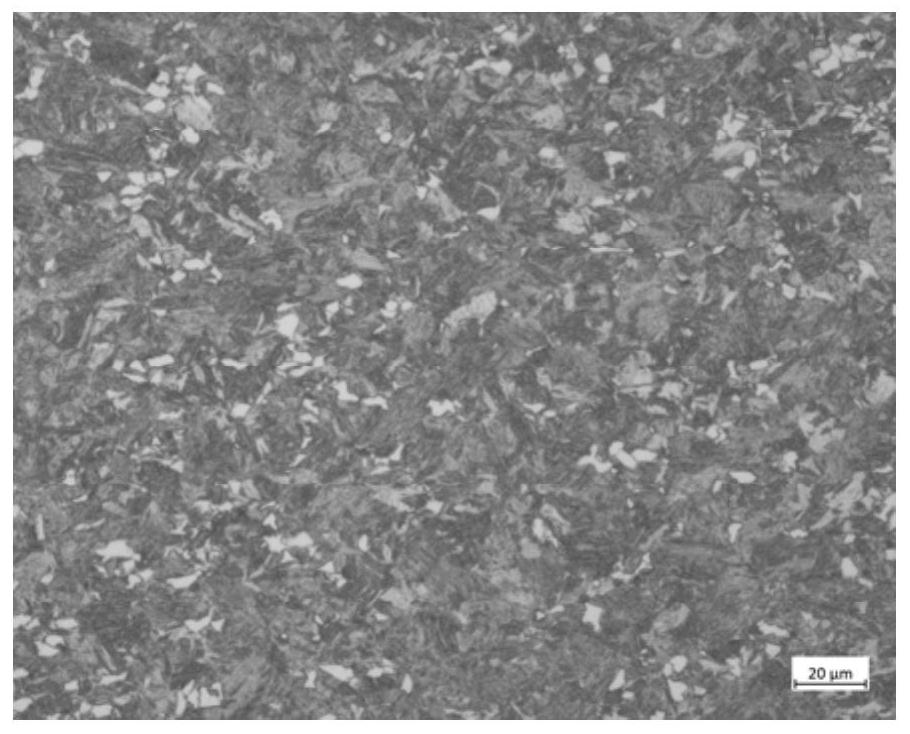

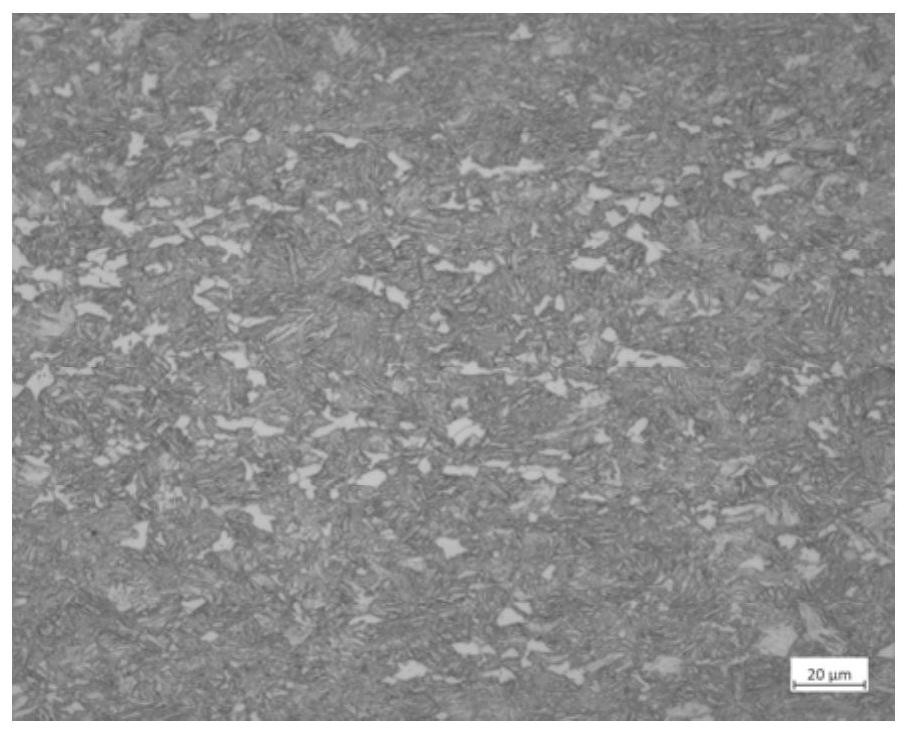

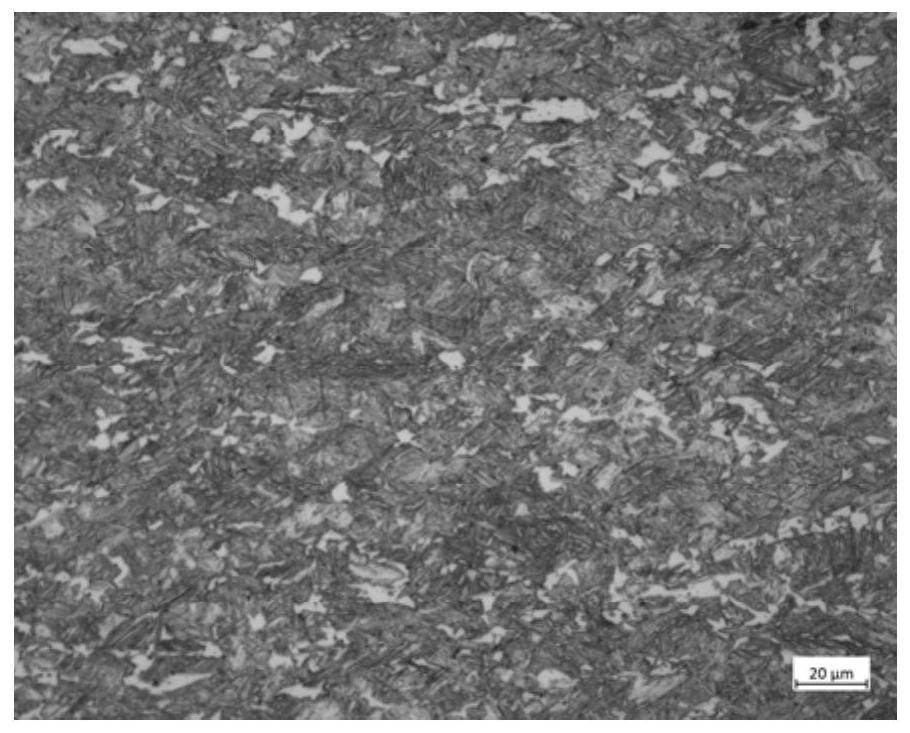

A high-toughness weather-resistant steel plate with a yield strength of 550mpa and its preparation method

ActiveCN108486466BDetrimental effects of reduced low temperature toughnessGood atmospheric corrosion resistanceChemical compositionPearlite

The invention discloses a high-toughness weather-resistant steel plate with the yield strength of 550MPa and a preparation method of the high-toughness weather-resistant steel plate. The high-toughness weather-resistant steel plate is prepared from the following chemical components by weight percent: 0.05 to 0.10 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.008 percent of S, 0.40 to 0.80 percent of Cr, 0.15 to 0.40 percent of Ni, 0.25 to 0.40 percent of Cu, 0.015 to 0.040 percent of Als, 0.030 to 0.070 percent of Nb, and 0.010 to 0.040 percent of Ti, and the balance of Fe and unavoidable impurities, wherein Pcm is equal to C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B and less than or equal to 0.20 percent. The microscopic tissue of the weather-resistant steel plate obtained according to the method disclosed in the invention is composite-phase tissue of ferrite, granular bainite and little pearlite,the ReL is 560 to 650MPa, Rm is 680 to 780MPa, A is 22.0 to 26.0 percent, and the longitudinal Charpy V-type impact power KV2 is greater than 70J at the temperature of -40 DEG C, and the high-toughness weather-resistant steel plate has excellent welding performance, cold bending forming performance and atmospheric corrosion resistance.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Heat-treatment-free NM360 wear-resistant steel plate and manufacturing method thereof

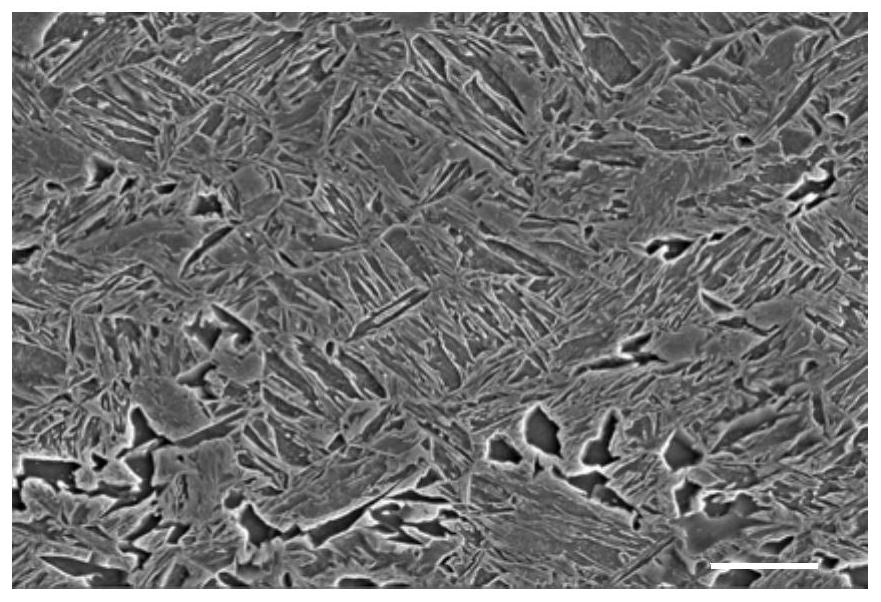

ActiveCN113215488AExcellent cold forming performanceShort processTemperature control deviceHardnessUltimate tensile strength

The invention provides a heat-treatment-free NM360 wear-resistant steel plate and a manufacturing method thereof. The heat-treatment-free NM360 wear-resistant steel plate comprises 0.15%-0.25% of C, 1.0%-2.5% of Si, 1.5%-2.5% of Mn, smaller than or equal to 0.012% of P, smaller than or equal to 0.005% of S, 0.010%-0.060% of Nb, 0.010%-0.060% of Ti, 0.010%-0.050% of V, 0.020%-0.060% of Als, 0.0010%-0.0030% of B, smaller than or equal-0.00015% of H, smaller than or equal to 0.0030% of N, smaller than or equal to 0.0030% of O and the balance Fe and inevitable inclusions. The manufacturing method of direct three-section cooling after rolling is adopted, the yield strength of the product is larger than or equal to 800 MPa, the tensile strength is larger than or equal to 1200 MPa, the cold bending performance is 180 degrees, D is equal to 4a and qualified, the technological process is short, the production cost is low, the product strength and hardness are high, the abrasion resistance is high, and the cold bending forming performance is good.

Owner:MAANSHAN IRON & STEEL CO LTD

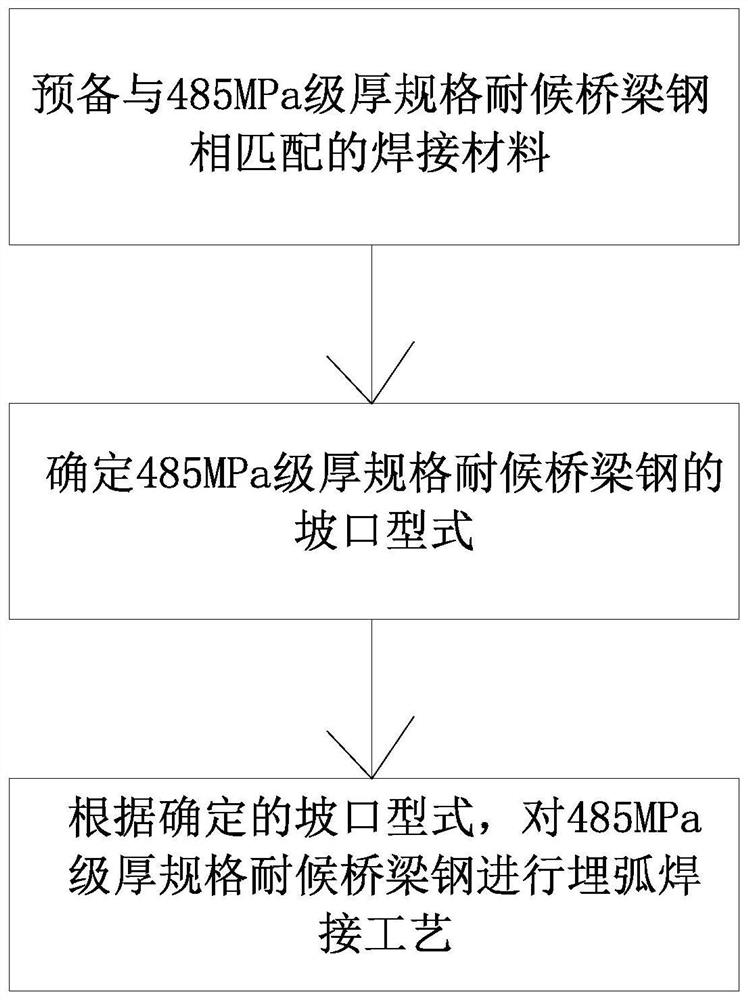

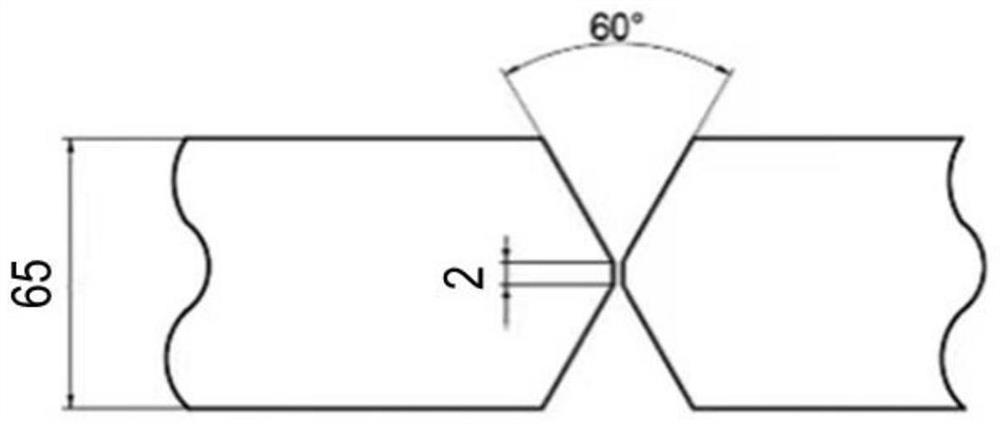

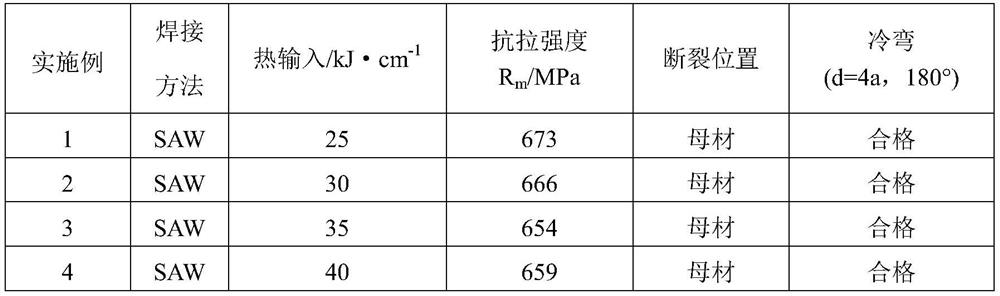

Submerged-arc welding process for 485 MPa-grade thick weather-proof bridge steel

PendingCN114734127AAddress low temperature toughnessSolve the strength problemArc welding apparatusWelding/cutting media/materialsEngineeringWeld seam

The invention discloses a submerged arc welding process for 485 MPa grade thick weather-proof bridge steel. The method belongs to the field of steel and iron material welding, and comprises the following specific steps: preparing a welding material matched with the 485MPa-grade thick weather-proof bridge steel; the groove type of the weather-proof bridge steel with the 485MPa-grade thickness specification is determined; and carrying out a submerged arc welding process on the 485MPa-grade thick weather-proof bridge steel. Welding materials and welding process parameters matched with high-performance bridge steel are adopted, the problem that low-temperature toughness, strength and cold bending performance of a thick-specification bridge steel welding joint are difficult to consider under the condition of large heat input is solved, and the high-standard requirement that the impact toughness of all parts of the joint at the temperature of-40 DEG C is higher than 60 J is met; the process of pre-welding low-temperature preheating and post-welding heat-free treatment is achieved, the effect of good welding joint performance and good welding seam forming is achieved in the implementation process, and the method is suitable for application and popularization of low-yield-ratio weather-proof series bridge steel for large-span structural engineering.

Owner:NANJING IRON & STEEL CO LTD

Process for producing V-N micro alloy high strength steel band using thin plate blank continuously casting and continuously rolling technology

InactiveCN100345641CObvious refinementThe degree of refinement is not as obvious as the present inventionMetal rolling arrangementsSteel platesWeldability

The continuous thin plate blank casting and rolling process for producing high strength V-N micro alloy steel belt includes smelting and refining in electric furnace or converter, continuous casting, heating after solidification inside bottom heating furnace, hot rolling, laminated flow cooling and winding. The continuous thin plate blank casting and rolling process has the technological parameters of: furnace entering temperature of cast blank 900-1050 deg c, homogeneous heating temperature 1050-1250 deg c, initially rolling temperature 1000-1170 deg c, finally rolling temperature 840-950 deg c and winding temperature 530-670 deg c. The molten steel contains: C 0.03-0.08 wt%, Si 0.01-0.8 wt%, Mn 0.1-2.0 wt%, V 0.01-0.20 wt%, Al 0.01-0.06 wt% and N 0.002-0.03 wt%. The produced high strength and fine grain steel belt and plate has ferrite grain size smaller than 6.0 micron, yield strength of 420-700 MPa, and excellent toughness, welding performance and forming performance.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Spring steel used for automobile suspension as well as preparation method and application thereof

ActiveCN102634735BHigh tensile strengthIncrease work stressProcess efficiency improvementSpring steelSmelting

The invention provides a spring steel used for an automobile suspension. the spring steel comprises the following ingredients in percentage by weight: 0.46-0.56% of C, 0.90-1.20% of Si, 0.80-1.20% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.70-1.0% of Cr, 0.90-1.50% of Ni, 0.60-0.90% of Mo, 0.50-0.80% of Cu, 0.02-0.07% of RE and the balance of Fe and inevitable impurities. The invention also provides a preparation method for the spring steel and a method for preparing a spring steel wire by using the spring steel. According to the invention, the chemical components of the spring steel are reasonably designed, and the smelting rolling and steel wire preparation method and the auxiliary material adding method and proportion are improved. Compared with the existing 55SiCr steel, the tensile strength of the spring steel disclosed by the invention is improved by 400MPa, the working stress is improved by 200MPa, and the fatigue life is improved by 200 thousand times.

Owner:GUANGZHOU ORSA WIRE SCI & TECH

A 600mpa high-strength hot-rolled structural steel and its manufacturing method

The invention discloses a kind of 600Mpa-grade high-strength hot continuous rolling structural steel and a manufacturing method thereof. The structural steel comprises the following chemical compositions in percentage by weight: 0.14-0.24% of C, less than or equal to 0.50% of Si, 0.5-1.5% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.04-0.15% of Ti, 0.0005-0.003% of B, less than or equal to 0.05% of Al, and the balance of Fe and unavoidable impurities. According to the composition design, through molten-iron deep desulphurization, external refining, slab preparation by continuous casting, slab reheating, controlled rolling, controlled cooling, and rolling, the structural steel disclosed by the invention is obtained, the yield strength is greater than or equal to 600 MPa, the tensile strength is greater than or equal to 650 MPa, the percentage of elongation is greater than or equal to 16%, and the impact energy at the temperature of 20 DEG C is greater than or equal to 100J, and the structural steel has a good cold-bent forming performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Novel low-temperature environment-friendly friction-resistant B-and-Ge-containing aluminum alloy for hot dipping

InactiveCN108456809AReduce thicknessImprove table qualityHot-dipping/immersion processesAluminium alloySteel plates

The invention discloses novel low-temperature environment-friendly friction-resistant B-and-Ge-containing aluminum alloy for hot dipping. The aluminum alloy comprises, by weight percentage, 0.2-0.4% of K, 0.5-0.8% of V, 0.4-0.5% of Ge, 1.0-2.0% of Sr, 0.3-0.5% of Sc, 0.1-0.2% of Ce, 0.1-0.2% of B and the balance aluminum. By means of the aluminum alloy, the current situation that at present, the field of hot dipping aluminum alloy of China is lag in technology is changed; and by means of technological innovation and optimization design, the development bottleneck of the production technology and device for hot dipping aluminum-steel plates applied to high-end fields of China is broken through. In the near future, the material can be definitely applied to more fields more widely.

Owner:GUANGZHOU YUZHI TECH CO LTD

Hot-rolled steel material for automobile friction plate and preparation method thereof

ActiveCN105063492BMeet the manufacturing process conditionsExcellent cold forming performanceChemical compositionHardness

Owner:武汉钢铁有限公司

Novel corrosion-resistant low-reactivity Al-Ba-Er aluminum alloy for hot dipping

InactiveCN108456810AImprove bindingReduce thicknessHot-dipping/immersion processesAlcladCorrosion resistant

The invention discloses novel corrosion-resistant low-reactivity Al-Ba-Er aluminum alloy for hot dipping. The novel corrosion-resistant low-reactivity Al-Ba-Er aluminum alloy comprises, by weight percentage, 0.1-0.2% of Na, 0.4-0.6% of Nb, 0.2-0.3% of Ba, 1.0-2.0% of Ge, 0.2-0.3% of Y, 0.1-0.2% of Er, 0.1-0.2% of P and the balance aluminum. By means of the aluminum alloy, the current situation that at present, the field of hot dipping aluminum alloy of China is lag in technology is changed; and by means of technological innovation and optimization design, the development bottleneck of the production technology and device for hot dipping aluminum-steel plates applied to high-end fields of China is broken through. In the near future, the material can be definitely applied to more fields morewidely.

Owner:GUANGZHOU YUZHI TECH CO LTD

Cold-rolled hot-dip galvanized steel sheet for easy-open lid pull ring and production method thereof

ActiveCN106191682BExcellent cold forming performanceSimple production processHot-dipping/immersion processesChemical compositionSheet steel

The invention relates to a cold-rolled hot-dip galvanized steel sheet for an easy-open lid pull ring and a production method thereof, which mainly solves the low tensile strength and high production cost of the existing cold-roll hot-dip galvanized steel sheet for an easy-open lid pull ring question. A cold-rolled hot-dip galvanized steel sheet for an easy-open lid pull ring provided by the invention, the mass percentage of its chemical composition is: C: 0.025%-0.04%, Si: 0.005%-0.03%, Mn: 0.26%-0.35% , P≤0.015%, S≤0.013%, Alt: 0.03%~0.07%, B: 0.004%~0.005%, the balance is iron and unavoidable inclusions. The invention is mainly used for making the pull ring of the easy-open end.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com