1300MPa-grade hot continuous rolling ultrahigh-strength steel plate and manufacturing method thereof

A manufacturing method and hot continuous rolling technology, applied in manufacturing tools, heat treatment process control, heat treatment equipment and other directions, can solve the problems of high cost, large amount of alloy addition, long process flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

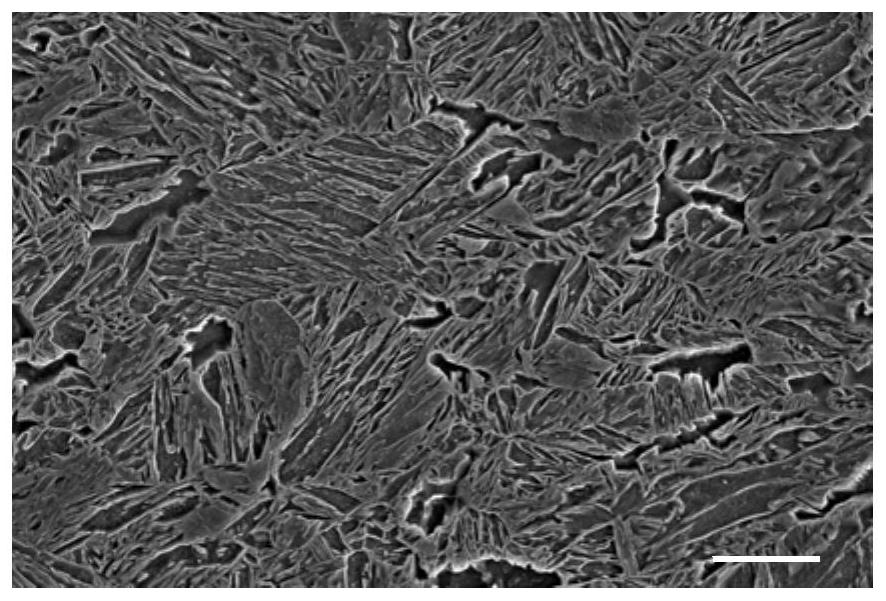

Image

Examples

Embodiment 1

[0058] A 1300MPa grade hot-rolled ultra-high-strength steel plate specifically includes the following chemical components in mass percentages:

[0059]C:0.17%;Si:1.15%;Mn:1.77%;P:0.010%;S:0.002%;Nb:0.028%,Ti:0.020%;Als:0.39%;B:0.0012%;H:0.00014%; N: 0.0025%; O: 0.0019%; the rest is Fe and inevitable inclusions.

[0060] The manufacturing method of the above-mentioned 1300MPa grade hot-rolled ultra-high-strength steel plate comprises the following steps:

[0061] 1) Hot metal pretreatment, converter smelting, alloy fine-tuning station, LF refining, RH refining: hot metal pretreatment requires pre-slagging and post-slagging, after hot metal desulfurization [S] = 0.0049%; refining adopts LF+RH dual process Control according to the chemical composition in the above formula, RH refining control deep degassing time is 15min and molten steel H content = 0.00014%;

[0062] 2) Continuous casting and heating: continuous casting adopts full protection pouring, adopts special medium-car...

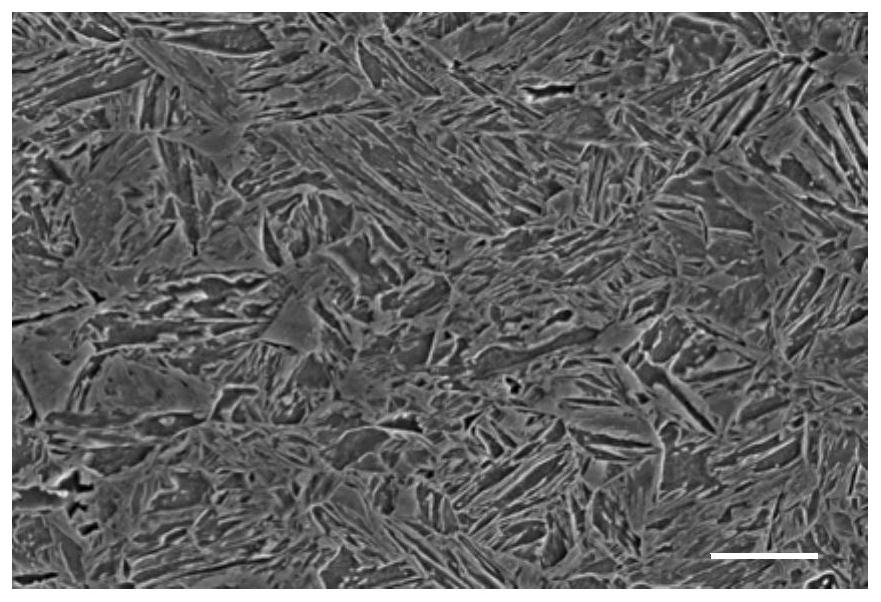

Embodiment 2

[0068] A 1300MPa grade hot-rolled ultra-high-strength steel plate, including the following chemical components in mass percentage: C: 0.16%; Si: 1.01%; Mn: 1.81%; P: 0.008%; S: 0.001%; Nb: 0.020%, Ti: 0.035%; Als: 0.45%; B: 0.0013%; H: 0.00012%; N: 0.0020%; O: 0.0016%; the rest is Fe and inevitable inclusions.

[0069] The manufacturing method of the above-mentioned 1300MPa grade hot rolling ultra-high-strength steel plate, the technological process is: molten iron pretreatment, converter smelting, alloy fine-tuning station, LF refining, RH refining, continuous casting, heating, rolling, direct quenching, coiling, leveling, Kaiping process, specifically:

[0070] 1) Hot metal pretreatment, converter smelting, alloy fine-tuning station, LF refining, RH refining: hot metal pretreatment requires pre-slagging and post-slagging, after hot metal desulfurization [S] = 0.0047%; refining adopts LF+RH dual process Control according to the chemical composition of the above formula, RH...

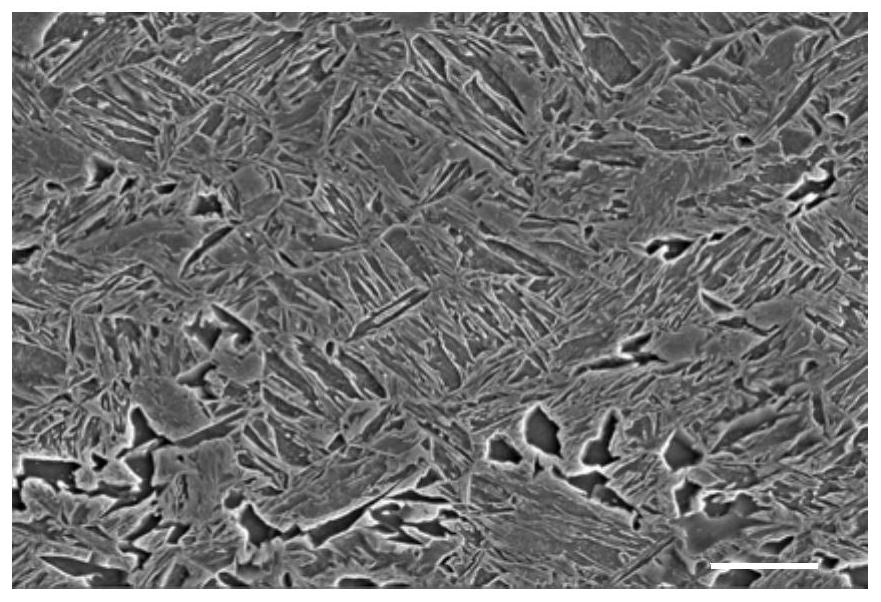

Embodiment 3

[0077] A 1300MPa grade hot-rolled ultra-high-strength steel plate, including the following chemical components in mass percentage: C: 0.18%; Si: 0.89%; Mn: 1.90%; P: 0.007%; S: 0.002%; Nb: 0.030%, Ti: 0.031%; Als: 0.40%; B: 0.0015%; H: 0.00013%; N: 0.0010%; O: 0.0019%; the rest is Fe and inevitable inclusions.

[0078] The manufacturing method of the above-mentioned 1300MPa grade hot rolling ultra-high-strength steel plate, the technological process is: molten iron pretreatment, converter smelting, alloy fine-tuning station, LF refining, RH refining, continuous casting, heating, rolling, direct quenching, coiling, leveling, Kaiping process, specifically:

[0079] 1) Hot metal pretreatment, converter smelting, alloy fine-tuning station, LF refining, RH refining: hot metal pretreatment requires pre-slagging and post-slagging, and [S]=0.0045% after hot metal desulfurization; refining adopts LF+RH dual process Control according to the chemical composition of the above formula, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com