Submerged-arc welding process for 485 MPa-grade thick weather-proof bridge steel

A submerged arc welding, thick gauge technology, applied in the field of steel material welding, can solve the problems of difficult to guarantee joint performance, difficult bridge steel welding, poor shock resistance, etc. The effect of matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

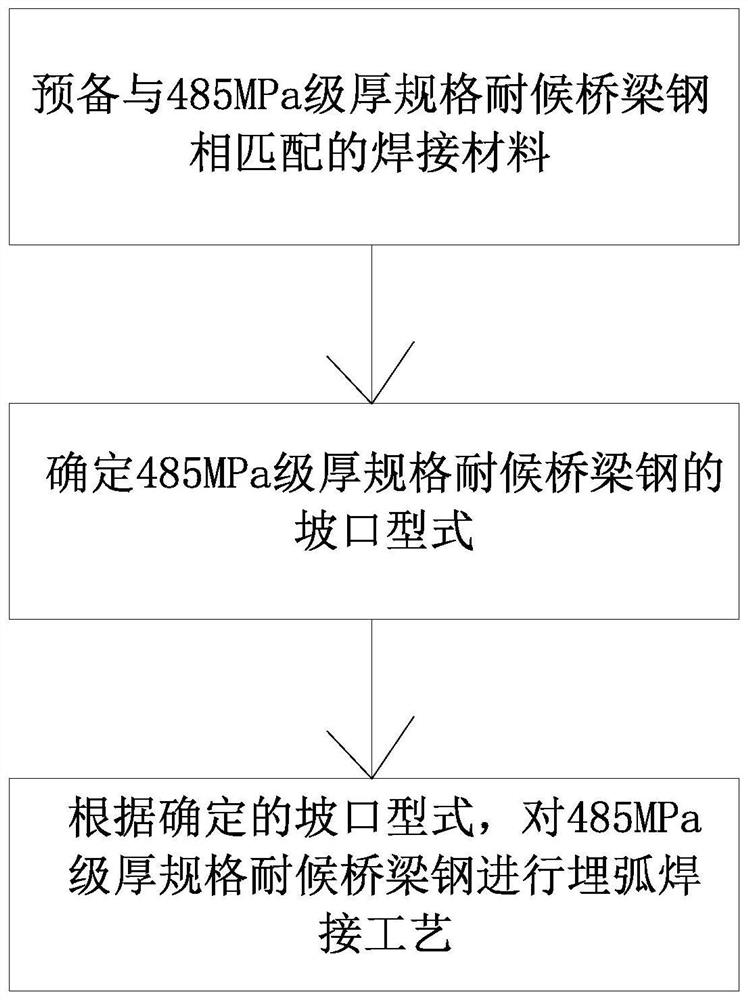

[0035] A submerged arc welding process of 485MPa grade thick specification weathering bridge steel includes the following steps:

[0036] (1) The 65mm thick bridge steel with excellent strength and toughness produced by thermomechanical controlled rolling (TMCP), the welding test plate combination is 65mm+65mm, and the test plate size is 800mm (length) × 200mm (width) × 65mm ( thick);

[0037] (2) Matching welding materials: The chemical composition and weight percentage of the welding wire are: C: 0.05-0.08%, Mn: 1.3-1.8%, Si: 0.1-0.3%, S: ≤ 0.005%, P: ≤ 0.020%, Ni: 0.4 to 0.8%, Cr: 0.4 to 0.8%, Cu: 0.2 to 0.5%, Alt: 0.02 to 0.04%, and the balance is Fe and inevitable impurities. Welding wire grade CHW-STH550III, diameter Φ4mm, tensile strength ≥620MPa, flux grade CHF101NQ;

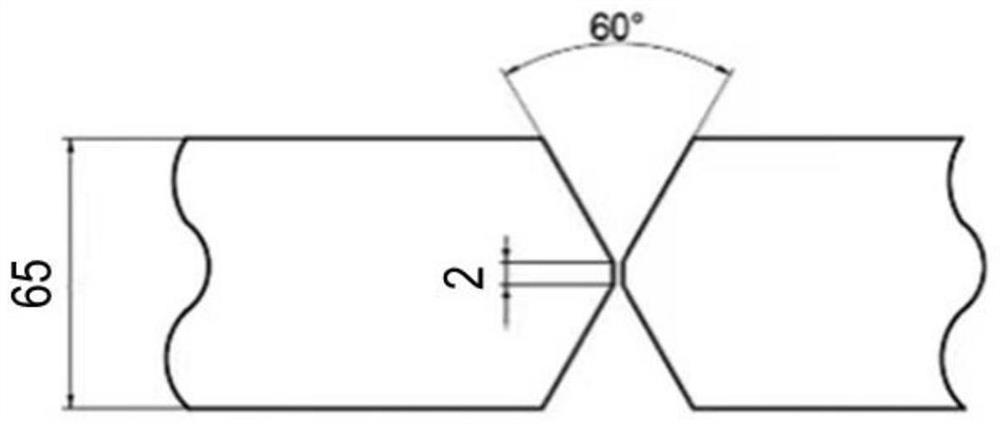

[0038] (3) Submerged arc welding groove: a symmetrical V-shaped groove is adopted, the angle of the front groove and the back groove are both 60°, and the root is left with a blunt edge of 2mm;

[003...

Embodiment 2

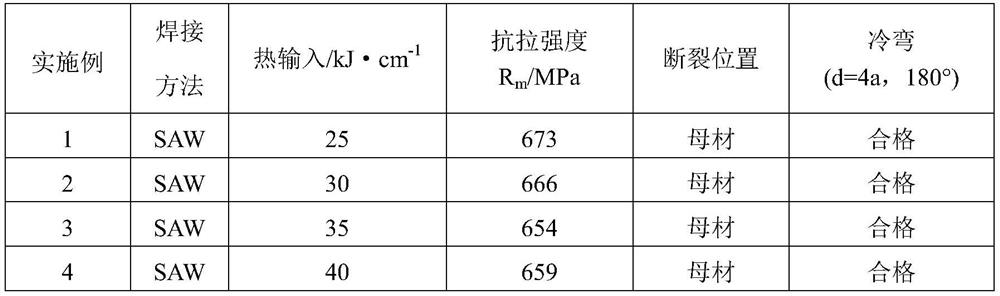

[0041] The welding process parameters of step (4) of Example 2: preheating temperature before welding is 70-90° C., submerged arc flux is treated at 150-200° C. × 2h, bottoming welding current is 400-410A, arc voltage is 28-30V, and welding is performed. The speed is 450~453mm / min, the heat input of bottom welding is 15~16kJ / cm; the welding current of filling is 545~555A, the arc voltage is 32~34V, the welding speed is 350~353mm / min, and the heat input of filling welding is 30~32kJ / cm. The butt joints of composite steel plates with a thickness of 65mm+65mm are welded by multi-layer multi-pass submerged arc welding and the interlayer temperature of the welding seam is controlled to be 80-120 °C.

Embodiment 3

[0042] The welding process parameters of step (4) of Example 3: preheating temperature before welding is 70-90° C., submerged arc flux is treated at 150-200° C. × 2h, bottoming welding current is 400-410A, arc voltage is 28-30V, and welding is performed. The speed is 450~453mm / min, the heat input of bottom welding is 15~16kJ / cm; the welding current of filling is 600~610A, the arc voltage is 34~36V, the welding speed is 350~353mm / min, and the heat input of filling welding is 35~37kJ / cm. The butt joints of composite steel plates with a thickness of 65mm+65mm are welded by multi-layer multi-pass submerged arc welding and the interlayer temperature of the welding seam is controlled to be 80-120 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com