08Ni3DR steel plate capable of resisting hydrogen-induced cracks and manufacturing method of 08Ni3DR steel plate

A technology of anti-hydrogen-induced cracking and manufacturing method, applied in the field of 08Ni3DR steel plate, to achieve the effects of reducing carbon emissions, improving HIC crack resistance, and reducing HIC sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

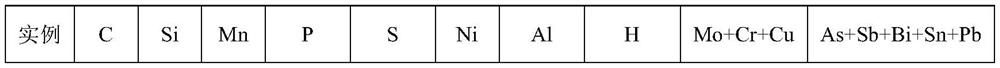

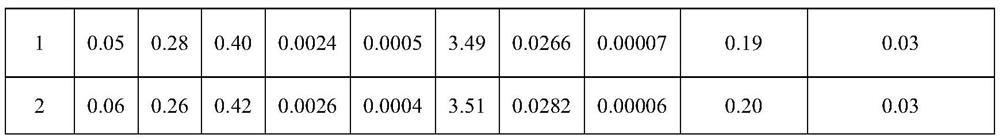

Examples

Embodiment 1

[0040] The thickness of the steel plate involved in Example 1 is 65 mm.

[0041] The production process of 65mm thick steel plate is as follows:

[0042] According to the chemical composition of the above-mentioned steel plate, the raw materials for smelting are arranged in order to carry out KR molten iron pretreatment-converter smelting-LF refining-RH refining-Ca treatment-370mm continuous casting-continuous casting slab with cover and slow cooling-continuous casting slab cleaning-continuous casting slab heating- Insulation treatment - high pressure water descaling - controlled rolling - straightening - heat treatment.

[0043] The high-temperature slab exiting the continuous casting machine is slowly cooled by covering and stacking. The temperature of entering the hood is not lower than 800°C, the slow cooling time is not less than 72h, and the temperature of the exiting hood is 150±20°C. The purpose of this slow cooling step is to reduce the temperature in the steel H con...

Embodiment 2

[0048] The thickness of the steel plate involved in Example 2 is 50 mm.

[0049] The production process of 50mm thick steel plate is as follows:

[0050] According to the chemical composition of the above-mentioned steel plate, the raw materials for smelting are arranged in order to carry out KR molten iron pretreatment-converter smelting-LF refining-RH refining-Ca treatment-370mm continuous casting-continuous casting slab with cover and slow cooling-continuous casting slab cleaning-continuous casting slab heating- Insulation treatment - high pressure water descaling - controlled rolling - straightening - heat treatment.

[0051] The high-temperature slab exiting the continuous casting machine is slowly cooled by covering and stacking. The temperature of entering the hood is not lower than 800°C, the slow cooling time is not less than 72h, and the temperature of the exiting hood is 150±20°C. The purpose of this slow cooling step is to reduce the temperature in the steel H con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com