1200MPa-grade hot-rolled high-strength dual-phase steel plate and manufacturing method thereof

A manufacturing method and high-strength technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of high castability of molten steel and achieve good formability, low yield ratio, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described below through specific examples.

[0030] According to the present invention, the weight percent content of chemical components is C: 0.10-0.18%; Si: 0.80-1.50%; Mn: 1.50-2.20%; P: ≤0.015%; S: ≤0.008%; Cr: 0.40-0.80% ; Nb: 0.010-0.050%, Ti: 0.010-0.040%; Als: 0.020-0.060%; the rest is Fe and unavoidable inclusions; the manufacturing method of 1200MPa grade hot-rolled high-strength dual-phase steel plate of the present invention, the production process includes converter smelting , refining, continuous casting, heating, rolling, cooling and coiling processes.

[0031] Such as figure 1 As shown, the microstructure of the hot-rolled steel plate produced by the present invention is ferrite+martensite, wherein the volume fraction of ferrite is 20-30%, and the volume fraction of martensite is 70-80%.

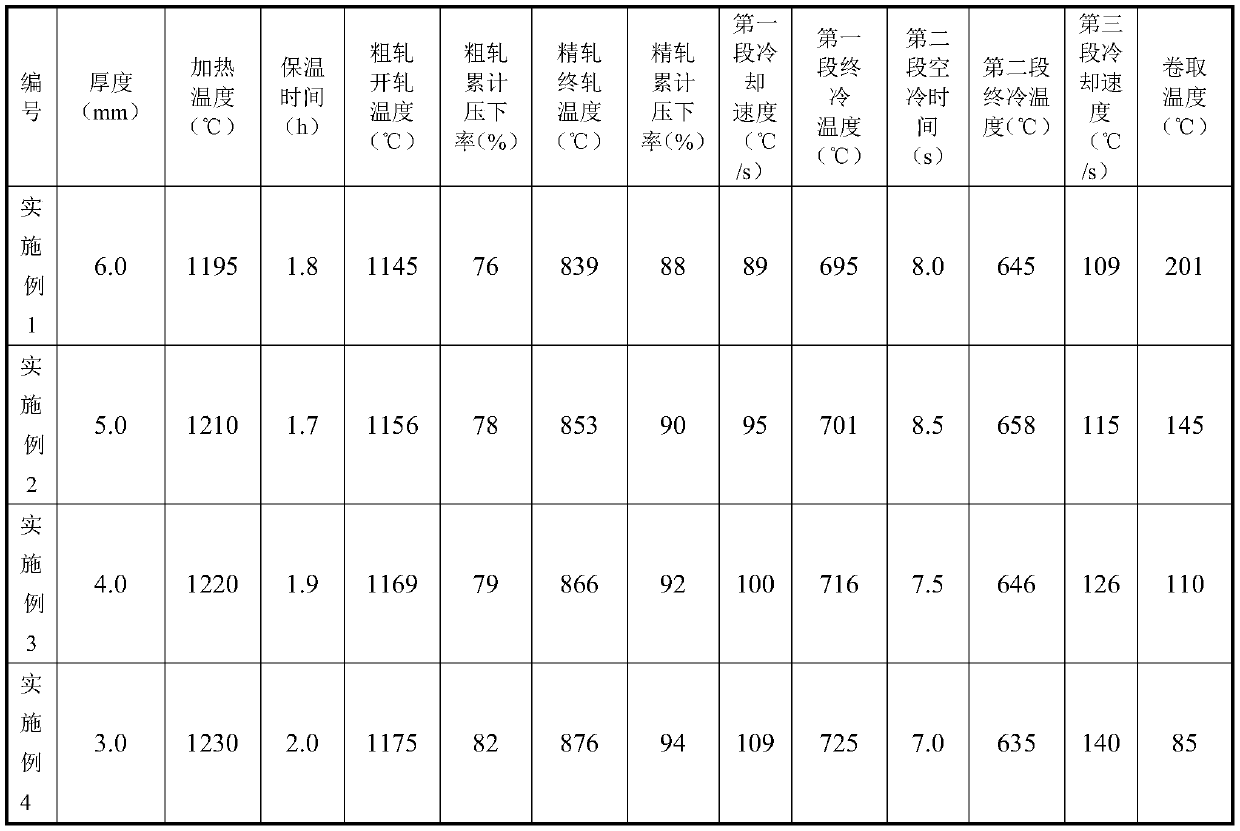

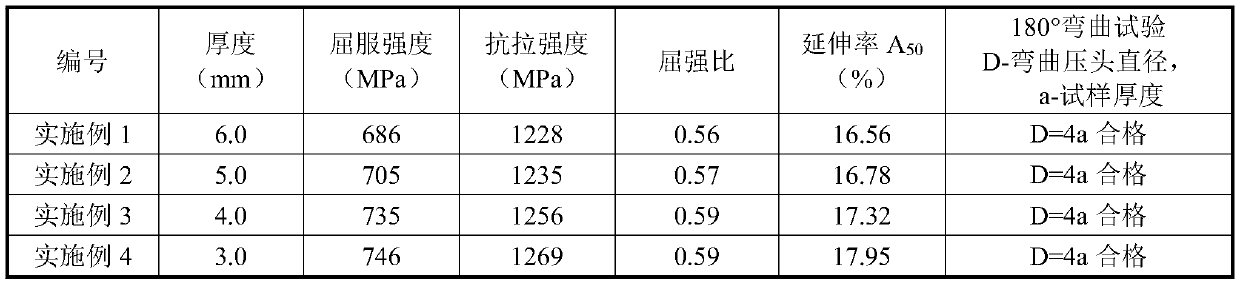

[0032]The chemical composition of the examples is shown in Table 1, the rolling process parameters are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com