700MPa-grade high-strength weather-resistant steel plate resistant to atmospheric corrosion and production method thereof

A technology of atmospheric corrosion resistance and production method, which is applied in the field of high-strength weather-resistant steel, can solve problems such as difficult production, and achieve the effects of reducing manufacturing costs, improving yield, and good atmospheric corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

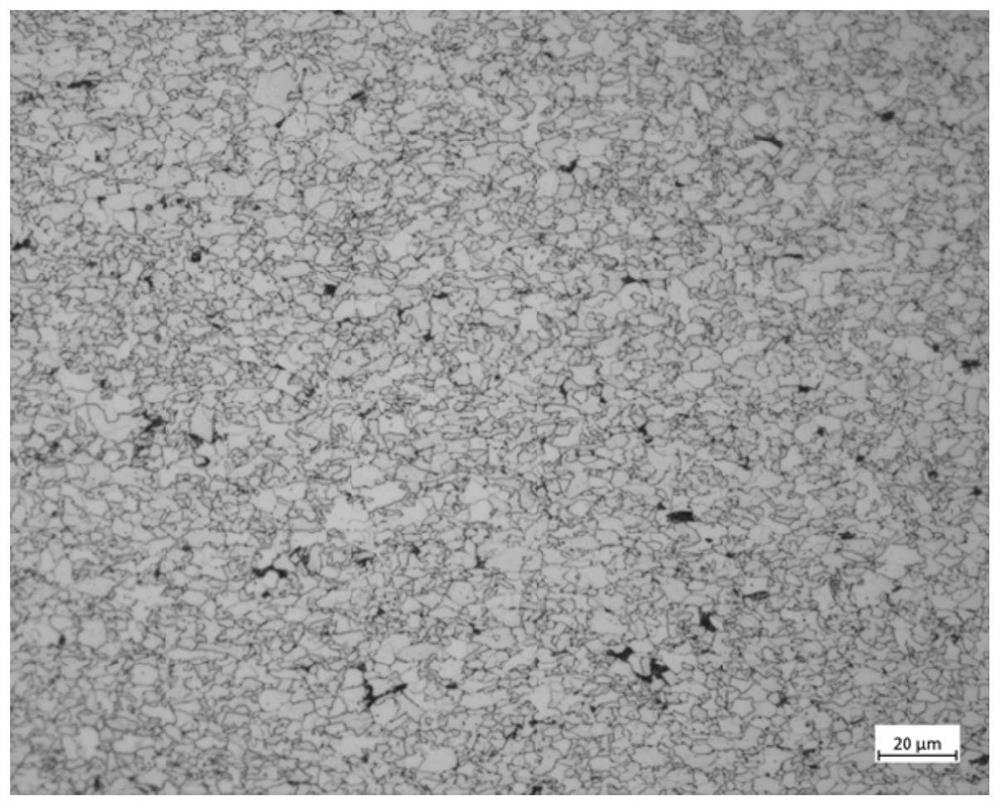

[0045] The main chemical composition and mass percentage content of a kind of atmospheric corrosion-resistant 700MPa high-strength weather-resistant steel plate of the present invention are shown in Table 1:

[0046] The chemical composition and weight percent (mass percent % of each embodiment of table 1 and comparative example, balance is Fe and unavoidable impurity)

[0047]

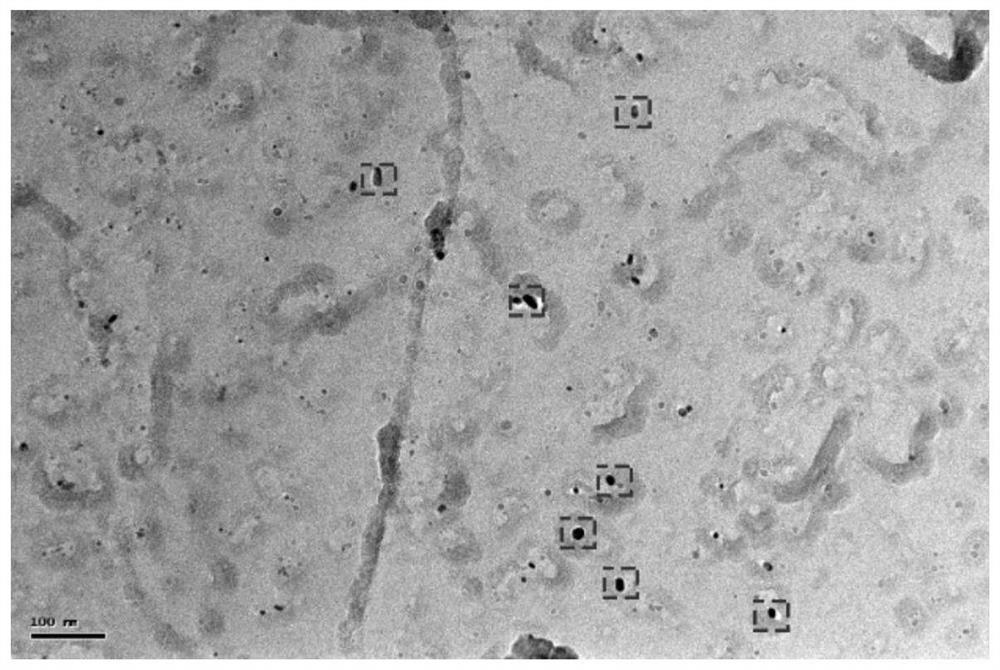

[0048] The composition of chemical elements in the above examples meets the following requirements: C: 0.06%-0.09%, Si: 0.30%-0.50%, Mn: 1.10%-1.50%, P: 0.010%-0.015%, S: ≤0.005%, Cr: 0.60%~1.00%, Ni: 0.03%~0.07%, Cu: 0.25%~0.40%, Als: 0.020%~0.045%, Ti: 0.100%~0.140%, N≤0.0040%, O≤0.0035%, The rest is Fe and unavoidable impurity elements.

[0049] The specific effect of the element composition in the above scheme in this application is as follows:

[0050] C (carbon): C is the most economical element to increase the strength of steel, but too high a content of C will deteriorate the weldability of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com