Niobium-titanium microalloyed acid medium corrosion-resistant steel plate with yield strength of 600MPa and production method thereof

A technology of microalloying and yield strength, which is applied in the field of steel materials and its manufacturing, can solve the problems of low strength and high manufacturing cost of acid-resistant steel, and achieve excellent strength and toughness matching, good atmospheric corrosion resistance, and good acid medium corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

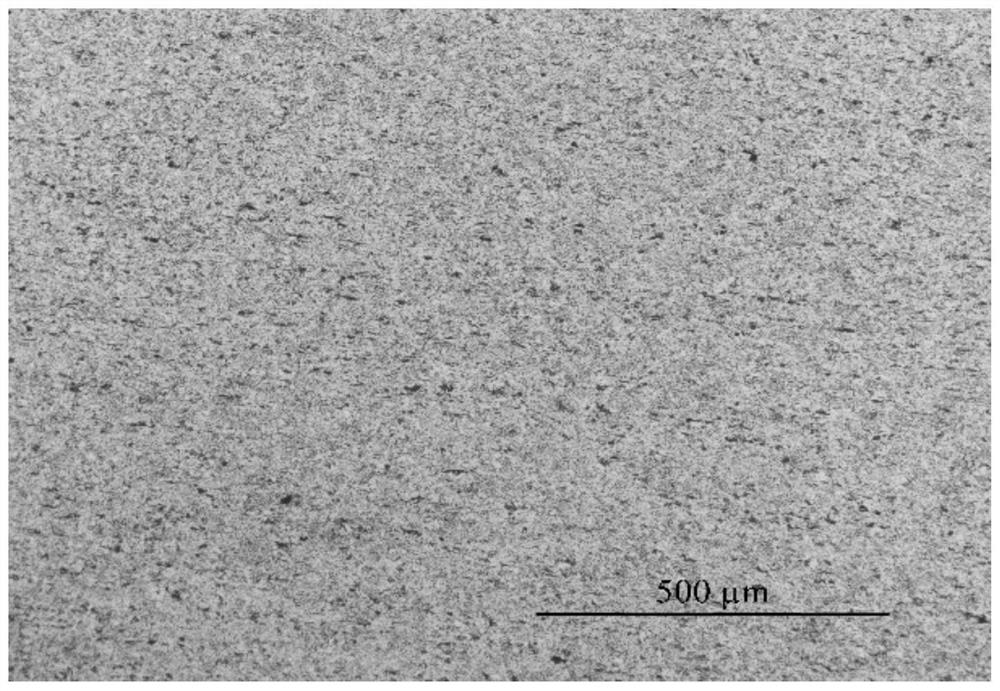

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below through specific examples.

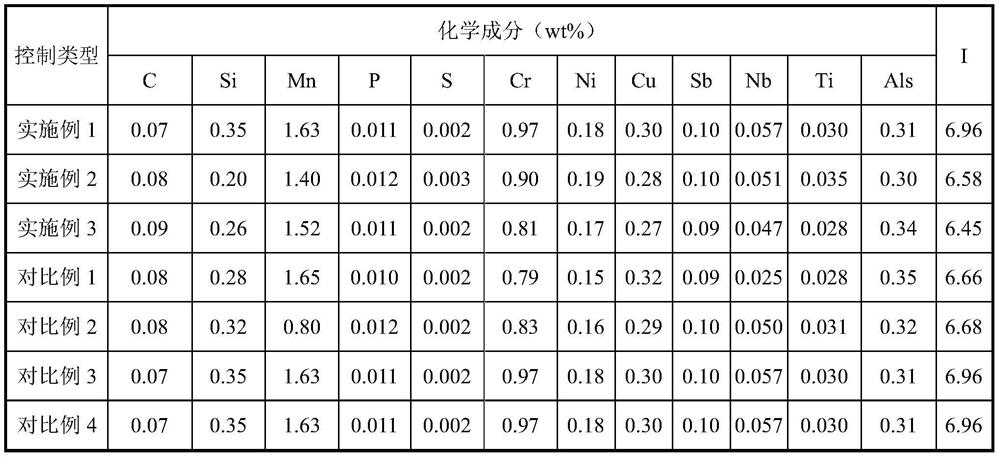

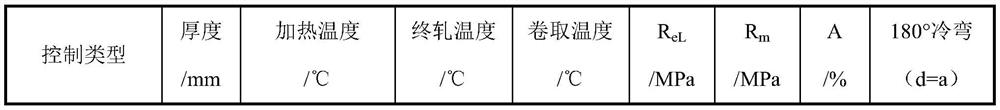

[0026] According to the chemical composition requirements provided by the present invention, molten iron pretreatment→converter steelmaking→LF refining→continuous casting process is adopted for smelting. Take wherein 3 furnace steels as 3 embodiments of the present invention. After refining outside the LF furnace, the chemical composition in the steel meets the weight percentage (wt%): C: 0.06-0.10%; Si: 0.20%-0.40%; Mn: 1.30-1.70%; P: ≤0.015%; S: ≤ 0.005%; Cr: 0.70-1.00%; Ni: 0.10-0.20%; Cu: 0.25-0.30%; Nb: 0.045-0.060%; Ti: 0.025-0.045%; Sb: 0.08-0.10%; %; the balance is Fe and unavoidable inclusions.

[0027] The chemical composition of each embodiment of the present invention is as shown in table 1, and weather resistance index I>6.0, I=26.01(%Cu)+3.88(%Ni)+1.20(%Cr)+1.49(%Si)+17.28(%P )-7.29(%Cu)×(%Ni)-9.10(%Ni)×(%P)-33.39(%Cu) 2 . Composition detectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com