Patents

Literature

30results about How to "Obvious refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

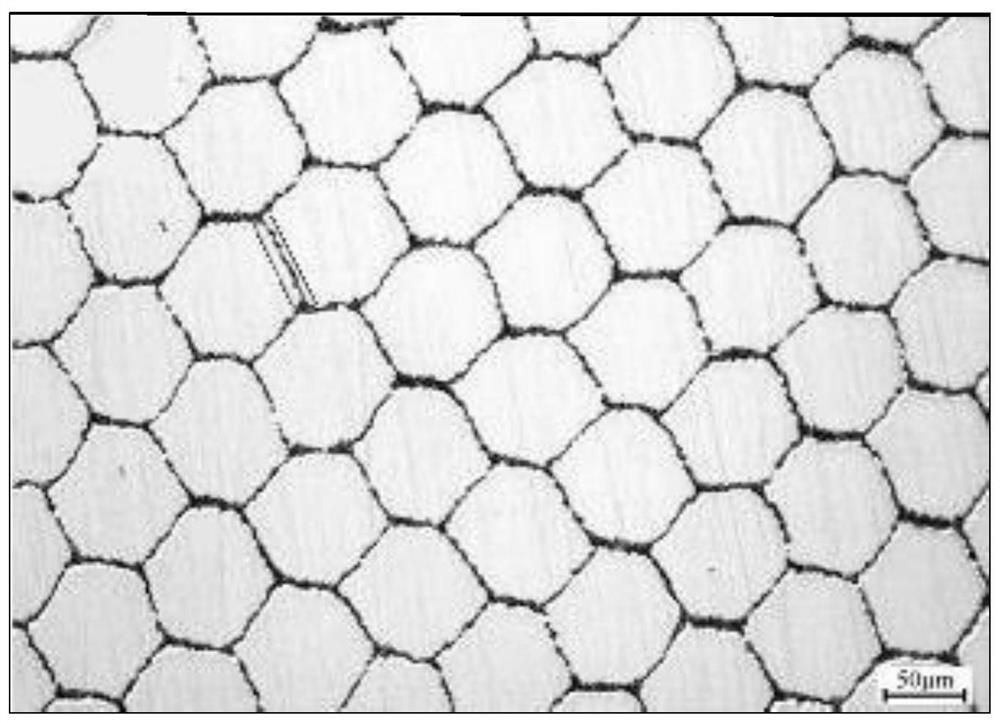

Process for producing V-N micro alloy high strength steel band using thin plate blank continuously casting and continuously rolling technology

InactiveCN1748883ASpeed up coolingInhibit growthMetal rolling arrangementsMaterials scienceSteel plates

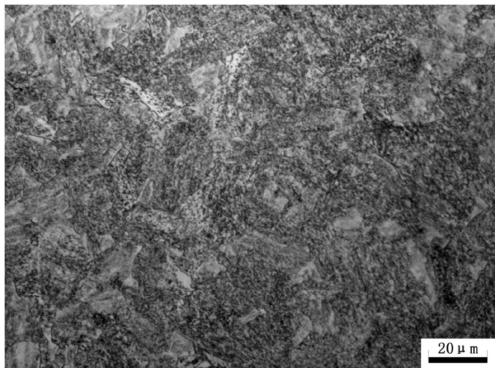

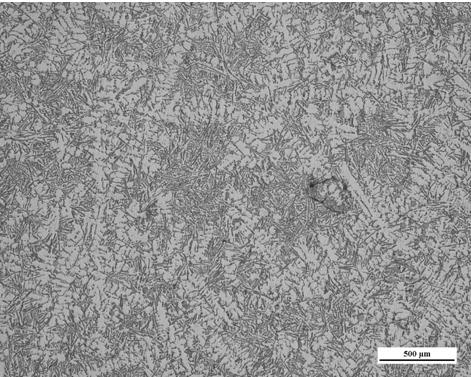

The continuous thin plate blank casting and rolling process for producing high strength V-N micro alloy steel belt includes smelting and refining in electric furnace or converter, continuous casting, heating after solidification inside bottom heating furnace, hot rolling, laminated flow cooling and winding. The continuous thin plate blank casting and rolling process has the technological parameters of: furnace entering temperature of cast blank 900-1050 deg c, homogeneous heating temperature 1050-1250 deg c, initially rolling temperature 1000-1170 deg c, finally rolling temperature 840-950 deg c and winding temperature 530-670 deg c. The molten steel contains: C 0.03-0.08 wt%, Si 0.01-0.8 wt%, Mn 0.1-2.0 wt%, V 0.01-0.20 wt%, Al 0.01-0.06 wt% and N 0.002-0.03 wt%. The produced high strength and fine grain steel belt and plate has ferrite grain size smaller than 6.0 micron, yield strength of 420-700 MPa, and excellent toughness, welding performance and forming performance.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

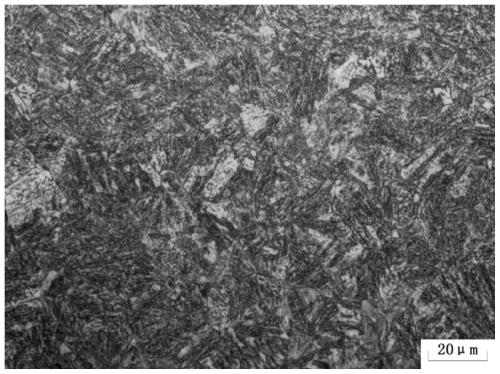

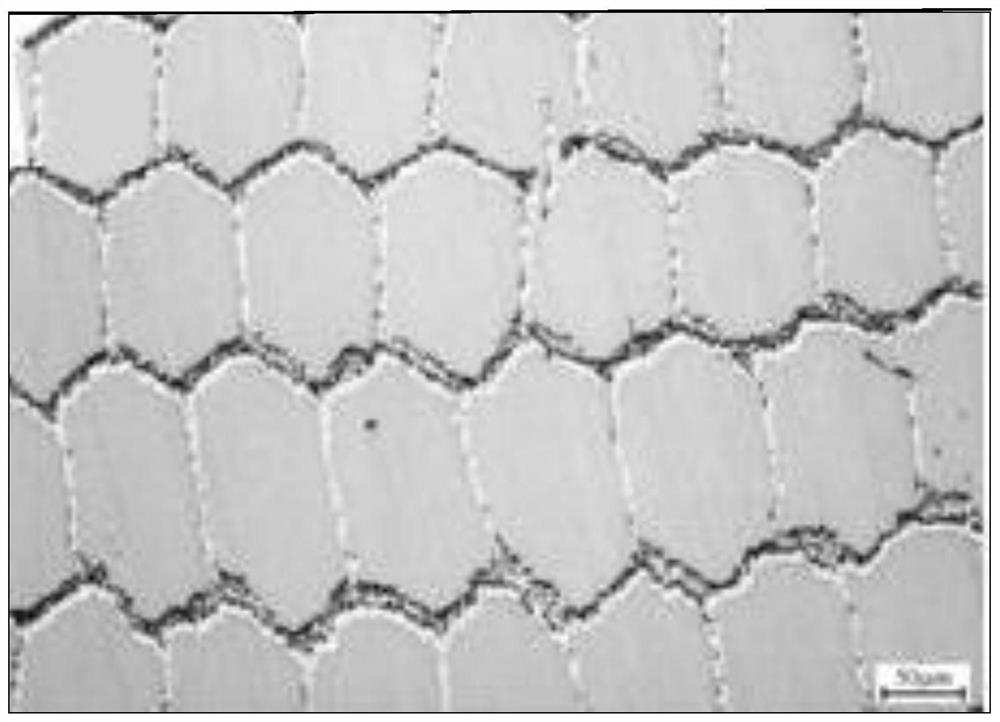

Ti-V composite microalloying superfine bainite non-quenched and tempered steel, and controlled forging and controlled cooling process and production process thereof

The invention discloses Ti-V composite microalloying superfine bainite non-quenched and tempered steel and a controlled forging and controlled cooling process and a production process thereof. The Ti-V composite microalloying superfine bainite non-quenched and tempered steel comprises following chemical components: by weight, 0.20-0.30% of C, 0.20-0.40% of Si, 1.90-2.10% of Mn, less than or equalto 0.010% of P, 0.030-0.050% of S, 0.40-0.60% of Cr, 0.10-0.20% of V, 0.030-0.050% of Ti, less than or equal to 0.20% of Ni, less than or equal to 0.20% of Mo, 0.015-0.045% of Al, less than or equal to 0.0070% of N, and the balance Fe and inevitable impurity elements; and moreover, Ti-3.43*N is greater than or equal to 0.017%, and Ti*N is less than or equal to 0.00016%. Compared with common bainite non-quenched and tempered steel, the Ti-V composite microalloying superfine bainite non-quenched and tempered steel has the advantages that the bainite structure is refined obviously, the similar tempered sorbite structure is obtained, and the strength and toughness are substantially improved through the high-Ti alloying design and V-N microalloying.

Owner:MAANSHAN IRON & STEEL CO LTD

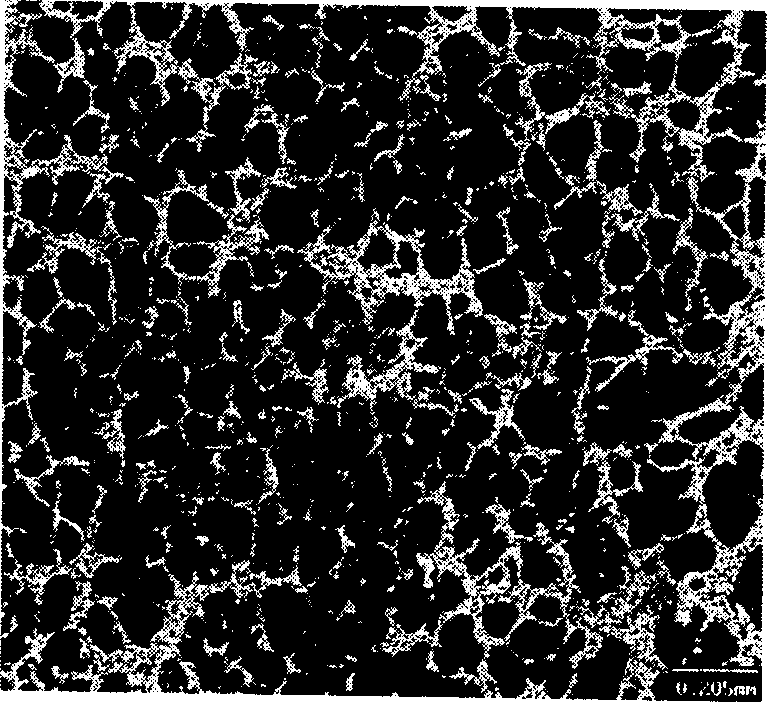

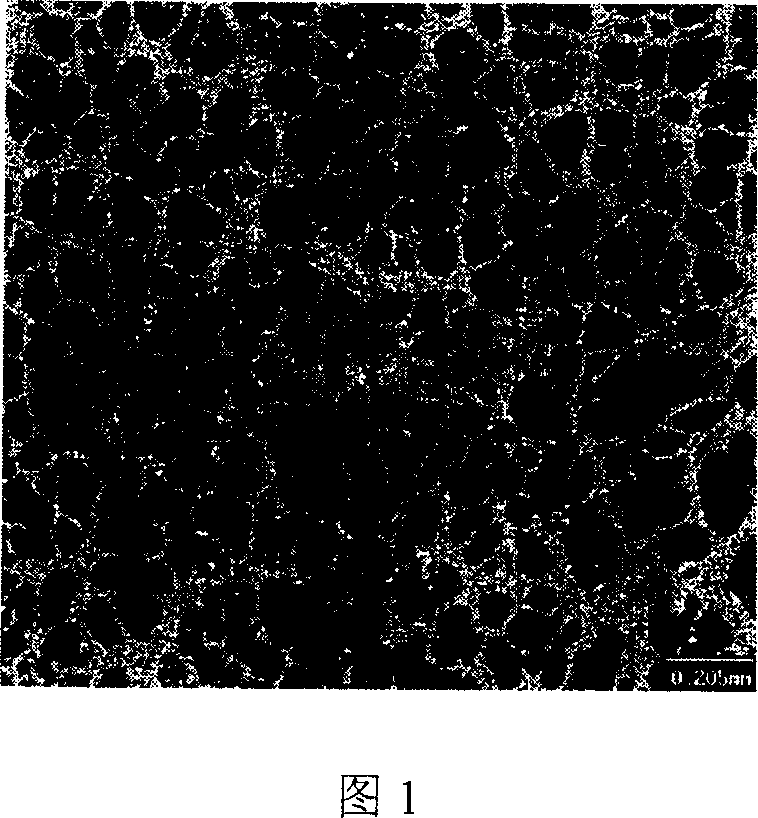

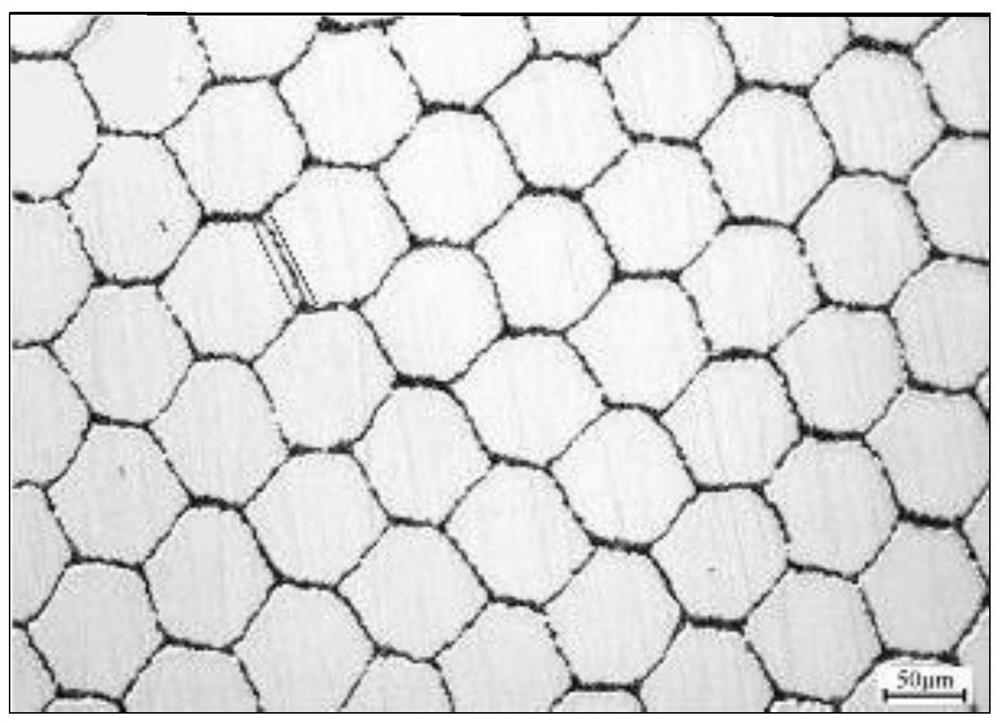

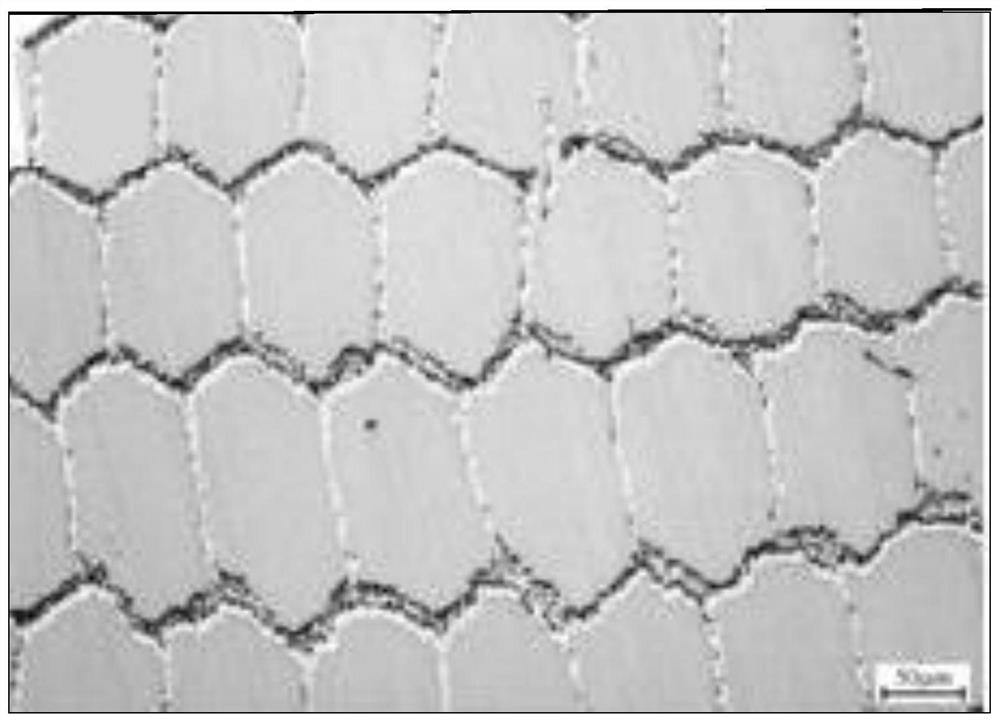

Fast production of subsphaeroidal crystal tissue semi-solid aluminium alloy

A prepared method of semi-solid spherocrystal A-alloy is to treating the alloy fusant by the process of 'refining after metamorphism' or 'metamorphism after refining'; preparing the semi-solid by the reversible electromagnetic stirring; monitoring the temperature while stirring until the temperature is under the liquid phase 3-5 Deg C., then cooling and geting the product. The efficient of the process has been improved more greatly than the traditional one, and the alloy has been more available crystal nucleus.

Owner:TSINGHUA UNIV

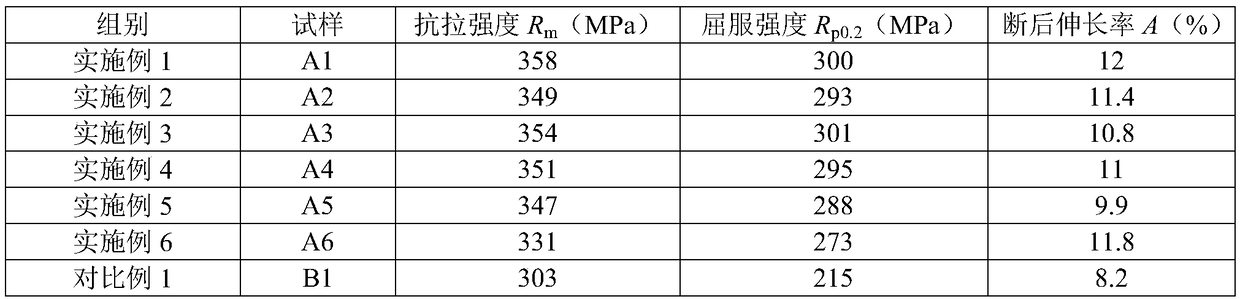

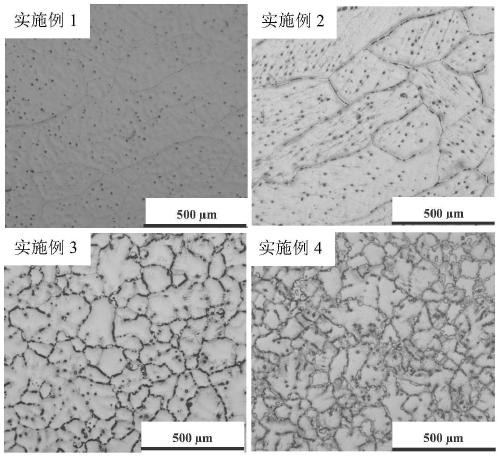

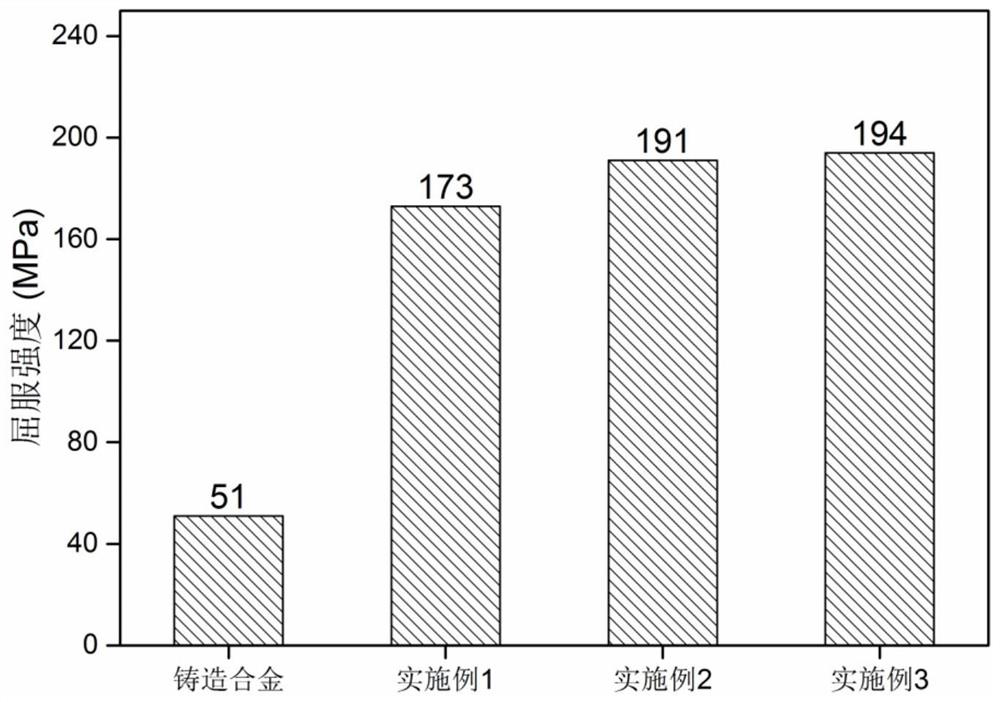

Process capable of improving mechanical properties of A356.2 aluminum alloy

The invention discloses a process capable of improving the mechanical properties of an A356.2 aluminum alloy. The process comprises following main steps: a melt combined modification-refinement treatment after alloy melting, casting, solid solution, and a double stage aging heat treatment. Specifically, the process comprises following steps: (1) heating and melting A356.2 aluminum alloy, and adding a refining agent and a modifying agent to process the melt; (2) removing gas from the alloy melt, refining the alloy melt, allowing the alloy melt to stand still, removing the slag, and carrying outcasting to obtain a casting; (3) maintaining the temperature of the casting in a range of 530 to 550 DEG C for 4 to 8 hours, and carrying out quenching by using water with a temperature of 20 to 80 DEG C; and (4) maintaining the temperature of the casting in a range of 100 to 120 DEG C for 0.5 to 2 hours, then maintaining the temperature of the casting in a range of 165 to 185 DEG C for 2 to 6 hours, taking out the casting out of a furnace, and cooling the casting in the air. After processing, the mechanical properties of the A356.2 aluminum alloy are obviously enhanced, the yield strength isimproved by 40 to 50%, and the elongation rate is increased by 20 to 40%.

Owner:SHANDONG HUAYU ALUMINUM & POWER +1

Method for producing nano alloy cast iron grinding balls by using nano material

The invention discloses a method for producing nano alloy cast iron grinding balls by using a nano material, which comprises the following steps of: adding nano boron carbide into smelted alloy cast iron solution according to a mass ratio of (0.5-2):10,000; and fully mixing the nano boron carbide and the iron solution, and casting to obtain the high-hardness and compact-texture nano alloy cast iron grinding balls. Nano particles are taken as an additive and can become nuclei in the alloy iron solution, so the produced grinding balls have better wear resistance.

Owner:TONGLING MINGCHENG FOUNDRY

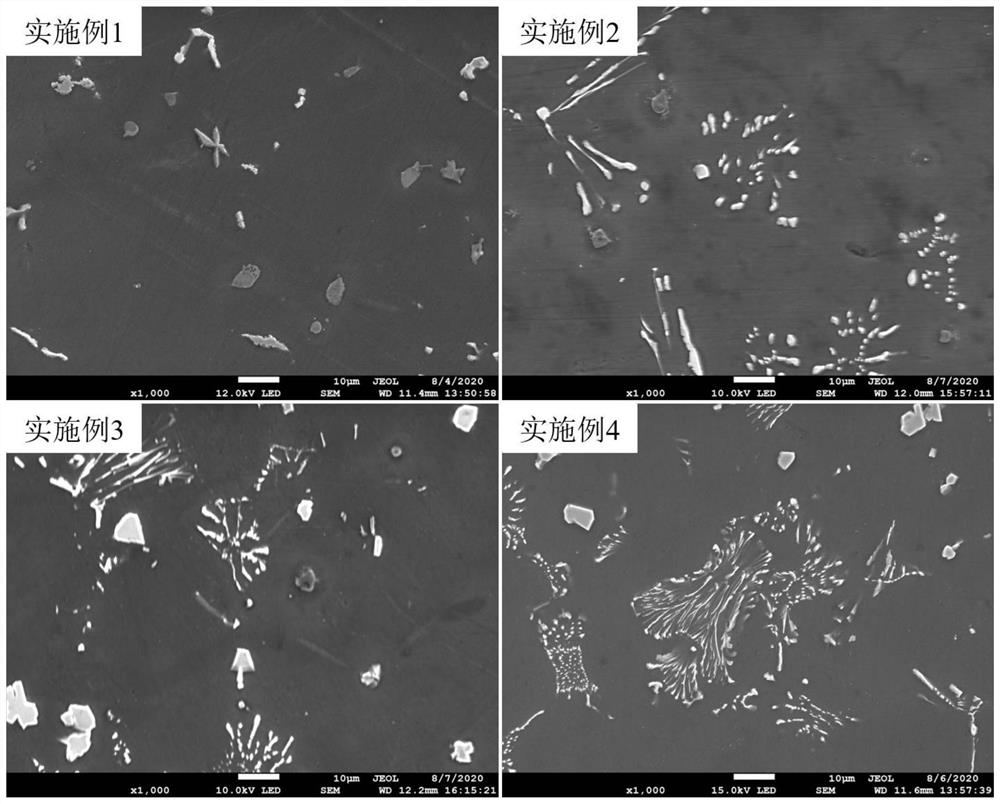

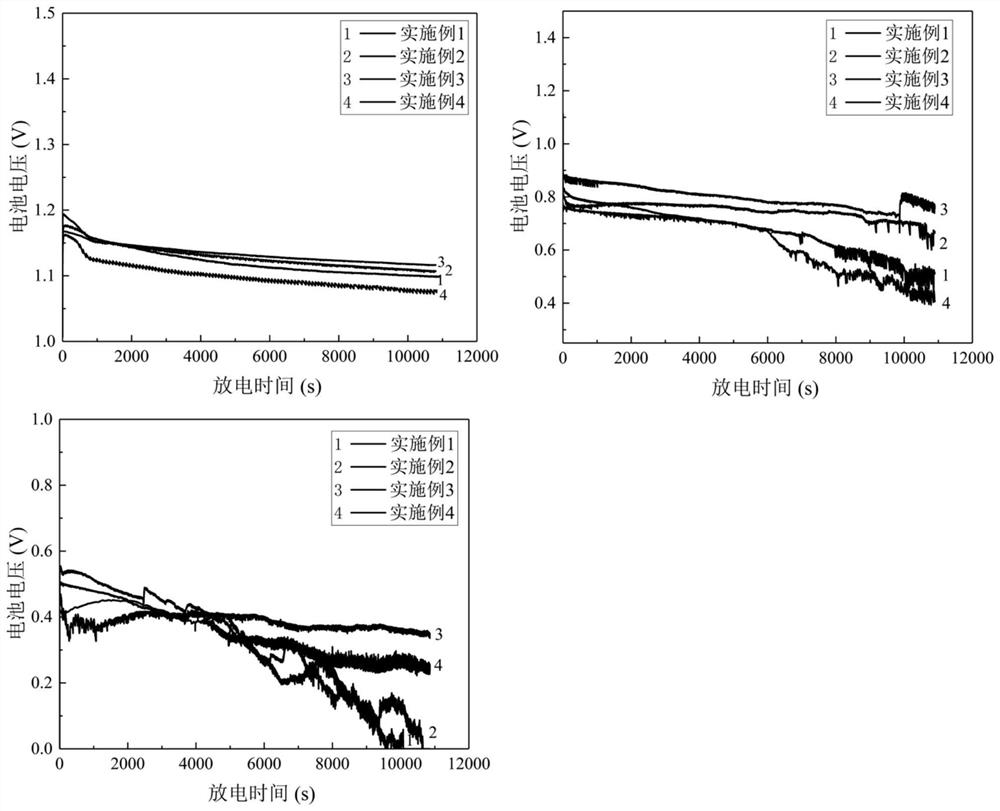

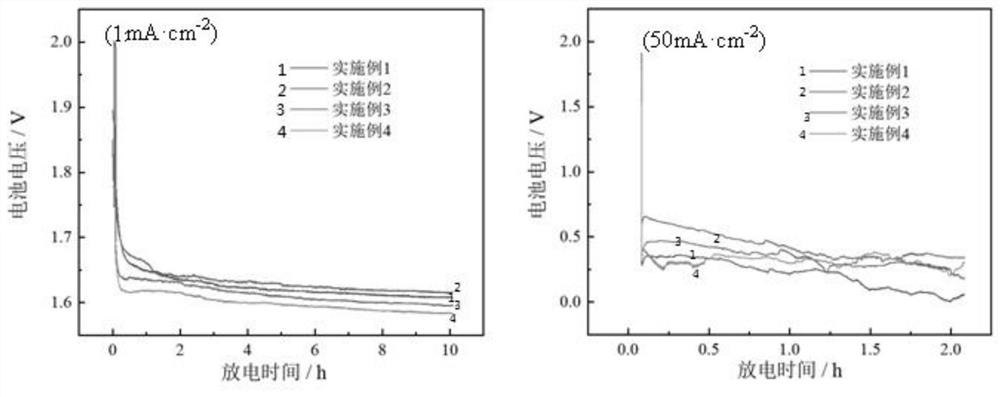

Magnesium-air battery cathode material and preparation method thereof

ActiveCN111455248ASlow dehydrogenation reactionOptimize the discharge processFuel and secondary cellsCell electrodesMetal anodeMetallurgy

The invention discloses a magnesium-air battery cathode material and a preparation method thereof, and relates to the technical field of magnesium-air batteries. The magnesium-air battery cathode material comprises the following components in percentages by weight: 1.0-5.0wt% of Zn, 0.1-2.0wt% of Ca and the balance of magnesium. The preparation method comprises the following steps: (1) weighing pure magnesium, pure zinc and Mg-Ca intermediate alloy according to 1.0-5.0wt% of Zn, 0.1-2.0wt% of Ca and the balance of magnesium, and removing oxide skin on the surface; (2) placing an alloy treatedin the step (1) in a crucible to be preheated, and sequentially placing the alloy in the crucible to be melted; and (3) casting molten liquid in the step (2) in a metal mold at a proper temperature for cooling. According to the preparation method, a hydrogen evolution reaction of a metal cathode in an NaCl neutral solution is relieved, the discharging process is optimized at the forming position of the second phase of dotted Ca2Mg6Zn3, the stacking thickness of a discharging product on the surface of the cathode is reduced, and product falling is accelerated.

Owner:BEIJING UNIV OF TECH

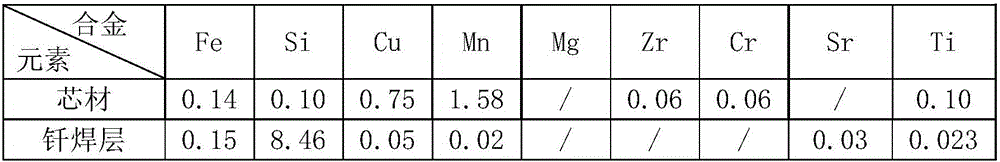

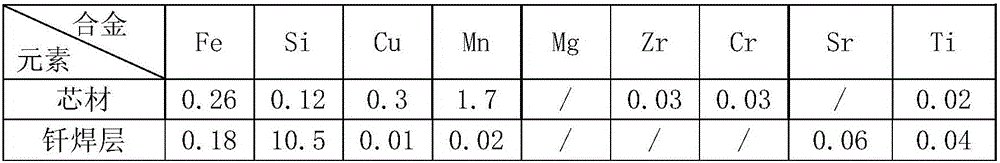

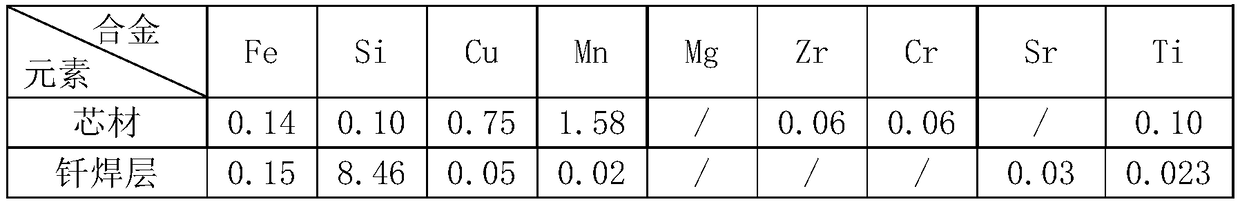

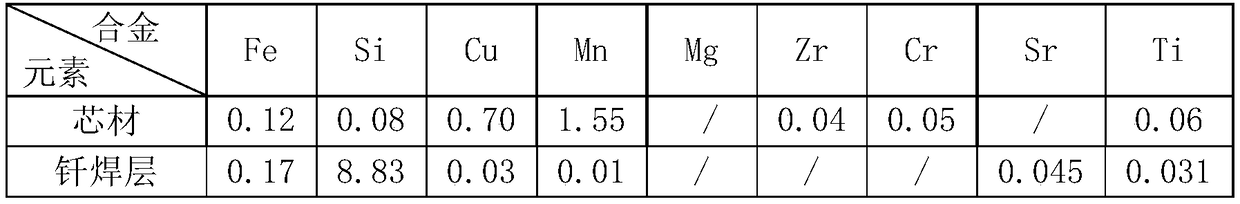

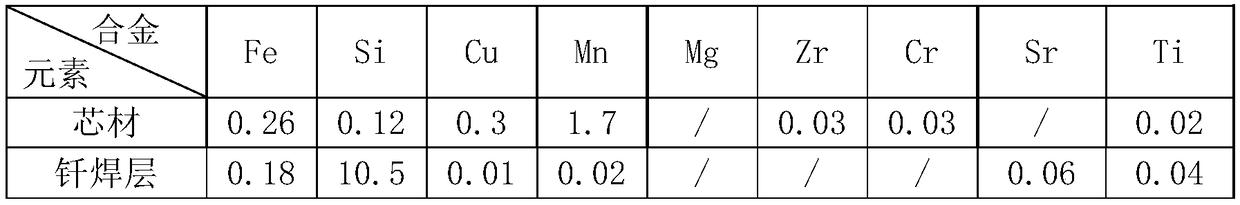

Ultrahigh-strength aluminum alloy composite strip for automobile water tank radiator and manufacturing method for ultrahigh-strength aluminum alloy composite strip

The invention discloses an ultrahigh-strength aluminum alloy composite strip for an automobile water tank radiator and a manufacturing method for the ultrahigh-strength aluminum alloy composite strip. The composite strip is composed of a core material and a single-sided or double-sided braze welding layer, wherein the thickness of the welding layer on each surface accounts for 5-10% of the total thickness; the core material consists of the following components in percentage by weight: 0.12-0.26% of Fe, less than or equal to 0.12% of Si, 0.30-0.80% of Cu, 1.5-1.8% of Mn, less than or equal to 0.04% of Mg, 0.02-0.15% of Cr, 0.02-0.15% of Zr, 0.02-0.15% of Ti, less than or equal to 0.03% of each of other elements, less than or equal to 0.15% of contents of all other elements, and the balance of aluminum; the welding layer is made of an aluminum-silicon alloy which consists of the following components in percentage by weight: less than or equal to 0.20% of Fe, 8.0-11.0% of Si, less than or equal to 0.10% of Cu, less than or equal to 0.05% of Mn, 0.03-0.06% of Sr, less than or equal to 0.05% of Ti, less than or equal to 0.03% of each of other elements, less than or equal to 0.15% of all other elements, and the balance of aluminum. The ultrahigh-strength aluminum alloy composite strip has very excellent mechanical property after braze welding, and has yield strength which exceeds 70 MPa after braze welding.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

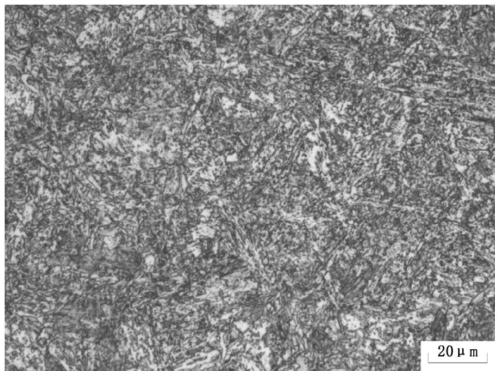

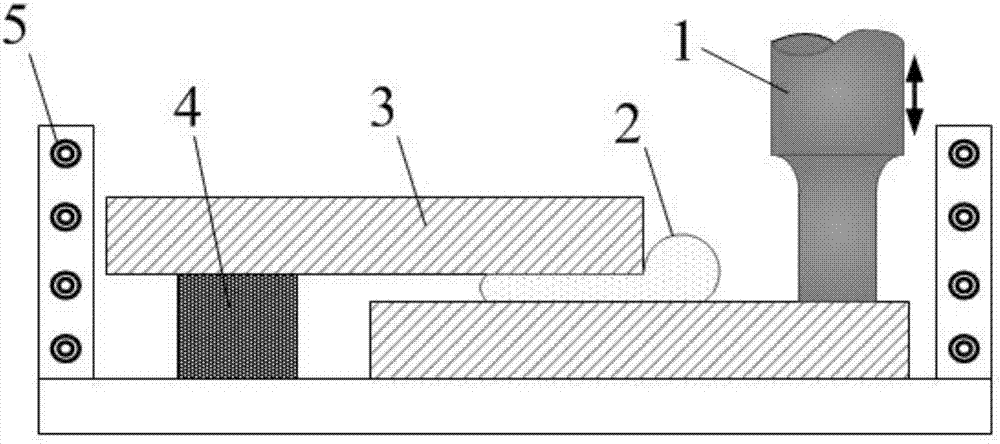

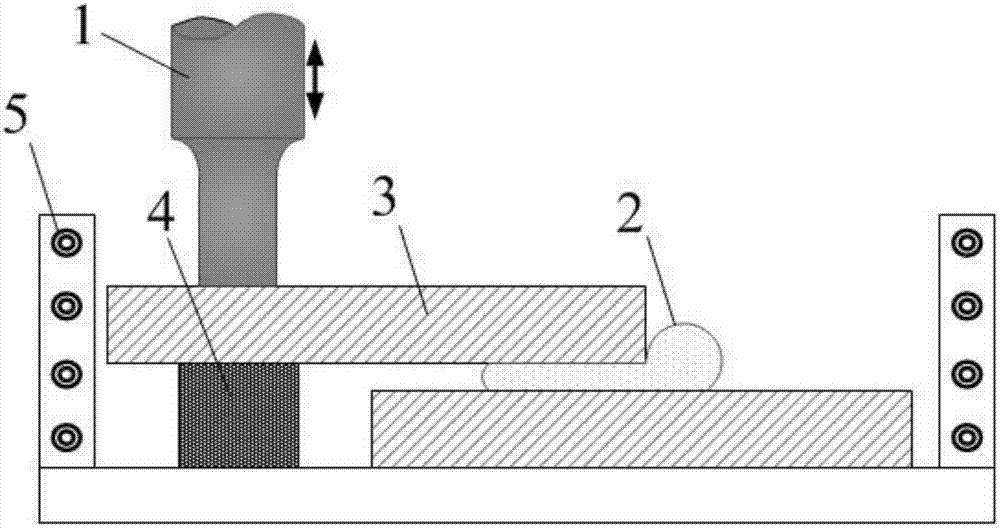

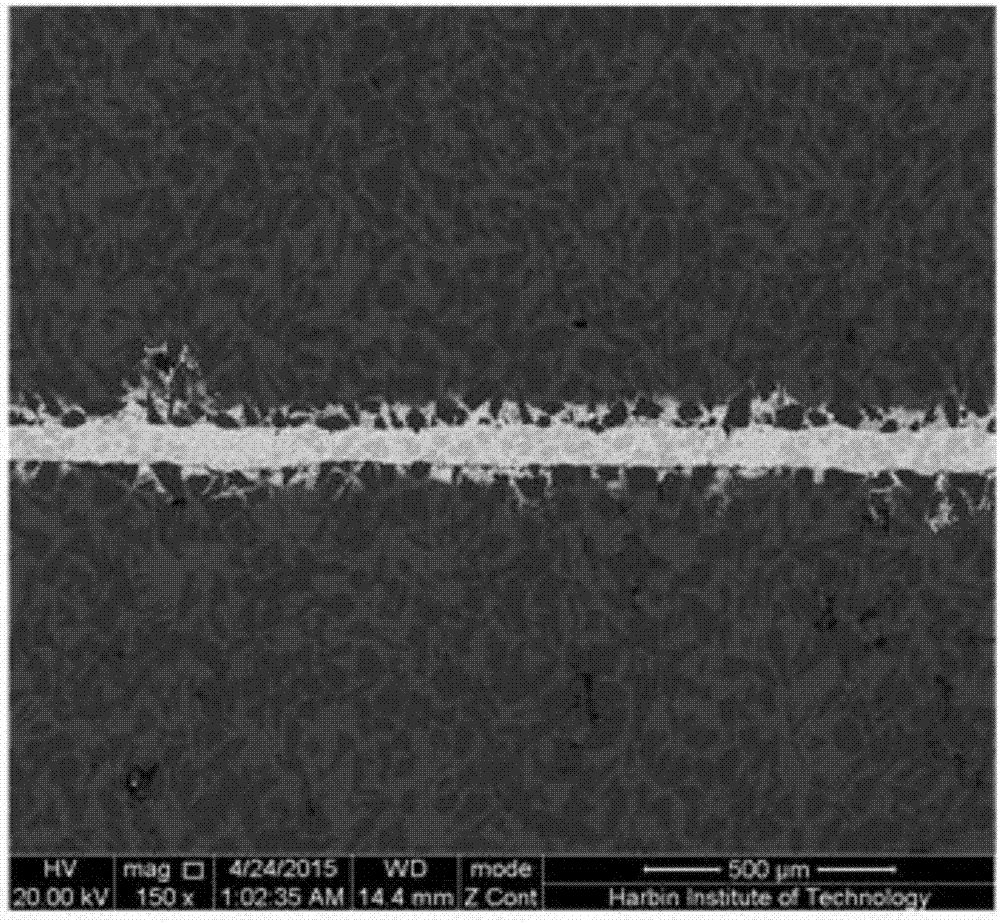

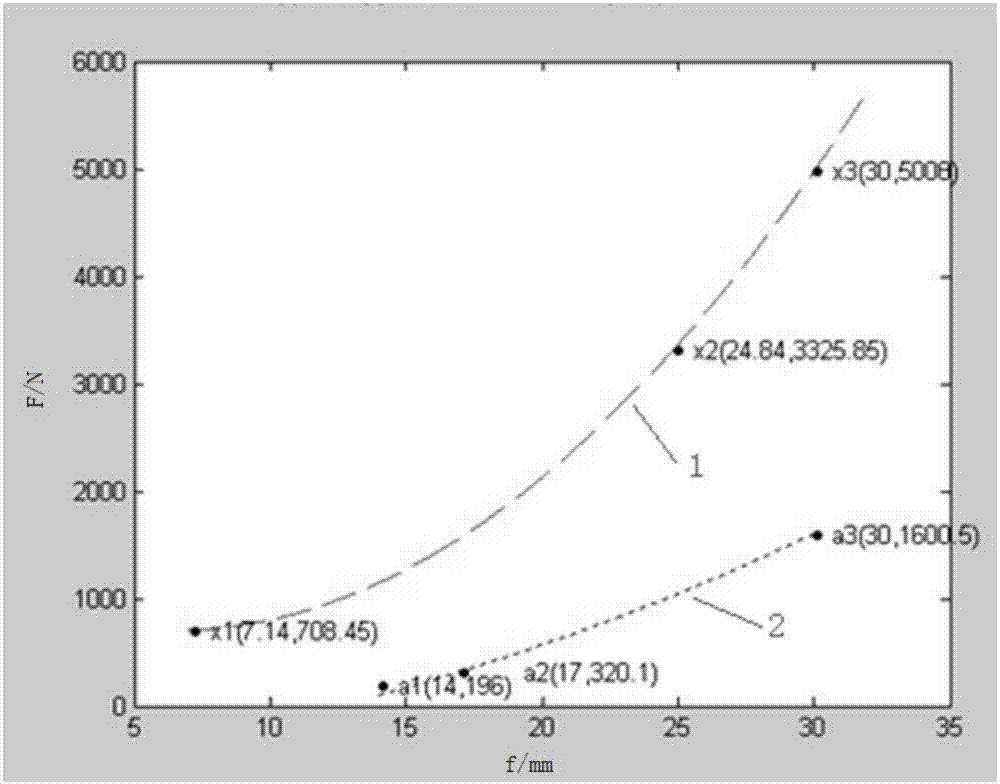

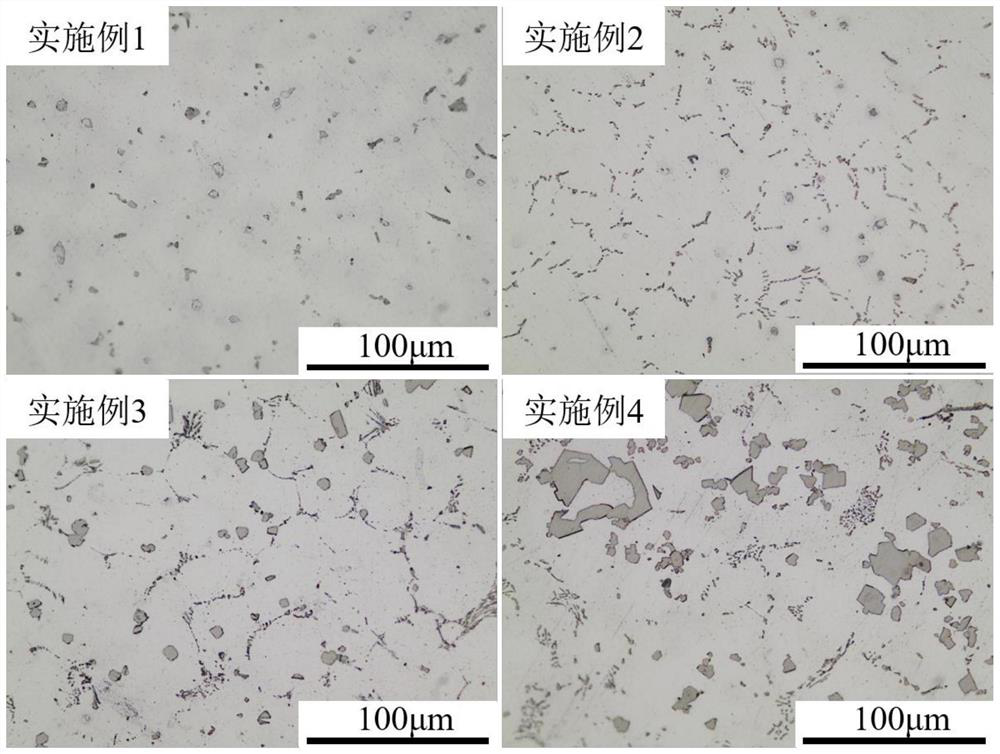

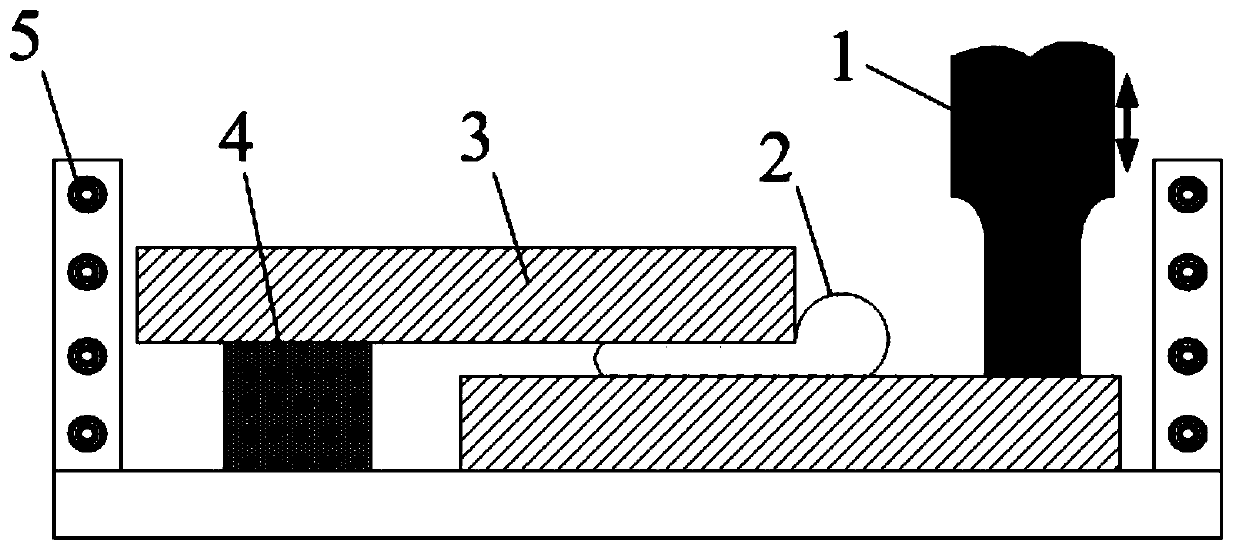

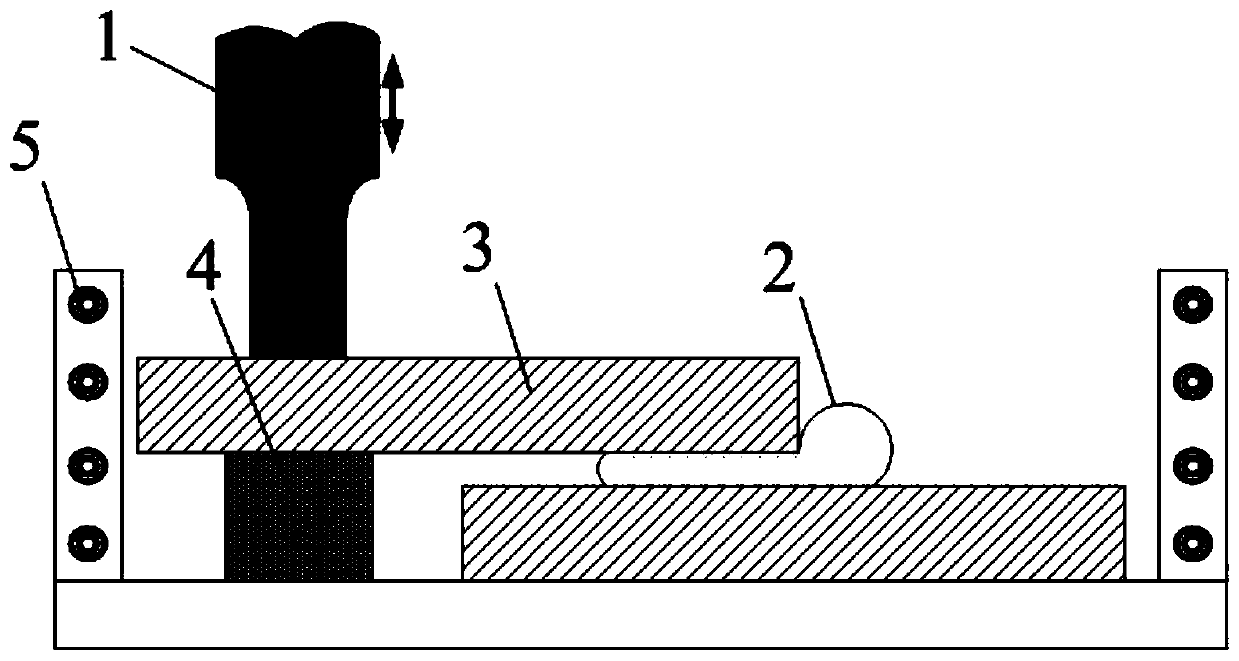

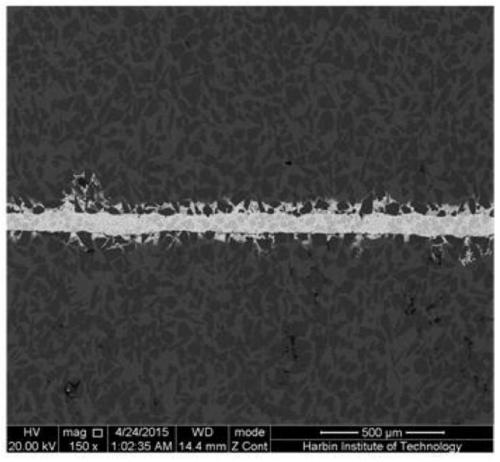

Method for improving strength of soldered seams on basis of thin-melt ultrasonic fine crystallization treatment in narrow gaps

ActiveCN107096974AEnhanced ultrasonic acoustic cavitation effectSolve the problem that the ultrasonic energy distribution is not uniform enoughSoldering auxillary devicesMaterials scienceAluminum matrix composites

The invention provides a method for improving strength of soldered seams on the basis of thin-melt ultrasonic fine crystallization treatment in narrow gaps, and relates to the technical field of material welding. The invention aims at solving the problems that for an existing soldering connection method, due to the fact that the welding cycle is long and the welding temperature is high, soldered seam metal is large in crystal size and nonuniform in texture, and the soldered seams are low in strength. The method comprises the steps that 1, soldering materials and parent metal are assembled into a to-be-soldered part, and parent metal lapping gaps are adjusted and controlled; 2, preliminary soldering is conducted; and 3, thin-melt ultrasonic fine crystallization treatment is conducted. After soldering is conducted through the method, the crystal size of the soldered seams is obviously refined, and toughness of the soldered seams is greatly improved. According to the method, the technology is simple, the operation cost is low, fine crystal strengthening of the soldered seams of aluminum-alloy, copper-alloy, magnesium-alloy and aluminum-matrix composite materials and ceramic and ceramic-matrix composite materials can be achieved, and the method can be used for the engineering application field of complex structural components.

Owner:HARBIN INST OF TECH

Wrought superalloy production process

The invention discloses a wrought superalloy production process. The process comprises the following steps: S1, pretreatment of alloy raw materials; S2: melting in a vacuum induction furnace; S3: electroslag remelting; S4: vacuum self-consumption remelting; S5: high temperature diffusion homogenization annealing; S6: extruding of a desired bar on an extruder; S7: sample cutting by wire cutting, and heat treating of the sample; and S8: oxidation treatment. The rought superalloy production process ensures good comprehensive performance of the alloy through the specific reasonable ratio of each alloying element. Compared with existing alloy, the processed wrought superalloy has the advantages of excellent workability, high high-temperature mechanical properties and tissue stability, and excellent oxidation resistance. The process has low total production cost, can meet the low-cost manufacturing requirements of aero-engine turbine disks, has good economic and social benefits, and is suitable for use and popularization.

Owner:宁国市华成金研科技有限公司

High-strength-and-toughness magnesium alloy with controllable long-period phase size and preparation method thereof

ActiveCN109913725AHigh strengthImprove plasticityTemperature control deviceMetal rolling arrangementsThermal compressionIngot

The invention discloses a high-strength-and-toughness magnesium alloy with the controllable long-period phase size and a preparation method thereof. The method comprises the following steps that A, aMg-Y-Zn alloy casting ingot is cut into a rod-shaped sample with the diameter being 10-14 mm, the sample is placed in a mold with a cylindrical cavity with the inner diameter being 15 mm, the sample is thermally compressed through a pressing head, and an alloy rod with 18R long-period phases being kinked to different degrees is obtained; and B, the above alloy rod is subjected to multi-pass hot drawing machining, and the high-strength-and-toughness magnesium alloy with the refined and dispersive 18R long-period phases is obtained. By means of the high-strength-and-toughness magnesium alloy, thermal compression is used for realizing pre-kinking of the 18R long-period phases, the compression ratio is controlled to achieve kink band density and degree control, then subsequent large-strain multi-pass hot drawing is used to break and refine the long-period phases from a kink band, the obtained 18R long-period phases are refined and controllable in size, and the strength and plasticity of the alloy are significantly improved.

Owner:HOHAI UNIV

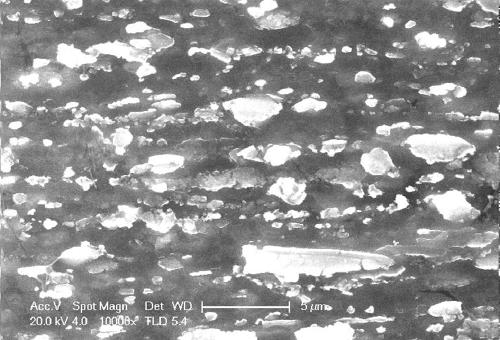

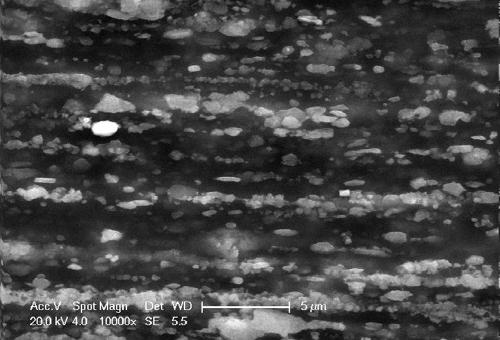

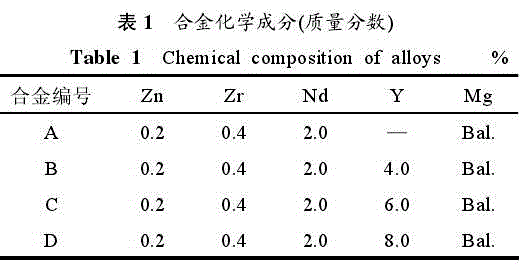

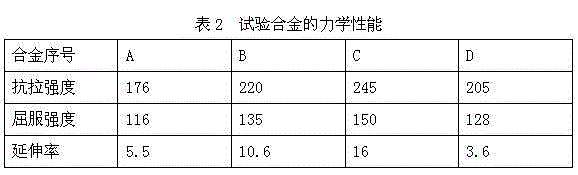

Mg-Nd-Zn-Zr alloy material containing Y and preparation process thereof

The invention discloses an Mg-Nd-Zn-Zr alloy material containing Y. The Mg-Nd-Zn-Zr alloy material is characterized by comprising the following components in parts by mass: 0.2 of Zn, 0.4 of Zr, 2.0 of Nd, 4-8 of Y, and the balance of Mg. A preparation process is characterized in that pure magnesium, pure zinc, 30% of Zr magnesium zirconium intermediate alloy and 31.72% of Y magnesium yttrium intermediate alloy are smelted by using a RJ-2 covering agent at a smelting temperature of 770 DEG C, are stood by 15 minutes after being totally molten, are poured in an iron mold, preheated to 200 DEG C, at 720 DEG C, and are molded by pouring.

Owner:黄晓艺

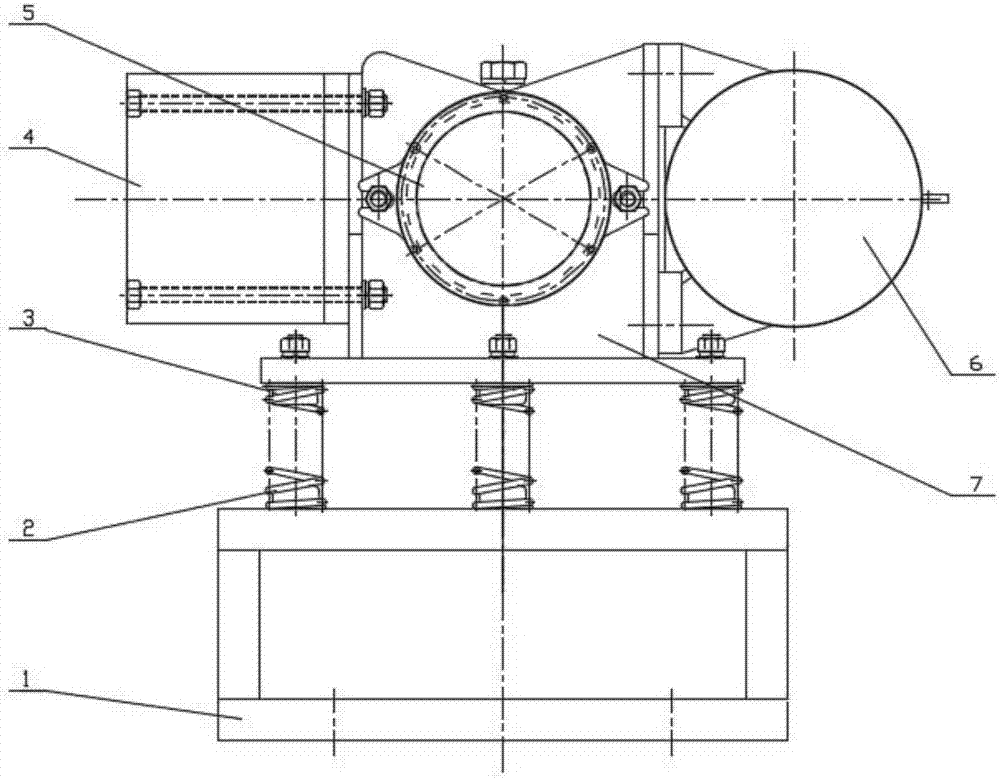

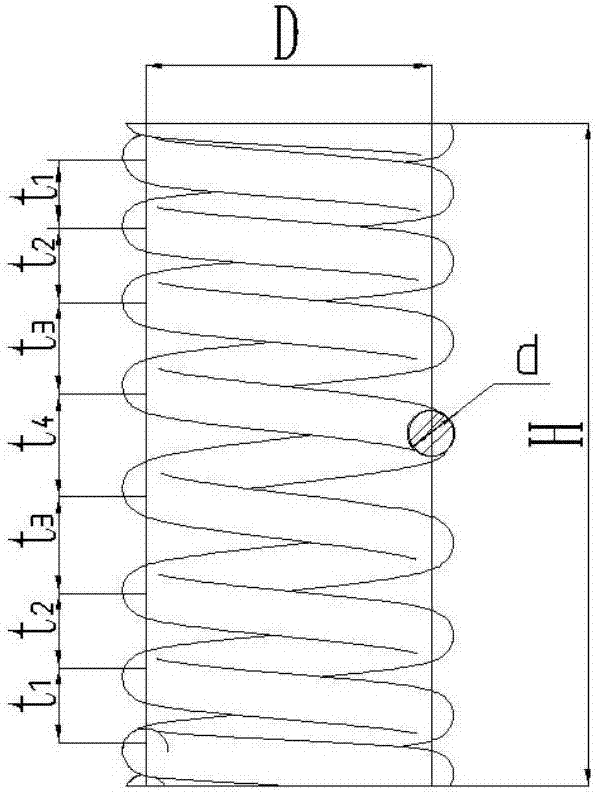

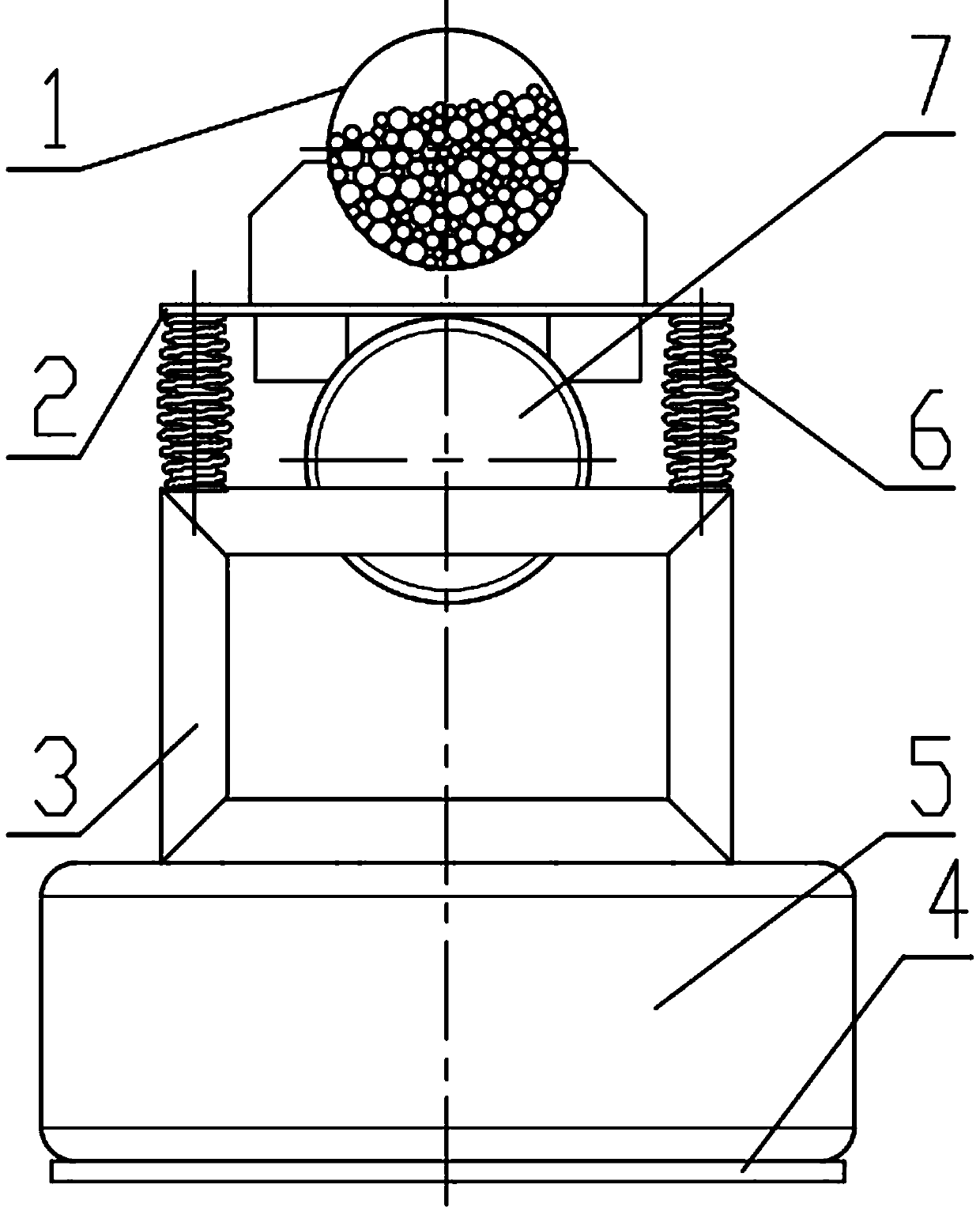

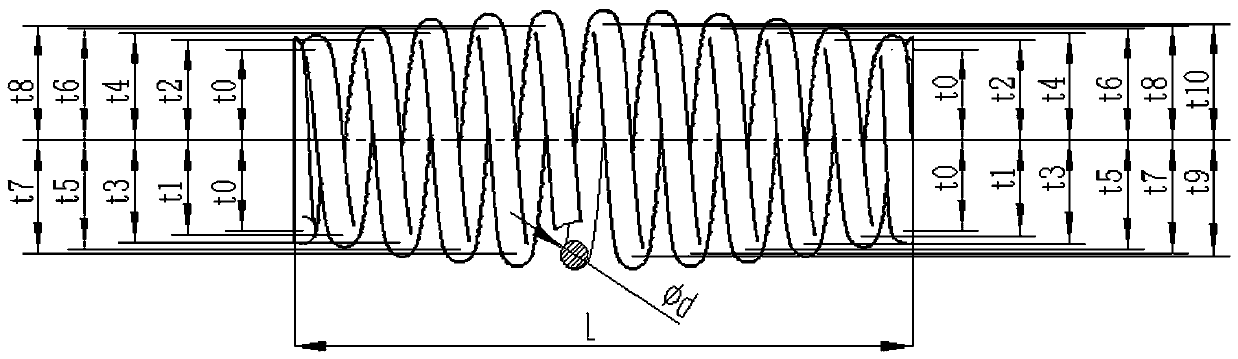

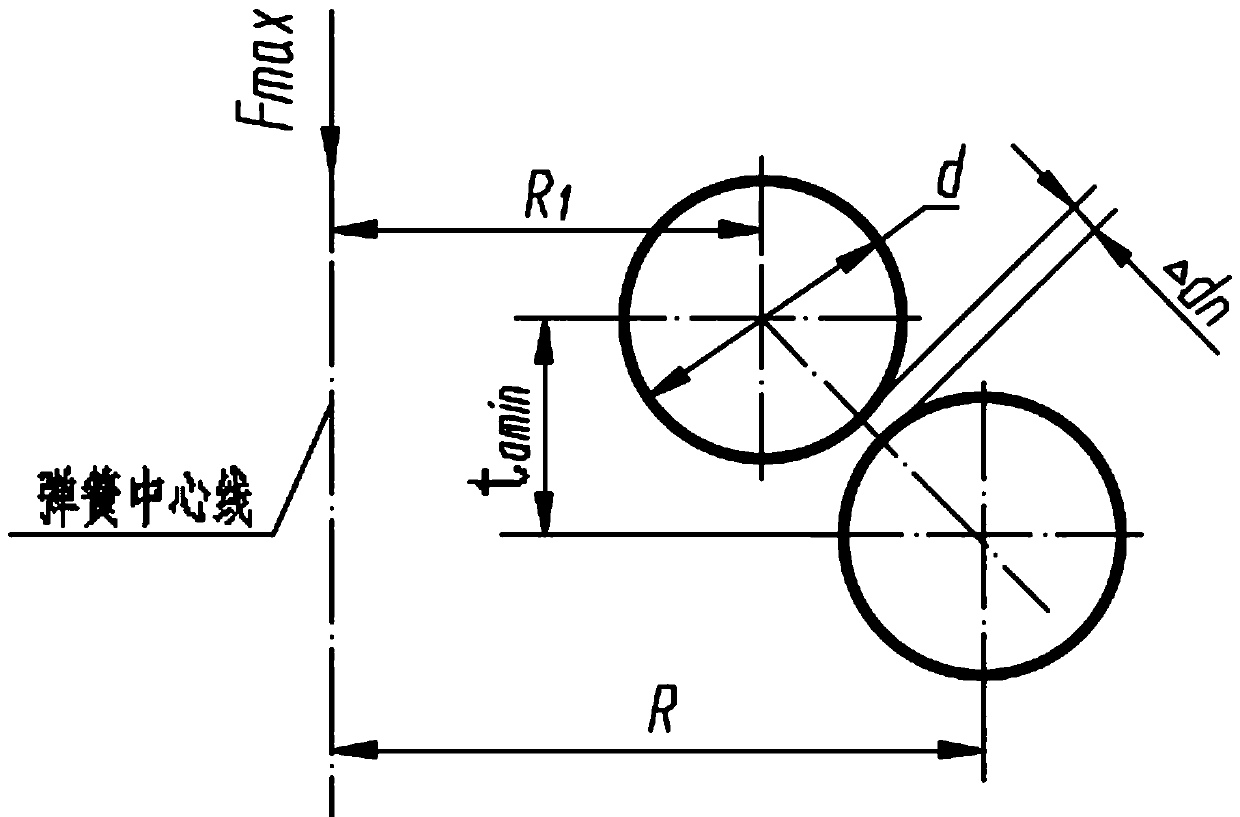

Side vibration mill adopting variable-pitch non-closed-coil springs and media in mixed density

The invention discloses a single-drum vibration mill adopting variable-pitch non-closed-coil springs and media in the mixed density. A main vibration system comprises a vibration motor which is controlled by a frequency converter and used as a vibration exciting source and a grinding drum fixed to the vibration motor; the vibration motor, the grinding drum and an upper mass plate form an upper mass; one end of a main vibration spring group is connected with the upper mass; the other end of the main vibration spring group is connected with a base; and the main vibration spring group comprises the multiple variable-pitch non-closed-coil helical springs, and each spring is formed by coiling one steel wire. The vibration mill has the positive, obvious and unique effects and has the characteristics of being capable of realizing ultrafine particle refining, realizing de-agglomeration and narrowing the powder product distributing zone, low in energy consumption, high in grinding efficiency, high in energy utilization rate, capable of realizing effective energy storage, saving energy, running stably and remarkably reducing the noise, good in vibration isolating effect and the like.

Owner:NANJING INST OF TECH

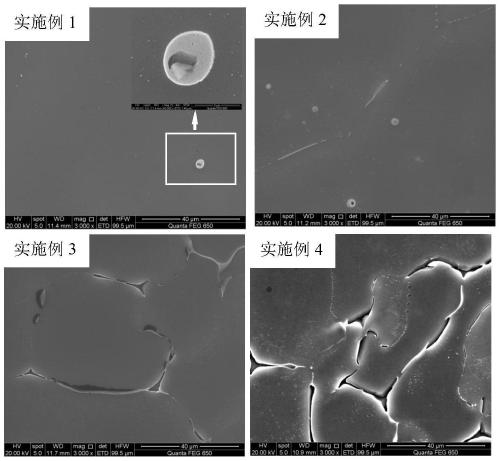

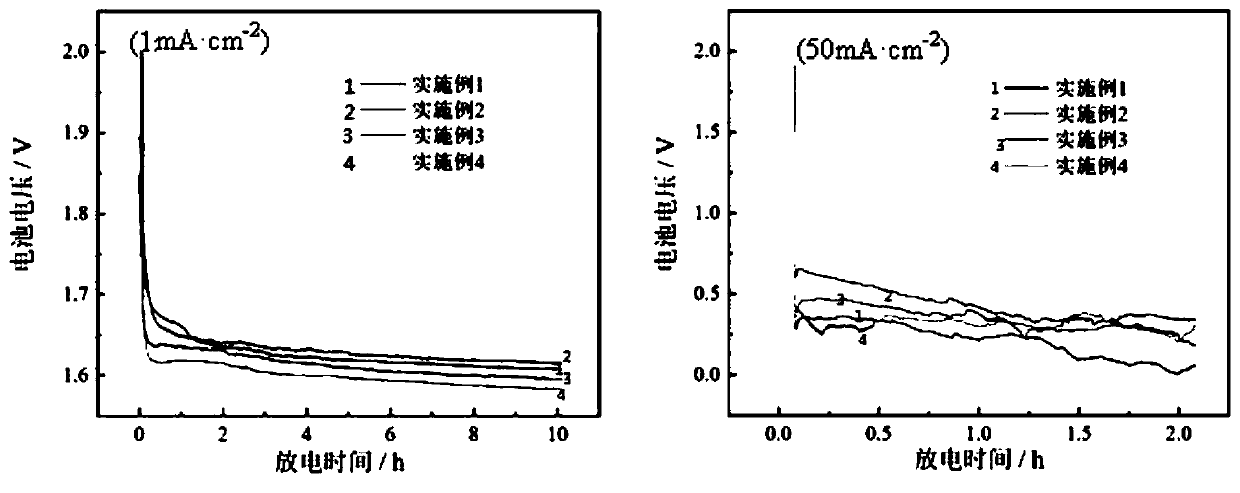

Magnesium-air battery anode material and preparation method thereof

InactiveCN112048652ASlow dehydrogenation reactionPromote sheddingFuel and secondary cellsCell electrodesGraphiteMetal particle

The invention discloses a magnesium-air battery anode material and a preparation method thereof, and relates to the technical field of magnesium-air batteries. The magnesium-air battery anode materialis prepared from the components: 2.0-3.0 wt.% of Al, 0.8-1.1 wt.% of Zn, 1.0- 7.5 wt.% of Gd and the balance of magnesium. The preparation method comprises the following steps that (1) an AZ31 magnesium alloy, pure aluminum, pure zinc and an Mg-Gd intermediate alloy are weighted according to 2.0-3.0 wt.% of Al, 0.8-1.1 wt.% of Zn, 1.0- 7.5 wt.% of Gd and the balance of magnesium, and surface oxide skin is removed; (2) the metal and the alloy of which the oxide skin is removed in the step (1) are put into a preheated crucible, and heating is carried out to 700 DEG C until the metal and the alloy are molten; and (3) the solution in the step (2) is heated to 780 DEG C, the temperature is kept for 5 minutes, rapidly cooling is carried out to 720 DEG C, and the solution is cast into a graphitemold preheated to 200 DEG C for cooling. Hydrogen evolution reaction of a metal anode in a NaCl neutral solution is inhibited, the formation of a needle-like Al2Gd second phase optimizes the discharge process, the falling of discharge products on the surface of an electrode is accelerated, the peeling of anode metal particles is reduced, the discharge reaction area is increased, and the specificcapacity and power density are improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

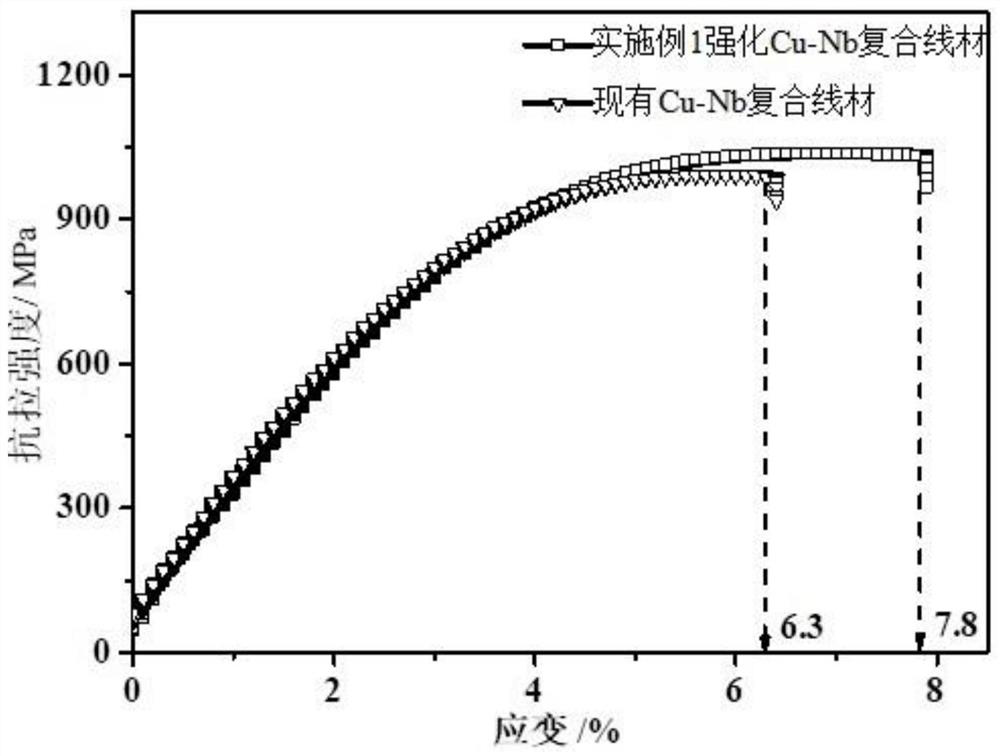

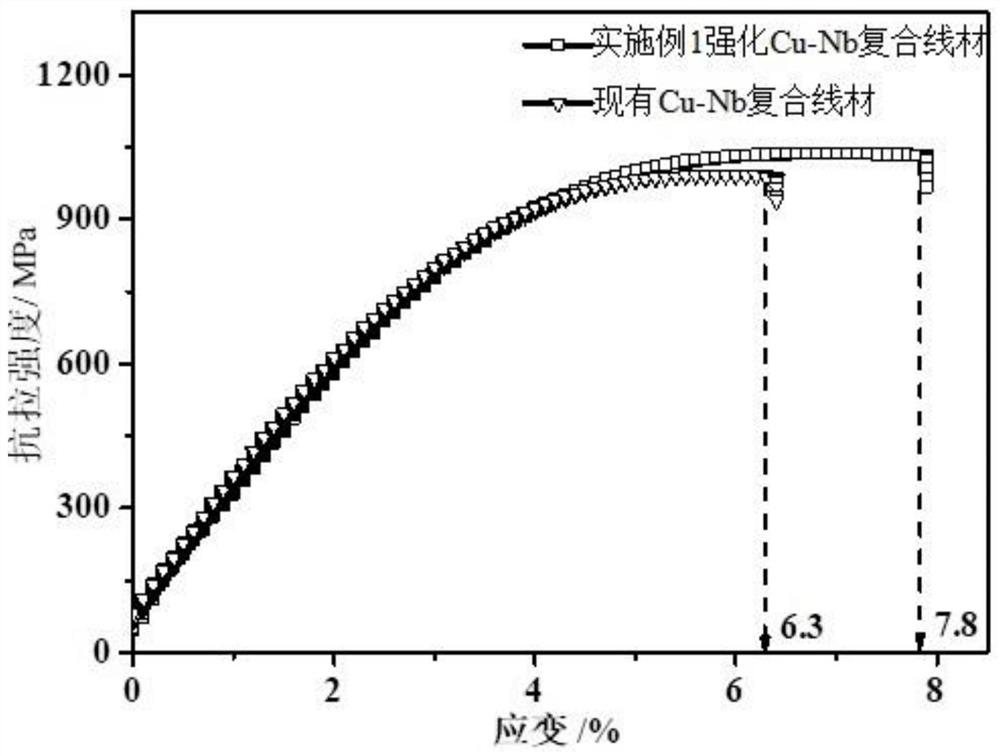

Preparation method of reinforced Cu-Nb composite wire

ActiveCN112007949AFacilitates longitudinal deformationQuality improvementMetal rolling arrangementsWire rodContinuous rolling

The invention discloses a preparation method of a reinforced Cu-Nb composite wire. The method comprises the following steps: 1, carrying out plastic drawing processing on a Cu-Nb three-time compositewire prepared by adopting a bundling drawing method, and then carrying out annealing treatment; 2, carrying out continuous multi-roll pass rolling on the annealed Cu-Nb three-time composite wire to obtain a Cu-Nb composite wire intermediate; and 3, carrying out plastic drawing processing on the Cu-Nb composite wire intermediate to obtain the reinforced Cu-Nb composite wire. According to the preparation method, a multi-roll pass rolling process is adopted for continuous rolling; the longitudinal deformation of the Cu-Nb three-time composite wire is promoted. Compared with the prior art, the plastic deformation is promoted to be improved, the plastic deformation amount is increased, the obtained reinforced Cu-Nb composite wire is more uniform in core wire distribution and deformation, and more obvious in core wire refinement, plastic deformation capacity is enhanced, the quality and performance of the reinforced Cu-Nb composite wire are improved, good matching of the mechanical propertyand the conductivity is achieved, and the engineering application requirement is met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

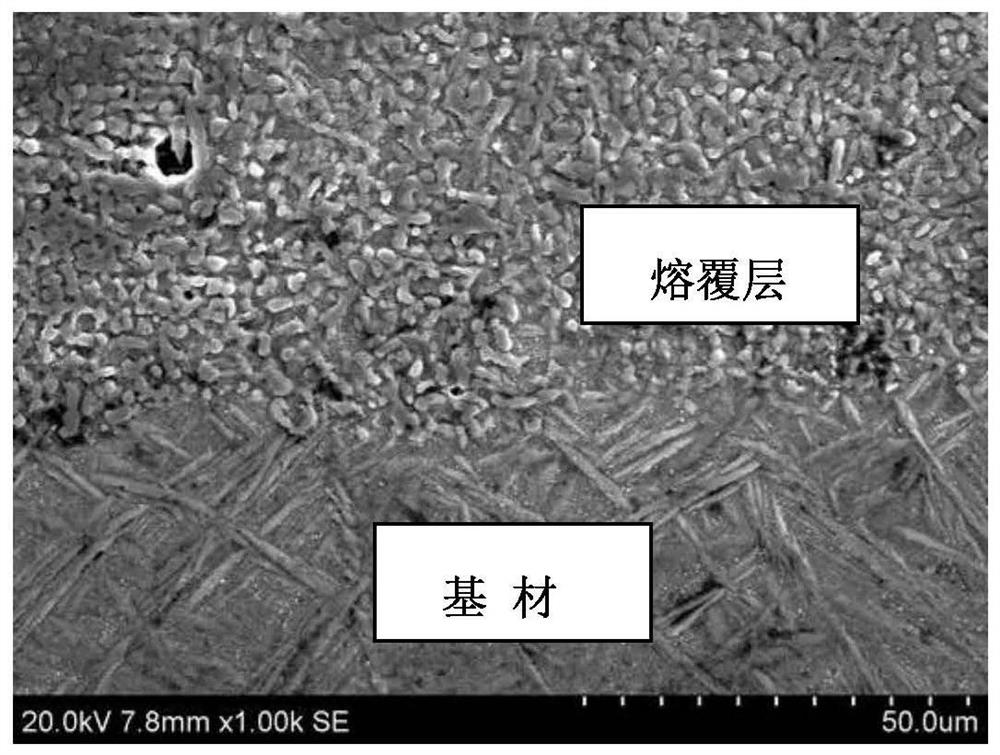

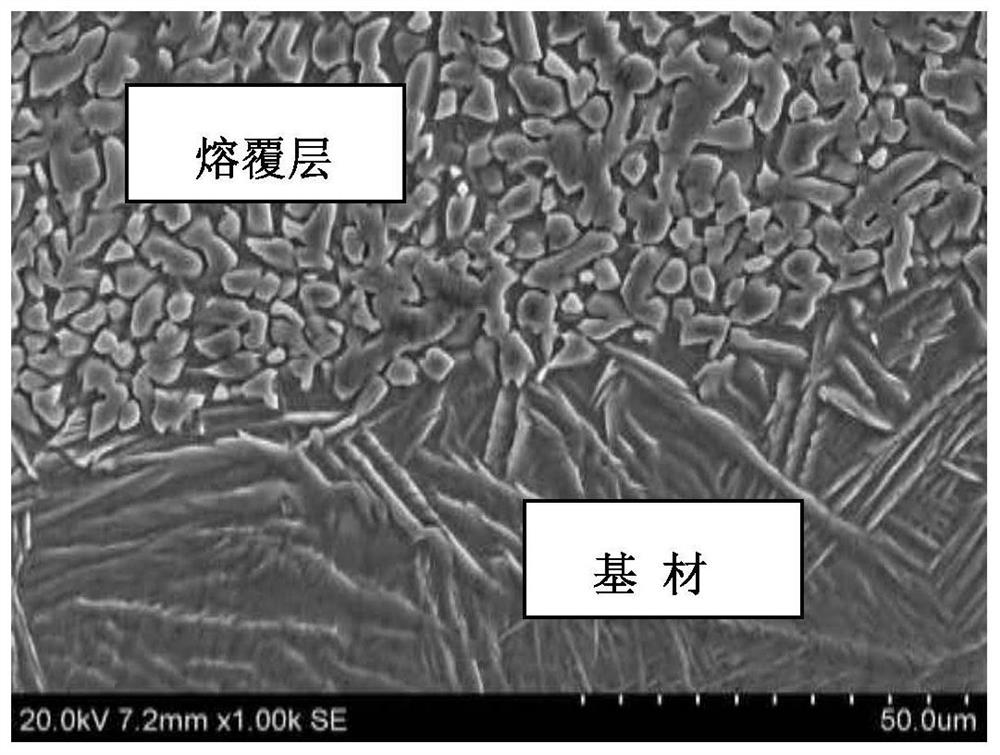

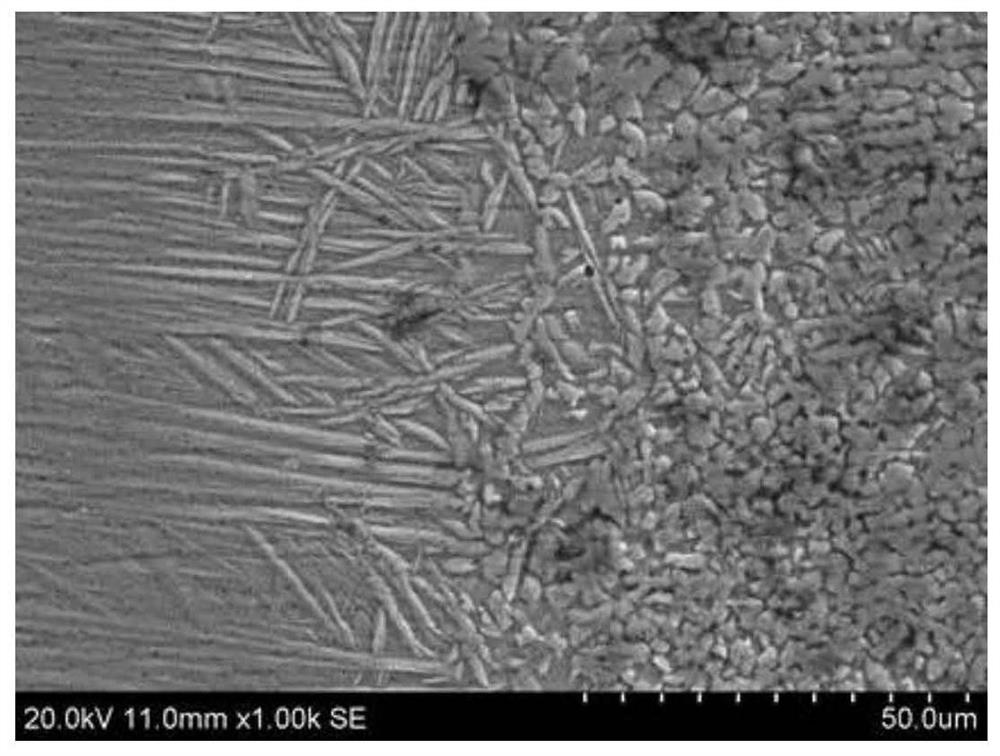

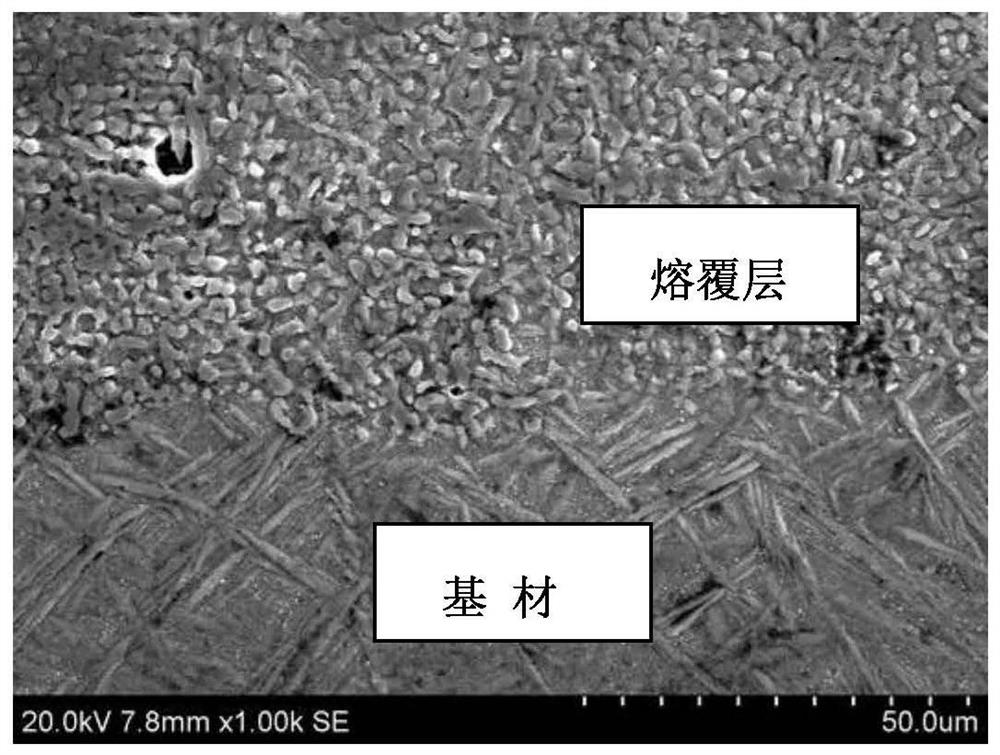

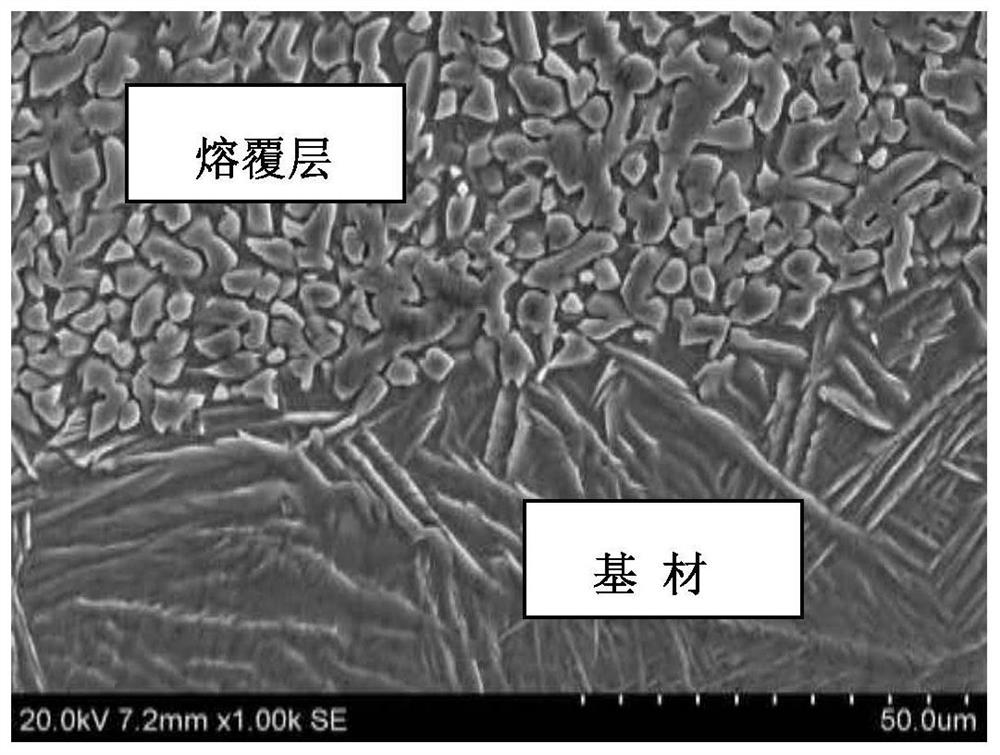

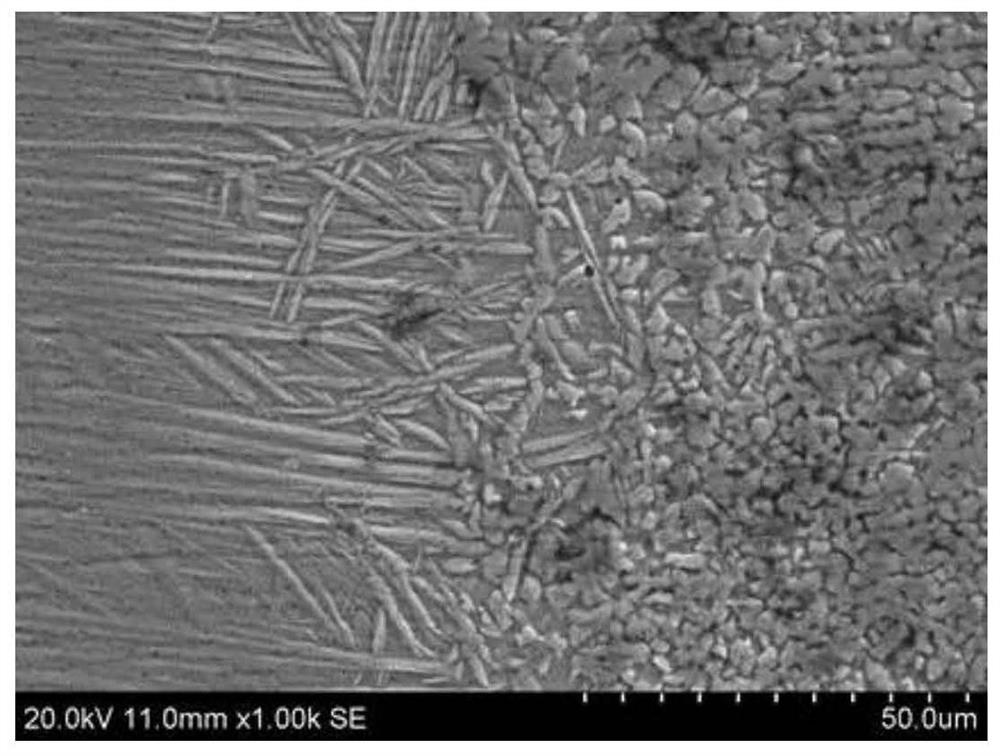

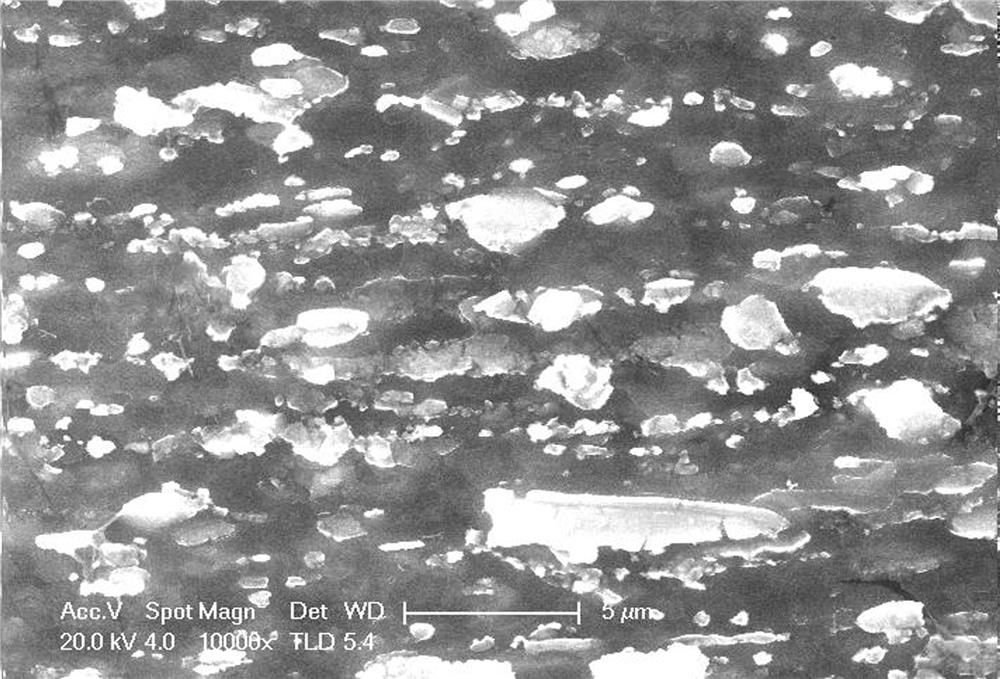

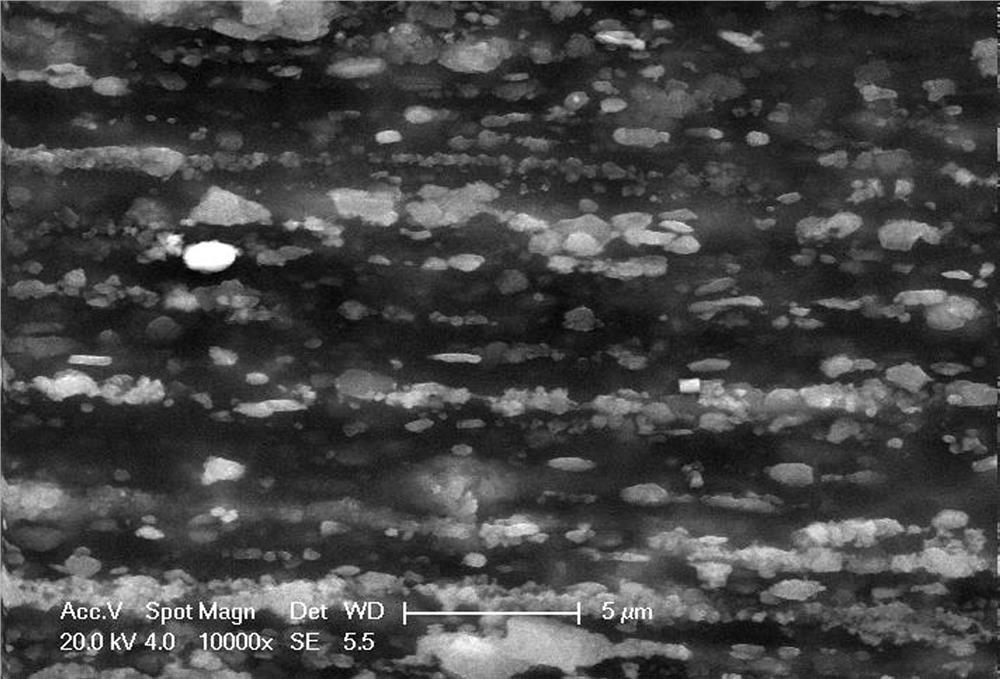

Preparation method of wear-resistant metal-multi-element ceramic composite modified coating on surface of titanium alloy

ActiveCN113667974AHigh hardnessImprove toughnessMetallic material coating processesSurface engineeringCeramic composite

The invention relates to a preparation method of a wear-resistant metal-multi-element ceramic composite modified coating on the surface of a titanium alloy, and belongs to the technical field of surface engineering. The preparation method of the wear-resistant metal-multi-element ceramic composite modified coating on the surface of the titanium alloy comprises the following steps: (1) preparing pre-alloyed powder for later use; (2) cleaning the to-be-clad surface of a base material by adopting industrial alcohol, and then carrying out blackening treatment on the surface of the base material; and (3) coaxially conveying the pre-alloyed powder prepared in the step (1) to the to-be-clad surface of a base material, which is treated in the step (2), carrying out laser cladding, and preparing to obtain the wear-resistant metal-multi-element ceramic composite modified coating on the surface of the titanium alloy. The composite modified coating prepared through the preparation method is obvious in grain refinement, the purpose of grain refinement strengthening is achieved, the coating is guaranteed to have high hardness and high toughness at the same time, and therefore the wear resistance of the titanium alloy can be greatly improved, and then the service life of the titanium alloy under a complex working condition is prolonged.

Owner:YANSHAN UNIV

A ti-v composite microalloyed ultrafine bainite non-quenched and tempered steel and its controlled forging and controlled cooling process and production process

Owner:MAANSHAN IRON & STEEL CO LTD

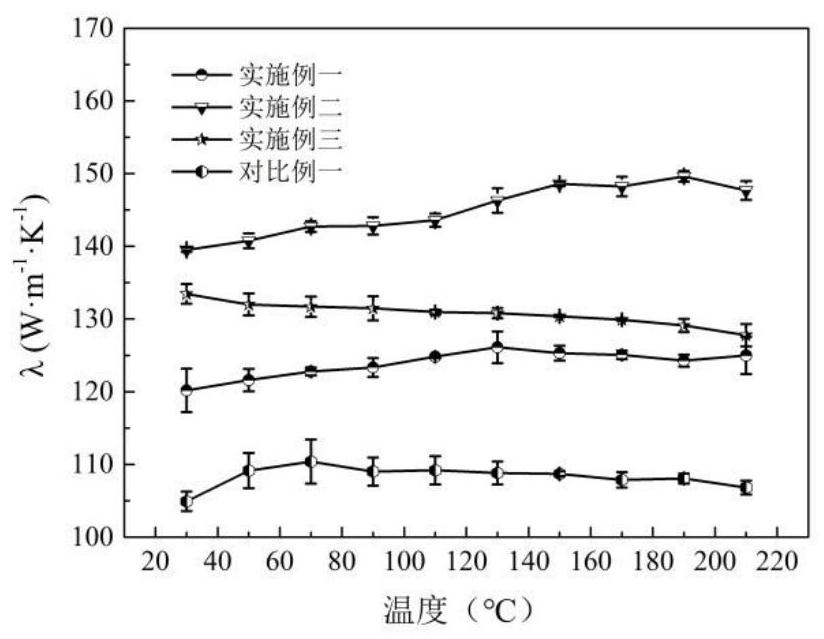

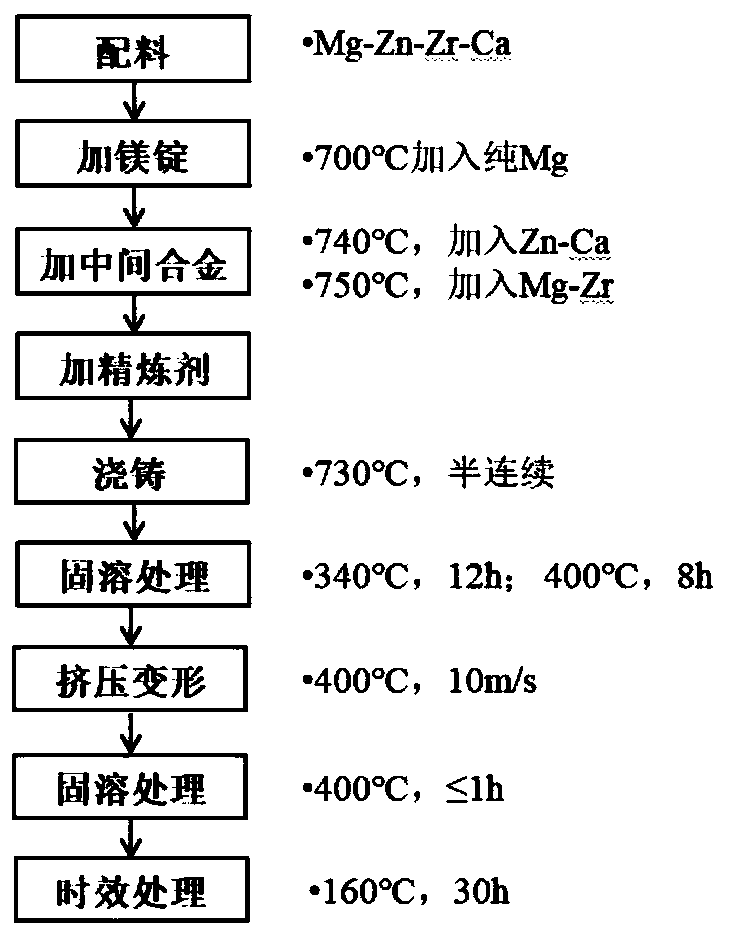

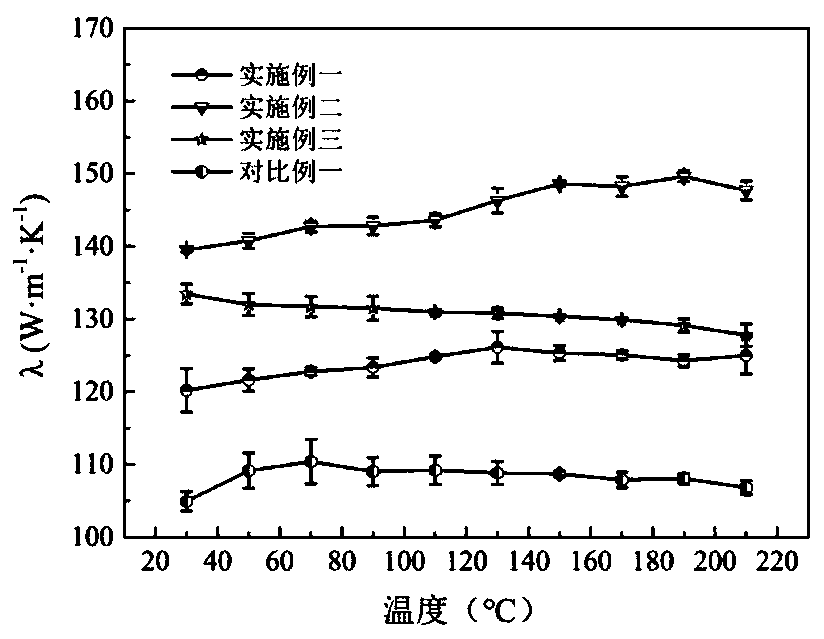

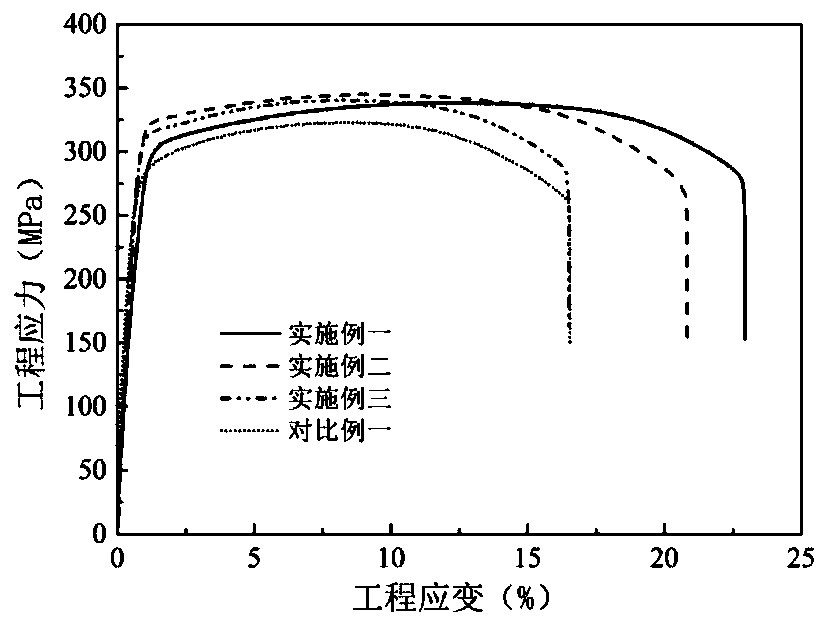

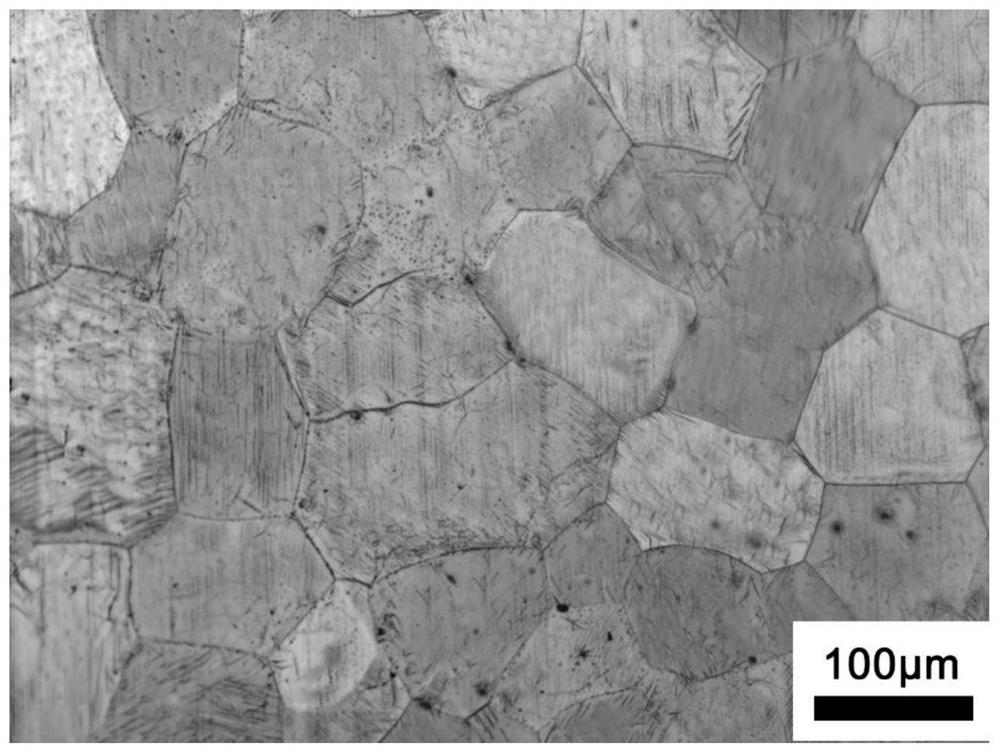

A kind of high-strength heat-conducting magnesium alloy and preparation method thereof

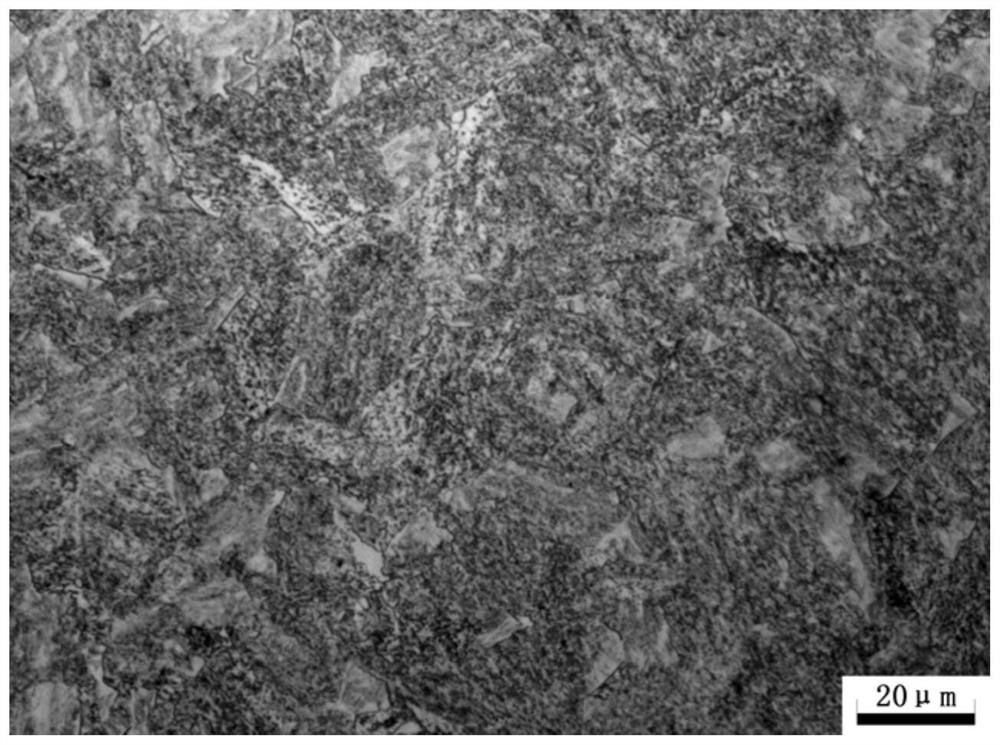

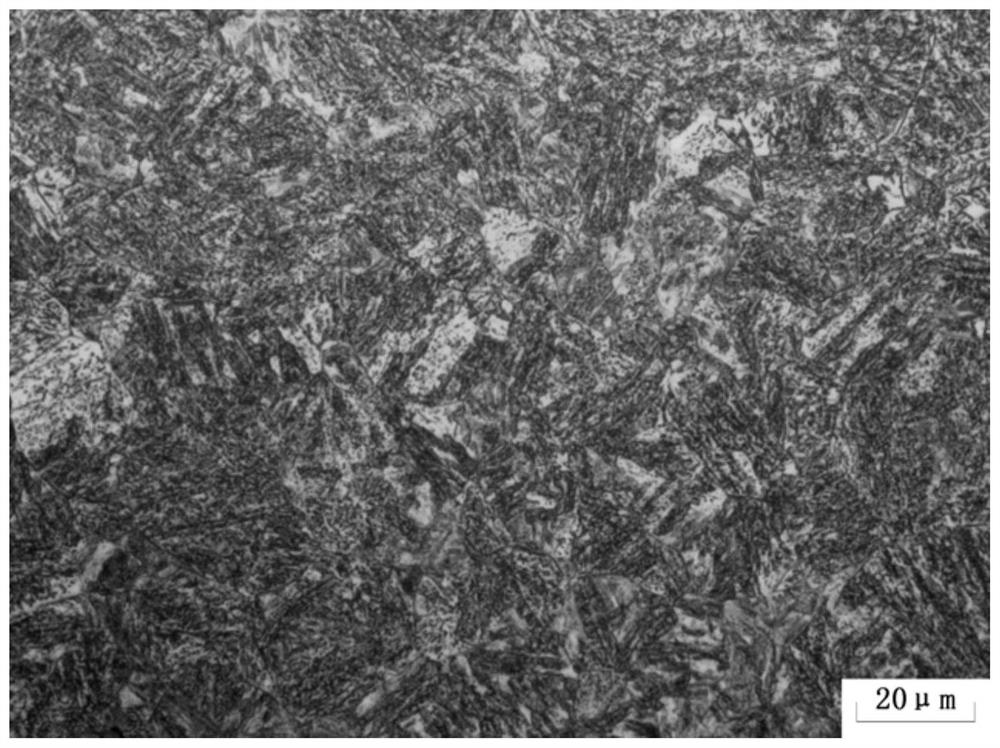

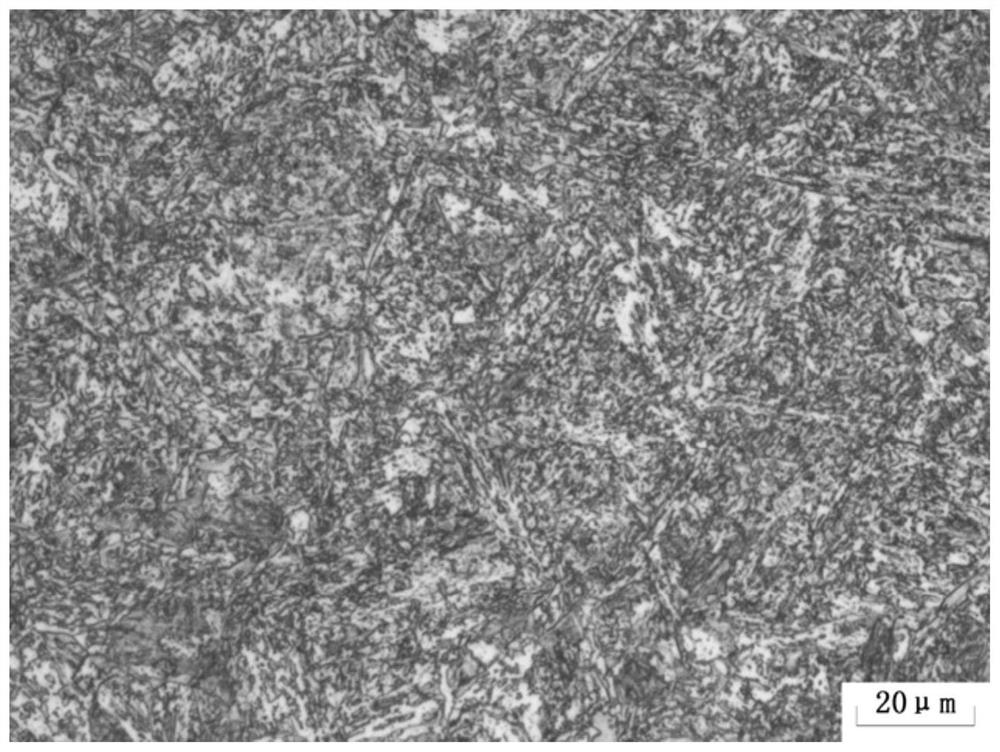

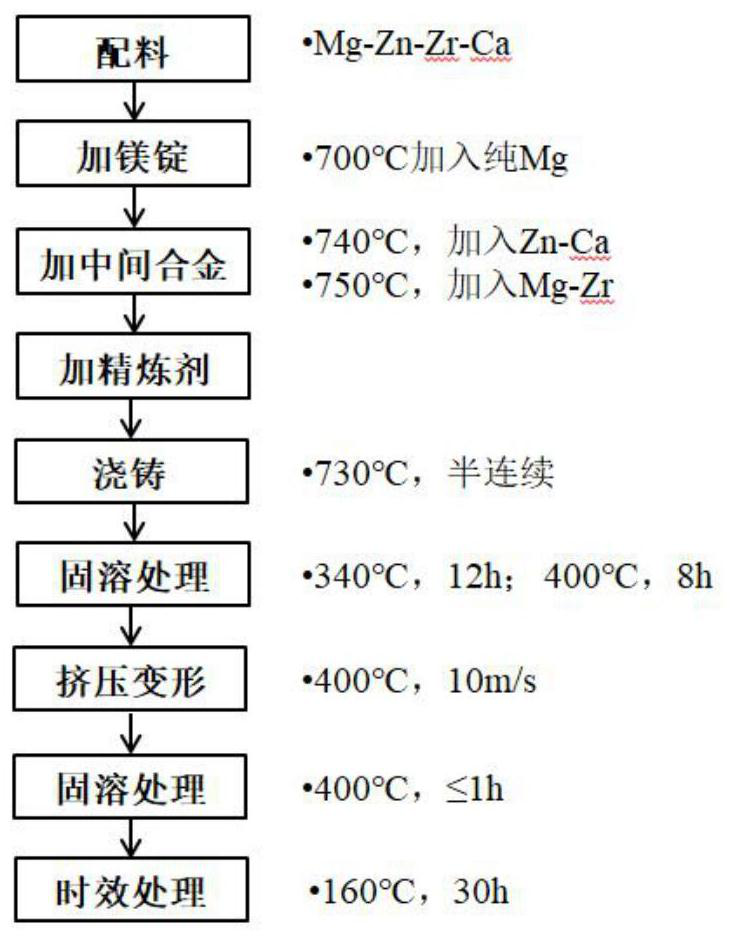

The invention discloses a high-strength heat-conducting magnesium alloy and a preparation method thereof. The element content of the magnesium alloy is: Zr: 0.2-0.6wt.%, Zn: 4-6wt.%, Ca: 0.4-0.8wt.%. The amount is Mg. The preparation method of the magnesium alloy includes batching, adding magnesium ingots, adding intermediate alloys, refining, casting, solid solution treatment, extrusion deformation, solid solution treatment again and aging treatment. In order to promote the formation of alloy Zn-Ca clusters, different Zn-Ca master alloys are selected during smelting, and a short-term solution treatment of no more than 1h is performed after hot extrusion. The tensile strength of the alloy is greater than 325MPa, the yield strength is greater than 280MPa, the elongation is greater than 15%, and the thermal conductivity is greater than 120W·(m·K) ‑1 , the magnesium alloy has a high yield, good formability, easy industrialization, and can be used as a heat dissipation structural material for power supplies and electronic devices in the field of new generation aerospace.

Owner:ALLITE (JIANGSU) MAGNESIUM TECH CO LTD

A method for improving the strength of brazed welds based on ultrasonic fine-grain treatment of thin-layer melts in narrow gaps

ActiveCN107096974BEnhanced ultrasonic acoustic cavitation effectObvious refinementSoldering auxillary devicesMaterials scienceAluminium alloy

The invention provides a method for improving strength of soldered seams on the basis of thin-melt ultrasonic fine crystallization treatment in narrow gaps, and relates to the technical field of material welding. The invention aims at solving the problems that for an existing soldering connection method, due to the fact that the welding cycle is long and the welding temperature is high, soldered seam metal is large in crystal size and nonuniform in texture, and the soldered seams are low in strength. The method comprises the steps that 1, soldering materials and parent metal are assembled into a to-be-soldered part, and parent metal lapping gaps are adjusted and controlled; 2, preliminary soldering is conducted; and 3, thin-melt ultrasonic fine crystallization treatment is conducted. After soldering is conducted through the method, the crystal size of the soldered seams is obviously refined, and toughness of the soldered seams is greatly improved. According to the method, the technology is simple, the operation cost is low, fine crystal strengthening of the soldered seams of aluminum-alloy, copper-alloy, magnesium-alloy and aluminum-matrix composite materials and ceramic and ceramic-matrix composite materials can be achieved, and the method can be used for the engineering application field of complex structural components.

Owner:HARBIN INST OF TECH

Mixed density medium double-plastid vibration mill with convex springs without join of cycles

InactiveCN107138237ARealization without mergingAvoid resonanceGrain treatmentsHigh energyCoil spring

The invention provides a mixed density medium double-plastid vibration mill with convex springs without join of cycles. The vibration mill comprises a main vibration system and a vibration isolation system; the main vibration system comprises a vibration motor controlled by a frequency converter and used as an excitation source, and a milling cylinder fixed to the vibration motor; an upper plastid is made up of the vibration motor, the milling cylinder and an upper plastid plate, and one end of a lower plastid is connected to a main vibration spring set; the lower plastid is connected to the vibration isolation system through the main vibration spring set; the vibration isolation system comprises isolation springs connected to the other end of the lower plastid, and each isolation spring is connected to a foundation through a base; and the main vibration spring set is composed of a plurality of convex coil springs without join of cycles, and each spring is formed by winding a steel wire. The vibration mill provided by the invention has the characteristics of ultrafine particle refinement, disaggregation, narrowing of powder product distribution zone, low energy consumption, high grinding efficiency, high energy utilization rate, effective energy storage, energy saving, stable operation, obvious noise reduction, good vibration isolation effect, etc.

Owner:NANJING INST OF TECH

High-strength heat-conducting magnesium alloy and preparation method thereof

The invention discloses a high-strength heat-conducting magnesium alloy and a preparation method thereof. The magnesium alloy comprises, by weight: Zr: 0.2-0.6%, Zn: 4-6%, Ca: 0.4-0.8% and the balanceMg. The preparation method of the magnesium alloy comprises the steps of burdening, adding a magnesium ingot, adding an intermediate alloy, refining, casting, carrying out solution treatment, carrying out extrusion deformation, carrying out the solution treatment again and carrying out aging treatment. According to the high-strength heat-conducting magnesium alloy and the preparation method thereof, in order to promote the formation of alloy Zn-Ca clusters, different Zn-Ca intermediate alloys are selected during the smelting, and the short-time solution treatment is carried out for 1 h or less after the hot extrusion; the tensile strength of the alloy is greater than 325 MPa, the yield strength of the alloy is greater than 280 MPa, the elongation of the alloy is greater than 15%, and theheat conductivity of the alloy is greater than 120 W.(m.K)<-1>; and the magnesium alloy is high in yield, good in processing formability, easy for realizing industrialization, and capable of being used as a heat dissipation structural material of a power supply and electronic device in the field of new generation aerospace.

Owner:ALLITE (JIANGSU) MAGNESIUM TECH CO LTD

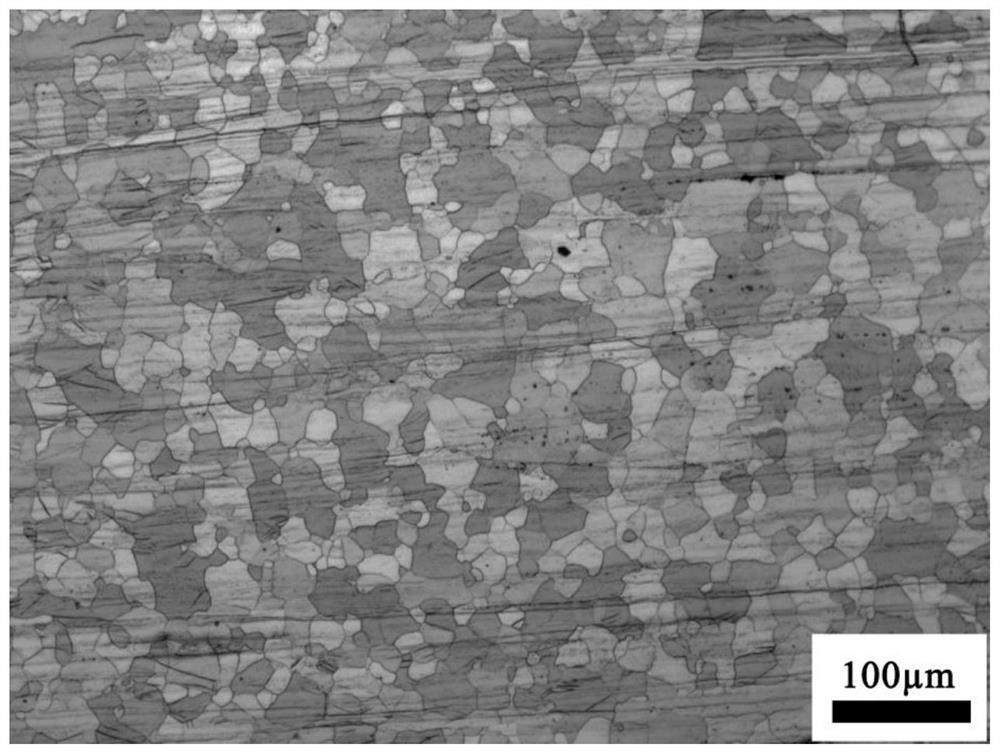

A Method of Improving the Strength and Corrosion Resistance of Cast ZK21 Magnesium Alloy

The invention provides a method for improving the strength and corrosion resistance of cast ZK21 magnesium alloy. The alloy comprises, by mass, 1.87% of Zn, 0.54% of Zr and the balance Mg and inevitable impurities. The method comprises the steps of performing solution treatment to cast magnesium alloy in an electric box furnace firstly, wherein the solution temperature is 360-400 DEG C, and the solution treatment time is 12-24 hours; adding pyrite powder (FeS2) for protection according to the volume ratio of 1:100 in order to prevent oxidization; and then, performing extrusion treatment to themagnesium alloy after solution treatment at the extrusion temperature of 350 DEG C and the extrusion speed of 3 mm / s to obtain bars. The method has the advantages that the ZK21 alloy after solution treatment contains few second phases, thereby benefiting reduction of galvanic corrosion; the grain refinement after extrusion is obvious, and the structure compactness is improved; the porosity is reduced, and the strength and corrosion resistance of the magnesium alloy are improved greatly. The alloy has high strength and corrosion resistance, and can be applied to the medical field of degradableabsorbable bone nails, bone plates and the like.

Owner:UNIV OF SCI & TECH BEIJING

Process for producing V-N micro alloy high strength steel band using thin plate blank continuously casting and continuously rolling technology

InactiveCN100345641CObvious refinementThe degree of refinement is not as obvious as the present inventionMetal rolling arrangementsSteel platesWeldability

The continuous thin plate blank casting and rolling process for producing high strength V-N micro alloy steel belt includes smelting and refining in electric furnace or converter, continuous casting, heating after solidification inside bottom heating furnace, hot rolling, laminated flow cooling and winding. The continuous thin plate blank casting and rolling process has the technological parameters of: furnace entering temperature of cast blank 900-1050 deg c, homogeneous heating temperature 1050-1250 deg c, initially rolling temperature 1000-1170 deg c, finally rolling temperature 840-950 deg c and winding temperature 530-670 deg c. The molten steel contains: C 0.03-0.08 wt%, Si 0.01-0.8 wt%, Mn 0.1-2.0 wt%, V 0.01-0.20 wt%, Al 0.01-0.06 wt% and N 0.002-0.03 wt%. The produced high strength and fine grain steel belt and plate has ferrite grain size smaller than 6.0 micron, yield strength of 420-700 MPa, and excellent toughness, welding performance and forming performance.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

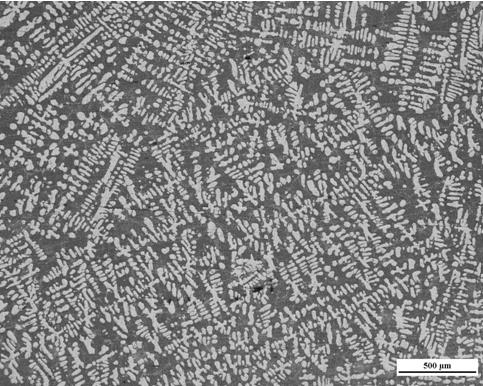

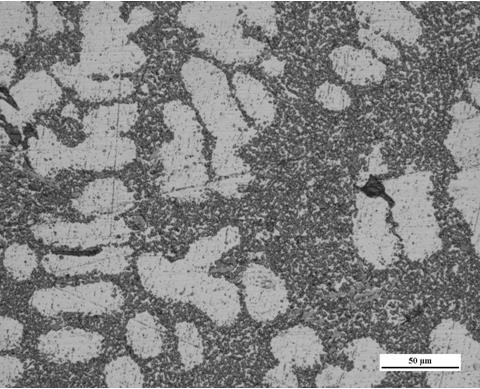

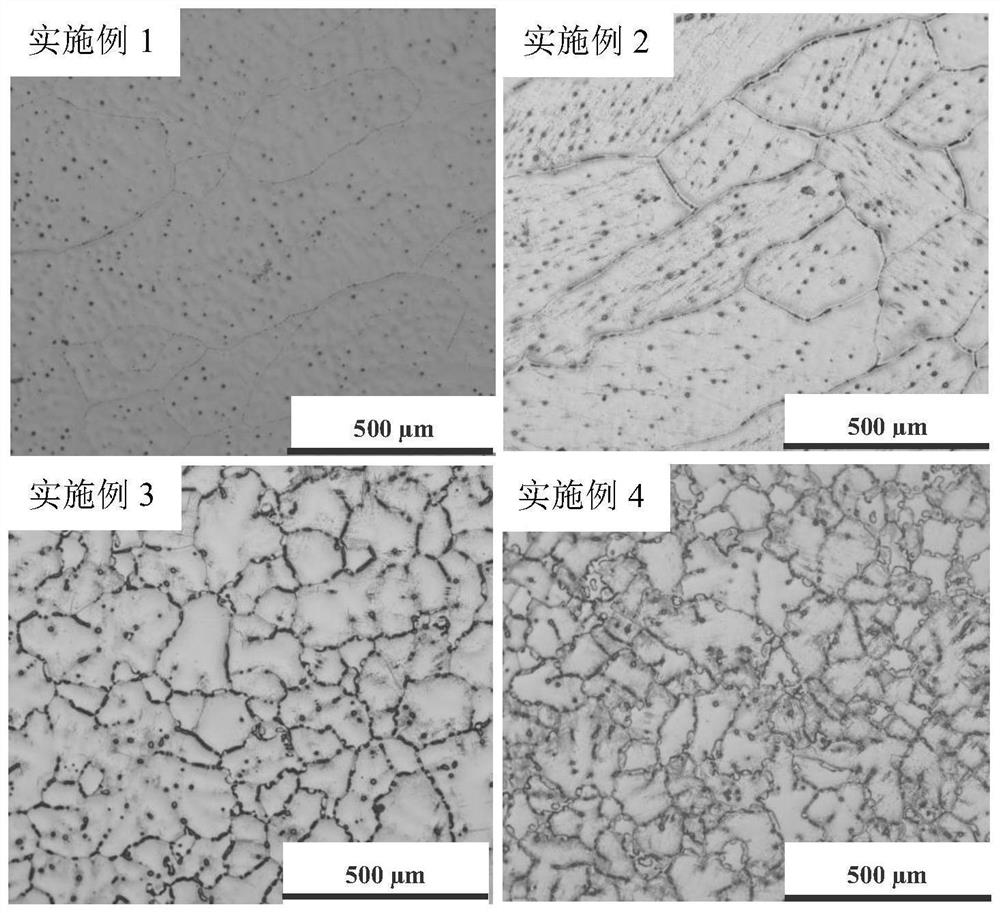

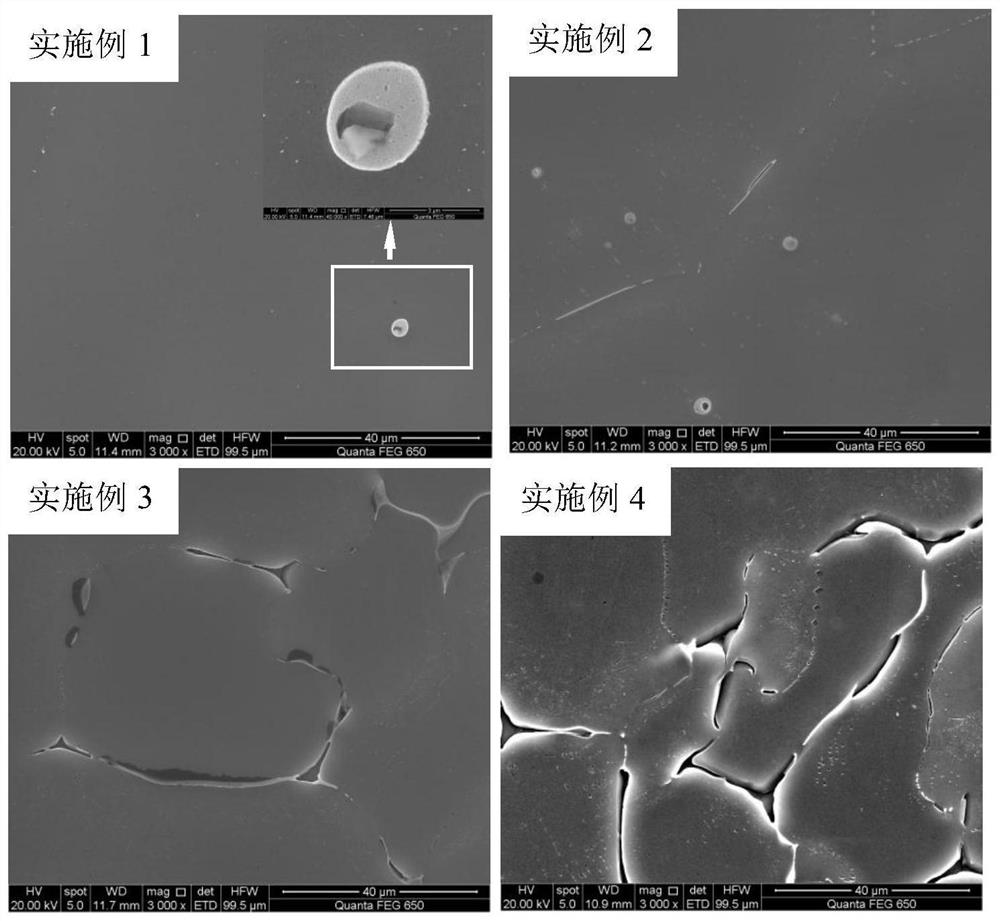

A composite modificator for regeneration of adc12 aluminum alloy and preparation method thereof

The invention discloses a composite modificator for regenerating an ADC12 aluminum alloy and a preparing method. The modificator comprises, by mass percent, 10%-20% of Te, 0.1%-10% of YbCl3 and the balance Al. After pure aluminum in a corundum crucible is melted and an Al-Te intermediate alloy and YbCl3 are added at the temperature ranging from 730 DEG C to 750 DEG C, heat preservation is conducted for 5-8 min, stirring is conducted for 3 min, and when the furnace temperature is reduced to 700-720 DEG C, argon inflation is conducted for refining, and heat preservation is conducted for 5-20 min; and surface dross is removed, and metal liquid is poured into a metal die to be solidified. The modificator can well avoid the action of alloy splitting due to mass thick needle-like iron-rich phases in the regenerated ADC12 aluminum alloy, the mechanical performance and machining performance of the regenerated ADC12 aluminum alloy are improved, gas in melt can be eliminated, generation of casting air holes is obviously reduced, and accordingly the product quality of castings is greatly improved.

Owner:NANCHANG UNIV

Fast production of subsphaeroidal crystal tissue semi-solid aluminium alloy

Owner:TSINGHUA UNIV

A kind of magnesium-air battery anode material and preparation method thereof

ActiveCN111455248BImprove corrosion resistanceReduce hydrogen evolution side reactionFuel and secondary cellsCell electrodesMetallurgyMetal mold

A magnesium-air battery anode material and a preparation method thereof relate to the technical field of magnesium-air batteries. The anode material of the magnesium-air battery is Zn 1.0-5.0 wt.%, Ca 0.1-2.0 wt.%, and the rest is magnesium. Preparation method: (1) According to Zn 1.0~5.0wt.%, Ca 0.1~2.0wt.%, the rest is magnesium, weigh pure magnesium, pure zinc, Mg-Ca master alloy, and remove the oxide scale on the surface; (2) ) Preheat the alloy treated in (1) in a crucible, and then put it into the crucible for melting; (3) cast the melt in (2) at a suitable temperature in a metal mold to cool. The hydrogen evolution reaction of metal anodes in neutral NaCl solution is alleviated, and the 2 Mg 6 Zn 3 The formation position of the second phase optimizes the discharge process, reduces the accumulation thickness of the discharge products on the anode surface, and accelerates the shedding of the products.

Owner:BEIJING UNIV OF TECH

Preparation method of wear-resistant metal-multi-component ceramic composite modified coating on titanium alloy surface

ActiveCN113667974BHigh hardnessImprove toughnessMetallic material coating processesSurface engineeringCeramic composite

Owner:YANSHAN UNIV

Ultra-high-strength aluminum alloy composite strip for radiator of automobile water tank and manufacturing method thereof

The invention discloses an ultrahigh-strength aluminum alloy composite strip for an automobile water tank radiator and a manufacturing method for the ultrahigh-strength aluminum alloy composite strip. The composite strip is composed of a core material and a single-sided or double-sided braze welding layer, wherein the thickness of the welding layer on each surface accounts for 5-10% of the total thickness; the core material consists of the following components in percentage by weight: 0.12-0.26% of Fe, less than or equal to 0.12% of Si, 0.30-0.80% of Cu, 1.5-1.8% of Mn, less than or equal to 0.04% of Mg, 0.02-0.15% of Cr, 0.02-0.15% of Zr, 0.02-0.15% of Ti, less than or equal to 0.03% of each of other elements, less than or equal to 0.15% of contents of all other elements, and the balance of aluminum; the welding layer is made of an aluminum-silicon alloy which consists of the following components in percentage by weight: less than or equal to 0.20% of Fe, 8.0-11.0% of Si, less than or equal to 0.10% of Cu, less than or equal to 0.05% of Mn, 0.03-0.06% of Sr, less than or equal to 0.05% of Ti, less than or equal to 0.03% of each of other elements, less than or equal to 0.15% of all other elements, and the balance of aluminum. The ultrahigh-strength aluminum alloy composite strip has very excellent mechanical property after braze welding, and has yield strength which exceeds 70 MPa after braze welding.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

A kind of preparation method of strengthened Cu-NB composite wire

ActiveCN112007949BFacilitates longitudinal deformationQuality improvementMetal rolling arrangementsWire rodContinuous rolling

The invention discloses a method for preparing a strengthened Cu-Nb composite wire. The method comprises: 1. annealing the Cu-Nb three-time composite wire prepared by a cluster drawing method after plastic drawing; 2. annealing The processed Cu-Nb three-time composite wire rod is carried out continuous multi-roller pass rolling to obtain the Cu-Nb composite wire rod intermediate; three, the Cu-Nb composite wire rod intermediate is subjected to plastic drawing processing to obtain a strengthened Cu-Nb composite wire rod wire. The present invention adopts the multi-roll pass rolling process for continuous rolling, which promotes the longitudinal deformation of the Cu-Nb tertiary composite wire rod, increases the amount of plastic deformation, and the distribution and deformation of the obtained strengthened Cu-Nb composite wire rod core wire are more uniform, The thinning of the core wire is more obvious, the plastic deformation ability is enhanced, the quality and performance of the reinforced Cu-Nb composite wire are improved, the mechanical properties and electrical conductivity are well matched, and the engineering application requirements are met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A high strength and toughness magnesium alloy with controllable long-period phase size and its preparation method

ActiveCN109913725BHigh strengthImprove plasticityTemperature control deviceMetal rolling arrangementsIngotUltimate tensile strength

The invention discloses a high-strength and tough magnesium alloy with controllable long-period phase size and a preparation method thereof. The method comprises the following steps: A. Cutting a Mg-Y-Zn alloy ingot into rods with a diameter of 10-14 mm The sample is placed in a mold with a cylindrical cavity with an inner diameter of 15 mm, and the sample is thermally compressed by the indenter to obtain an alloy rod in which the 18R long-period phase is twisted to varying degrees; B. The above alloy rod is subjected to multiple Sub-hot drawing process to obtain 18R long-period phase refinement and dispersion of high strength and toughness magnesium alloy. The present invention realizes the pre-kink of the 18R long-period phase by thermal compression, and realizes the control of the kink band density and degree by controlling the compression rate, and then utilizes subsequent large-strain multi-pass thermal drawing to make the long-period phase from kink With fracture refinement, 18R long-period phase refinement and size control are obtained, which significantly improves the strength and plasticity of the alloy.

Owner:HOHAI UNIV

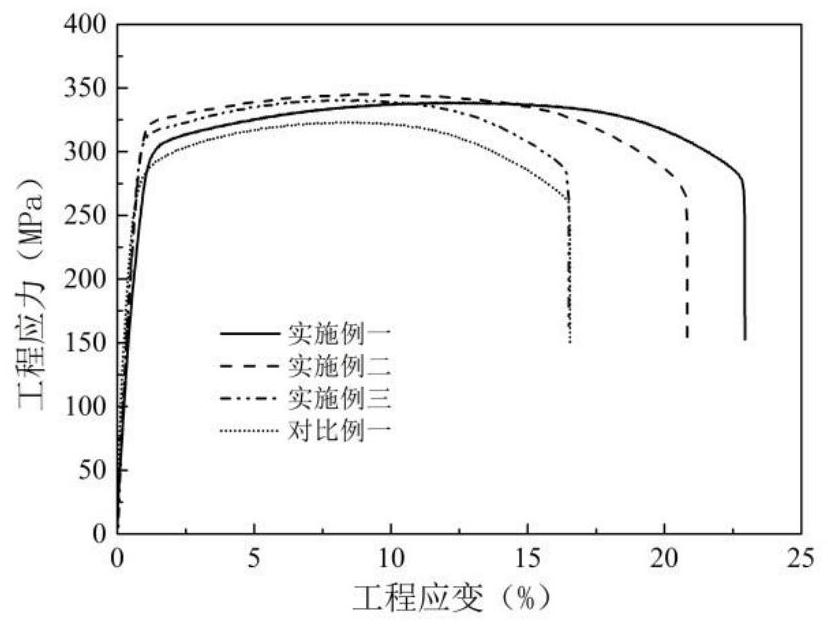

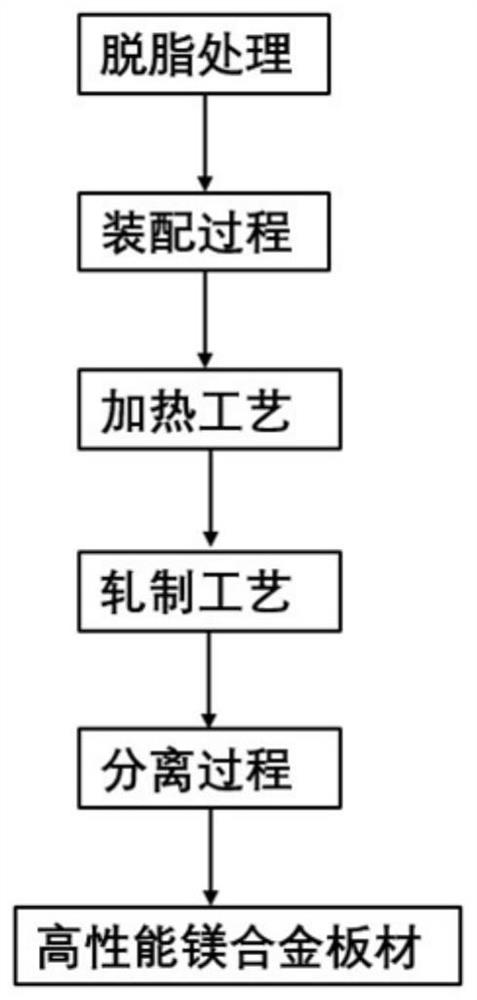

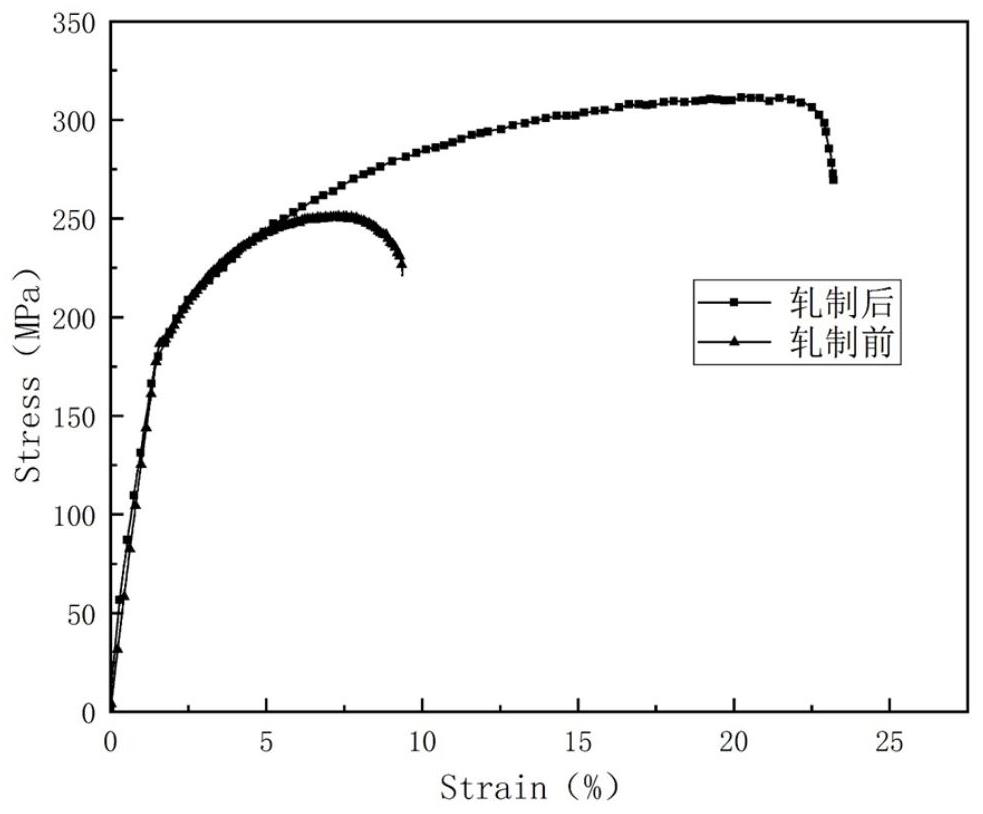

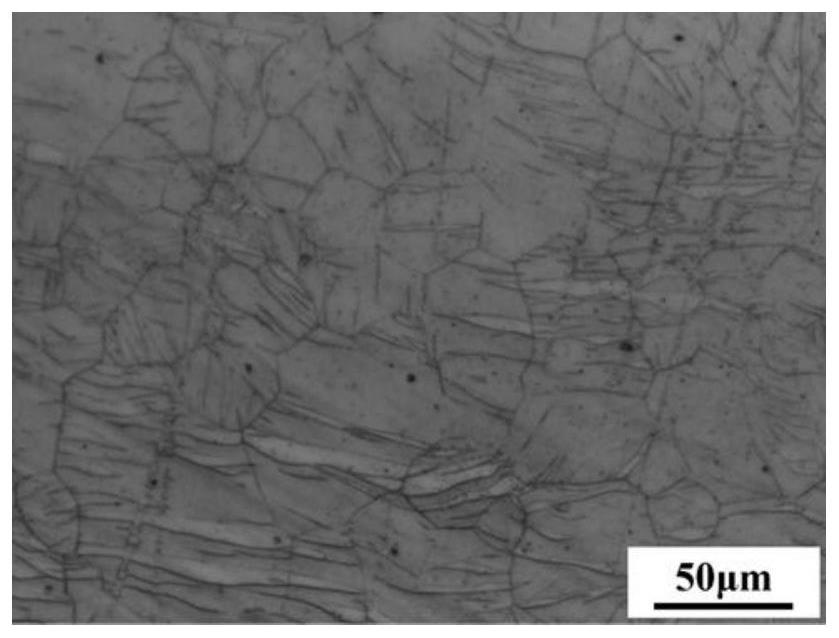

Single-pass and large-rolling-reduction magnesium alloy plate preparation method

ActiveCN114082783ASimple rolling processReduce energy consumptionProcess efficiency improvementAuxillary arrangementsSteel tubeMachine press

The invention is suitable for the field of metal processing, and provides a single-pass and large-rolling-reduction magnesium alloy plate preparation method which comprises the steps of respectively degreasing the outer surface of a magnesium alloy bar and the inner wall of a stainless steel pipe to obtain a clean surface; assembling the magnesium alloy bar into the steel pipe, and sealing the edges of the two ends of the steel pipe by using a press machine to obtain a completely closed sample; putting the completely closed sample into a heating furnace, and preserving heat for a certain time; carrying out a rolling process on the sample of which the temperature is kept; and cutting off the steel pipe by using a cutting means to obtain the formed magnesium alloy plate. According to the preparation method for rolling the magnesium alloy plate with the single-pass and large rolling reduction, the problems that in the traditional magnesium alloy plate rolling process, the pass number is large, and the single-pass rolling reduction is small are solved, the room-temperature strength of the magnesium alloy plate prepared through the technology is 300 MPa or above, the room-temperature ductility reaches 23% or above, and the strength and the ductility can be realized at the same time.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com