Mg-Nd-Zn-Zr alloy material containing Y and preparation process thereof

A technology of alloy material and preparation process, which is applied in the field of Y-containing Mg-Nd-Zn-Zr alloy material and its preparation process, can solve the problems of less impact research, achieve obvious grain refinement, and increase elongation , The effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

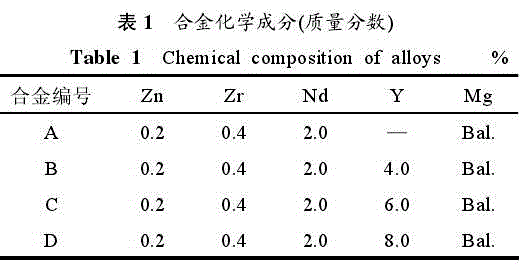

[0008] The materials used in the experiment are pure magnesium (99.96% mass fraction), pure zinc (99.92%), magnesium zirconium master alloy (30% Zr) and magnesium yttrium master alloy (31.72% Y). The design alloy composition is shown in Table 1. The alloy is smelted in a resistance crucible furnace. RJ-2 covering agent is used for smelting. The smelting temperature is 770 °C. After the alloy is completely melted, it is left for 15 minutes. The diameter×height of the obtained alloy ingot is 60mm×130mm. The mechanical properties of the samples were tested by CSS-44100 universal electronic testing machine, and the tensile rate was 2 mm / min.

[0009]

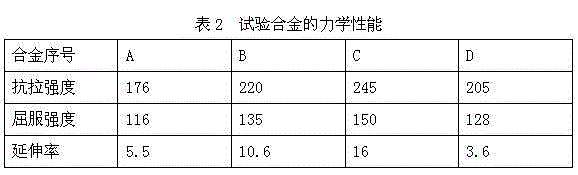

[0010] Table 2 shows the room temperature mechanical properties of each alloy as-cast. It can be seen from Table 2 that when the content of rare earth element Y is 4% and 6%, the tensile strength, yield strength and elongation of the alloy gradually increase, and when the content of Y element is 6%, the alloy shows the best perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com