Patents

Literature

35results about How to "Grain refinement is obvious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy ingot

The invention discloses an aluminum alloy ingot. The aluminum alloy ingot comprises, by weight , 9.6%-12.0% of Si, 1.5%-3.5% of Cu, less than 0.3% of Mg, less than 1.3% of Fe, less than 1.0% of Zn, less than 0.5% of Mn, less than 0.5% of Ni, less than 0.3% of Sn, 1%.-2%. of Sr, 1%.-2%. of Ti, 1%.-2%. of B and the balance Al. The Si element is added to the aluminum alloy ingot so that strength and toughness of the aluminum alloy ingot are effectively improved, and the Ti and B elements added into the aluminum alloy ingot enables a die-casting product to generate good grain refinement, casting cracks are effectively avoided, the appearance of a casting is improved, the surface quality of the ingot is improved, particularly cold shut of the ingot is reduced, and the impact toughness of the aluminum alloy ingot is effectively improved by 15%-20% on the condition that the strength of the aluminum alloy ingot is not reduced.

Owner:WUXI GREAT TECH

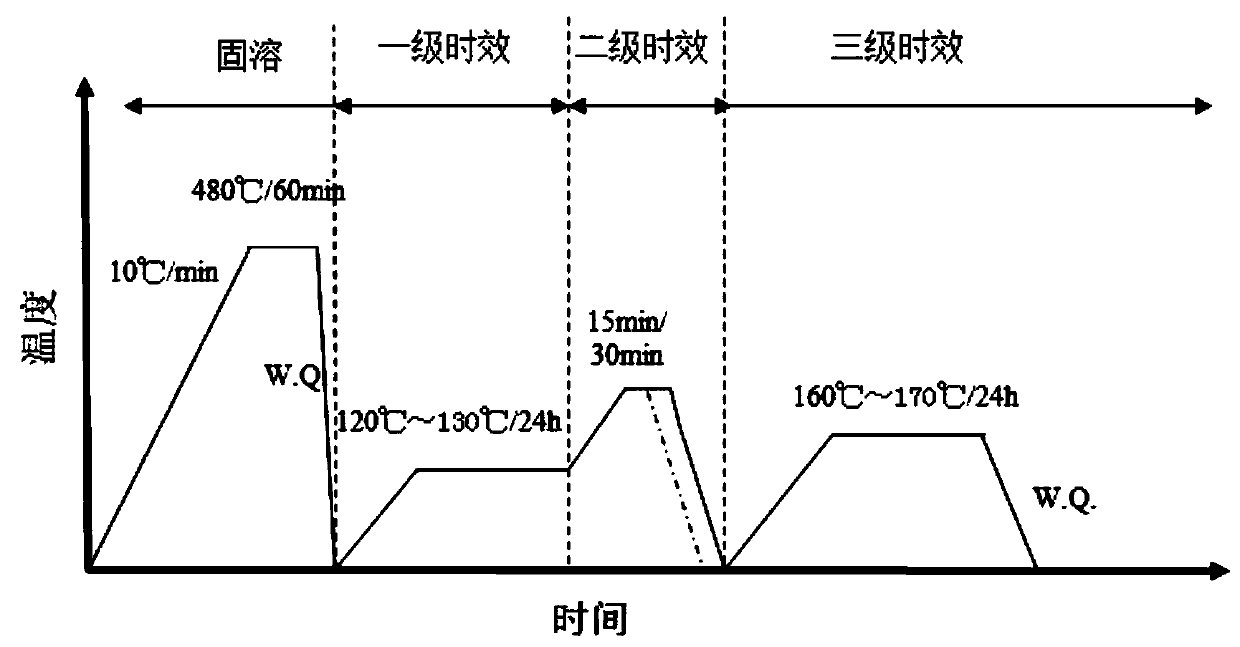

Aging treatment method for improving toughness of Al-Zn-Mg-Cu aluminum alloy, high-toughness aluminum alloy and preparation method thereof

The invention relates to the technical field of aluminum alloys, in particular to an aging treatment method for improving the toughness of an Al-Zn-Mg-Cu aluminum alloy, a high-toughness aluminum alloy and a preparation method thereof. The aging treatment method provided by the invention comprises the following steps that three stages of aging treatment are carried out on the Al-Zn-Mg-Cu aluminumalloy; the Al-Zn-Mg-Cu aluminum alloy is an Al-Zn-Mg-Cu aluminum alloy subjected to solution treatment; the temperature of the first-stage aging treatment is 120-130 DEG C, and the heat preservation time is 22-26 h; the temperature of the second-stage aging treatment is 200-220 DEG C, and the heat preservation time is 10-20 min; and the temperature of the third-stage aging treatment is 160-170 DEGC, and the heat preservation time is 22-26 h. The alloy obtained after the three stages of aging treatment has good strength and fracture toughness at the same time.

Owner:YANSHAN UNIV

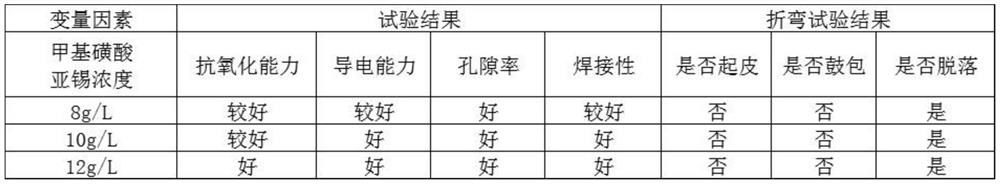

Lead-free electroless tin plating solution

InactiveCN102994994AEnables continuous autocatalytic depositionReduce typesLiquid/solution decomposition chemical coatingSolubilityPorosity

The invention relates to a lead-free electroless tin plating solution. The lead-free electroless tin plating solution is characterized by comprising the following components: 20 to 30g / L of stannous mono-sulphate, 60 to 120g / L of thiourea, 15 to 25g / L of citric acid, 20 to 50g / L of sulfur dioxide, 3 to 5g / L of ethylene diamine tetraacetic acid, 0.01 to 0.05g / L of polyethylene glycol, 20 to 55m / L of 98% of concentrated sulfuric acid, 0.5 to 1.0g / L of gelatin, and the balance of regulator. The lead-free electroless tin plating solution has the advantages that few categories of chemical materials are used and cost is low; the tin can be continuously deposited at a high speed on copper and a copper alloy substrate, thus semi-bright chemical coatings with different thicknesses can be produced, and the flatness of the chemical coatings can be improved; and the lead-free electroless tin plating solution is remarkable in grain refinement, low in porosity, simple in formula of plating solution, easy to control, stable in plating solution, long in service life and high in stability in batch production; and polyethylene glycol is a nontoxic and nonirritating substance with high water solubility, and can be combined with other materials without producing harmful substances.

Owner:NANTONG HUIFENG ELECTRONICS TECH

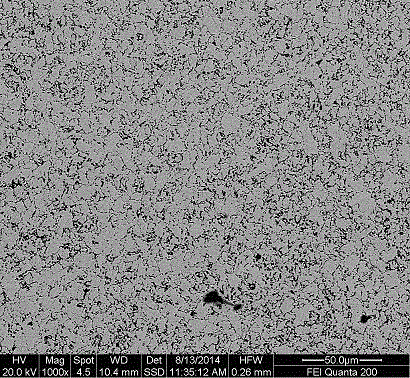

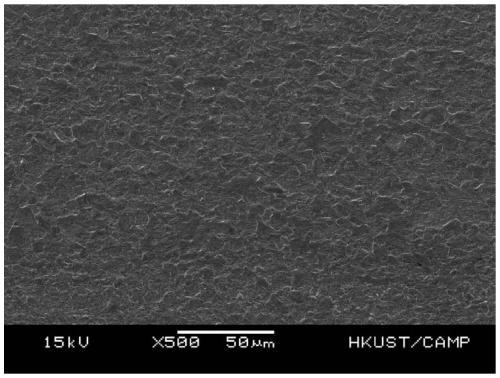

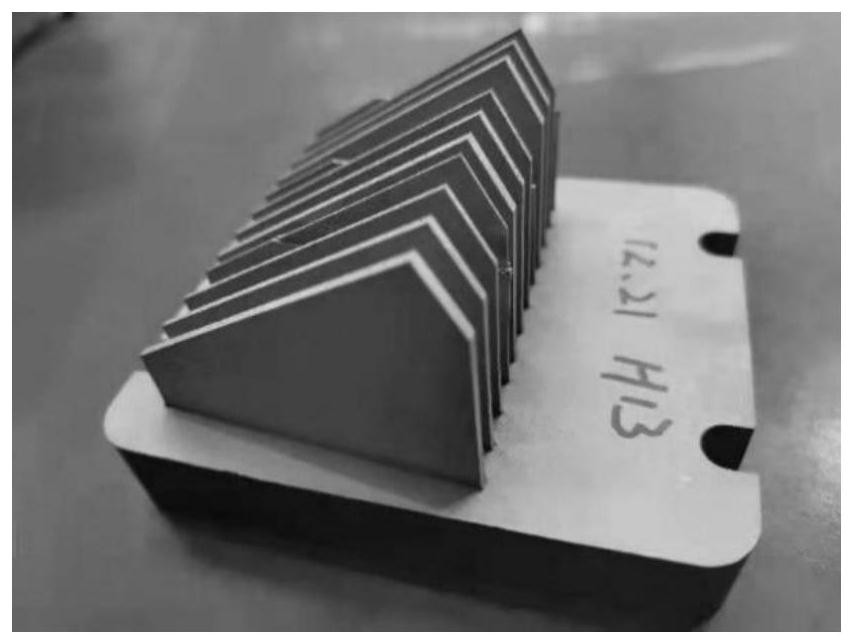

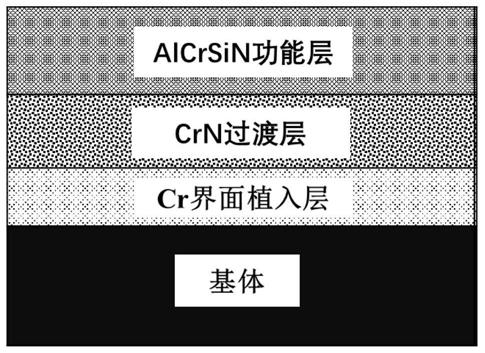

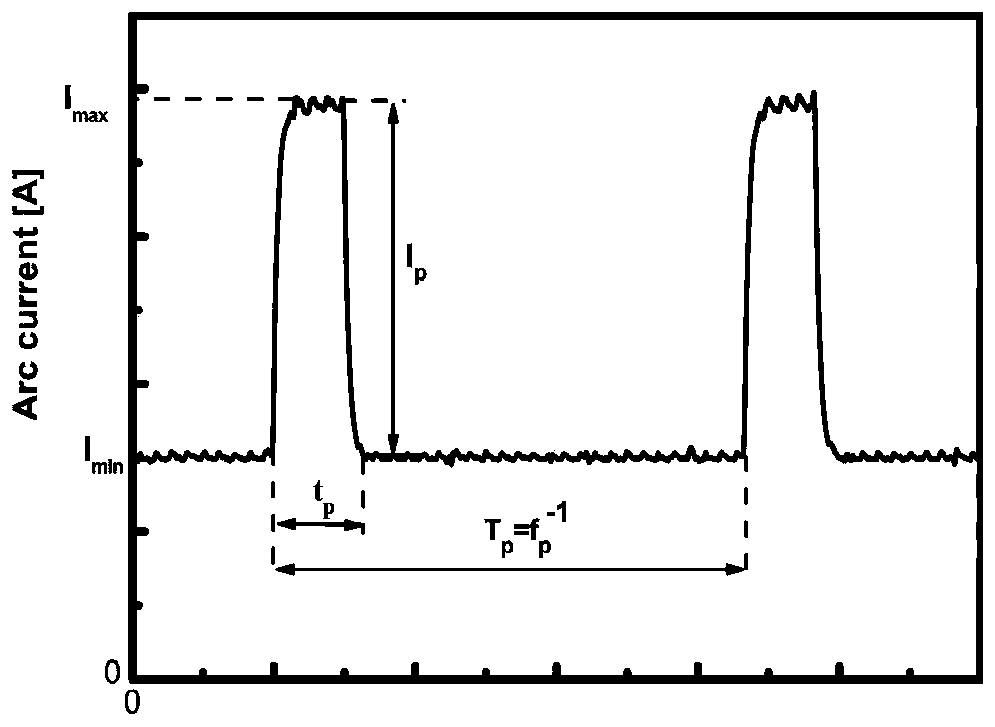

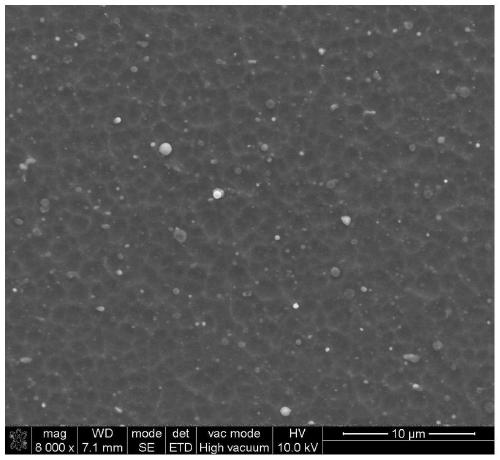

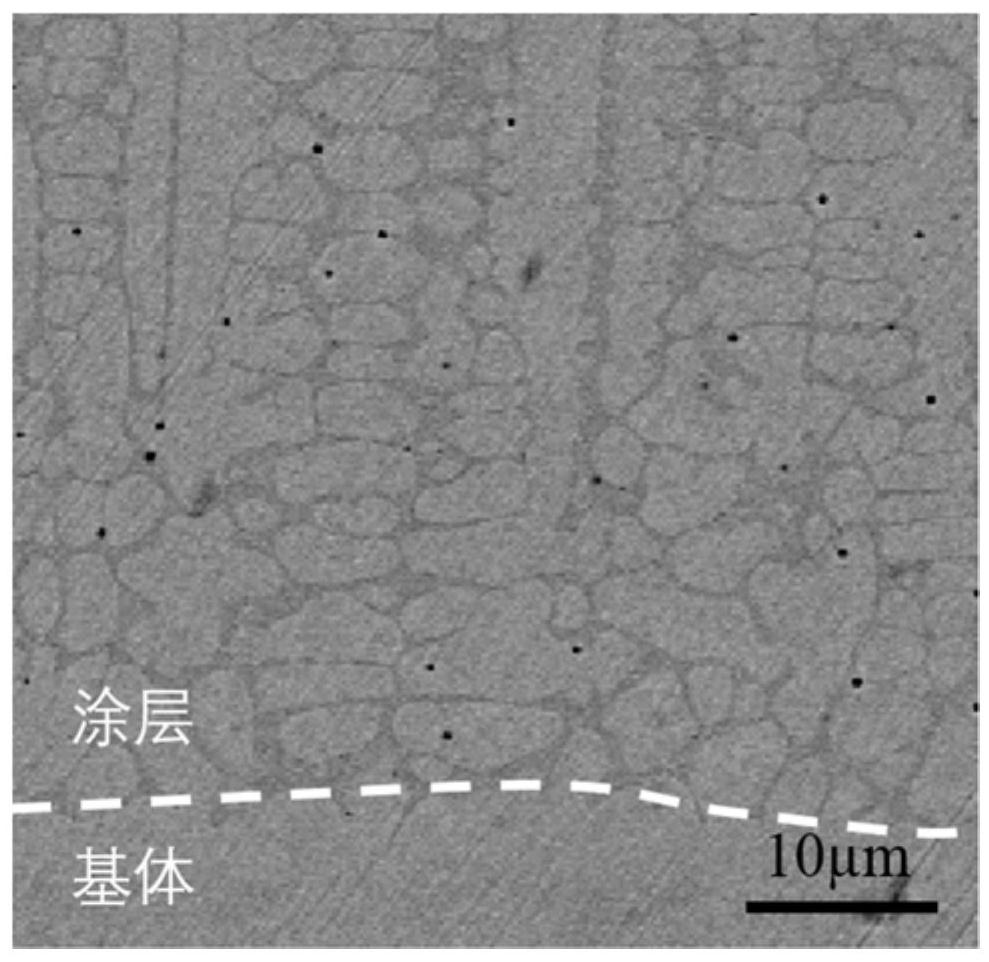

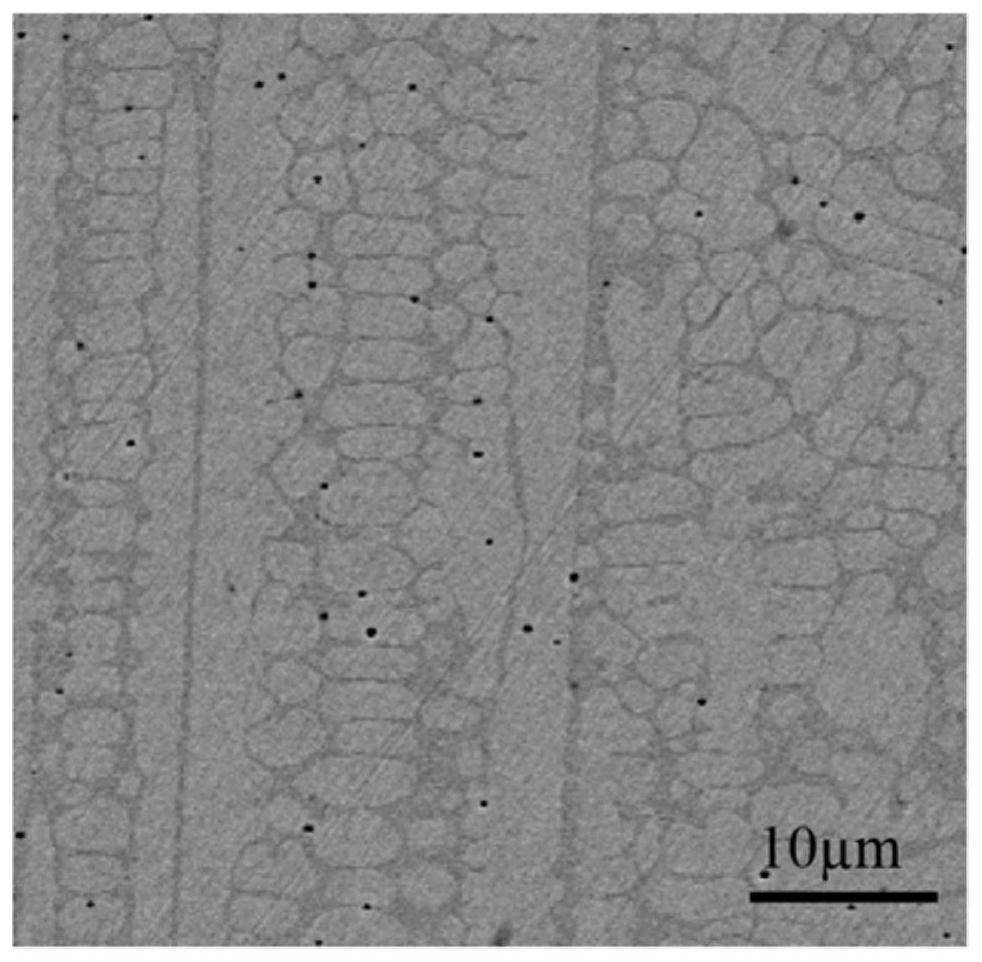

AlCrSiN nano-composite coating resistant to high temperature and abrasion and preparation method thereof

ActiveCN108796453AHigh hardnessImprove high temperature stabilityVacuum evaporation coatingSputtering coatingFilm baseUltimate tensile strength

The invention belongs to the technical field of coating preparation and particularly relates to an AlCrSiN nano-composite coating resistant to high temperature and abrasion and a preparation method thereof. According to the AlCrSiN nano-composite coating resistant to high temperature and abrasion and the preparation method thereof, a pulsed arc ion plating method is adopted; and a Cr interface implantation layer, a CrN transition layer and an AlCrSiN surface functional layer are sequentially deposited on the surface of a base body from bottom to top. Experimental results show that the AlCrSiNnano-composite coating obtained through the preparation method is excellent in high-temperature stability and abrasion resistance and has the advantages of being small in number of surface large particles, low in internal stress, high in film base bonding strength and the like; and the AlCrSiN nano-composite coating is applicable to surface protection of products such as mechanical parts, tools and molds.

Owner:GUANGDONG UNIV OF TECH

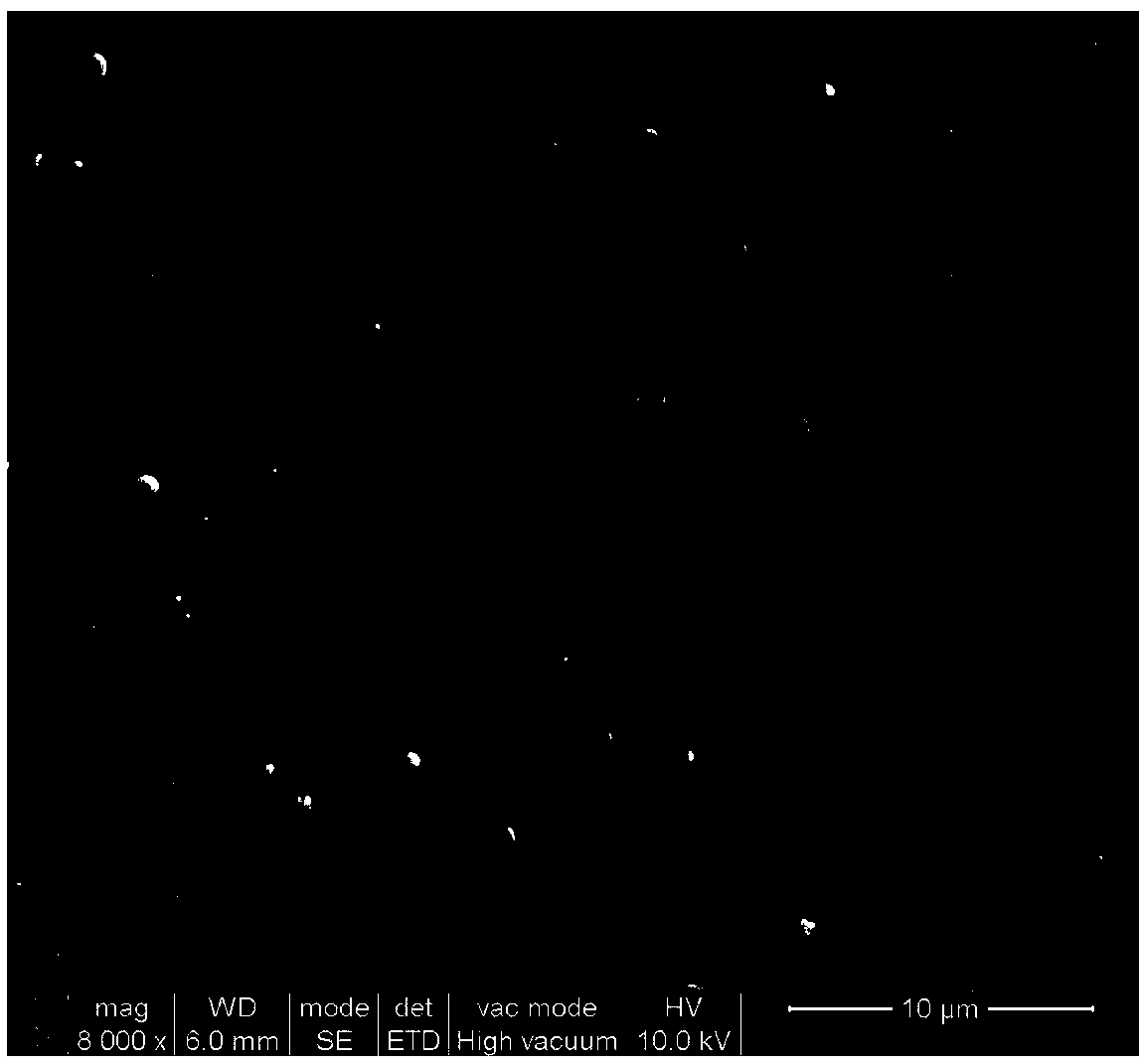

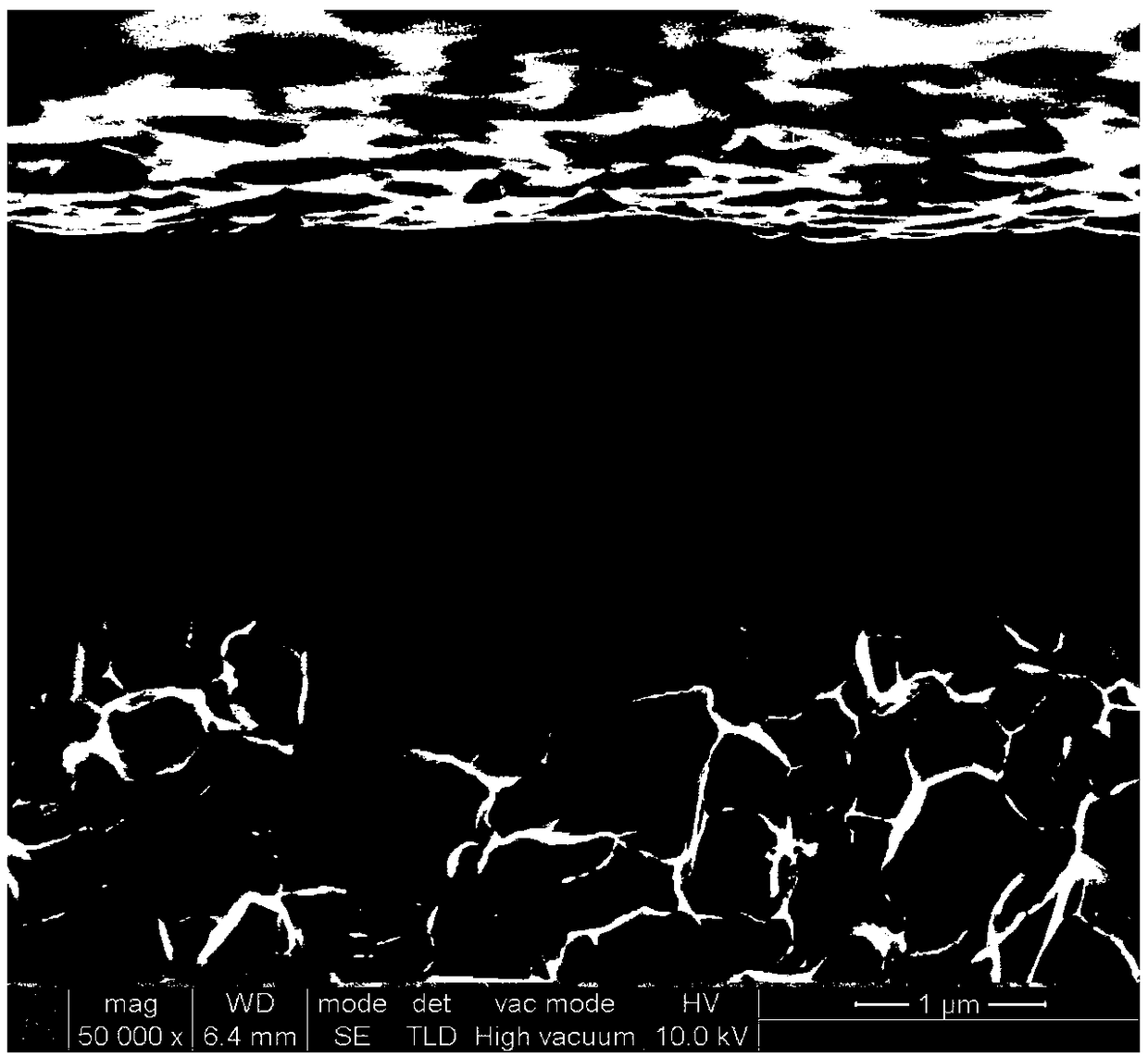

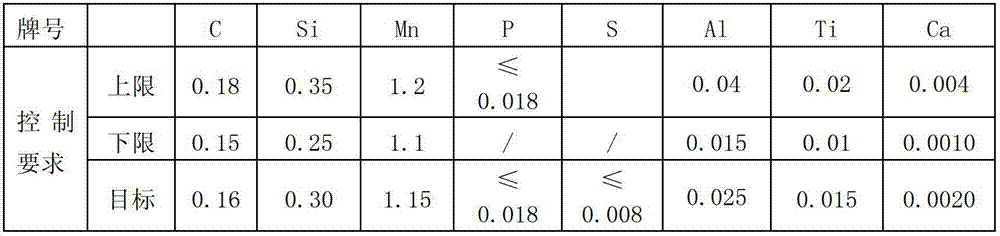

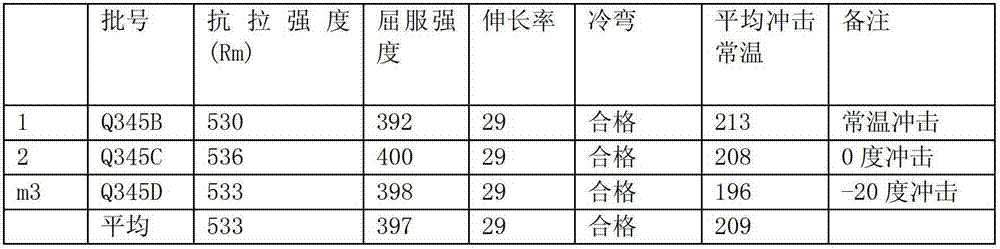

Production method for controlling fault detection defect of medium thick plate Q345 steel

InactiveCN103031490AImprove the qualified rate of flaw detectionImproving the pass rate of strong flaw detection of steelThick plateSlag

The invention provides a production method for controlling fault detection defect of medium thick plate Q345 steel. The composition design is: 0.15-0.18% of C, 0.25-0.35% of Si, 1.1-1.2% of Mn, equal to or less than 0.018% of P, equal to or less than 0.008% of S, 0.025-0.04% of Al, 0.015-0.02% of Ti, and 0.002-0.004% of Ca; an Al-Ca refining agent is added during LF refining, the Al-Ca reining agent is began to feed into a steel ladle when the temperature reaches 1530 DEG C, and the addition amount is 0.5-1.0kg / t steel; the S content of the pretreated molten iron is 0.001-0.002%, and the tapping temperature of a converter is kept at 1620 DEG C to 1630 DEG C; the Al2O3 content of refined slag of an LF refining furnace is 30-35%, the delivery of current is 10min to 15min, and the final molten steel nitrogen content is 0.002-0.004%; and the molten steel liquid level of a casting pot is controlled to be 500mm to 550mm, and the steel ladle long nozzle is protected by argon seal, thus the nitrogen content of the continuous casting molten steel is enhanced by 0.0003-0.0008%, and the molten steel continuous casting temperature is 1525 DEG C to 1535 DEG C.

Owner:宝钢集团八一钢铁股份有限公司

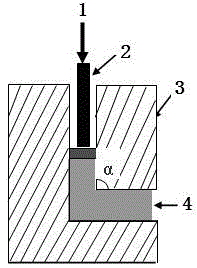

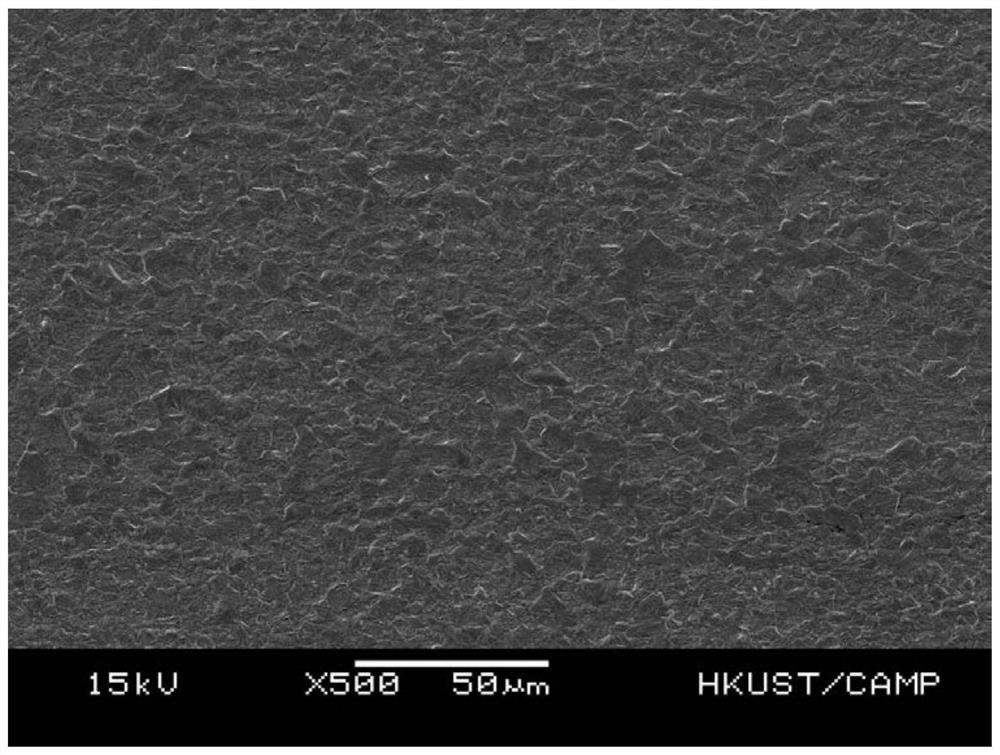

Method for preparing dispersion strengthened copper-based composites through equal channel angular pressing (ECAP)

InactiveCN105478507AExcellent performanceGrain refinement is obviousExtrusion control devicesCrystalliteHardness

Disclosed is a method for preparing dispersion strengthened copper-based composites through equal channel angular pressing (ECAP). The dispersion strengthened copper-based composites after hot extrusion, rolling, drawing or rotary swaging forming are sent to an ECAP die (3) which is preheated to 100-500 DEG C and coated with lubricants after preheating at the temperature of 200-900 DEG C and preserving heat for 0.5-5h; dispersion strengthened copper-based composite sticks, plates, tubes, square materials and the like are pressed and formed under pressing pressure (1) of 100-1000MPa at the pressing speed of 1-100 mm / min; the next pressing process is performed after each pressing process, and altogether 2-10 pressing processes are performed. According to the method, grains of the dispersion strengthened copper-based composites are refined effectively; comprehensive performance such as strength, hardness and electric conductivity of the dispersion strengthened copper-based composites is improved; the method has the advantages that operation is easy, machining efficiency is high, and cost is low. The dispersion strengthened copper-based composites prepared through the method can be widely applied to the aviation field, the aerospace field, the electronic field, the manufacturing field and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

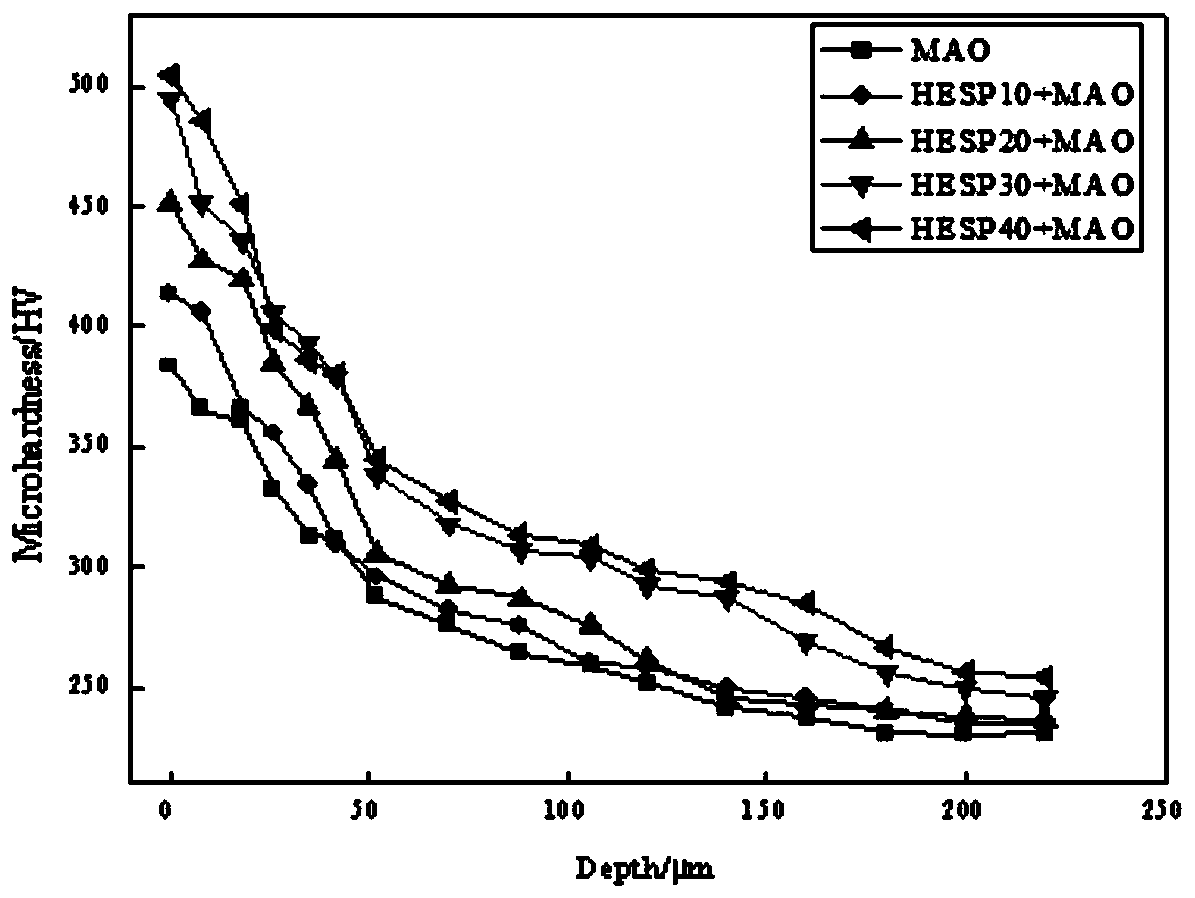

Preparation method of high-wear-resistance high-hardness titanium alloy composite sleeve

InactiveCN110093650AHigh hardnessChemically stableSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a preparation method of a high-wear-resistance high-hardness titanium alloy composite sleeve. The preparation method comprises the following steps that 1, shot blasting treatment is carried out on the outer surface of a conventional titanium alloy composite sleeve; 2, 2, pretreatment is carried out on the outer surface of the titanium alloy composite sleeve; 3, the titaniumalloy composite sleeve is fixed into a micro-arc oxidation groove set; 4, micro-arc oxidation treatment is carried out on the outer surface of the titanium alloy composite sleeve; 5, the outer surface of the titanium alloy composite sleeve obtained after micro-arc oxidation is cleaned and dried. An outer surface micro-arc oxidation coating of the titanium alloy composite sleeve adopting shot blasting is uniform and compact, the hardness of the surface layer of the sleeve is increased, and the titanium alloy composite sleeve has certain wear resistance and mechanical stability. According to the method, the conventional titanium alloy composite sleeve is subjected to shot blasting treatment and micro-arc oxidation treatment, and a protective layer high in hardness and resistant to wear andcorrosion is formed on the outer surface layer of the titanium alloy composite sleeve, so that the service life of the titanium alloy composite sleeve is prolonged, the production cost is reduced, andthe application of the technology in the field of oil and gas wells is further accelerated.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

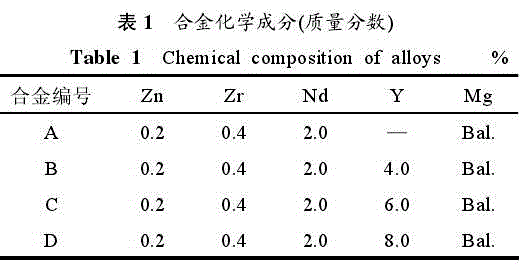

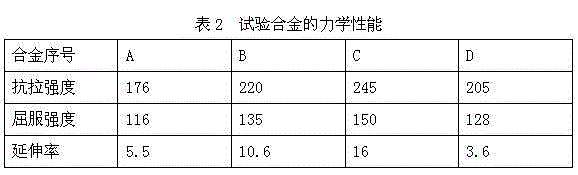

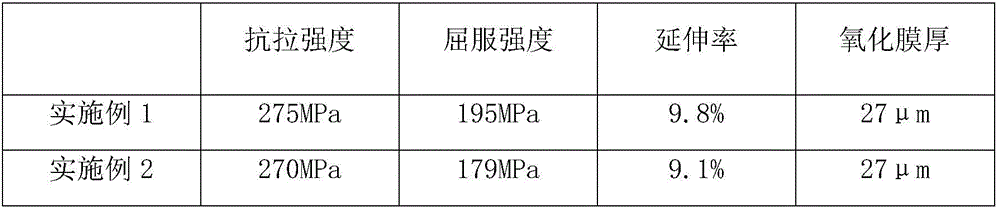

Mg-Nd-Zn-Zr alloy material containing Y and preparation process thereof

The invention discloses an Mg-Nd-Zn-Zr alloy material containing Y. The Mg-Nd-Zn-Zr alloy material is characterized by comprising the following components in parts by mass: 0.2 of Zn, 0.4 of Zr, 2.0 of Nd, 4-8 of Y, and the balance of Mg. A preparation process is characterized in that pure magnesium, pure zinc, 30% of Zr magnesium zirconium intermediate alloy and 31.72% of Y magnesium yttrium intermediate alloy are smelted by using a RJ-2 covering agent at a smelting temperature of 770 DEG C, are stood by 15 minutes after being totally molten, are poured in an iron mold, preheated to 200 DEG C, at 720 DEG C, and are molded by pouring.

Owner:黄晓艺

Aluminum alloy ingot

The invention relates to an aluminum alloy ingot. The aluminum alloy ingot is prepared from, by weight percent, 7.2%-11.4% of Si, 1.2%-1.5% of Cu, 0.1%-0.3% of Mg, 0.2%-0.4% of Fe, 1.2%-1.4% of Zn, 0.2%-0.4% of Ni, 0.1%-0.3% of Sn, 1.2%-2.4% of Sr, 2.1%-2.4% of Ti, 2.1%-2.4% of B, 1.2%-1.4% of Sb, 0.3%-0.5% of As, 0.22%-0.44% of RE, 0.4%-1.4% of LaCe, 0.3%-0.5% of Pr and the balance Al and inevitable impurities, wherein the content of the impurities is not larger than 0.1%. The aluminum alloy ingot is good in comprehensive performance, resistant to corrosion and stable in performance.

Owner:肇庆南都再生铝业有限公司

Aluminum alloy sheet

The invention provides an aluminum alloy sheet. The aluminum alloy sheet comprises, by weight, 8.0%-11.0% of Si, 0.8%-1.0% of Cu, 0-0.1% of Mg, 0-1.5% of Fe, 0-1.0% of Zn, 0-0.1% of Mn, 0-0.4% of Ni, 0-0.3% of Sn, 0.1%-0.2% of Sr, 0.1%-0.2% of Ti, 0.1%-0.2% of B, and the balance Al, and the total amount of the Sr, the Ti and the B is smaller than 0.3%. The Sr is added into the aluminum alloy sheet, so that the strength and the toughness of the aluminum alloy sheet are effectively improved; the Ti and the B are added into the aluminum alloy sheet so that good grain refinement can be generated, impact cracks are effectively avoided, the appearance of castings is improved, and the surface quality is improved; under the condition that the strength is not lowered, the impact toughness of the aluminum alloy sheet is effectively improved, and good heat conductivity is achieved.

Owner:宁波市鄞州兴达旅游用品厂

High-strength wear-resistant aluminum alloy

The invention discloses high-strength wear-resistant aluminum alloy prepared from the following components in percentage by weight: 0.23% of yttrium oxide and neodymium oxide, 1.52% of silicon, 1.4% of copper, 0.37% of iron, 0.88% of cobalt and nickel, 0.14% of magnesium, 0.028% of titanium, strontium and beryllium, 0.14% of manganese, 0.02% of chromium and the balance of aluminum. The elements including titanium, strontium and beryllium which are at a fixed ratio are added into the aluminum alloy, so that the strength, wear resistance and toughness of the aluminum alloy are effectively improved; in addition, after the elements including cobalt and nickel which are at a fixed ratio are added into the aluminum alloy, a cast product can generate a favorable grain refinement function, casting cracks are effectively overcome, the appearance of a casting and the surface quality are improved, and the hardness of the aluminum alloy is improved; yttrium oxide and neodymium oxide which are at a fixed ratio are added and take a synergistic effect, so that the corrosion resistance of the aluminum alloy is improved; and the impact toughness of the aluminum alloy is effectively improved by 25.2%.

Owner:JINYU METAL MATERIALS CO LTD

Aluminum alloy ingot

The invention discloses an aluminum alloy ingot. The aluminum alloy ingot comprises, by weight , 9.6%-12.0% of Si, 1.5%-3.5% of Cu, less than 0.3% of Mg, less than 1.3% of Fe, less than 1.0% of Zn, less than 0.5% of Mn, less than 0.5% of Ni, less than 0.3% of Sn, 1%.-2%. of Sr, 1%.-2%. of Ti, 1%.-2%. of B and the balance Al. The Si element is added to the aluminum alloy ingot so that strength and toughness of the aluminum alloy ingot are effectively improved, and the Ti and B elements added into the aluminum alloy ingot enables a die-casting product to generate good grain refinement, casting cracks are effectively avoided, the appearance of a casting is improved, the surface quality of the ingot is improved, particularly cold shut of the ingot is reduced, and the impact toughness of the aluminum alloy ingot is effectively improved by 15%-20% on the condition that the strength of the aluminum alloy ingot is not reduced.

Owner:WUXI GREAT TECH

Alloy material easy to mold at a time

The invention relates to the technical field of alloys, in particular to an alloy material easy to mold at a time. The alloy material is characterized in that the alloy material comprises, by weight, 0.2-0.4% of zirconium, 0.1-0.3% of zinc, 5-7% of silicon, 0.02-0.1% of strontium, 0.05-0.2% of molybdenum, 0.1-0.3% of nickel, 0.08-0.3% of copper, 0.02-0.04% of scandium, 2-15 ppm of beryllium, and the balance aluminum and less than 0.1% of impurities. Castings cannot crack due to uneven cooling in the cooling process, and the cooling speed is 5% higher than that of conventional alloys. Accordingly, castings cast through one-step molding are smooth in surface and high in strength and impact toughness.

Owner:蚌埠冠宜型材科技有限公司

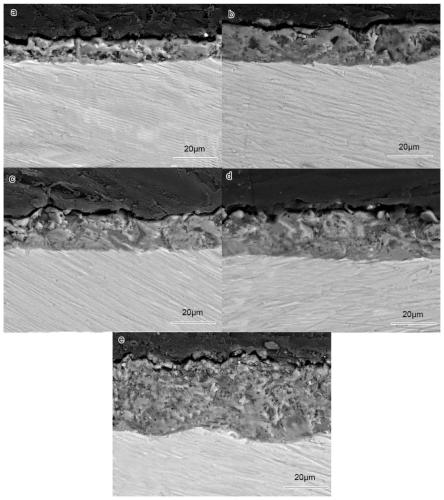

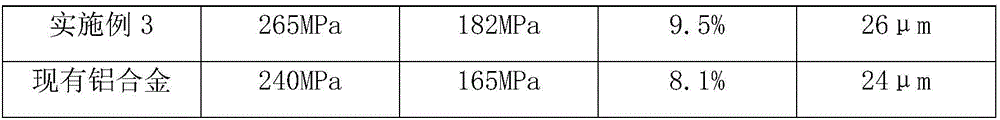

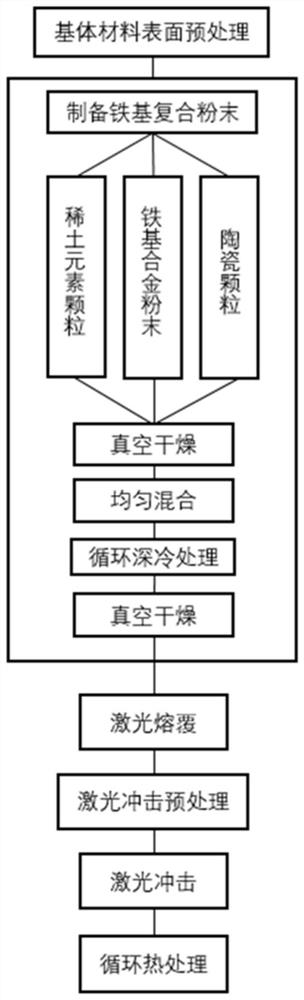

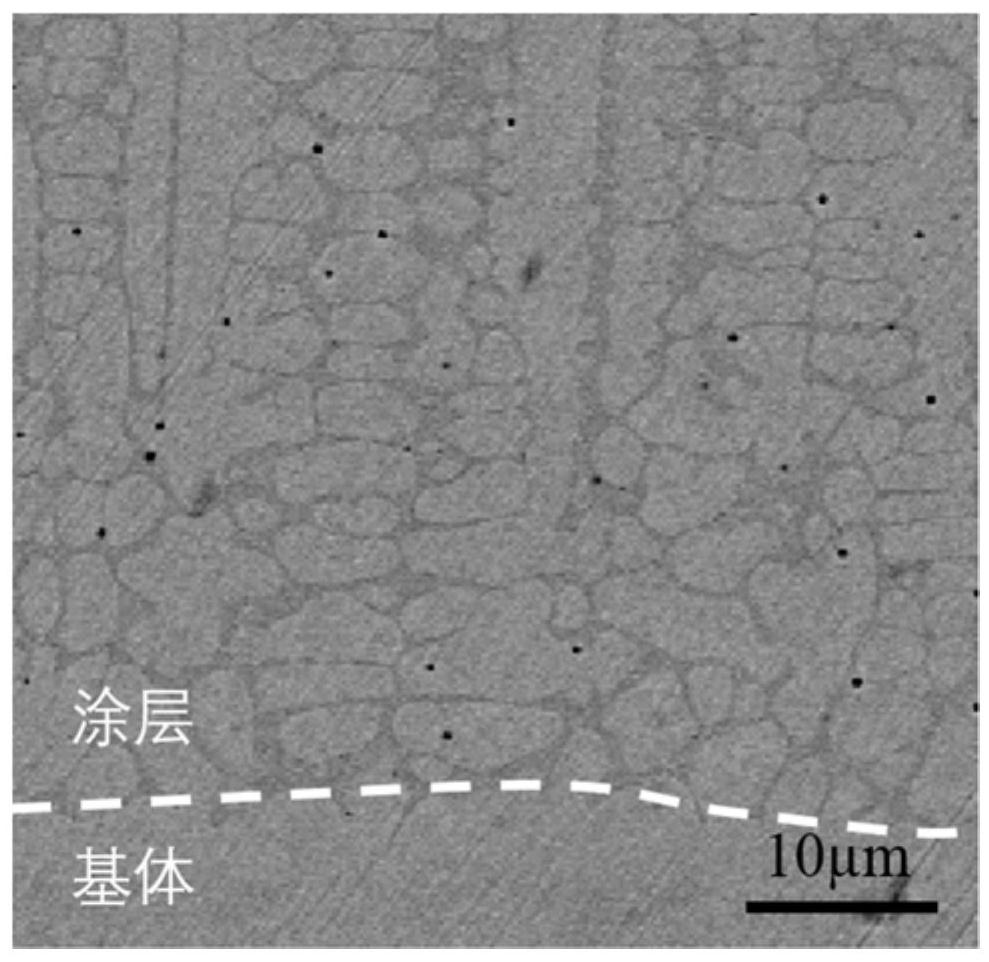

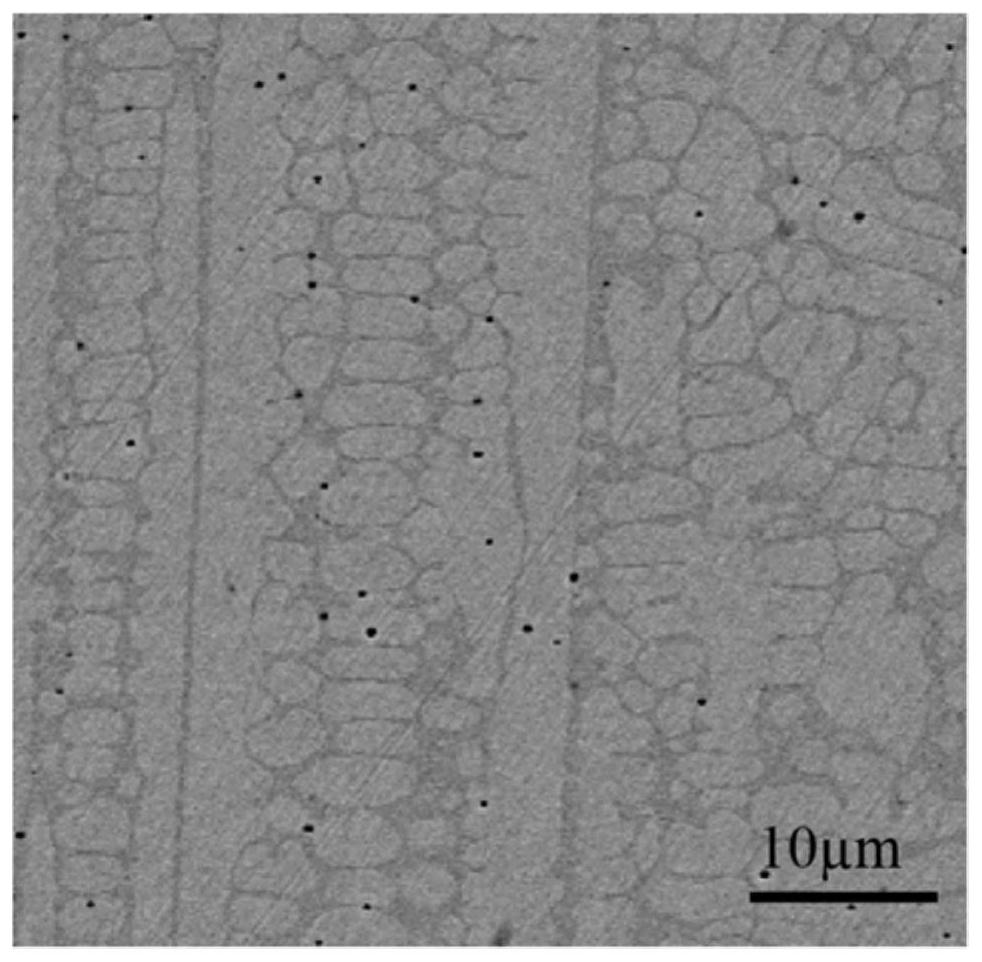

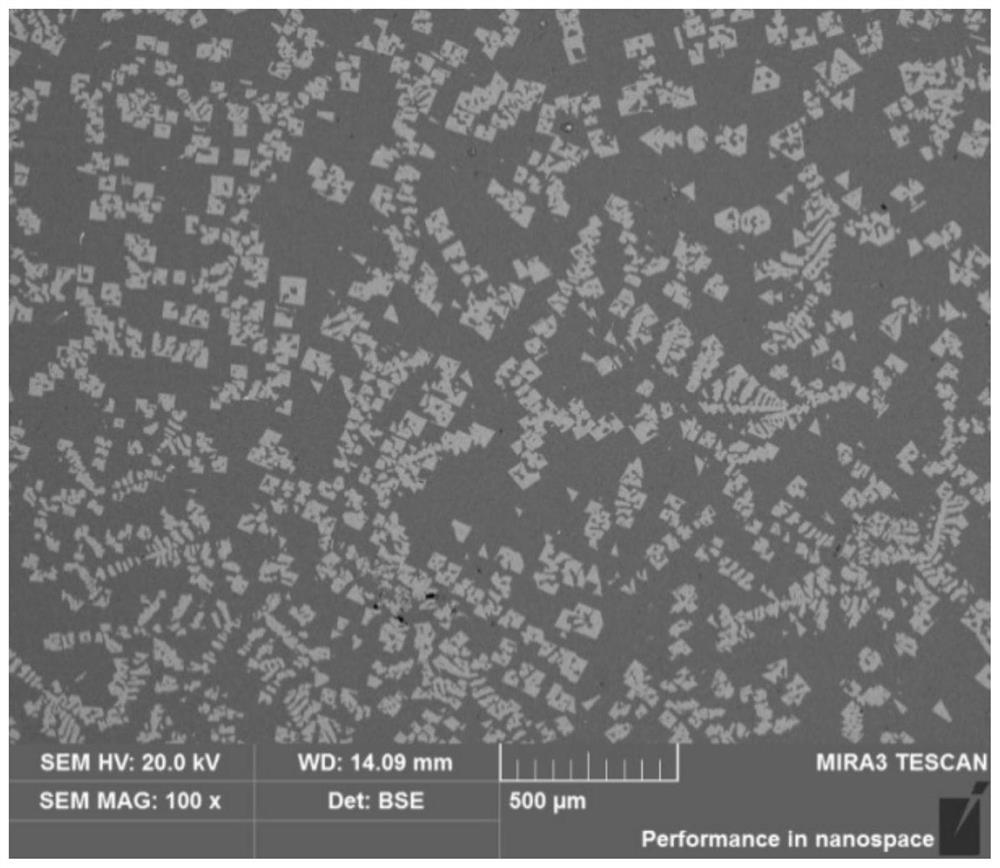

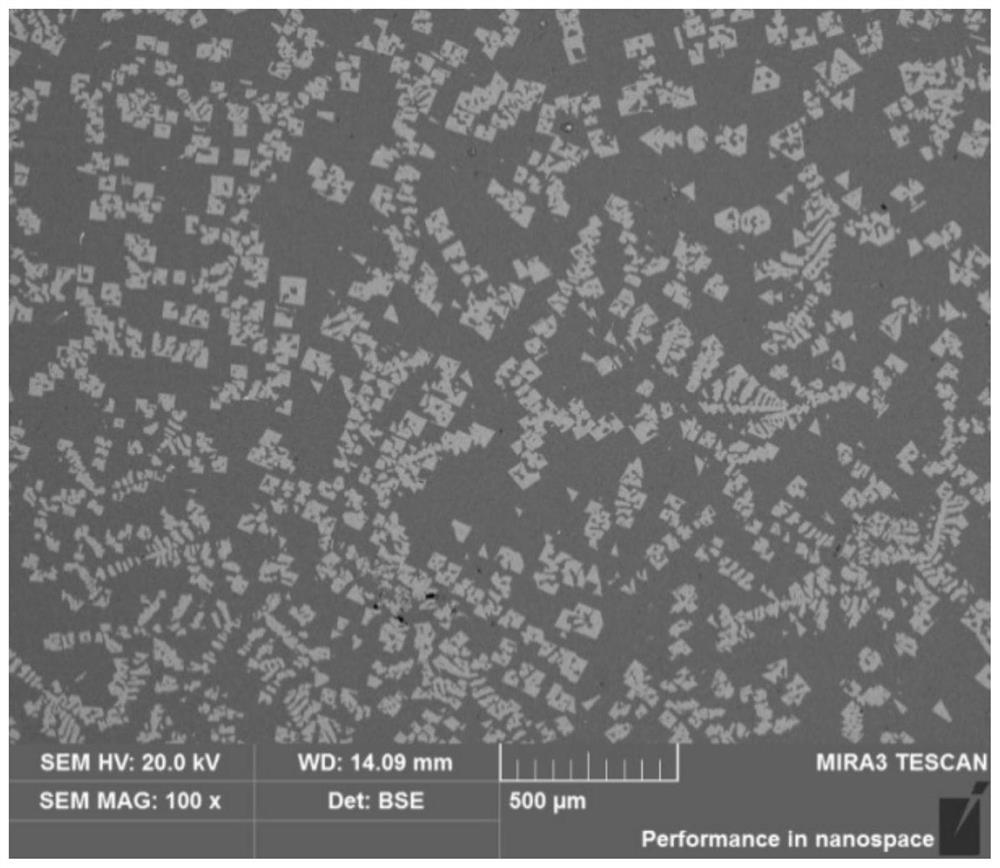

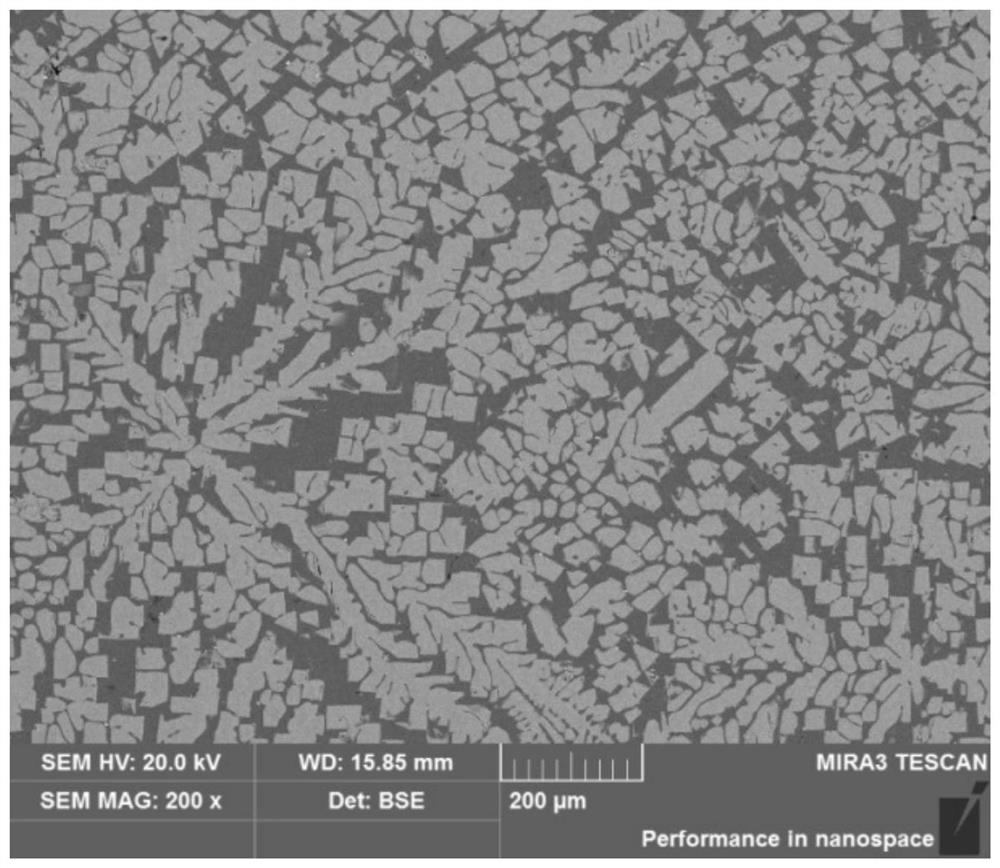

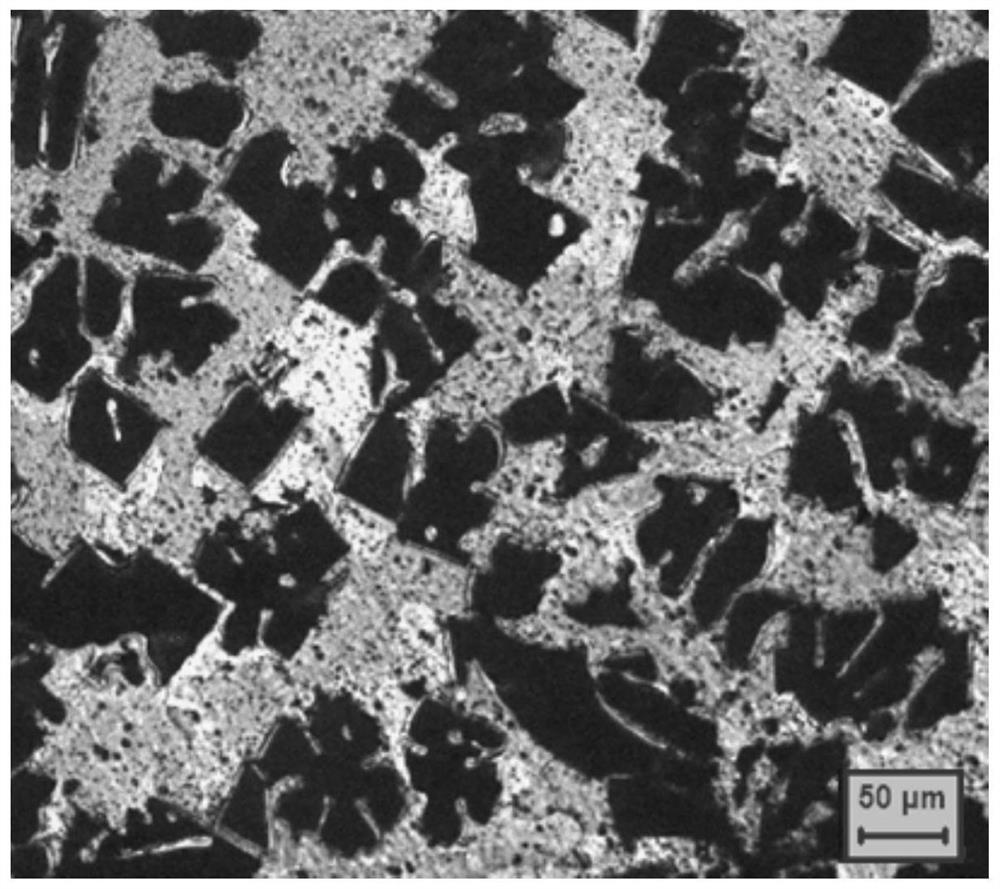

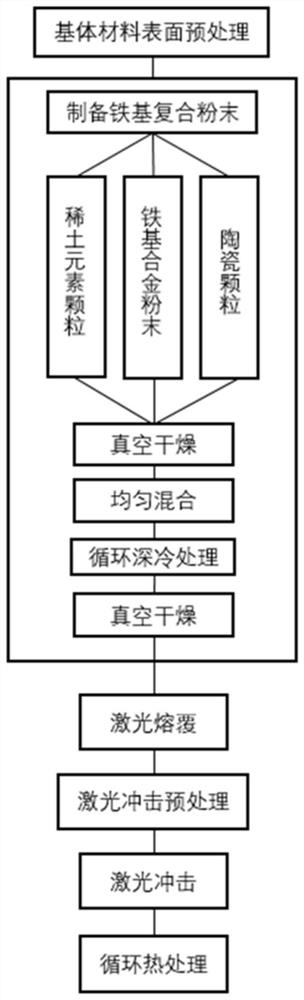

Iron-based wear-resistant composite material and preparation method thereof

ActiveCN113215564AHigh densityImprove refinementTransportation and packagingMetal-working apparatusCoated surfaceHeat treated

The invention discloses an iron-based wear-resistant composite material and a preparation method thereof. The preparation method comprises the following steps: preparing an iron-based wear-resistant composite coating on the surface of an iron-based alloy matrix material by using iron-based composite powder by using a laser cladding method to obtain a composite body; polishing and cleaning the surface of the composite body; then carrying out laser shock, and surface enhancement treatment of the iron-based wear-resistant composite coating is achieved; performing cyclic heat treatment on the composite with the surface subjected to laser shock to eliminate residual stress; and the iron-based composite powder is obtained by uniformly mixing micron La2O3 powder, micron Al2O3 powder and micron FeCrNiSiB powder, carrying out liquid nitrogen circulation subzero treatment and drying, and the iron-based composite powder contains the following components in percentage by mass: 0.05%-10% of the micron La2O3 powder, 0.1%-45% of the micron Al2O3 powder and 50%-95% of the micron FeCrNiSiB powder. According to the iron-based wear-resistant composite material and the preparation method thereof provided by the invention, the composite coating with good performance is prepared on the surface of an iron-based alloy material, the service life of an iron-based alloy matrix is prolonged, and the preparation method has great significance in repairing and reconstruction of engineering machinery.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

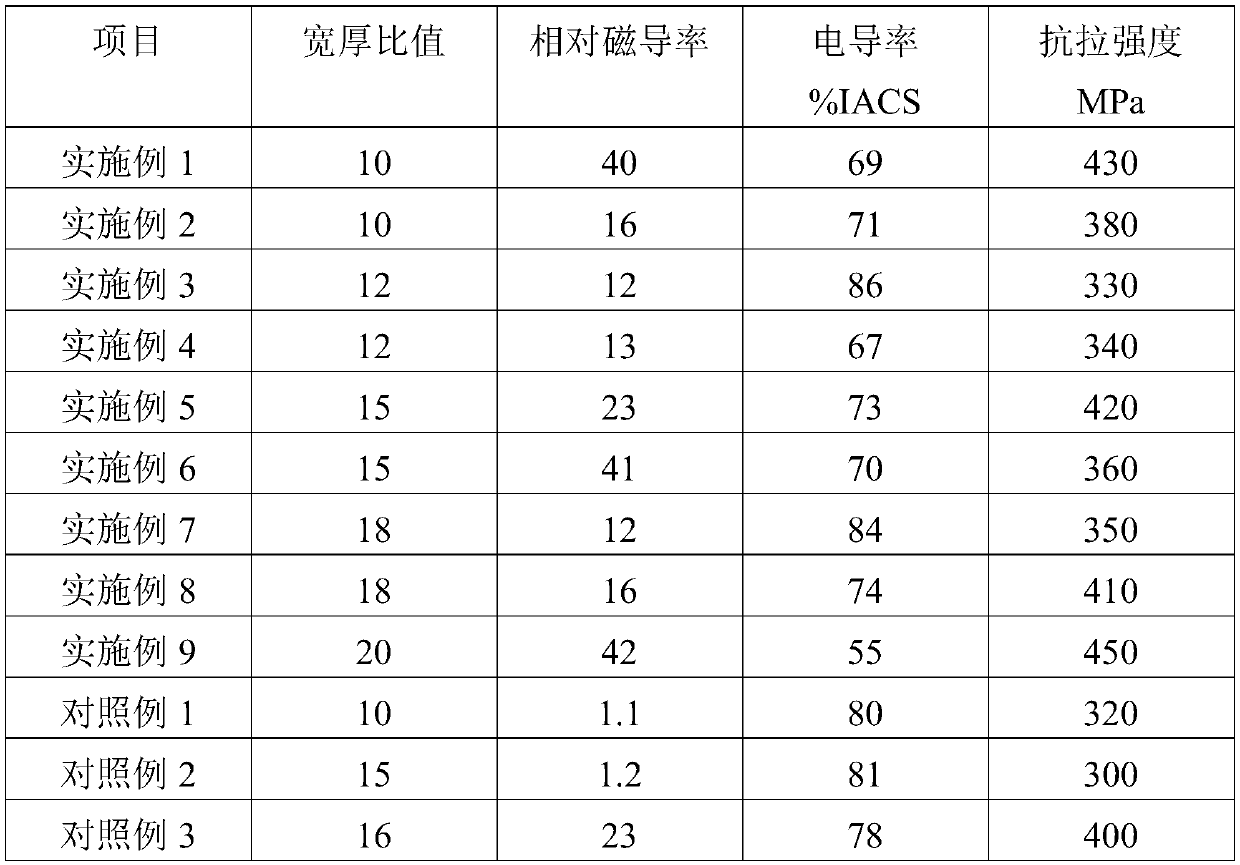

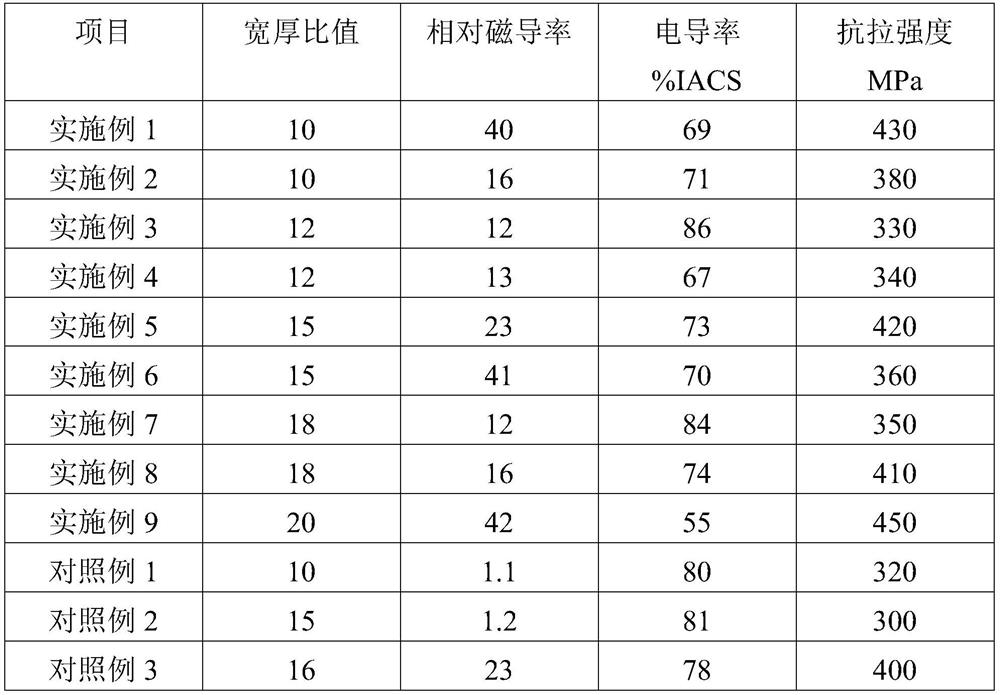

Tantalum-containing copper alloy wire/strip and preparation method thereof

ActiveCN111118320AImprove magnetic permeabilityHigh strengthUltimate tensile strengthContinuous caster

The invention provides a tantalum-containing copper alloy wire / strip comprising the following components of, by mass, 0.01%-1.0% of tantalum, 0.01%-1.0% of silver, 0.01%-0.5% of iron, and the balancecopper. The invention further provides a preparation method of the tantalum-containing copper alloy wire / strip. A continuous casting machine conducts high-temperature treatment on copper-tantalum intermediate alloy, silver, copper-iron intermediate alloy and copper, drawing casting is conducted after cooling, then repeated drawing is conducted, after micro machining, continuous heat treatment is conducted through annealing equipment, the tantalum-containing copper alloy wire is obtained, and the tantalum-containing copper alloy strip of the needed specifications is obtained through rolling ofa double-roller rolling mill. With adding of the tantalum, magnetoconductivity of the copper alloy is improved effectively, the strength of the copper alloy is improved through adding of the silver, good electroconductibility of the copper alloy wire / strip is ensured, magnetoconductivity of the copper alloy can be further enhanced through the iron element in the copper alloy, and the copper alloymaterial has good magnetoconductivity, electroconductibility and strength through the element combination of tantalum, silver, iron and copper.

Owner:HENAN POLYTECHNIC UNIV +2

Method for preparing aluminum-scandium alloy with high scandium content

The invention discloses a method for preparing an aluminum-scandium alloy with high scandium content. The method comprises the steps that metal scandium and metal aluminum are weighed according to thescandium content in the aluminum-scandium alloy needing to be prepared; the obtained materials are added into a medium-frequency induction melting furnace, continuously vacuumizing is carried out, and then heating is carried out to 1200-1600 DEG C to melt the metal scandium and the metal aluminum; after complete melting is achieved, alloy liquid is obtained, and heat preservation is carried out for 20-40 min; and high-purity argon is introduced in, the alloy liquid subjected to heat preservation is poured into a water-cooled copper die, circulating water is cooled to 1-15 DEG C by adopting amold circulating water refrigerating system, the cooled circulating water is introduced into the water-cooled copper die to circularly cool the alloy liquid, and cooling and solidifying of the alloy liquid can be completed within 3-8 seconds to obtain an aluminum-scandium alloy cast ingot with scandium content of 5%-99%. According to the method, rapid cooling can be achieved within 3-8 s, the aluminum-scandium alloy with high scandium content which is high in purity, high in compactness, low in segregation, uniform in component and low in cost can be prepared, and the requirement of the current market for the aluminum-scandium alloy with high scandium content is met.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

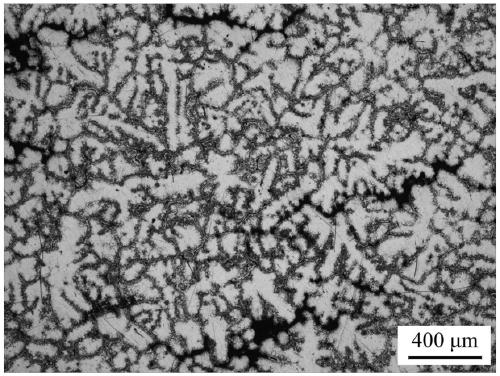

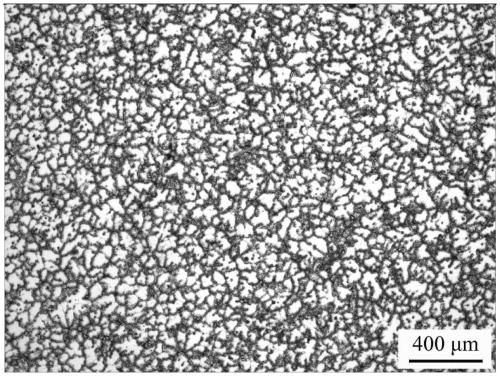

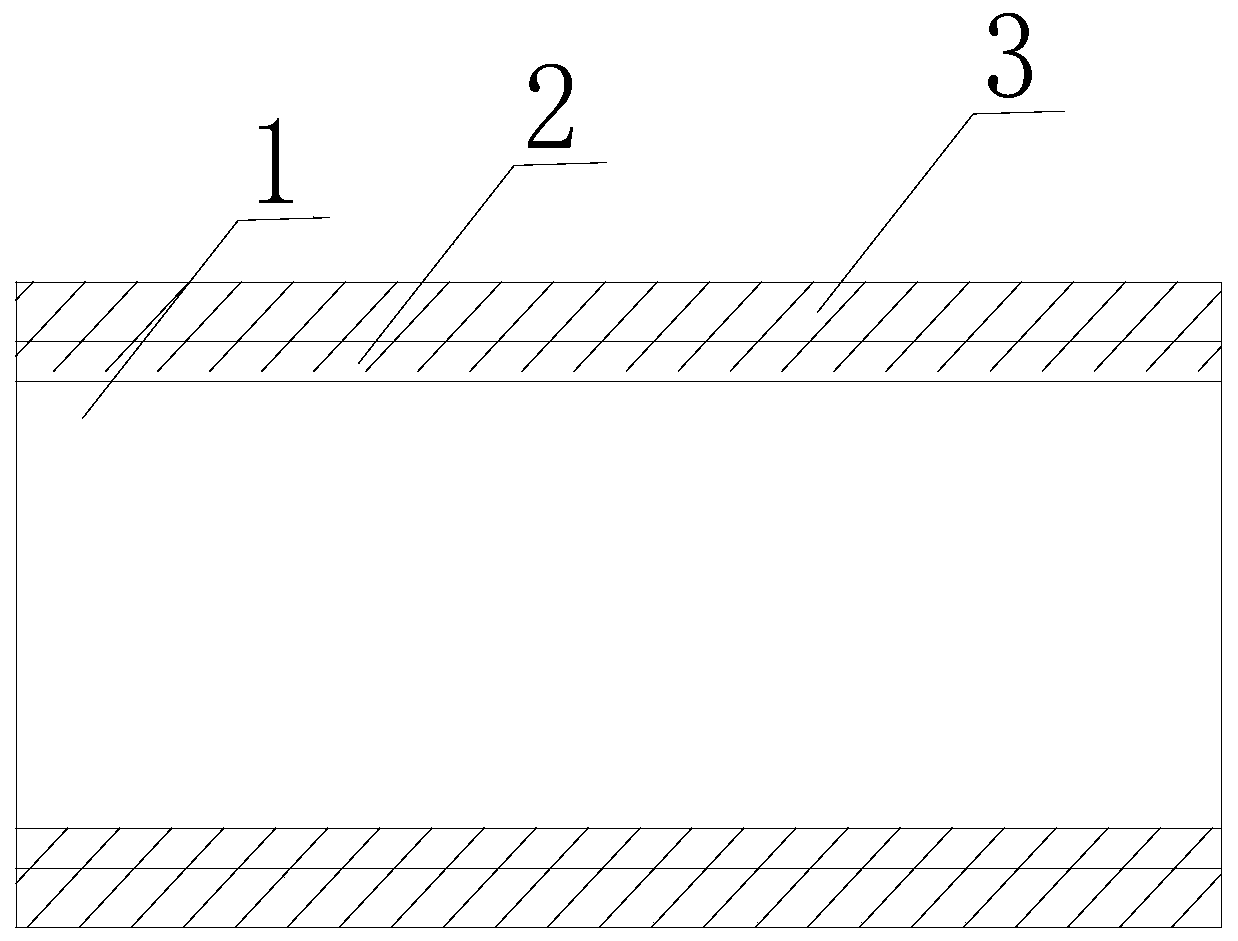

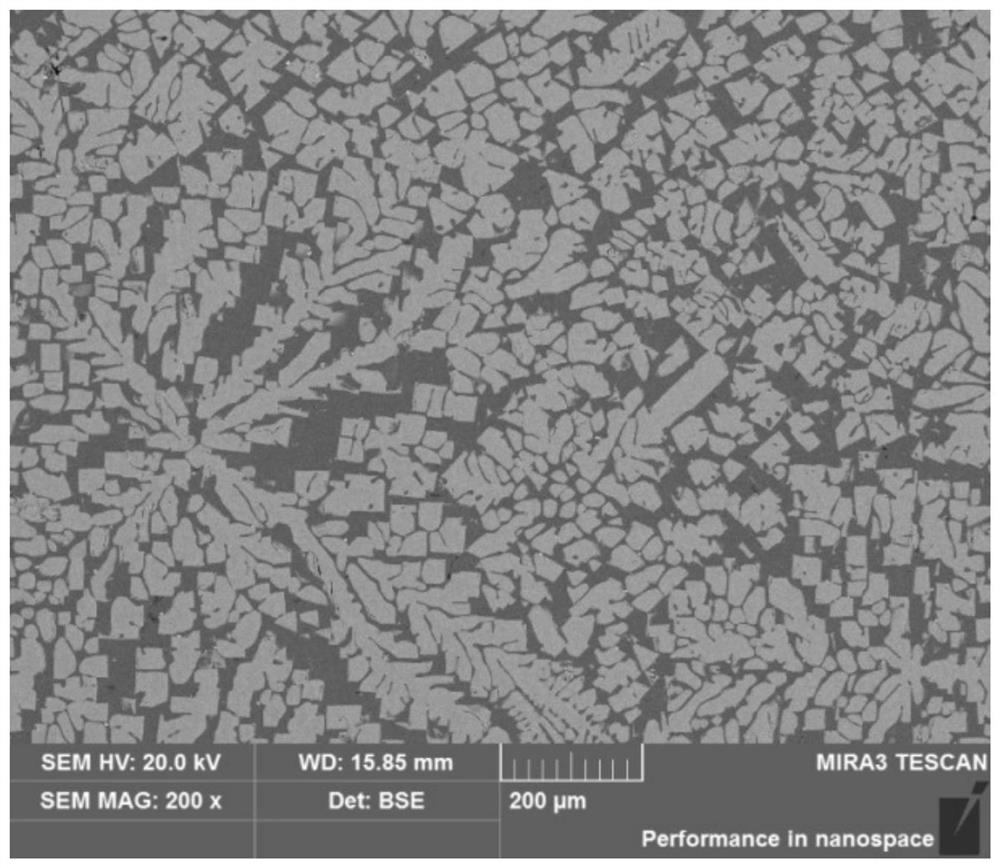

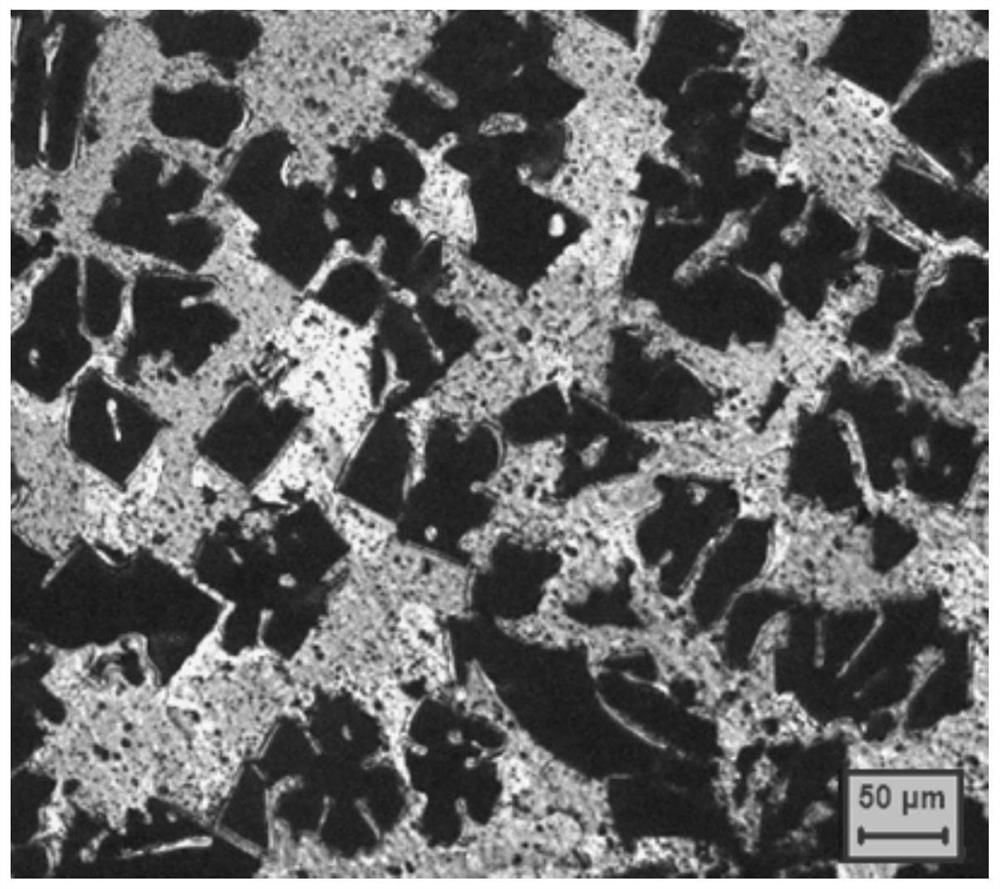

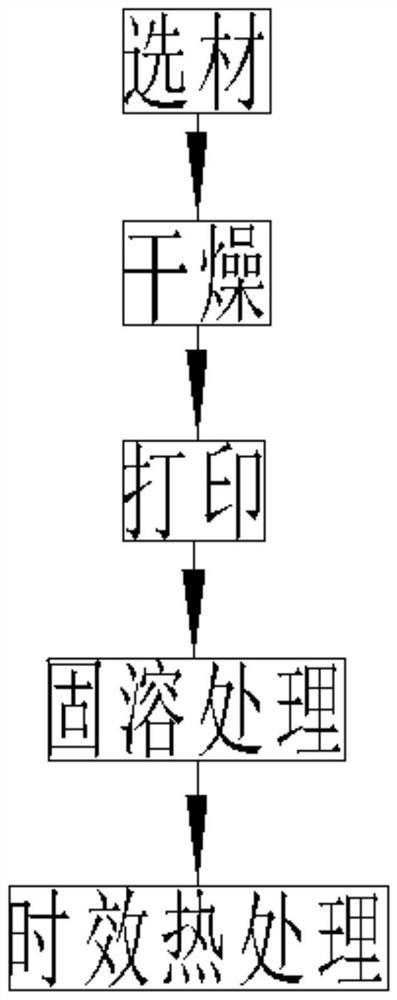

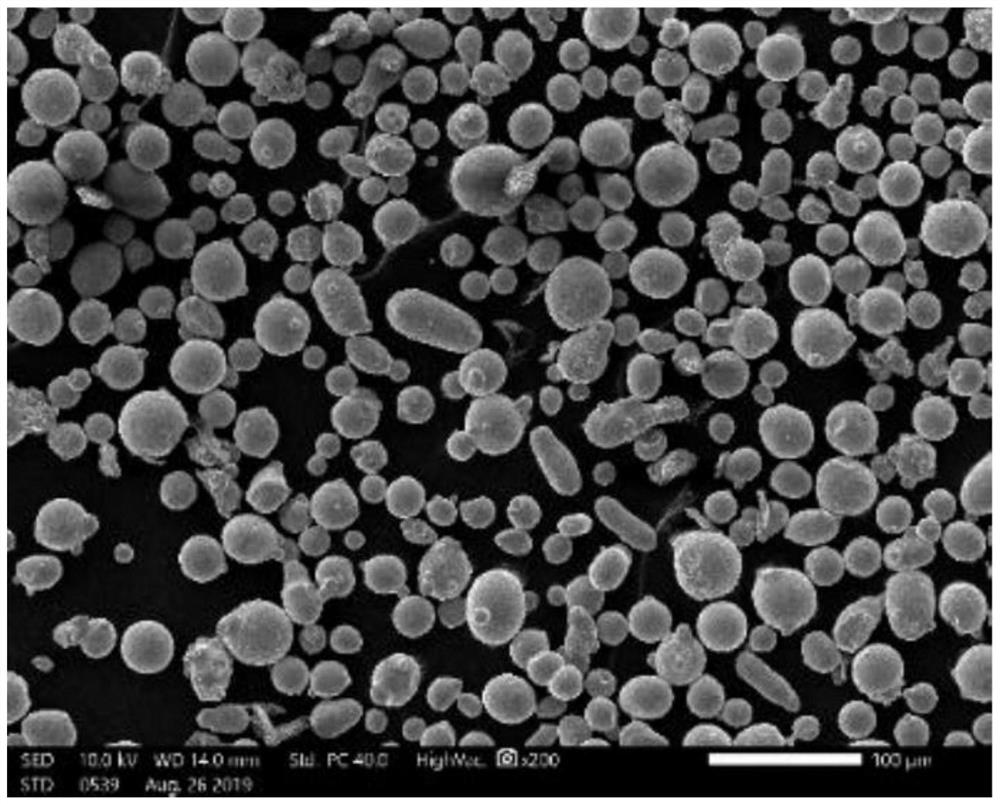

Method for additive manufacturing of H13 steel

ActiveCN113414404AMeet the intensityFulfil requirementsAdditive manufacturing apparatusIncreasing energy efficiencySolution treatmentAdditive layer manufacturing

The invention discloses a method for additive manufacturing of H13 steel, and relates to the technical field of additive manufacturing die steel rear end heat treatment. The method comprises the following steps: S1, material selection: selecting 15-53 [mu] m H13 steel powder; S2, drying: drying the H13 steel powder in a protective atmosphere; S3, printing: printing the H13 steel on CAD modeling software; S4, performing solution treatment: performing solution treatment on a H13 steel profile formed through additive manufacturing; S5, performing aging heat treatment: performing double aging heat treatment on the H13 steel profile subjected to solid solution treatment and then air cooling to the room temperature. Compared with casting-state H13 steel, the printing-state H13 steel subjected to the heat treatment process has the advantages that the internal microstructure defects are fewer, pores are greatly reduced, grain refinement is obvious, and the microstructure is uniform.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method of aluminum-copper alloy material

The invention discloses a preparation method of an aluminum-copper alloy material. The aluminum-copper alloy material comprises the following components in percentages by weight: 1-4% of copper, 2-5% of titanium, 0.1-1.5% of iron, 0.2-1.5% of silicon, less than 1% of rare earth and the balance of aluminum; and the rare earth element is at least one of lanthanum, cerium, neodymium and yttrium. The preparation method comprises the following steps: (1) casting, and (2) heat treatment. The aluminum-copper alloy material has high strength, excellent plasticity and good mobility; and after casting of the aluminum-copper alloy material, defects such as sand holes, pores and shrinkage cannot be caused easily.

Owner:JIANGSU SUFENG MECHANICAL DEV CO LTD

A kind of high-temperature wear-resistant alcrsin nanocomposite coating and preparation method thereof

ActiveCN108796453BImprove bindingHigh densityVacuum evaporation coatingSputtering coatingFilm baseNanocomposite coating

The invention belongs to the technical field of coating preparation and particularly relates to an AlCrSiN nano-composite coating resistant to high temperature and abrasion and a preparation method thereof. According to the AlCrSiN nano-composite coating resistant to high temperature and abrasion and the preparation method thereof, a pulsed arc ion plating method is adopted; and a Cr interface implantation layer, a CrN transition layer and an AlCrSiN surface functional layer are sequentially deposited on the surface of a base body from bottom to top. Experimental results show that the AlCrSiNnano-composite coating obtained through the preparation method is excellent in high-temperature stability and abrasion resistance and has the advantages of being small in number of surface large particles, low in internal stress, high in film base bonding strength and the like; and the AlCrSiN nano-composite coating is applicable to surface protection of products such as mechanical parts, tools and molds.

Owner:GUANGDONG UNIV OF TECH

Preparation method for aluminum copper alloy material

The invention discloses a preparation method for an aluminum copper alloy material. The aluminum copper alloy material prepared through the preparation process of the preparation method is high in strength, excellent in plasticity, good in fluidity and good in heat treatability, machinability and polishability. The aluminum copper alloy material prepared through the preparation method comprises 0.30-1.20 wt% of titanium, 0.03-0.10 wt% of silicon and 0.01-0.30 wt% of copper.

Owner:JIANGSU DOUSHENG TECH DEV CO LTD

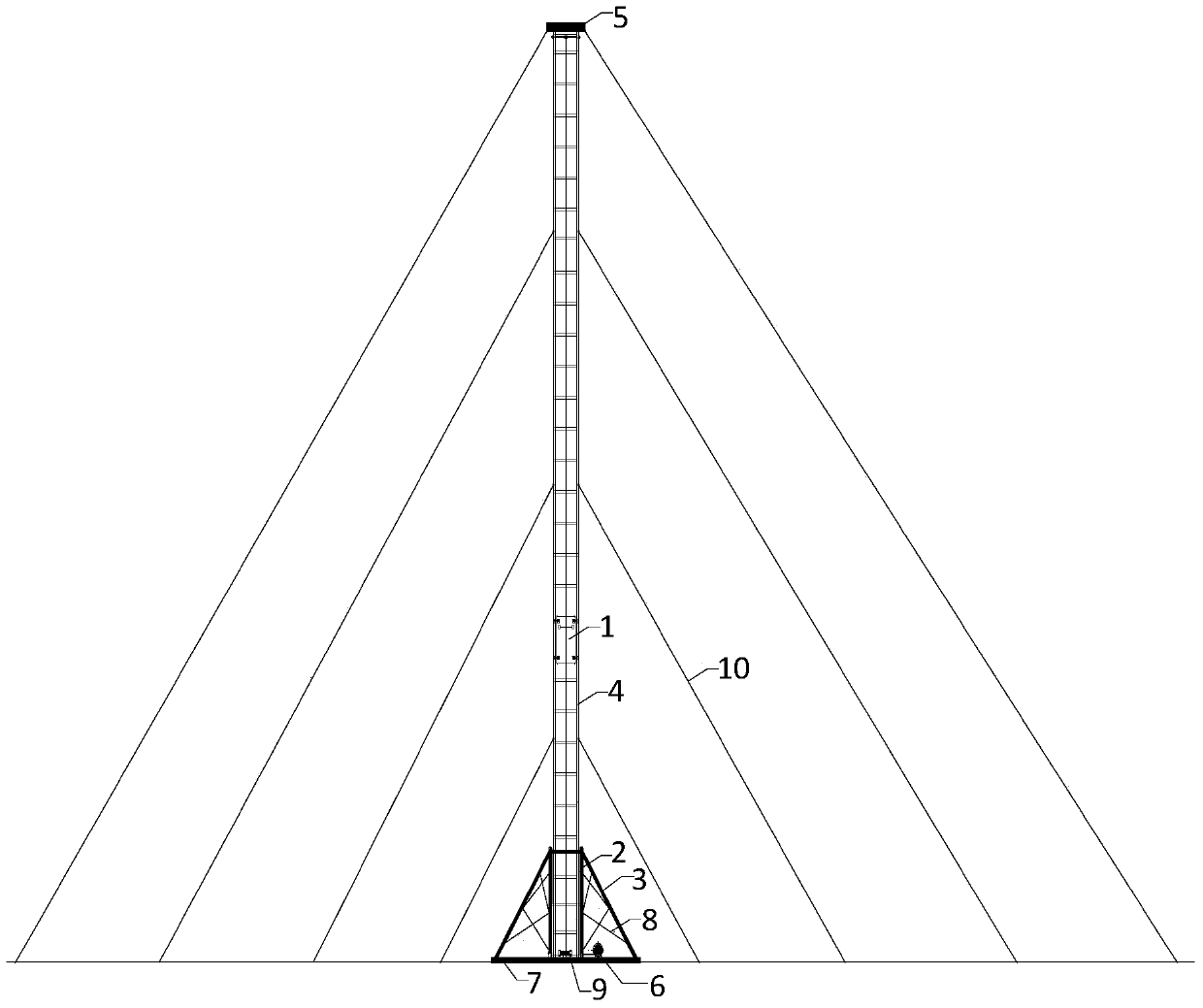

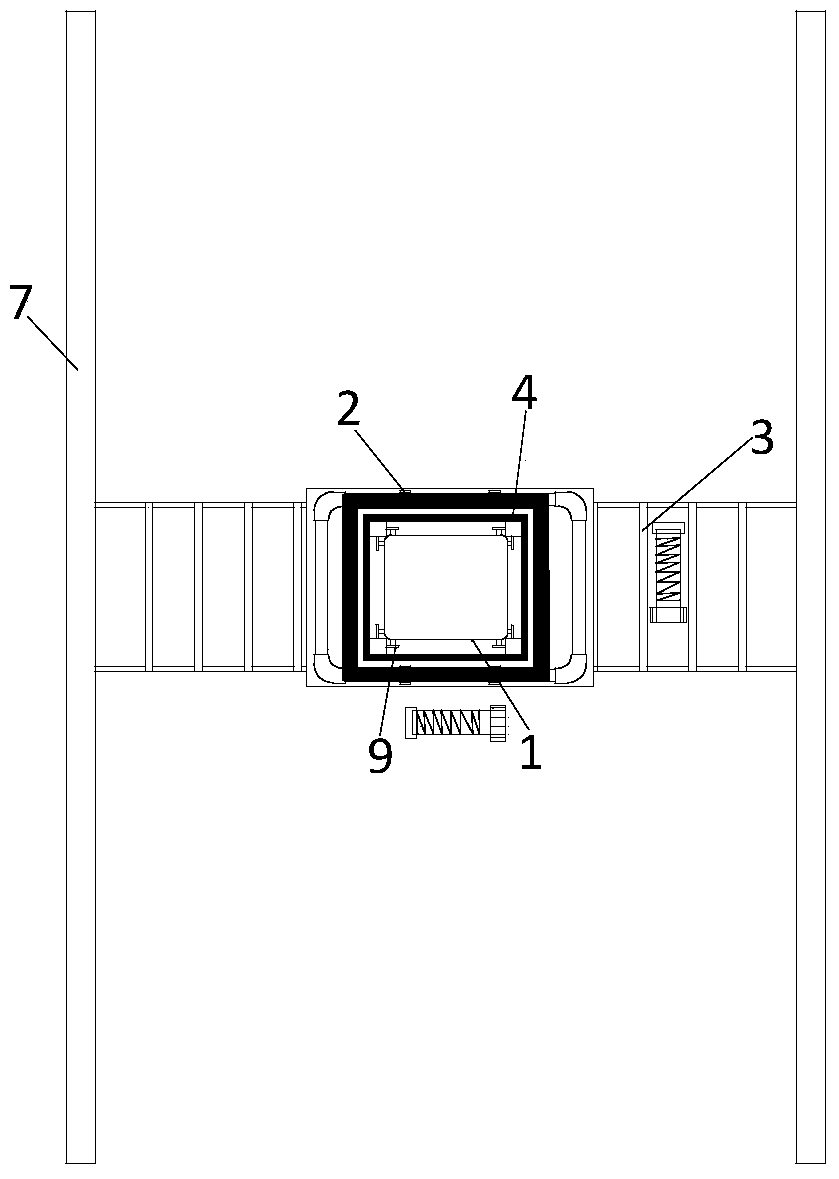

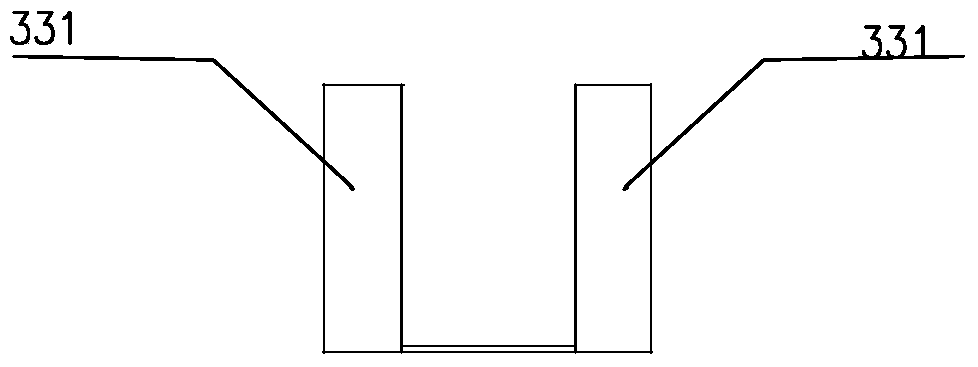

An insulated lifting platform

ActiveCN106542469BEasy to operateEnsure personal safetyLifting devicesEngineeringStructural engineering

The invention provides an insulation lifting platform. The insulation lifting platform comprises a base 7, a stand rod frame 2, a lifting frame 4 and an operation table 5 coaxially arranged in sequence from bottom to top, and is characterized in that a lifting basket 1 is arranged in the lifting frame 4. The insulation lifting platform is excellent in electric insulation performance, can satisfy the requirements of 1000 kilovolt electrified operation, is light in weight, is firm, satisfy safe operation demands, and is convenient to operate, use and transport.

Owner:CHINA ELECTRIC POWER RES INST +2

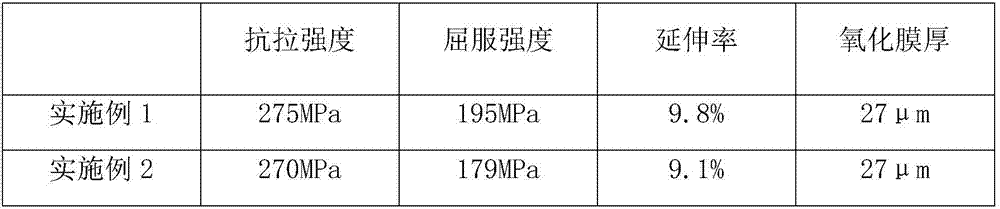

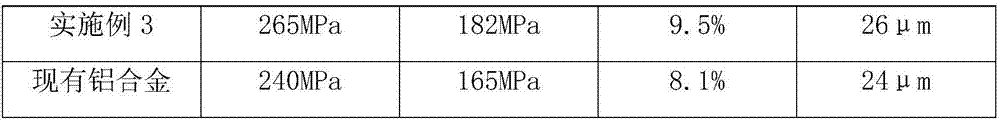

A high-strength and tough aluminum profile for rail transit

The invention discloses a high-strength and tough aluminum section material for rail transit. Its chemical composition includes: Zn, Mg, Cu, Mn, Cr, Ti, Zr, Bi, B, Gd, Sc, Ho, Y, V, and the balance is Al; the preparation method of aluminum profiles includes: melting and casting raw materials, homogenizing, rolling, solid solution, quenching and aging treatment; the cooling rate of quenching is 10000×C Zr +15000×C Sc +15°C / s; C Zr 、C Sc are the mass percentages of Zr and Sc respectively; the aging treatment is a four-stage aging treatment; the temperature of the first-stage aging treatment is 155-180°C, and the time is 10-22h; the temperature of the second-stage aging treatment is 200-230°C, and the time is The temperature of the third-stage aging treatment is 90-120°C and the time is 5-15h; the temperature of the fourth-stage aging treatment is 160-170°C and the time is 3-5h.

Owner:安徽鑫铂铝业股份有限公司

Copper alloy strip containing tantalum and preparation method thereof

ActiveCN111118320BImprove magnetic permeabilityHigh strengthUltimate tensile strengthContinuous caster

The invention provides a tantalum-containing copper alloy wire / ribbon, which comprises the following components in mass percentage: tantalum: 0.01-1.0%, silver: 0.01-1.0%, iron: 0.01-0.5%, and the balance is copper. It also provides a preparation method of tantalum-containing copper alloy wire / strip. The continuous casting machine performs high-temperature treatment on copper-tantalum master alloy, silver, copper-iron master alloy and copper, draws and casts after cooling, and then draws for many times. After processing, it is continuously heat-treated on annealing equipment to obtain tantalum-containing copper alloy wires, which are rolled into tantalum-containing copper alloy strips of required specifications by twin-roll rolling mills. The addition of tantalum in the present invention effectively improves the magnetic permeability of the copper alloy, the addition of silver improves the strength of the copper alloy, and ensures the good electrical conductivity of the copper alloy wire / band, and the iron element in the copper alloy is conducive to further strengthening the copper alloy. Magnetic permeability, the elemental combination of tantalum, silver, iron, and copper makes the copper alloy material have good magnetic permeability, electrical conductivity and high strength.

Owner:HENAN POLYTECHNIC UNIV +2

A kind of aluminum alloy material for automobile wheel hub

ActiveCN103924136BLow densityAchieve lightweightHubsRolling resistance optimizationRare earthToughness

The invention discloses an aluminum alloy material for an automobile hub. The material comprises the following components in percentage by mass: 12-15% of Si, 14.4-22.5% of Mg, 1-1.5% of Cu, 0.2-1.3% of Fe, 0.3-0.9% of Zn, 0.1-0.4% of Mn, 0.3-0.6% of Nb, 0.1-0.3% of Ni, 1-1.8% of Li, 0.1-1.5% of Re, 0.1-0.3% of Cr, 0.5-1% of Sr, 0.3-0.5% of Sn, 1-2% of mixed rare earth and the balance of Al. As aluminum is used as a main substance of the alloy, the density of the material is reduced, and the purpose of lightening the automobile hub is achieved; due to adoption of the element Sr added into the aluminum alloy, the strength and the toughness of the aluminum alloy are effectively improved; due to adoption of elements Ti and B, good grain refinement can be achieved for a pressure cast product, cast crack can be effectively overcome, and meanwhile good heat radiation properties are achieved.

Owner:吉林万丰奥威汽轮有限公司

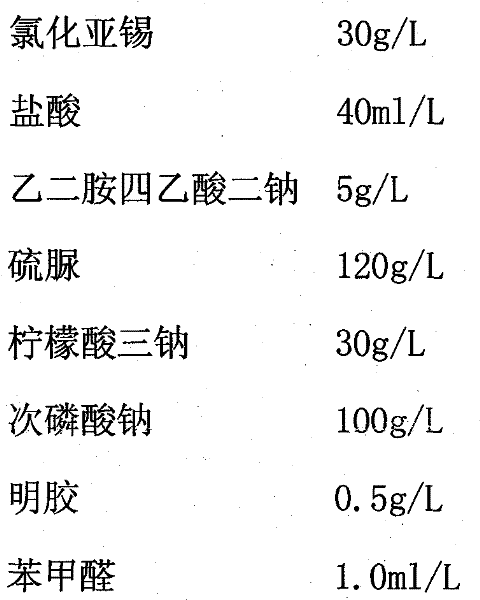

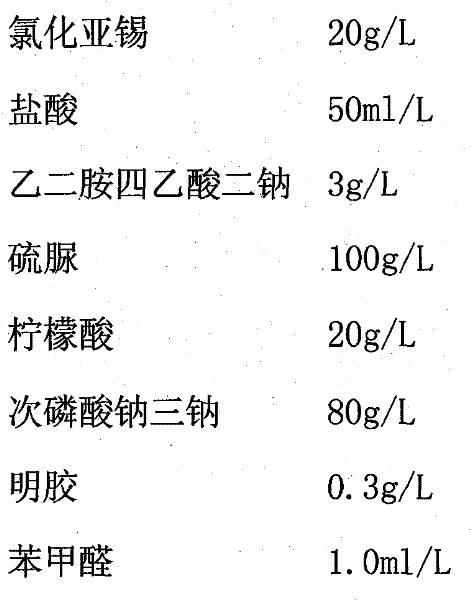

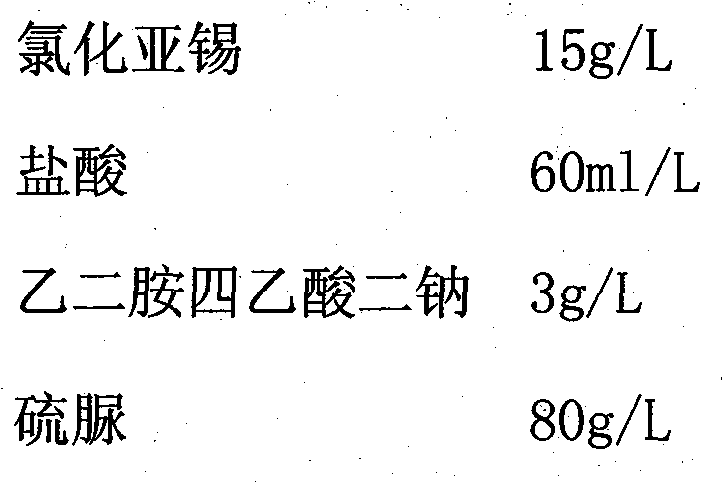

Continuously self-catalyzed deposition chemical plating solution of tin and using method thereof

InactiveCN101724834BEnables continuous autocatalytic depositionFast depositionLiquid/solution decomposition chemical coatingAntioxidantBenzaldehyde

The invention discloses continuously self-catalyzed deposition chemical plating solution of tin and a using method thereof. Half-bright and silvery-white tin-copper alloy deposition layers are obtained on pure copper and a copper alloy substrate. In the chemical plating solution, stannous chloride serves as a main salt, thiourea serves as a main complexing agent, trisodium citrate serves as an auxiliary complexing agent, sodium hypophosphite serves as a reducing agent, disodium ethylene diamine tetraacetate serves as an antioxidant, a hydrochloric acid serves as a stabilizing agent, gelatin serves as a leveling agent and benzaldehyde serves as an auxiliary brightening agent. The using method comprises the following operating conditions that: the pH value of the plating solution is 0.8 to 2.0; the temperature is 80 to 90 DEG C; the loading capacity is 0.8 to 1.5 dm2 / L; and the mechanical stirring speed is 50 to 100 rpm. The continuously self-catalyzed deposition chemical plating solution of the tin and the using method thereof have the advantages of capability of obtaining half-bright and silvery-while tin-copper alloy clad layers with different thicknesses by controlling chemical plating time, high deposition rate, remarkable grain refinement, improvement on surface evenness of the clad layer and batch production stability, secure interface combination, strong change resistance of the clad layer after being passivated, and broad application prospect in the products of deep hole elements, blind hole elements, difficult-to-handle miniature electronic components and parts, printed circuit boards PCBs and the like.

Owner:KUNMING UNIV OF SCI & TECH

Aluminum copper alloy material and casting heat-treatment technique

The invention relates to an Al-Cu alloy material and the casting and heat treatment process thereof. The material is produced by the pure aluminum, the Al-Cu alloy, the Al-Mg alloy and the Al-Ti alloy being taken as raw materials and made a casting and heat treatment. The weight proportion of the compositions is: pure aluminum of 75 to 88, Al-Cu alloy of 6-12, Al-Mg alloy of 2-7, and Al-Ti alloy of 4-8. The Al-Cu alloy material of the invention has higher strength, excellent plasticity, good fluidness as well as good heat treatment, cutting process and polishing performance, and is not easy to appear sand holes, air holes and shrinkage porosity after casting.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

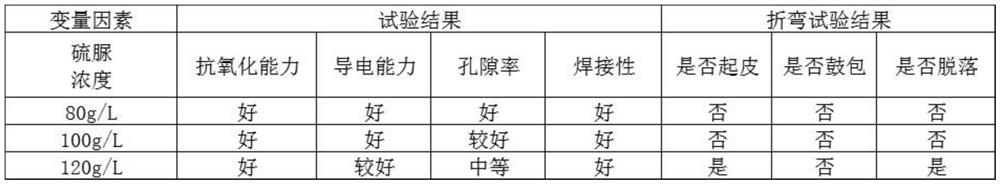

Tin plating solution for copper electronic material as well as preparation method and application method of tin plating solution

PendingCN114574840ATo preventEasy to degradeLiquid/solution decomposition chemical coatingPhosphorous acidMeth-

The invention discloses a copper electronic material tin plating solution, a preparation method and an application method, and the formula of an additive of the copper electronic material tin plating solution comprises the following components: main salt: stannous methanesulfonate with the concentration of 10-13g / L; a hydrolysis agent: 96 to 112 ml / L of methanesulfonic acid; the complexing agent is thiourea with the concentration of 75 g / L or 80 g / L; a tin whisker inhibitor: 0.8-1.2 g / L of silver methanesulfonate; the antioxidant is ethylenediamine tetraacetic acid with the concentration of 3-5g / L; the auxiliary brightening agent is benzaldehyde with the concentration of 0.2 g / L to 0.3 g / L; the reducing agent is at least one of hypophosphorous acid and sodium hypophosphite, and the concentration of the reducing agent is 50-82ml / L; gelatin is also added into the plating solution, and the concentration of the gelatin is 0.2-1.0 g / L; the complex solubilizer is polyalcohol with the concentration of 50 to 500g / L; and the crystal refiner is a polyoxyalkylene ether or amino acid type solution with the concentration of 0.1-10g / L.

Owner:深圳市虹喜科技发展有限公司

aluminum alloy ingot

The invention relates to an aluminum alloy ingot. The aluminum alloy ingot is prepared from, by weight percent, 7.2%-11.4% of Si, 1.2%-1.5% of Cu, 0.1%-0.3% of Mg, 0.2%-0.4% of Fe, 1.2%-1.4% of Zn, 0.2%-0.4% of Ni, 0.1%-0.3% of Sn, 1.2%-2.4% of Sr, 2.1%-2.4% of Ti, 2.1%-2.4% of B, 1.2%-1.4% of Sb, 0.3%-0.5% of As, 0.22%-0.44% of RE, 0.4%-1.4% of LaCe, 0.3%-0.5% of Pr and the balance Al and inevitable impurities, wherein the content of the impurities is not larger than 0.1%. The aluminum alloy ingot is good in comprehensive performance, resistant to corrosion and stable in performance.

Owner:肇庆南都再生铝业有限公司

Method for preparing high scandium content aluminum scandium alloy

The invention discloses a method for preparing aluminum-scandium alloy with high scandium content. The method comprises: weighing metal scandium and metal aluminum according to the content of scandium in the aluminum-scandium alloy to be prepared; adding them to a medium-frequency induction melting furnace, continuously pumping the vacuum, and then raising the temperature to 1200-1600° C. to melt the metal scandium and metal aluminum; completely After melting, the alloy liquid is obtained and kept warm for 20-40 minutes; filled with high-purity argon, pouring the heat-preserved alloy liquid into a water-cooled copper mold, using the mold circulating water refrigeration system to cool the circulating water to 1-15 °C first, and then The cooled circulating water is passed into the water-cooled copper mold to circulate and cool the alloy liquid, and the alloy liquid can be cooled and solidified within 3-8 seconds, and an aluminum-scandium alloy ingot with a scandium content of 5%-99% can be obtained. The present invention can realize rapid cooling within 3-8s, and can produce high-scandium-content aluminum-scandium alloys with high purity, high density, low segregation, uniform composition, and low cost, which meets the current market demand for high-scandium-content aluminum-scandium alloys .

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

A kind of iron-based wear-resistant composite material and preparation method thereof

ActiveCN113215564BHigh densityImprove refinementTransportation and packagingMetal-working apparatusCoated surfaceAlloy substrate

The invention discloses an iron-based wear-resistant composite material and a preparation method thereof. The preparation method includes the following process: using a laser cladding method to prepare an iron-based wear-resistant composite coating on the surface of an iron-based alloy base material with iron-based composite powder. layer to obtain the composite body; the surface of the composite body is polished and cleaned; then laser shock is carried out to realize the surface enhancement treatment of the iron-based wear-resistant composite coating; the composite body subjected to laser shock on the surface is subjected to cyclic heat treatment to eliminate residual stress; The iron-based composite powder is micron La 2 o 3 Powder, Micron Al 2 o 3 The powder and micron FeCrNiSiB powder are uniformly mixed, cryogenically treated with liquid nitrogen circulation, and dried. In terms of mass percentage, the iron-based composite powder contains: 0.05% to 10% of micron La 2 o 3 Powder, 0.1%~45% micron Al 2 o 3 powder and 50% to 95% micron FeCrNiSiB powder. The invention improves the service life of the iron-based alloy matrix by preparing a composite coating with good performance on the surface of the iron-based alloy material, and has great significance for the repair and reconstruction of engineering machinery.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com