Preparation method of high-wear-resistance high-hardness titanium alloy composite sleeve

A composite casing, high wear resistance technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as unfavorable corrosion protection of substrates, inability to meet wear resistance, low coating hardness, etc. Achieve the effects of inhibiting the initiation of micro-cracks, high production efficiency, and obvious grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

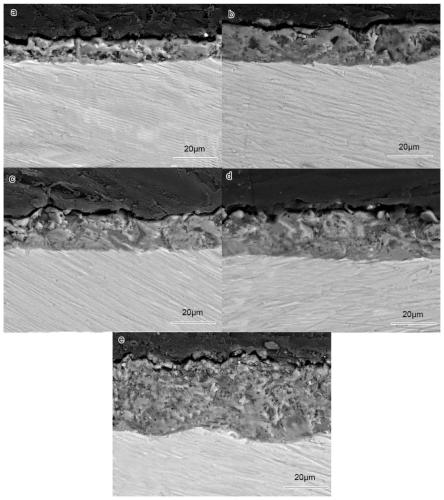

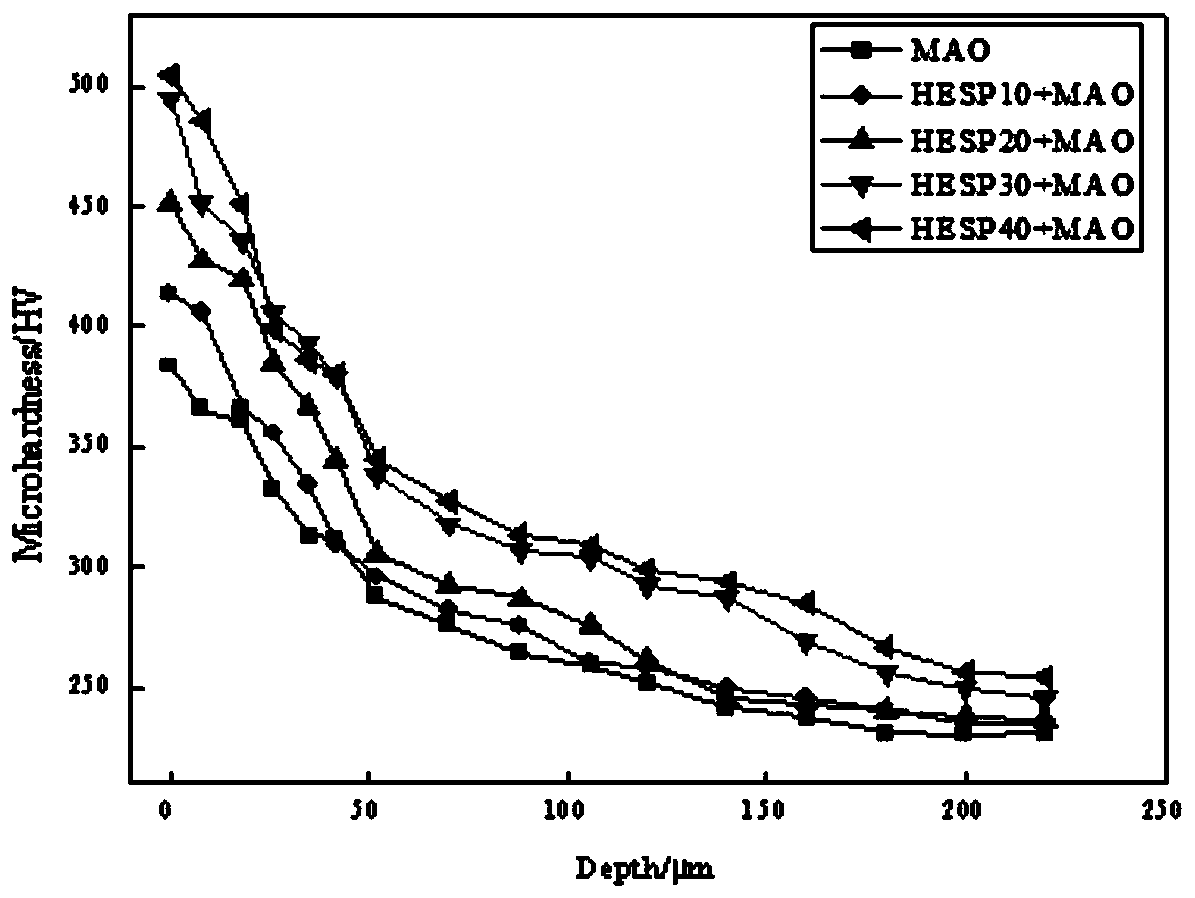

[0024] The preparation method of the present embodiment comprises the following steps:

[0025] Step 1: Shot peening. The defects on the outer surface of the workpiece are firstly ground by means of grinder grinding and other methods, and then the visible dirt of the Ti-6Al-4V titanium alloy composite casing is removed, and then the outer surface of the titanium alloy composite casing is shot peened. Turn on the shot-peening start switch, and control the gas pressure at 0.4MPa, and the shot-peening time is 10min. Among them, DT1480 CNC shot blasting machine is used, and the projectile is cast steel shot ZG30, with a hardness of 55-65HRC and a diameter of 0.3mm.

[0026] Step 2: Perform surface pretreatment on the outer surface of the titanium alloy composite casing. Perform surface pretreatment on the shot peened in step one. The pretreatment process is as follows: 1) Turn on the switch of the ultrasonic generator, control the ultrasonic frequency to 30-40 kHz, and the ultr...

Embodiment 2

[0033] The preparation method of the present embodiment comprises the following steps:

[0034] Step 1: Shot peening. The defects on the outer surface of the workpiece are firstly ground by means of grinder grinding and other methods, and then the visible dirt of the Ti-6Al-4V titanium alloy composite casing is removed, and then the outer surface of the titanium alloy composite casing is shot peened. Turn on the shot peening start switch, and control the gas pressure at 0.4MPa, and the shot peening time is 20min. Among them, DT1480 CNC shot blasting machine is used, and the projectile is cast steel shot ZG30, with a hardness of 55-65HRC and a diameter of 0.3mm.

[0035] Step 2: Perform surface pretreatment on the outer surface of the titanium alloy composite casing. Perform surface pretreatment on the shot peened in step one. The pretreatment process is as follows: 1) Turn on the switch of the ultrasonic generator, control the ultrasonic frequency to 30-40 kHz, and the ultras...

Embodiment 3

[0042] The preparation method of the present embodiment comprises the following steps:

[0043] Step 1: Shot peening. The defects on the outer surface of the workpiece are firstly ground by means of grinder grinding and other methods, and then the visible dirt of the Ti-6Al-4V titanium alloy composite casing is removed, and then the outer surface of the titanium alloy composite casing is shot peened. Turn on the shot peening start switch, and control the gas pressure at 0.4MPa, and the shot peening time is 30min. Among them, DT1480 CNC shot blasting machine is used, and the projectile is cast steel shot ZG30, with a hardness of 55-65HRC and a diameter of 0.3mm.

[0044] Step 2: Perform surface pretreatment on the outer surface of the titanium alloy composite casing. Perform surface pretreatment on the shot peened in step one. The pretreatment process is as follows: 1) Turn on the switch of the ultrasonic generator, control the ultrasonic frequency to 30-40 kHz, and the ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com