Method for additive manufacturing of H13 steel

An additive manufacturing and 3D technology, applied in the field of additive manufacturing H13 steel, can solve the problems of shrinkage porosity, H13 cracks, easy inclusions, etc., and achieve the effects of less microstructure defects, obvious grain refinement, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

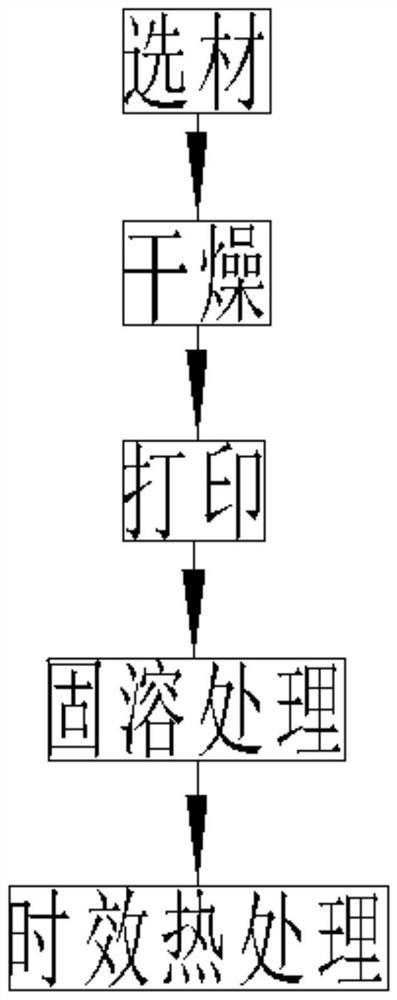

[0043] Such as figure 1 As shown, a method for additively manufacturing H13 steel comprises the following steps:

[0044] S1: material selection

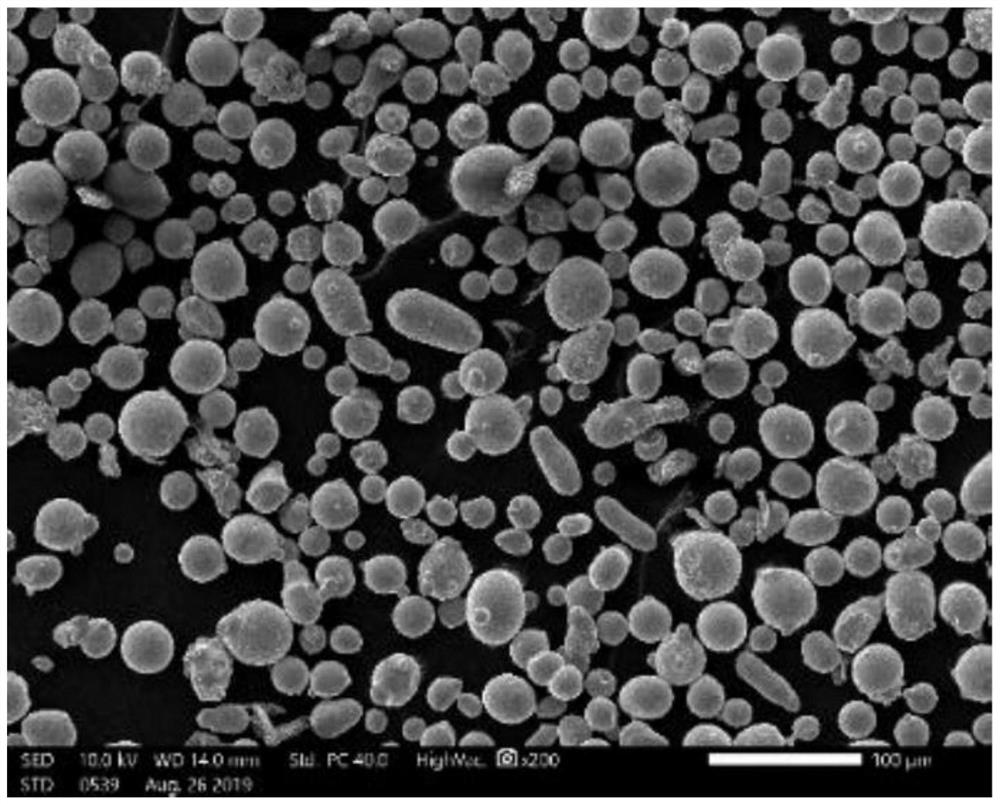

[0045] H13 steel powder with a thickness of 15-25 μm is selected. The H13 steel powder is composed of the following mass percentages: C content 0.32%, Si content 0.80%, Mn content 0.20%, Cr content 4.75%, Mo content 1.10%, V content 0.80%, P The content is 0.01%, the S content is 0.01%, and the balance is Fe; the average sphericity of H13 steel powder is SPHT=0.906, the powder fluidity is 23.4s / 50g, and the bulk density is 3.951g / cm 3 , the tap density is 4.793g / cm 3 ,, such H13 steel powder has good forming effect in additive manufacturing, and has high strength after forming;

[0046] S2: dry

[0047] Dry the H13 steel powder selected in step S1 under a protective atmosphere, the protective atmosphere used is argon or nitrogen, the drying temperature is 60°C, and the drying time is 24h to ensure that the H13 steel powder is fu...

Embodiment 2

[0055] Such as figure 1 As shown, a method for additively manufacturing H13 steel comprises the following steps:

[0056] S1: material selection

[0057] H13 steel powder with a thickness of 25-35 μm is selected. The H13 steel powder is composed of the following mass percentages: C content 0.35%, Si content 1%, Mn content 0.3%, Cr content 5%, Mo content 1.5%, V content 1%, P The content is 0.02%, the S content is 0.02%, and the balance is Fe; the average sphericity of H13 steel powder is SPHT=0.906, the powder fluidity is 23.4s / 50g, and the bulk density is 3.951g / cm 3 , the tap density is 4.793g / cm 3 ,, such H13 steel powder has good forming effect in additive manufacturing, and has high strength after forming;

[0058] S2: dry

[0059] Dry the H13 steel powder selected in step S1 under a protective atmosphere, the protective atmosphere used is argon or nitrogen, the drying temperature is 60-80°C, and the drying time is 24h to ensure that the H13 steel powder is fully drie...

Embodiment 3

[0067] Such as figure 1 As shown, a method for additively manufacturing H13 steel comprises the following steps:

[0068] S1: material selection

[0069] H13 steel powder with a thickness of 35-45 μm is selected. The H13 steel powder is composed of the following mass percentages: C content 0.45%, Si content 1.20%, Mn content 0.50%, Cr content 5.50%, Mo content 1.75%, V content 1.20%, P The content is 0.03%, the S content is 0.03%, and the balance is Fe; the average sphericity of H13 steel powder is SPHT=0.906, the powder fluidity is 23.4s / 50g, and the bulk density is 3.951g / cm 3 , the tap density is 4.793g / cm 3 ,, such H13 steel powder has good forming effect in additive manufacturing, and has high strength after forming;

[0070] S2: dry

[0071] Dry the H13 steel powder selected in step S1 under a protective atmosphere, the protective atmosphere used is argon or nitrogen, the drying temperature is 80°C, and the drying time is 24h to ensure that the H13 steel powder is fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com