Method for preparing high scandium content aluminum scandium alloy

An aluminum-scandium content technology, which is applied in the field of preparing high-scandium-content aluminum-scandium alloys, can solve the problems of coarse grains, fast cooling rate, and low scandium content of the alloy, and achieves obvious grain refinement, improved cooling rate, and uniform composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

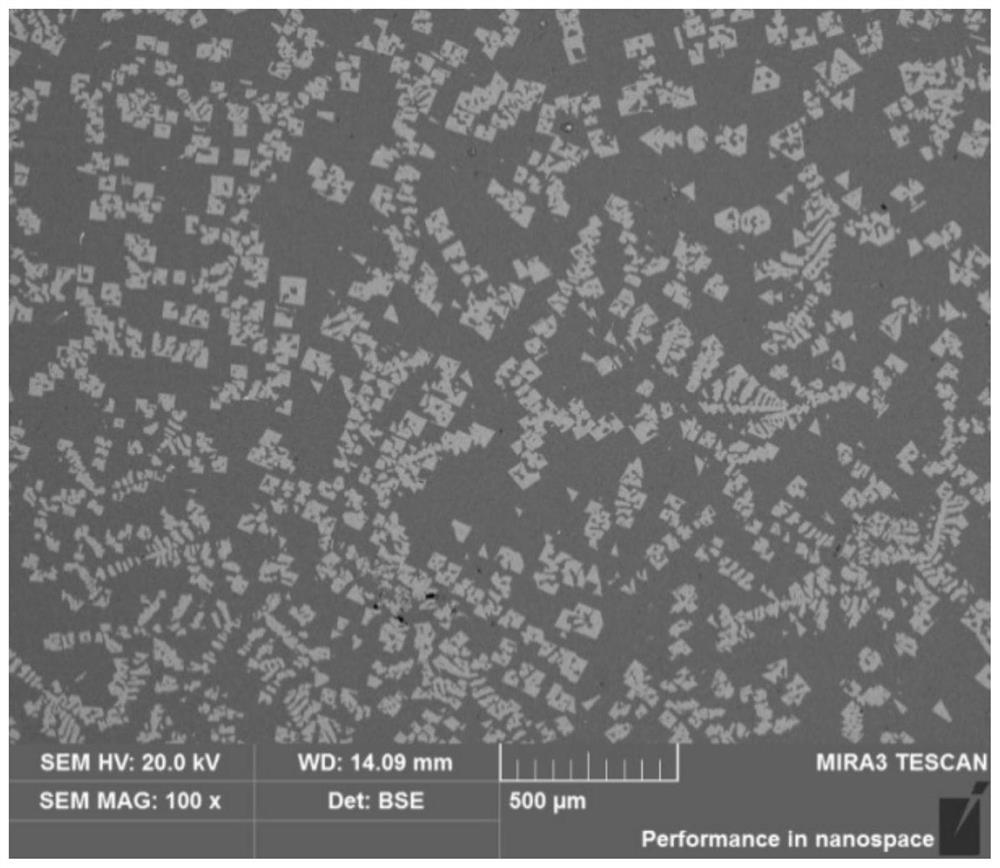

[0042] In this embodiment, the preparation of an aluminum-scandium alloy ingot with a scandium content of 10% is taken as an example for illustration, and the specific steps are as follows:

[0043] S1. Feeding: Weigh 1.6 kg of bulk high-purity metal scandium with a purity of 99.99%, and 14.4 kg of massive high-purity metal aluminum with a purity of 99.99%, and put them into a 50 kg medium-frequency induction melting furnace.

[0044] S2. Vacuuming: Vacuuming after closing the furnace cover, the vacuum degree is lower than 5×10 -2 After Pa, the temperature was raised.

[0045] S3. Melting: continue vacuuming, adjust the power output of the intermediate frequency induction melting furnace to 55KW, and heat up to 1200°C to melt the metal raw material.

[0046] S4. Heat preservation: continue heat preservation for 30 minutes after the metal is completely melted.

[0047] S5. Pouring: fill with high-purity argon, pour the aluminum-scandium alloy liquid into the Φ300×200mm water-...

Embodiment 2

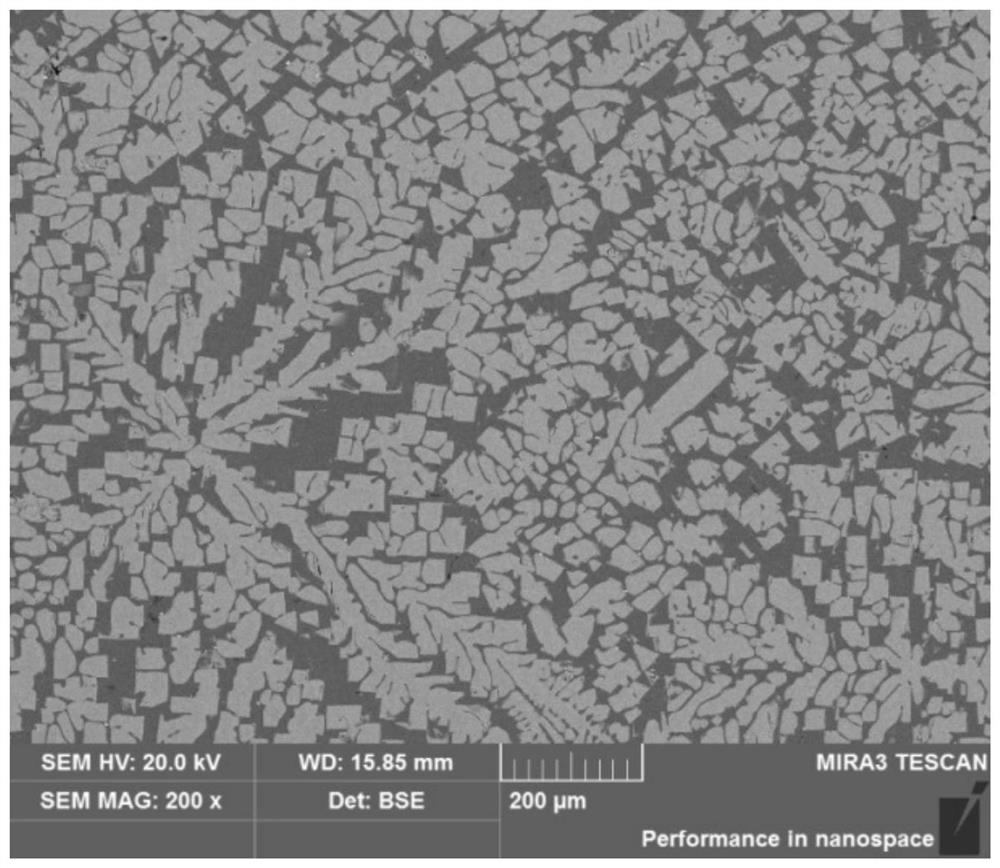

[0050] In this embodiment, the preparation of an aluminum-scandium alloy ingot with a scandium content of 20% is taken as an example for illustration, and the specific steps are as follows:

[0051] S1. Feeding: Weigh 1.5 kg of massive high-purity metal scandium with a purity of 99.99%, and 6 kg of massive high-purity metal aluminum with a purity of 99.99%, and put them into a 20 kg medium-frequency induction melting furnace.

[0052] S2. Vacuuming: Vacuuming after closing the furnace cover, the vacuum degree is lower than 5×10 -2 After Pa, the temperature was raised.

[0053] S3. Melting: continue vacuuming, adjust the output power of the intermediate frequency induction melting furnace to 70KW, and heat up to 1300°C to melt the metal raw material.

[0054] S4. Heat preservation: continue heat preservation for 30 minutes after the metal is completely melted.

[0055] S5. Pouring: fill with high-purity argon, pour the aluminum-scandium alloy liquid into the Φ220×150mm water-...

Embodiment 3

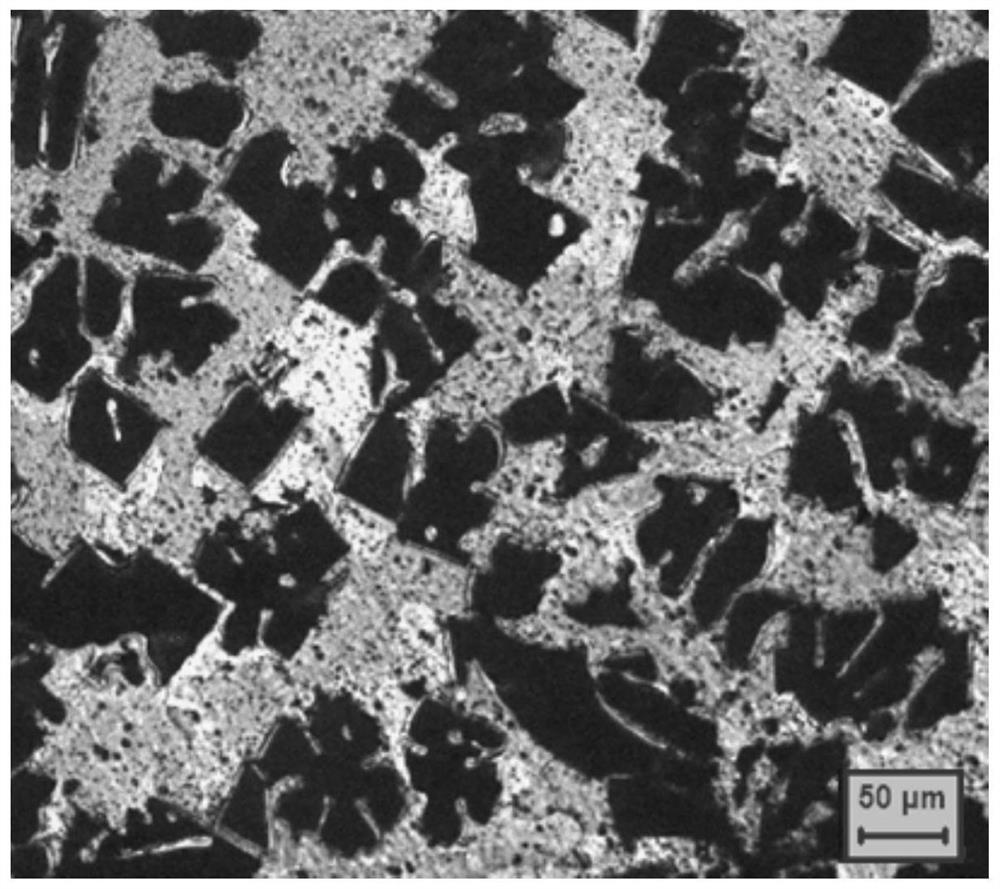

[0079] In this embodiment, the preparation of an aluminum-scandium alloy ingot with a scandium content of 30% is taken as an example for illustration, and the specific steps are as follows:

[0080] S1. Feeding: Weigh 1.2 kg of bulk high-purity metal scandium with a purity of 99.99%, and 2.8 kg of massive high-purity metal aluminum with a purity of 99.99%, and put them into a 10 kg medium-frequency induction melting furnace.

[0081] S2. Vacuuming: Vacuuming after closing the furnace cover, the vacuum degree is lower than 5×10 -2 After Pa, the temperature was raised.

[0082] S3. Melting: continue vacuuming, adjust the output power of the intermediate frequency induction melting furnace to 75KW, and heat up to 1390°C to melt the metal raw material.

[0083] S4. Heat preservation: heat preservation for 30 minutes after the metal is melted.

[0084] S5. Pouring: Fill with high-purity argon, pour the aluminum-scandium alloy liquid into a 200×200×80mm water-cooled copper mold to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com