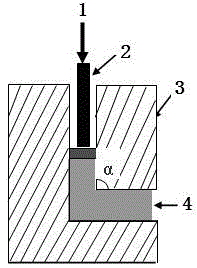

Method for preparing dispersion strengthened copper-based composites through equal channel angular pressing (ECAP)

A dispersion-strengthened copper and equal-channel corner technology is applied to metal extrusion control equipment, metal extrusion, manufacturing tools, etc., to achieve obvious effects, obvious grain refinement, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

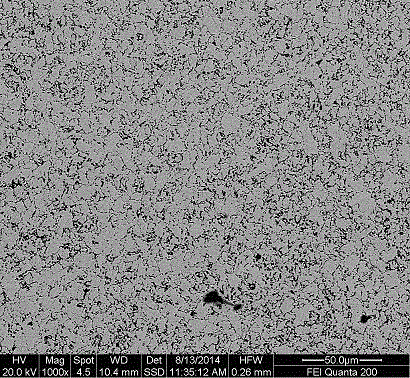

[0021] 1% Al after hot extrusion, drawing or swaging 2 o 3 The / Cu copper-based composite material is preheated at 600 °C for 1 hour, and then sent to an equal-channel angular extrusion die that has been preheated to 200 °C and coated with lubricant. The dispersion-strengthened copper-based Composite material rods, plates, pipes, square materials, etc. are extruded, and after each pass of extrusion, the next pass of extrusion is carried out, and a total of 2 passes of extrusion are performed. The scanning electron micrograph of the structure of the aluminum oxide dispersion strengthened copper matrix composite material prepared by equal channel angular extrusion used in this example is as follows figure 2 shown.

Embodiment 2

[0023] 0.8%TiB after hot extrusion, drawing or swaging 2 The / Cu copper-based composite material was preheated at 700 °C for 2 hours, and then sent to an equal-channel angular extrusion die that had been preheated to 300 °C and coated with lubricant. The dispersion-strengthened copper-based Composite material rods, plates, pipes, square materials, etc. are extruded, and after each pass of extrusion, the next pass of extrusion is carried out, and a total of 4 passes of extrusion are performed.

Embodiment 3

[0025] The 0.6% WC / Cu copper-based composite material after hot extrusion, drawing or rotary forging is preheated at 800°C for 3 hours, and then sent to an equal-channel angular extrusion die that has been preheated to 350°C and coated with lubricant Among them, the dispersion-strengthened copper-based composite material rods, plates, pipes, square materials, etc. are extruded at a pressure of 800MPa and an extrusion speed of 20mm / min. After each extrusion, the next extrusion is carried out. A total of 6 extrusion passes were performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com