Aging treatment method for improving toughness of Al-Zn-Mg-Cu aluminum alloy, high-toughness aluminum alloy and preparation method thereof

A technology of aging treatment and three-stage aging treatment, which is applied in the field of aluminum alloy, can solve the problems of poor fracture toughness and corrosion resistance, reduce material fracture toughness, and decrease alloy strength, so as to improve strength performance, improve fracture toughness, and reduce difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention provides a method for preparing a high-strength and tough Al-Zn-Mg-Cu aluminum alloy, which includes the following steps: sequentially smelting, casting, homogenizing, and solidifying raw materials corresponding to the Al-Zn-Mg-Cu aluminum alloy composition. Solution treatment and aging treatment to obtain high strength and toughness Al-Zn-Mg-Cu aluminum alloy;

[0046] The method adopted for the aging treatment is the aging treatment method described in the above technical solution.

[0047] The invention melts the raw materials corresponding to the Al-Zn-Mg-Cu aluminum alloy composition to obtain a melt. In the present invention, the raw materials preferably include pure metallic aluminum, pure metallic magnesium, pure metallic zinc, and Al-Cu master alloy. When the Al-Zn-Mg-Cu aluminum alloy further includes Cr, Zr, and Ti, the raw material preferably further includes Al-Cr master alloy, Al-Zr master alloy and Al-Ti master alloy. The present invent...

Embodiment 1

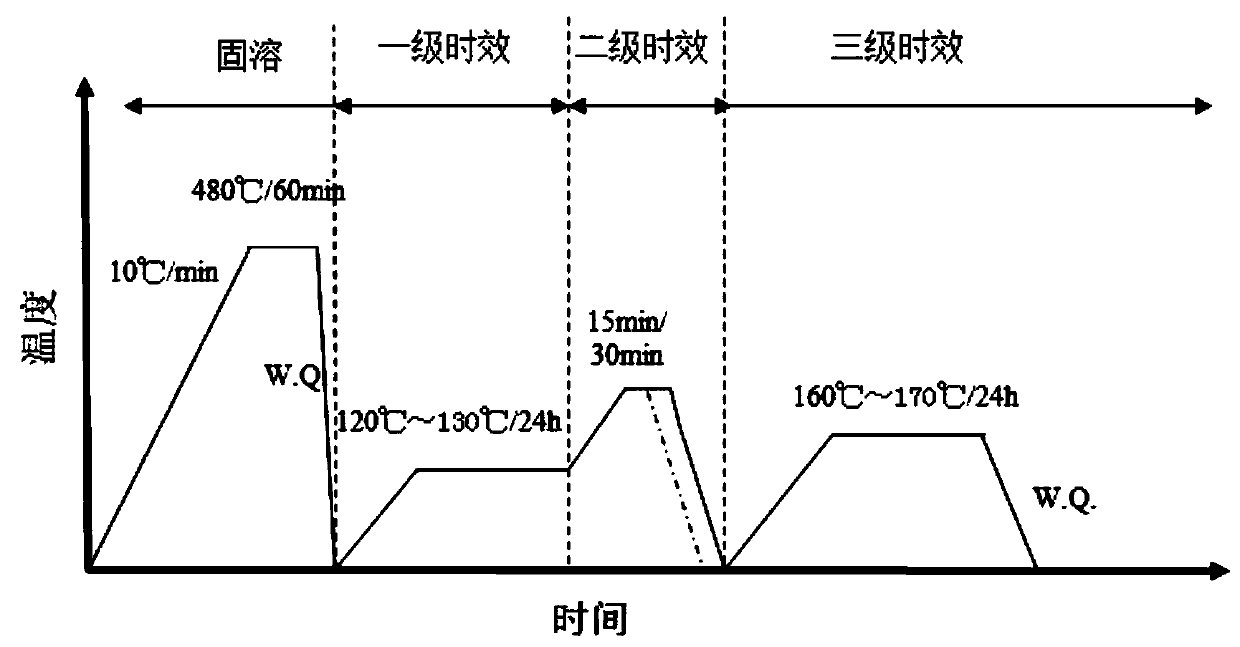

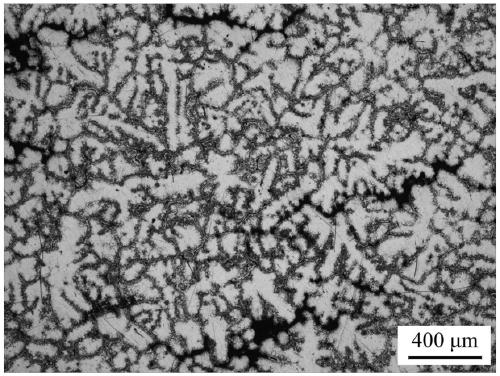

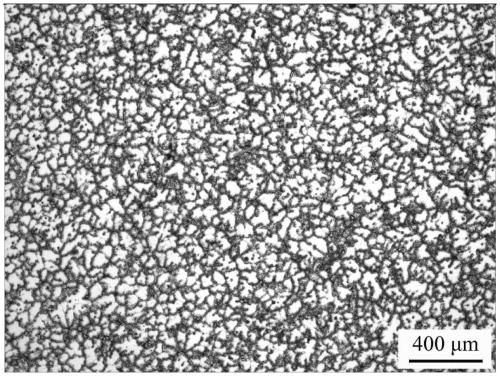

[0067] according to figure 1 In the process shown, the solid solution alloy obtained in Comparative Example 1 is subjected to three-stage aging treatment. The specific implementation steps are as follows: the first-stage aging is raised from room temperature to 130°C, the heating rate is 10°C / min, and the temperature is kept for 24 hours; The aging is increased from 130°C to 210°C with the furnace at a heating rate of 10°C / min, holding for 15 minutes, and cooling to room temperature; the third-stage aging increases the resulting alloy from room temperature to 170°C at a heating rate of 10°C / min. Keep for 24h and cool to room temperature. After three-stage aging treatment, the alloy was subjected to microhardness and tensile tests. The results are shown in Table 1. The TEM picture of the alloy after three-level aging is as follows Figure 5 Shown.

Embodiment 2

[0069] according to figure 1 In the process shown, the solid solution alloy obtained in Comparative Example 2 is subjected to three-stage aging treatment. The specific implementation steps are as follows: the first-stage aging is increased from room temperature to 130°C, the heating rate is 10°C / min, and the temperature is kept for 24h; The aging is increased from 130°C to 210°C with the furnace at a heating rate of 10°C / min, holding for 15 minutes, and cooling to room temperature; the third-stage aging increases the resulting alloy from room temperature to 170°C at a heating rate of 10°C / min. Keep for 24h and cool to room temperature. After three-stage aging treatment, the alloy was subjected to microhardness and tensile tests. The results are shown in Table 1. The SEM picture of the alloy after three-stage aging is as follows Image 6 As shown, the TEM photo is as Figure 7 Shown.

[0070] Table 1 Strength and toughness of the alloys obtained in Comparative Examples 1-2 and E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com