Patents

Literature

32results about How to "Overcome casting cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot-top casting process of 7075 aluminium alloy round rod with diameter of phi582 mm

ActiveCN102328065AImprove bottom plasticityReasonable control of impurity contentRound bar7075 aluminium alloy

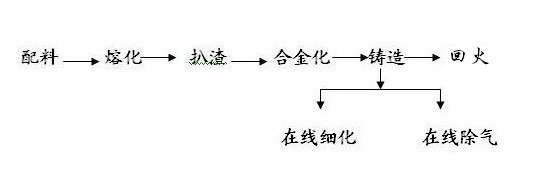

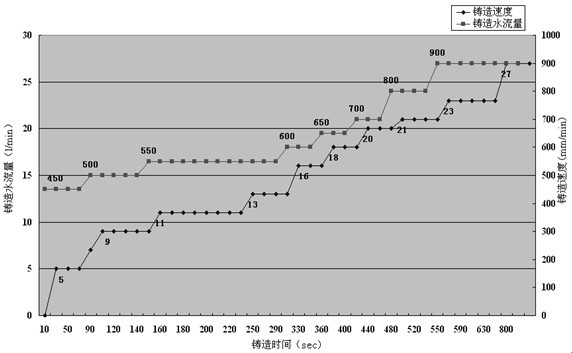

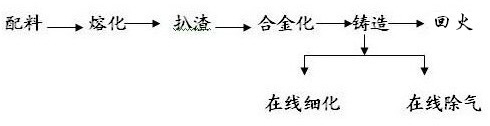

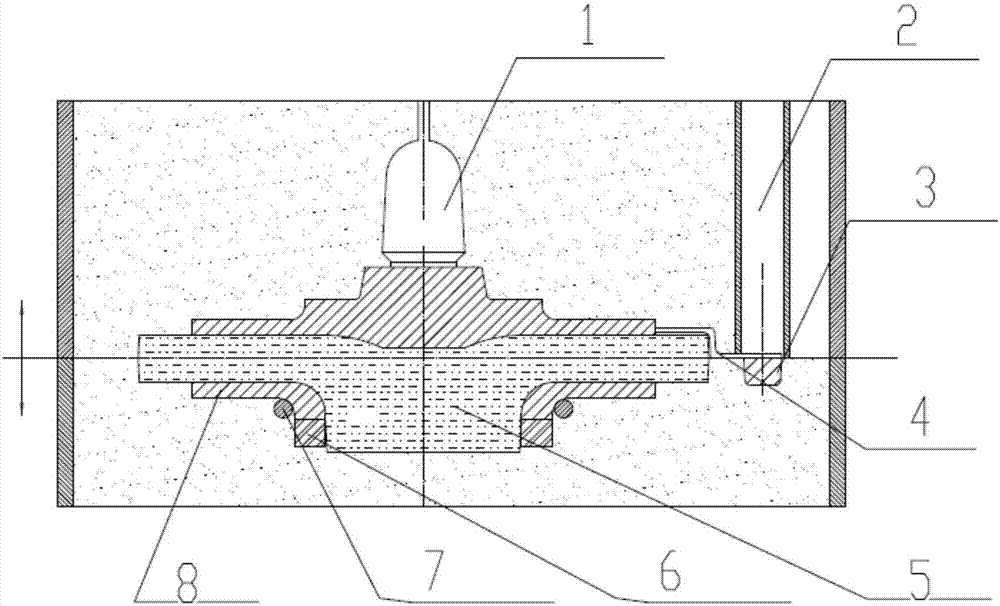

The invention discloses a hot-top casting process for casting a large-diameter hard aluminium alloy round rod by using a wiping disc. The process comprises the following steps of: a, batching; b, melting; and c, casting, wherein the casting step is a key process. The process protected by the invention is a casting process of a largest-diameter hard aluminium alloy which is put into operation in the country currently. Namely, the process comprises: hot-top casting equipment is used; the wiping disc is configured at the same time; step type casting process parameters are adopted; the suspension height of the wiping disc and the three casting process parameters are searched; and finally, the best casting process of the 7075 aluminium alloy round rod with a diameter of phi582 mm is established. According to the process disclosed by the invention, the crack tendency in the process of casting the large-diameter hard aluminium alloy can be greatly reduced without the bottoming process; the cast round bar has good grain size, thin coarse grain layer and good surface quality; and the turning quantity on the cast rod before extruding is reduced, therefore, the production cost is reduced, and the yield is increased.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

Centrifugal cast high-speed steel roll manufacture

InactiveCN1439472ASuppression of gravity segregationDecrease the peripheral speedElectromagnetic fieldQuenching

A centrifugal casting technology for manufacturing roller of high-speed steel, which is composed of the roller body made of high-C high-W high-speed steel and the core made of cast iron, includes such steps as pouring the molten high-speed steel in the rotating mould of centrifugal machine, applying an electromagnetic field in the pouring and solidifying procedure, adding protecting agnet to the inner surface of roller body, pouring molten iron, cooling to lower than 100 deg.C, demoulding, coarse machining, quenching, tempering, and fine machining. Its advantages are high uniformity without segregation, and compact structure.

Owner:XI AN JIAOTONG UNIV

Hot top casting process for phi 784-mm 7xxx-series superhard aluminum alloy round bar

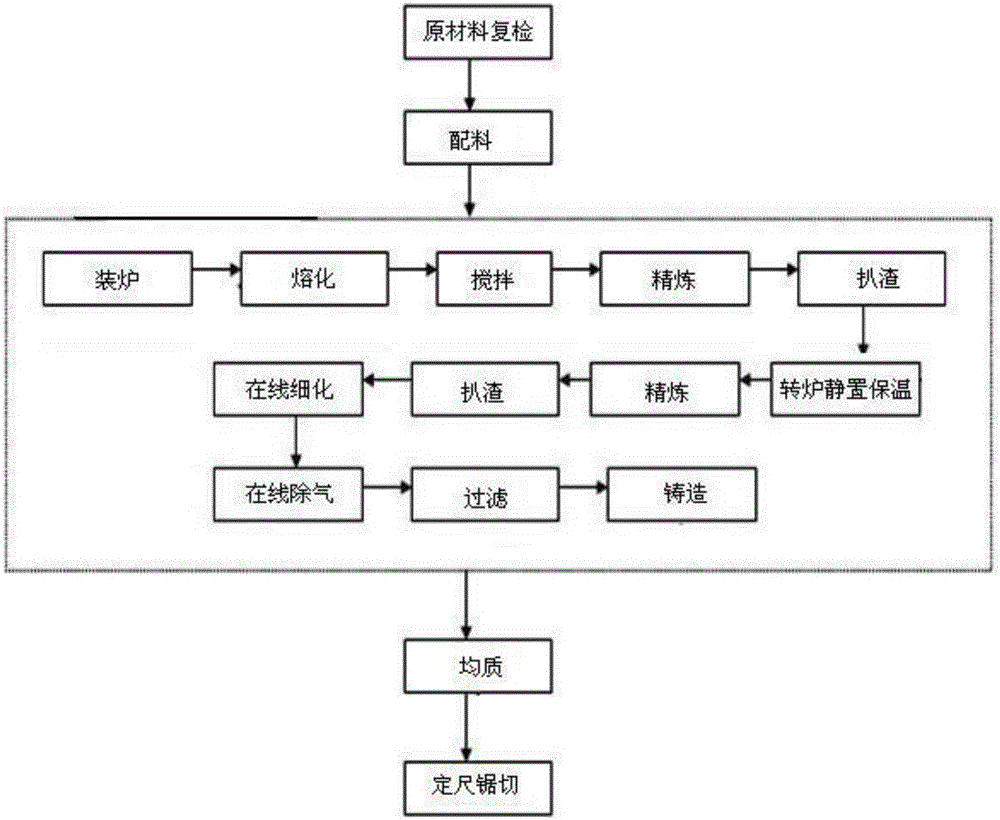

The invention discloses a hot top casting process for a phi 784-mm 7xxx-series superhard aluminum alloy round bar. The aluminum alloy round bar is composed of, by mass, 0.25% of Si, 0.4% of Fe, 1.55-1.65% of Cu, 0.25% of Mn, 2.55-2.65% of Mg, 0.19-0.25% of Cr, 5.6-5.7% of Zn, 0.15% of Ti, 0.03% of Zr and the balance Al. The manufacturing process comprises the steps of a, material preparation; b, smelting; c, stirring; d, refining; e, slagging-off; f, heat preservation and standing; g, online thinning; h, online degassing; i, filtration; j, casting; k, homogenizing. Through the process, the defects, such as cracks, component segregation, bright grains, thick grains and loose pores, which often appear when a direct condensation casting technology is adopted for large-diameter superhard aluminum alloy are overcome, and by the adoption of hot top casting, the defects of surface segregation tumors, thick coarse-grain layers and the like are overcome.

Owner:CHINA ZHONGWANG

Aluminum alloy ingot

The invention discloses an aluminum alloy ingot. The aluminum alloy ingot comprises, by weight , 9.6%-12.0% of Si, 1.5%-3.5% of Cu, less than 0.3% of Mg, less than 1.3% of Fe, less than 1.0% of Zn, less than 0.5% of Mn, less than 0.5% of Ni, less than 0.3% of Sn, 1%.-2%. of Sr, 1%.-2%. of Ti, 1%.-2%. of B and the balance Al. The Si element is added to the aluminum alloy ingot so that strength and toughness of the aluminum alloy ingot are effectively improved, and the Ti and B elements added into the aluminum alloy ingot enables a die-casting product to generate good grain refinement, casting cracks are effectively avoided, the appearance of a casting is improved, the surface quality of the ingot is improved, particularly cold shut of the ingot is reduced, and the impact toughness of the aluminum alloy ingot is effectively improved by 15%-20% on the condition that the strength of the aluminum alloy ingot is not reduced.

Owner:WUXI GREAT TECH

Flange with neck

The present invention relates to a pipe connecting piece flange. In order to raise utilization rate of material and ensure product quality said invention provides a flange with neck, and it is characterized by that said flange is made up by adopting extrusion casting method, it has no welded seam, its texture possesses continuous streamline structure characteristics, and its streamline form is identical to the member form in alignment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-intensity aluminum alloy material for automobile hub and production technology thereof

The invention provides a high-intensity aluminum alloy material for an automobile hub and a production technology thereof. The aluminum alloy material comprises the following components in percentage by mass: 2.2-3.7% of Si, 0.4-0.8% of Mg, 0.05-0.12% of Mn, 0.2-0.35% of Ti, 0.02-0.04% of W, 0.01-0.025% of Sr, 0.05-0.09% of Y, 0.02-0.07% of Cu, 0.12-0.26% of Ni, 0.05-0.12% of Zr, and the balance Al and inevitable impurities. The aluminum alloy material produced by the technology is high in mechanical intensity, and outstanding in processing performance, casting performance and corrosion resistance, and can meet the requirement of modern science development on high-load and light-mass aluminum alloy structural components.

Owner:马鞍山常裕机械设备股份有限公司

Process for producing electronic aluminium alloy from recycled aluminium

ActiveCN111020256AIncrease valueImprove ecological effectProcess efficiency improvementRefining (metallurgy)Ti element

The invention relates to the field of metallurgy, in particular to a process for producing electronic aluminium alloy from recycled aluminium. The process comprises the following steps of (1) smelting, (2) stirring and slagging off; (3) standing; (4) sampling analysis; (5) burdening; (6) degassing and refining; (7) alloy replenishing; (8) segregating modifier adding; (9) filtering and secondary sampling; and (10) ultrasonic casting. An aluminium alloy product comprises the following elements in percentage by mass: 0.3%-0.6% of Si, 0.5%-0.6% of Fe, 0.45%-1.32% of Mg, 0.12%-0.27% of Cu, 0.11%-0.13% of Mn, 0.10%-0.22% of Zn, 0.03%-0.13% of Cr, and the balance of Al and inevitable impurity elements. The recycled aluminium produced through the process can reach the performance index of the aluminium alloy for an electronic product, and has higher economy and higher environment-friendly value.

Owner:SHANDONG INNOVATION METAL TECH

Stainless steel impeller for phosphoric acid slurry pump and its preparation method

InactiveCN107574390AGood shape and toughnessGood strengthProcess efficiency improvementImpellerZircon

The invention discloses a stainless steel impeller for a phosphoric acid slurry pump and its preparation method. The preparation method comprises the following steps: (1) smelting: adding raw materials into an intermediate-frequency furnace for smelting; (2) casting: putting round steel, a sand core and chill into a mold, winding the round steel with a gunpowder rope as the core bar of the sand core, kindling the gunpowder rope after completion of molding of the sand core, brushing the interior surface of the mold with an alcohol-based zircon powder paint, carrying out surface drying via a blowtorch, and then carrying out mold closing and casting; and (3) heat treatment: cooling a casting without a riser to a temperature of less than 300 DEG C, then putting the casting into a bogie-hearthresistance furnace for heat treatment, and carrying out cooling again so as to obtain a high-carbon high-chromium ferrite stainless steel impeller product. The high-carbon high-chromium ferrite stainless steel impeller prepared by using the method in the invention can effectively avoid the problem of casting cracks caused by easy precipitation of a brittle phase due to high ferrite content duringcasting.

Owner:遵义拓特铸锻有限公司

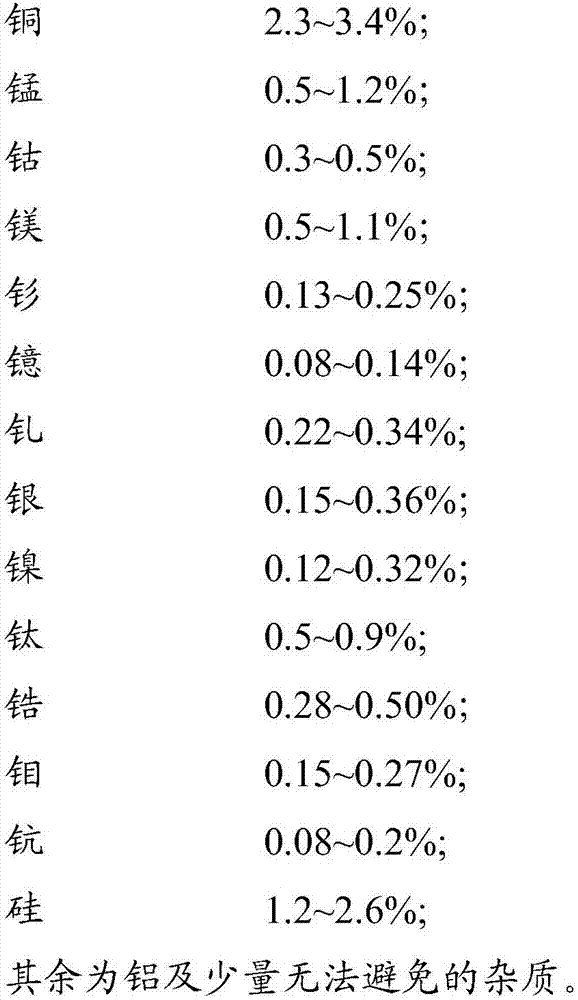

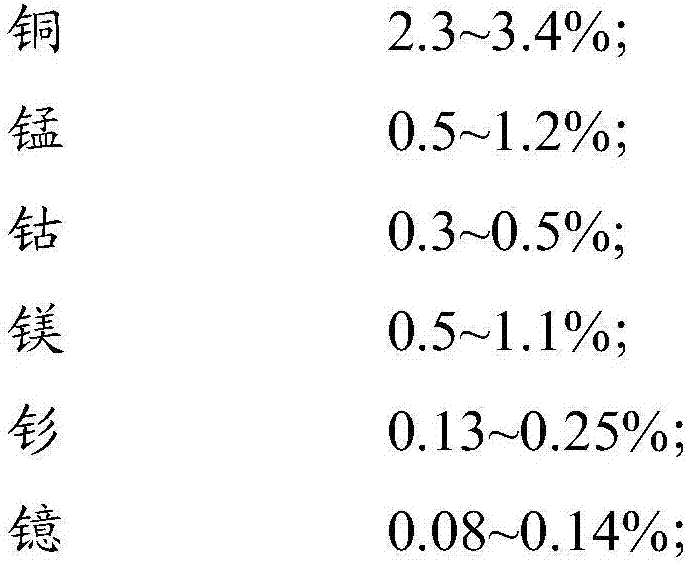

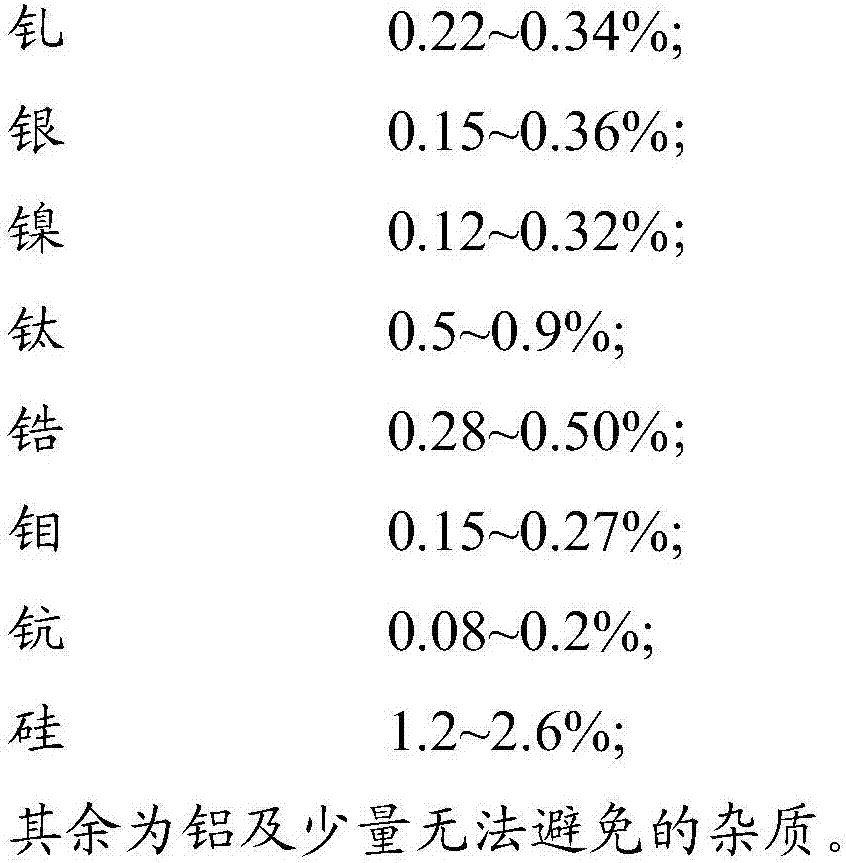

Antibacterial aluminum alloy material and preparation method thereof

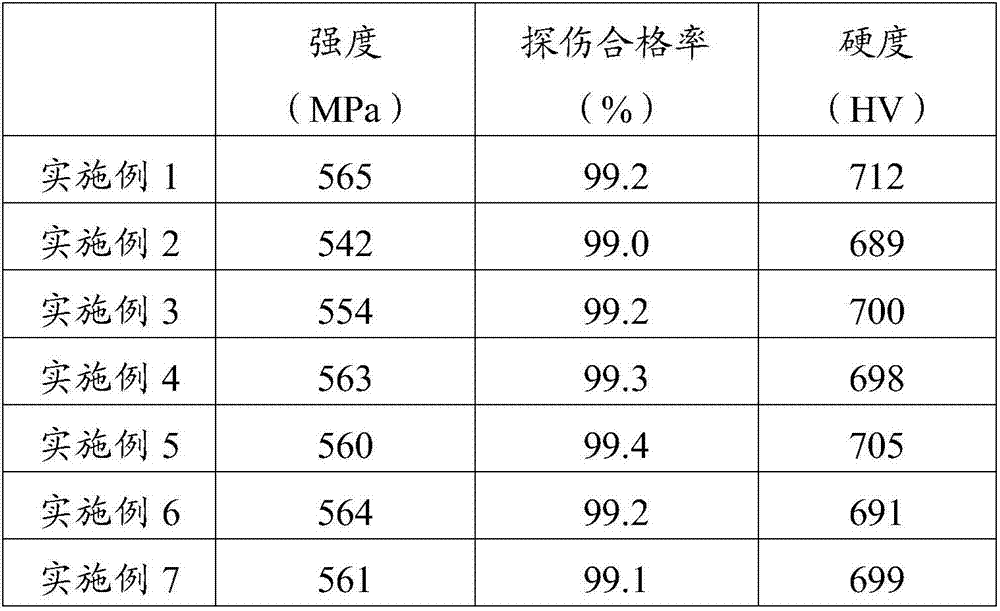

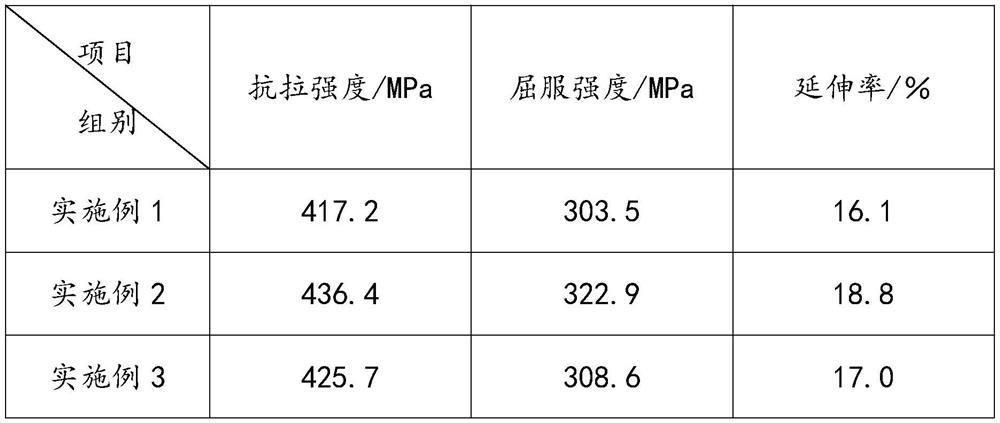

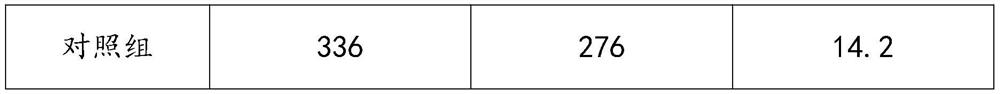

The invention provides an antibacterial aluminum alloy material and a preparation method thereof. The antibacterial aluminum alloy material consists of the following components in percentage by weight: 2.3-3.4% of copper, 0.5-1.2% of manganese, 0.3-0.5% of cobalt, 0.5-1.1% of magnesium, 0.13-0.25% of samarium, 0.08-0.14% of ytterbium, 0.22-0.34% of gadolinium, 0.15-0.36% of silver, 0.12-0.32% of nickel, 0.5-0.9% of titanium, 0.28-0.50% of zirconium, 0.15-0.27% of molybdenum, 0.08-0.2% of scandium, 1.2-2.6% of silicon, and the balance aluminum and a few inevitable impurities. According to the antibacterial aluminum alloy material provided by the invention, samarium, ytterbium, gadolinium and silver are added into the aluminum alloy material, so that the antibacterial property of the aluminum alloy material is improved, and bacteria breeding is restrained; zirconium and molybdenum are added into the aluminum alloy material, so that strength and plasticity of the aluminum alloy material are improved; cobalt and scandium are added into the aluminum alloy material, so that casting cracks are effectively overcome, quality of aluminum alloy is improved, and the cost rate of the aluminum alloy product is increased. According to the experimental results, the antibacterial ratio of the aluminum alloy product is 99.999% or higher, hardness is 88 HAR or higher, strength is 552 MPa or higher, the elongation is 8.1% or higher, and a flow inspection qualification rate is 99% or higher.

Owner:合肥饰界金属制品有限公司

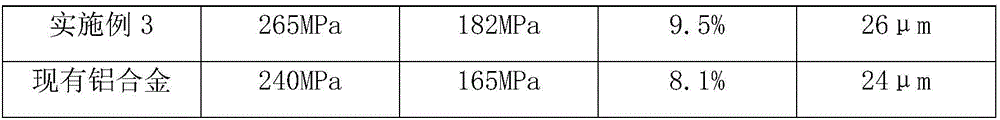

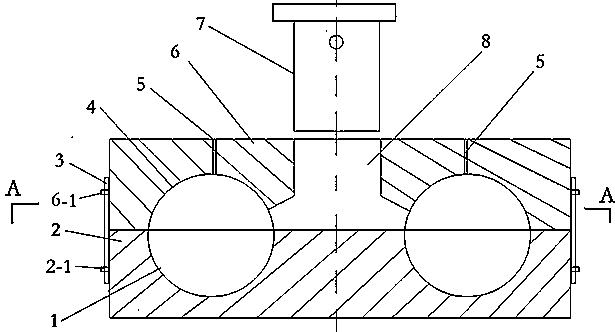

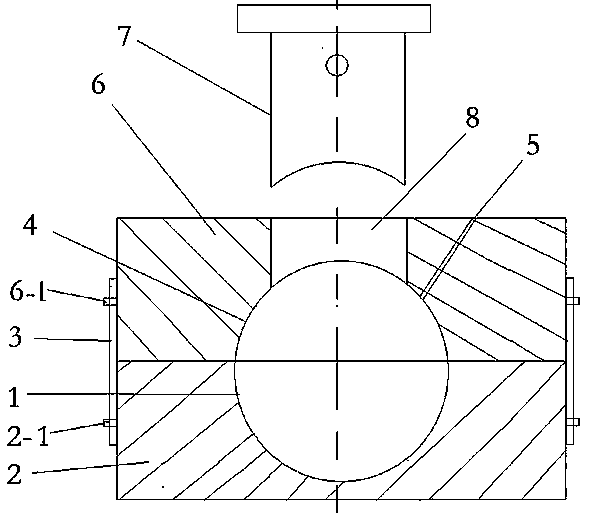

7xxx series aluminum alloy large-specification hollow cast ingot production device and process thereof

The invention discloses a 7xxx series aluminum alloy large-specification hollow cast ingot production device and process. The device comprises a crystallizer, a water jacket, a core and a core support, wherein the core support is arranged above the crystallizer through an annular groove formed in the top of the crystallizer, the core support is a circular frame, and a protruding connecting opening is formed in the center of the core support; the connector is fixed to the edge of the core support through reinforcing ribs, a connecting sleeve connected with the core water inlet is arranged in the connector, the upper portion of the connecting sleeve is connected with the connector in a threaded fit mode and extends out of the connector, a lower end opening of the connecting sleeve is arranged in the core water inlet, a connecting plate matched with an end opening of the core is arranged on the outer side wall of the connecting sleeve, and a bolt hole is formed in the connecting plate. The 7xxx series aluminum alloy large-specification hollow cast ingot is prepared by smelting, refining and casting through a specific device and a bipolar uniform fire treatment process, and the formability and the structure of the cast ingot are ensured by utilizing accurate matching of process parameters.

Owner:西北铝业有限责任公司

Aluminum alloy ingot

The invention relates to an aluminum alloy ingot. The aluminum alloy ingot is prepared from, by weight percent, 7.2%-11.4% of Si, 1.2%-1.5% of Cu, 0.1%-0.3% of Mg, 0.2%-0.4% of Fe, 1.2%-1.4% of Zn, 0.2%-0.4% of Ni, 0.1%-0.3% of Sn, 1.2%-2.4% of Sr, 2.1%-2.4% of Ti, 2.1%-2.4% of B, 1.2%-1.4% of Sb, 0.3%-0.5% of As, 0.22%-0.44% of RE, 0.4%-1.4% of LaCe, 0.3%-0.5% of Pr and the balance Al and inevitable impurities, wherein the content of the impurities is not larger than 0.1%. The aluminum alloy ingot is good in comprehensive performance, resistant to corrosion and stable in performance.

Owner:肇庆南都再生铝业有限公司

Liquid extrusion forming method of steel ball

InactiveCN110142392AEliminate shrinkageReduce porosityFurnace typesProcess efficiency improvementLiquid stateSteel ball

The invention discloses a liquid extrusion forming method for liquid extrusion of a steel ball. The forming method comprises the following steps of smelting, liquid die forging and heat treatment, wherein liquid extrusion comprises the following steps that after a liquid extrusion die is fixed to an indirect extrusion casting machine, a smelted steel ball solution is quantitatively poured into theliquid extrusion die, the casting temperature is 1500-1600 DEG C, the pressurization speed is 20-50 mm / s, the filling time is 1-8 s, the specific pressure is 150-250 mpa, and the pressure is maintained for 10-40 seconds under the pressure to obtain the near-final steel ball; and the residual-temperature quenching and low-temperature tempering of the liquid-state extruded near-end steel ball are utilized. According to the liquid-state extruded steel ball, the cost is reduced, and the production efficiency is improved; and meanwhile the microstructure state of the steel ball can be effectivelyensured, and the comprehensive mechanical property is improved.

Owner:陈铁石

High-strength wear-resistant aluminum alloy

The invention discloses high-strength wear-resistant aluminum alloy prepared from the following components in percentage by weight: 0.23% of yttrium oxide and neodymium oxide, 1.52% of silicon, 1.4% of copper, 0.37% of iron, 0.88% of cobalt and nickel, 0.14% of magnesium, 0.028% of titanium, strontium and beryllium, 0.14% of manganese, 0.02% of chromium and the balance of aluminum. The elements including titanium, strontium and beryllium which are at a fixed ratio are added into the aluminum alloy, so that the strength, wear resistance and toughness of the aluminum alloy are effectively improved; in addition, after the elements including cobalt and nickel which are at a fixed ratio are added into the aluminum alloy, a cast product can generate a favorable grain refinement function, casting cracks are effectively overcome, the appearance of a casting and the surface quality are improved, and the hardness of the aluminum alloy is improved; yttrium oxide and neodymium oxide which are at a fixed ratio are added and take a synergistic effect, so that the corrosion resistance of the aluminum alloy is improved; and the impact toughness of the aluminum alloy is effectively improved by 25.2%.

Owner:JINYU METAL MATERIALS CO LTD

Aluminum alloy ingot

The invention discloses an aluminum alloy ingot. The aluminum alloy ingot comprises, by weight , 9.6%-12.0% of Si, 1.5%-3.5% of Cu, less than 0.3% of Mg, less than 1.3% of Fe, less than 1.0% of Zn, less than 0.5% of Mn, less than 0.5% of Ni, less than 0.3% of Sn, 1%.-2%. of Sr, 1%.-2%. of Ti, 1%.-2%. of B and the balance Al. The Si element is added to the aluminum alloy ingot so that strength and toughness of the aluminum alloy ingot are effectively improved, and the Ti and B elements added into the aluminum alloy ingot enables a die-casting product to generate good grain refinement, casting cracks are effectively avoided, the appearance of a casting is improved, the surface quality of the ingot is improved, particularly cold shut of the ingot is reduced, and the impact toughness of the aluminum alloy ingot is effectively improved by 15%-20% on the condition that the strength of the aluminum alloy ingot is not reduced.

Owner:WUXI GREAT TECH

Alloy material easy to mold at a time

The invention relates to the technical field of alloys, in particular to an alloy material easy to mold at a time. The alloy material is characterized in that the alloy material comprises, by weight, 0.2-0.4% of zirconium, 0.1-0.3% of zinc, 5-7% of silicon, 0.02-0.1% of strontium, 0.05-0.2% of molybdenum, 0.1-0.3% of nickel, 0.08-0.3% of copper, 0.02-0.04% of scandium, 2-15 ppm of beryllium, and the balance aluminum and less than 0.1% of impurities. Castings cannot crack due to uneven cooling in the cooling process, and the cooling speed is 5% higher than that of conventional alloys. Accordingly, castings cast through one-step molding are smooth in surface and high in strength and impact toughness.

Owner:蚌埠冠宜型材科技有限公司

Centrifugal cast high-speed steel roll manufacture

Owner:XI AN JIAOTONG UNIV

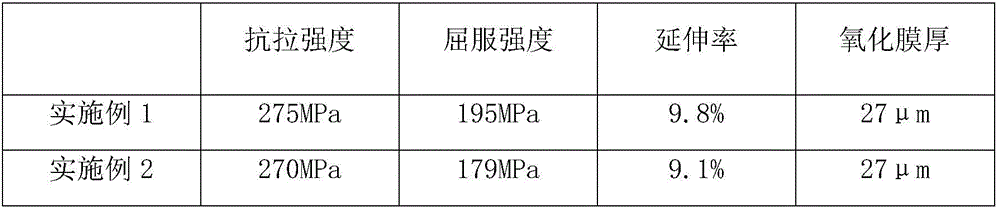

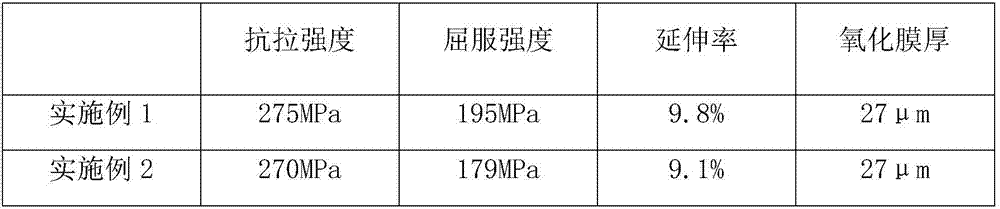

A high-strength high-magnesium aluminum alloy and its casting process

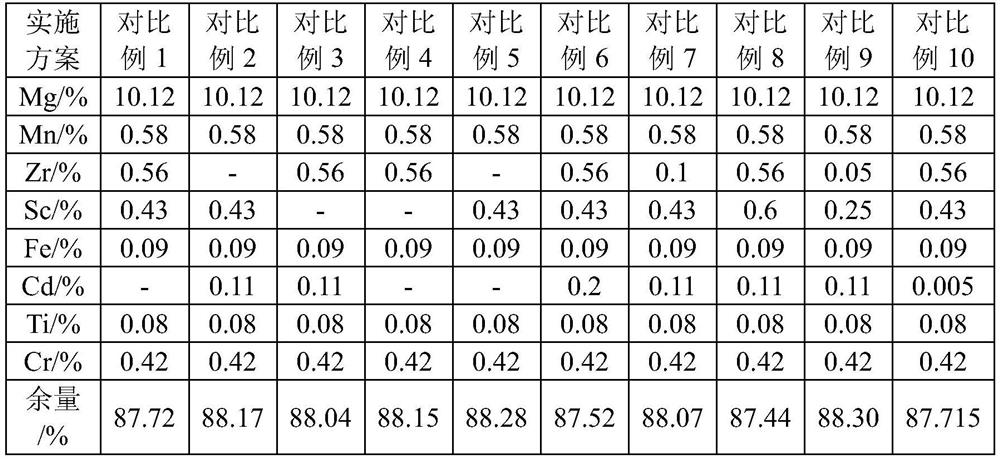

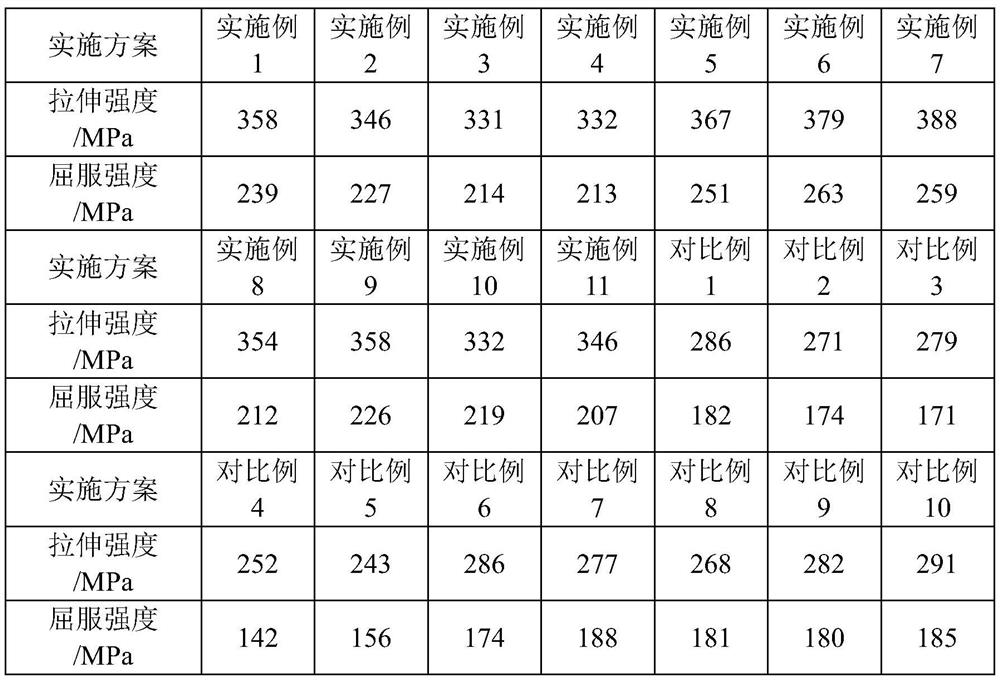

The application relates to the technical field of magnesium-aluminum alloy and its manufacture, and specifically discloses a high-strength, high-magnesium-aluminum alloy and its casting process. The high-magnesium aluminum alloy casting process includes the following steps: S1. Prepare raw materials for high-magnesium aluminum alloy preparation: prepare high-magnesium aluminum alloy raw materials in mass percentages, including Mg 7.96-11.02%, Mn 0.50-0.80%, Zr 0.1-0.9 %, Sc 0.30~0.56%, Fe 0.01~0.15%, Cd 0.02~0.16%, Ti 0.03~0.12%, Cr 0.3~0.52%, the balance is Al and other unavoidable impurities; S2, add after smelting aluminum ingot Other alloy raw materials and smelting; S3, refining; S4, adding grain refiner and removing slag; S5, casting; S6, annealing. The high-magnesium aluminum alloy of the present application has the advantage of excellent mechanical properties.

Owner:康硕(山西)智能制造有限公司

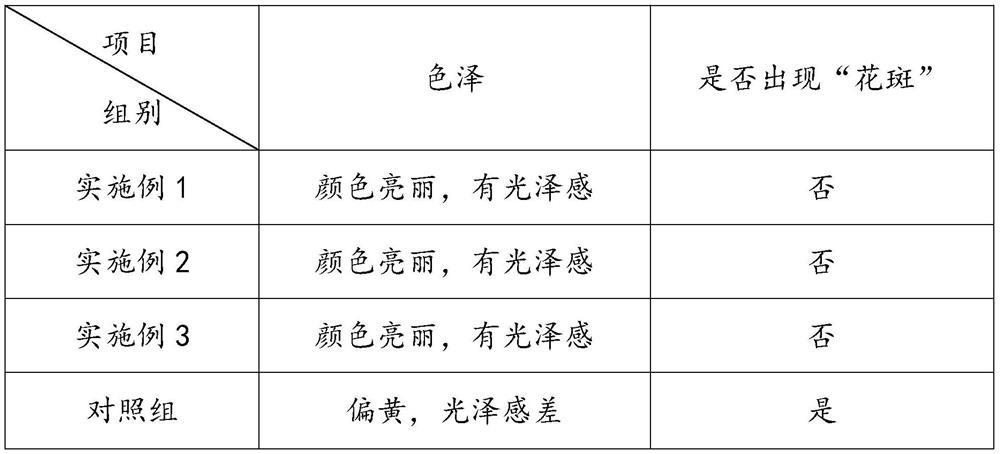

Stainless-steel-colored aluminum alloy and preparation method thereof

The invention relates to the technical field of aluminum alloys, in particular to a stainless-steel-colored aluminum alloy and a preparation method thereof. The stainless-steel-colored aluminum alloyis prepared from the following components in percentage by weight: 0.38-0.41% of silicon, less than 0.15% of iron, less than 0.1% of copper, less than 0.1% of manganese, 0.48-0.51% of magnesium, lessthan 0.1% of chrome, less than 0.1% of zinc, less than 0.1% of titanium and the balance of aluminum and impurities, wherein the single impurity is less than 0.05%, and the total amount of the impurities is less than 0.15%. The stainless-steel-colored aluminum alloy has the color and gloss of an existing stainless steel profile, has a mirror effect of stainless steel, has the smaller density and lower cost than those of the stainless steel profile, and can replace the existing stainless steel profile to be applied to building decoration.

Owner:东莞市润华铝业有限公司

High-abrasive-resistance aluminum alloy material and preparation method thereof

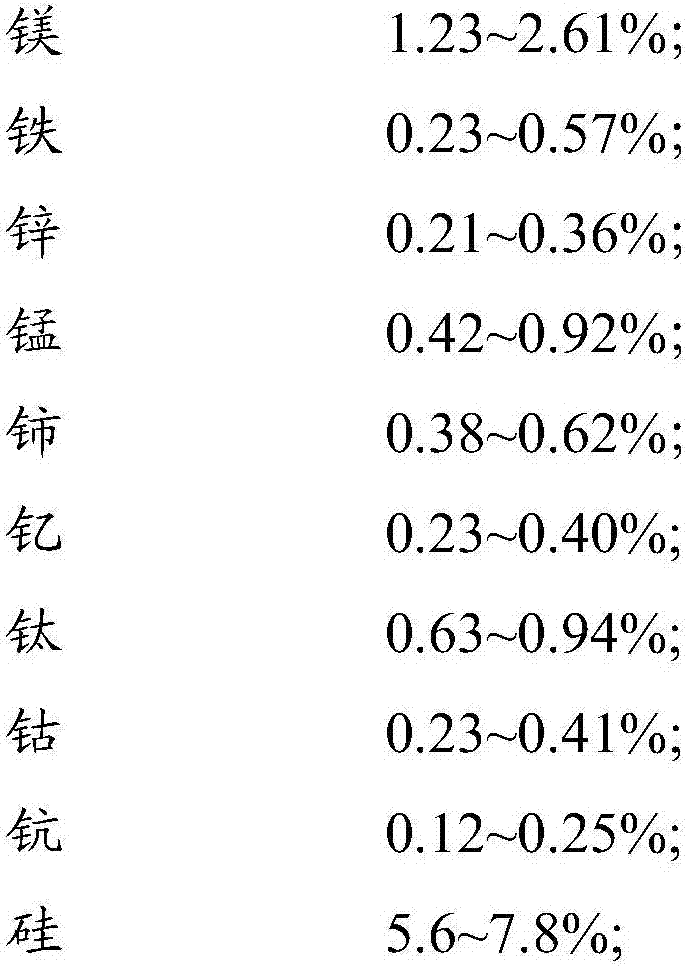

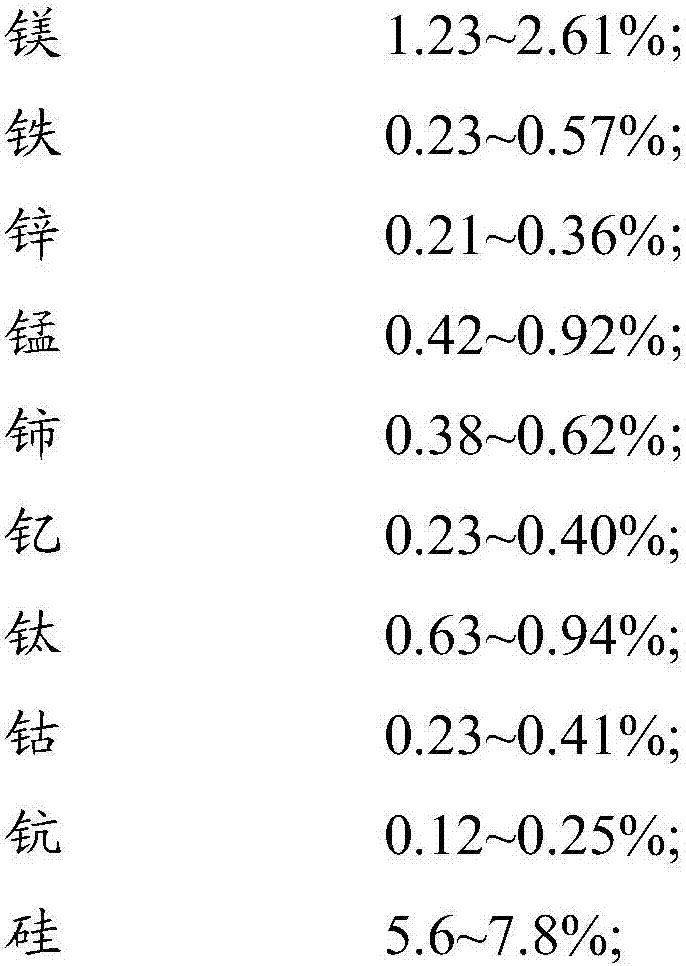

The invention provides a high wear-resistant aluminum alloy material and a preparation method thereof. The high wear-resistant aluminum alloy material is composed of the following components by weight percentage: 1.23-2.61% of magnesium, 0.23-0.57% of iron, 0.21-0.36% zinc, 0.42-0.92% manganese, 0.38-0.62% cerium, 0.23-0.40% yttrium, 0.63-0.94% titanium, 0.23-0.41% cobalt, 0.12-0.25% scandium, 5.6- 7.8% silicon, the rest is aluminum and a small amount of unavoidable impurities. In the present invention, the addition of cerium and yttrium in the aluminum alloy material can improve the wear resistance of the aluminum alloy material; the addition of cobalt and scandium can improve the toughness of the aluminum alloy material, overcome casting cracks, improve the quality of the aluminum alloy, and improve the quality of the aluminum alloy. Product cost rate. According to the experimental results, the hardness of aluminum alloy products is above 689HV, the strength is above 542MPa, and the qualified rate of flaw detection is above 99%.

Owner:合肥饰界金属制品有限公司

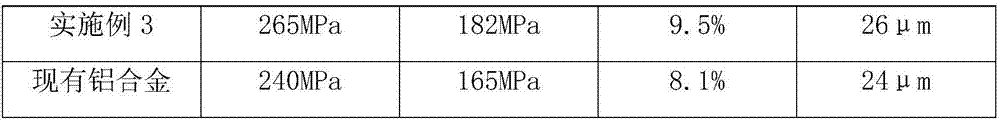

Production process of aluminum alloy shell for electronic product

ActiveCN113083923AImprove securityGood formabilityProcess efficiency improvementUltimate tensile strengthAnodic oxidation

The invention relates to a production process of an aluminum alloy shell for an electronic product. The production process comprises the following steps of molten aluminum alloy melting, grain refinement, blowing refining in a furnace, online degassing filtering, semi-continuous casting, extrusion, quenching, aging treatment, hot isostatic pressing treatment and the like. The aluminum alloy product comprises the following elements in percentage by mass, including 9-11% of Si; 5-6% of Mg; 1.5-2.0% of Cu; 1.0-1.3% of Zn; 0.5-0.7% of Cu; 0.21-0.26% of Mn; 0.13-0.16% of Zr; 0.15-0.25% of Y; 0.015-0.03% of Ti; 0.003-0.006% of B; and the balance of Al and inevitable impurity elements. On the basis of ensuring the anodic oxidation performance of the aluminum alloy, the strength of the aluminum alloy is improved, and the aluminum alloy is an ideal material for manufacturing shells for electronic products and has very wide market application prospects.

Owner:SHANDONG INNOVATION METAL TECH +1

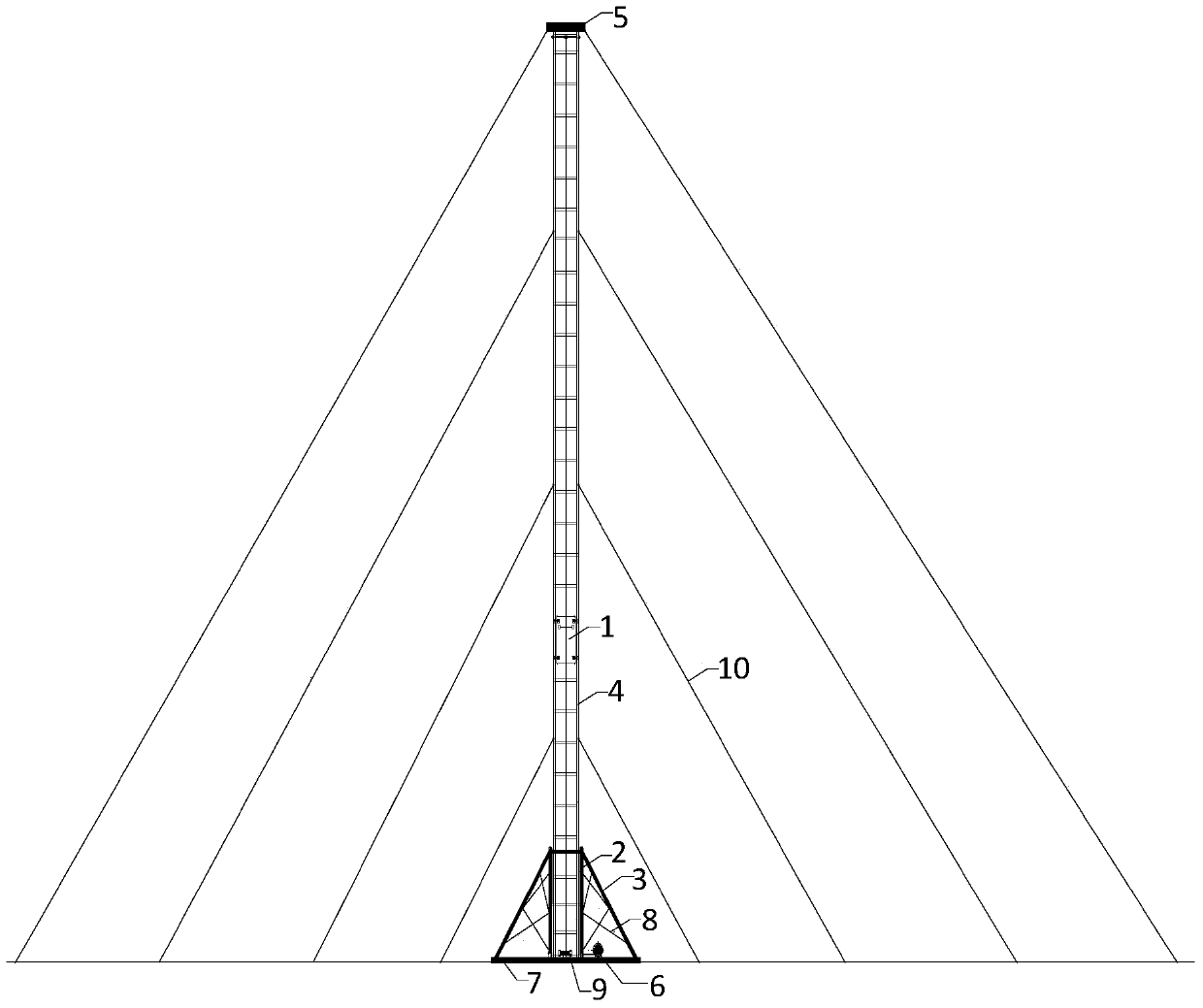

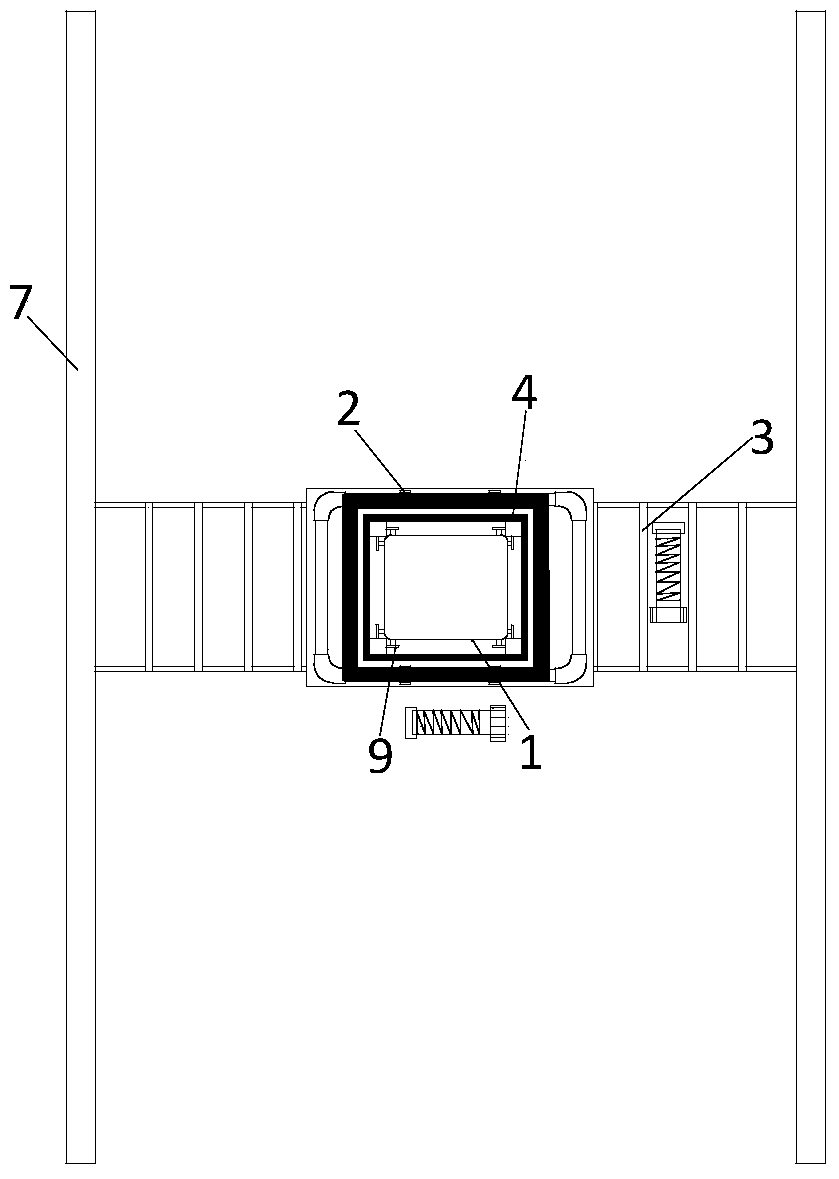

An insulated lifting platform

ActiveCN106542469BEasy to operateEnsure personal safetyLifting devicesEngineeringStructural engineering

The invention provides an insulation lifting platform. The insulation lifting platform comprises a base 7, a stand rod frame 2, a lifting frame 4 and an operation table 5 coaxially arranged in sequence from bottom to top, and is characterized in that a lifting basket 1 is arranged in the lifting frame 4. The insulation lifting platform is excellent in electric insulation performance, can satisfy the requirements of 1000 kilovolt electrified operation, is light in weight, is firm, satisfy safe operation demands, and is convenient to operate, use and transport.

Owner:CHINA ELECTRIC POWER RES INST +2

High-strength aluminum alloy material and preparation method thereof

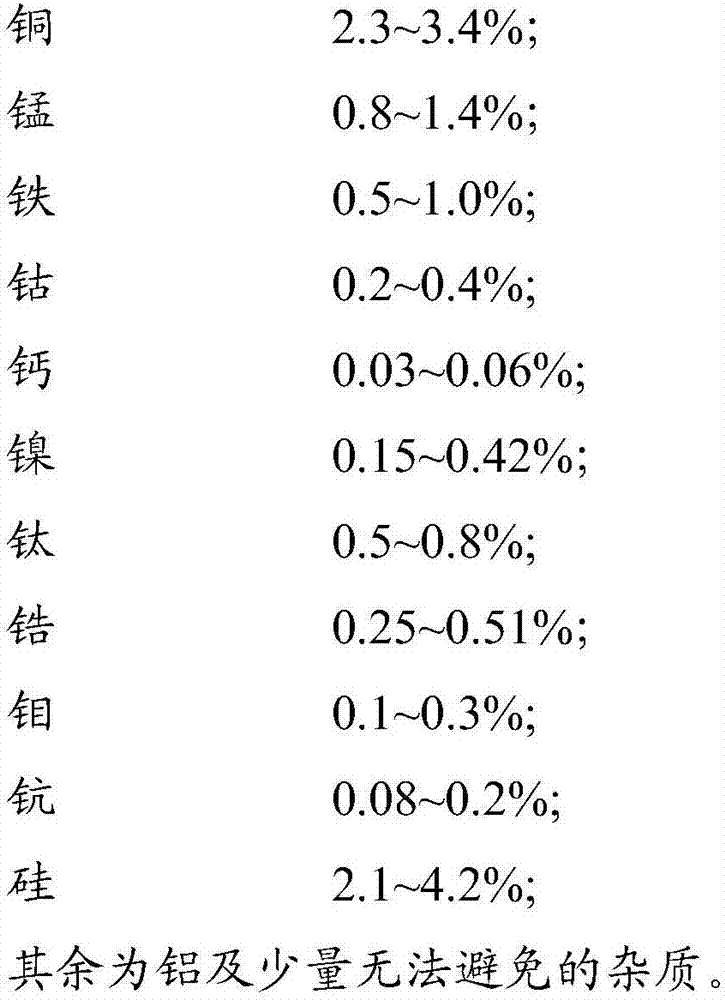

The invention provides a high-strength aluminum alloy material and a preparation method thereof. The high-strength aluminum alloy material is composed of the following components by weight percentage: 2.3-3.4% copper, 0.8-1.4% manganese, 0.5-1.0% iron, 0.2-0.4% cobalt, 0.03-0.06% calcium, 0.15-0.42% nickel, 0.5-0.8% titanium, 0.15-0.42% nickel, 0.25-0.51% zirconium, 0.1-0.3% Molybdenum, 0.08-0.2% scandium, 2.1-4.2% silicon. In the present invention, the strength and plasticity of the aluminum alloy material are improved by adding zirconium and molybdenum to the aluminum alloy material, and the addition of cobalt and scandium to the aluminum alloy material can effectively overcome casting cracks, improve the quality of the aluminum alloy, and improve the quality of the aluminum alloy product. Cost rate. According to the experimental results, the strength of aluminum alloy products is above 547MPa, the elongation rate is above 7.9%, and the qualified rate of flaw detection is above 99%.

Owner:合肥饰界金属制品有限公司

A kind of aluminum alloy material for automobile wheel hub

ActiveCN103924136BLow densityAchieve lightweightHubsRolling resistance optimizationRare earthToughness

The invention discloses an aluminum alloy material for an automobile hub. The material comprises the following components in percentage by mass: 12-15% of Si, 14.4-22.5% of Mg, 1-1.5% of Cu, 0.2-1.3% of Fe, 0.3-0.9% of Zn, 0.1-0.4% of Mn, 0.3-0.6% of Nb, 0.1-0.3% of Ni, 1-1.8% of Li, 0.1-1.5% of Re, 0.1-0.3% of Cr, 0.5-1% of Sr, 0.3-0.5% of Sn, 1-2% of mixed rare earth and the balance of Al. As aluminum is used as a main substance of the alloy, the density of the material is reduced, and the purpose of lightening the automobile hub is achieved; due to adoption of the element Sr added into the aluminum alloy, the strength and the toughness of the aluminum alloy are effectively improved; due to adoption of elements Ti and B, good grain refinement can be achieved for a pressure cast product, cast crack can be effectively overcome, and meanwhile good heat radiation properties are achieved.

Owner:吉林万丰奥威汽轮有限公司

Super large specification aluminum alloy slab ingot and casting method

The invention discloses a super large specification aluminum alloy slab ingot and a casting method. The method comprises the following steps: preparing raw materials according to ratio, then adding in a melting furnace for melting and removing the slag; conversing to a heat preserving furnace for on-line degassing and refining, degassing, removing the slag and purifying, adding an aluminum titanium boron grain-refining agent for refining the crystal grains; then casting to the aluminum alloy slab ingot; and finally homogenizing to obtain the aluminum alloy slab ingot with difficult cracking and refined tissue. The produced 650*2750mm slab ingot is capable of eliminating the segregation and casting stress of the slab ingot, and guaranteeing the product quality, the mechanical properties can satisfy the requirements of the large-scale structural members.

Owner:广西南南铝加工有限公司

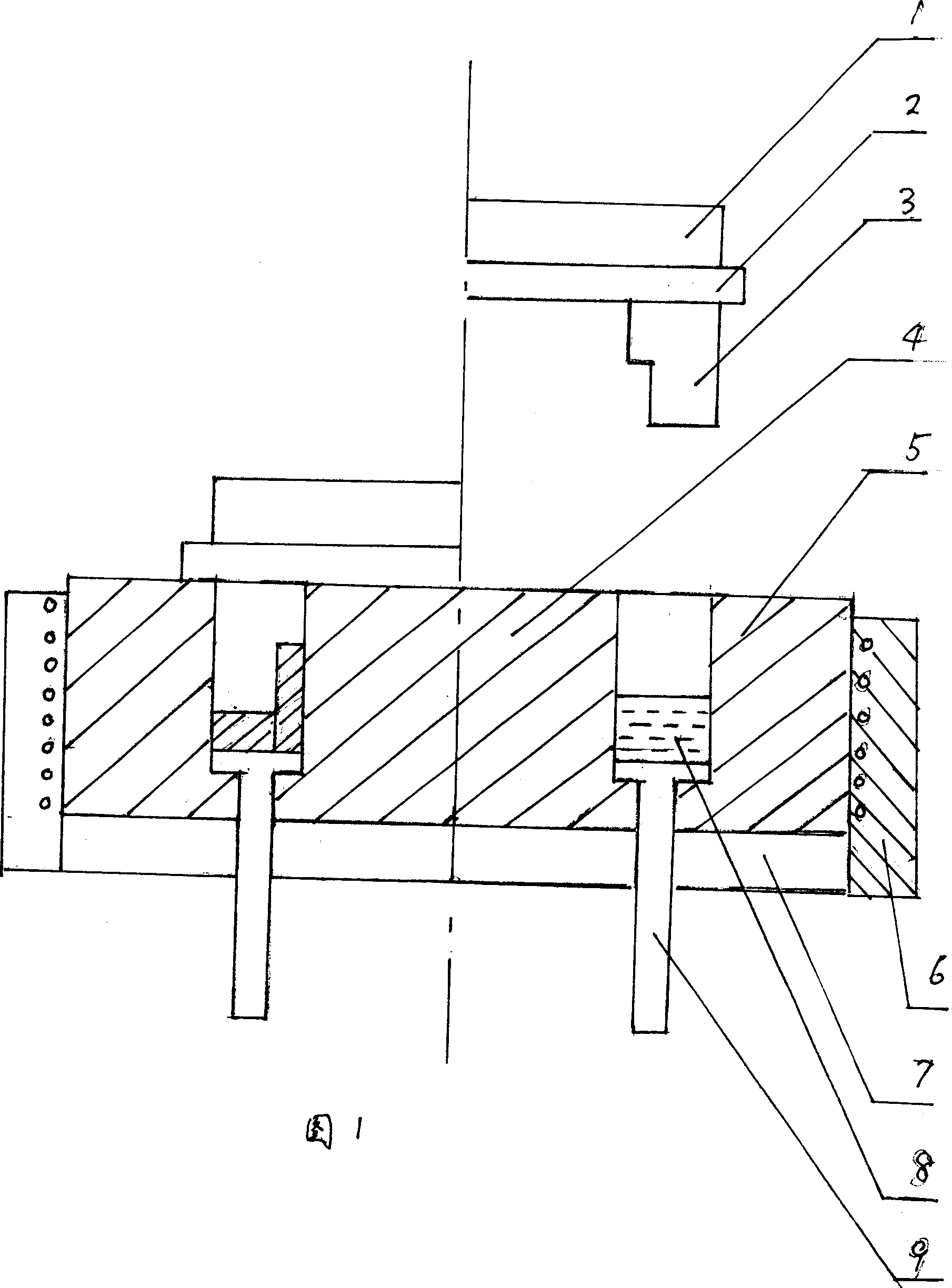

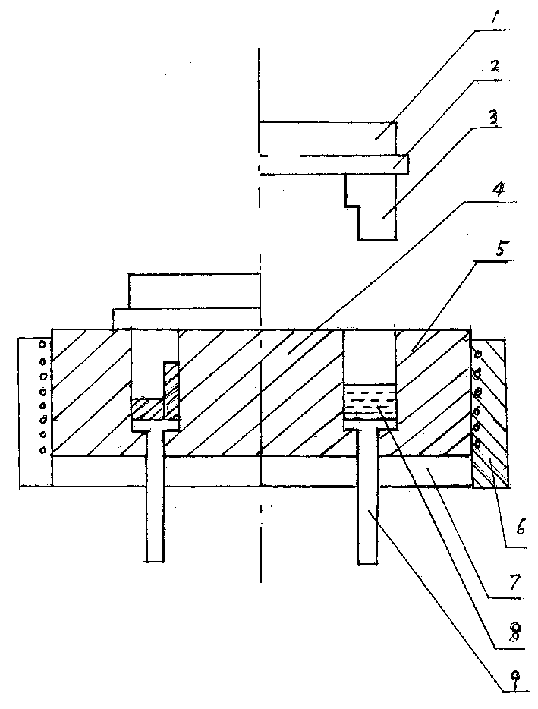

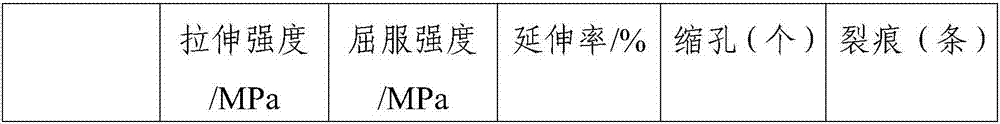

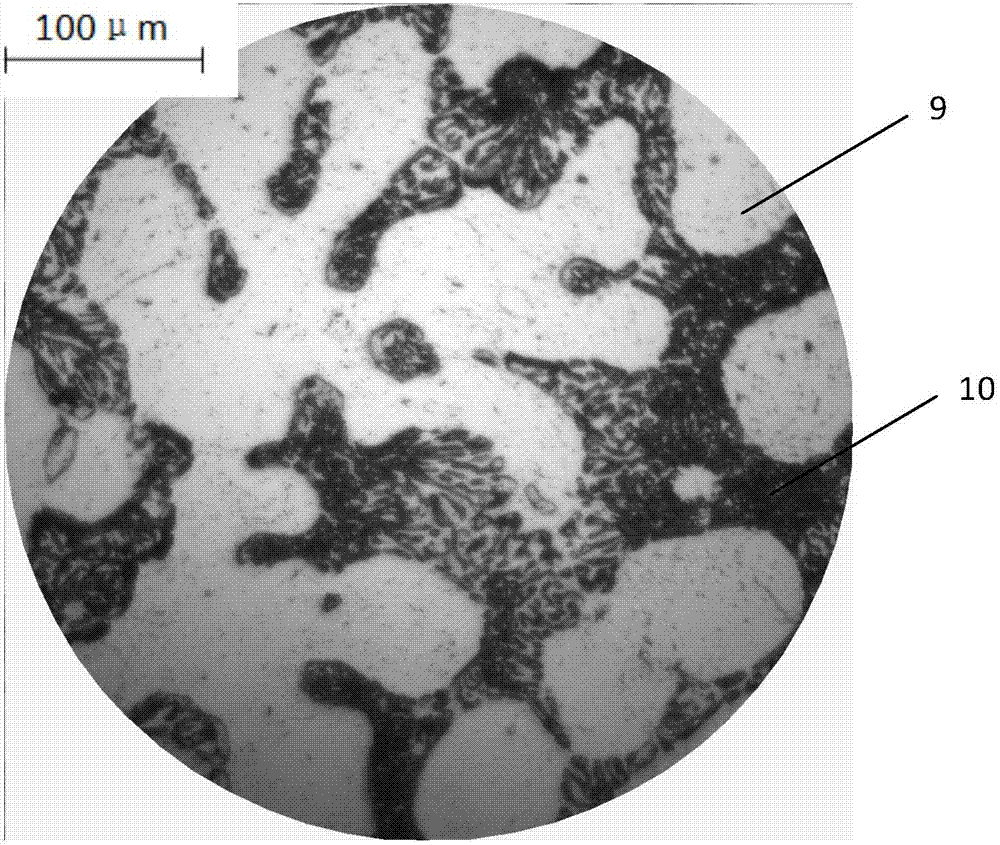

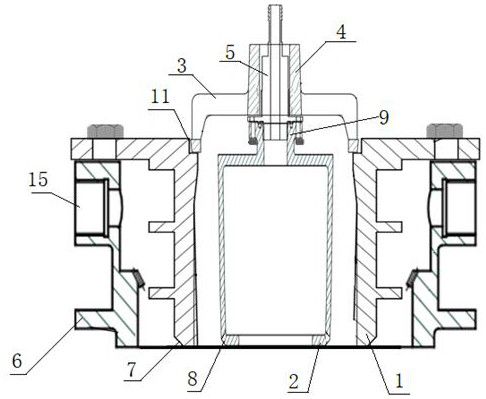

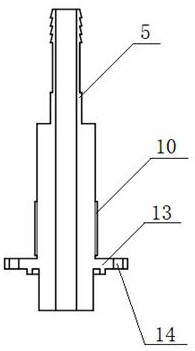

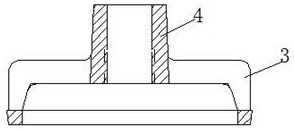

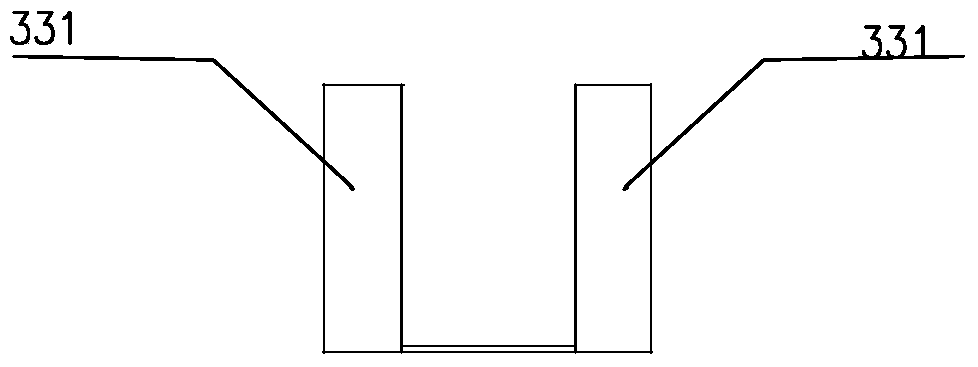

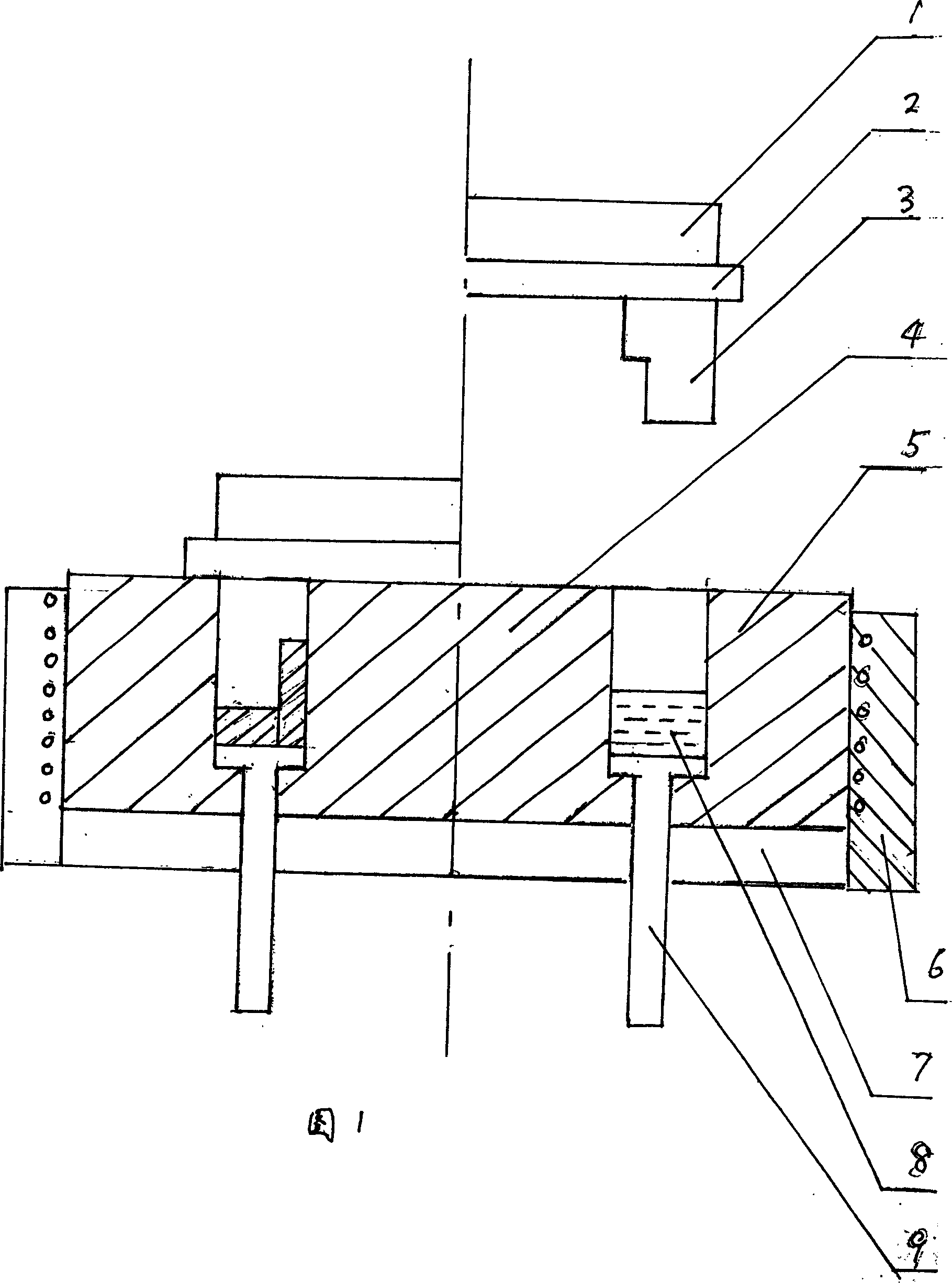

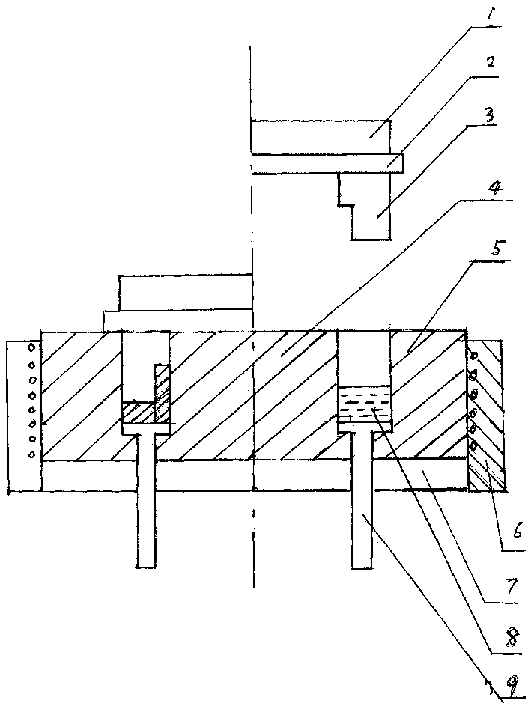

Flange with neck and its preparing method

The present invention relates to a LF 2R High-neck flange, obtained by extrusion casting, has no weld seam, and its microstructure presents a continuous streamlined structural feature, and its streamlined shape is consistent with the direction of the flange shape; a preparation method of a LF2R high-neck flange of the present invention , the metal liquid crystallizes and solidifies under the pressure in the mold casting cavity composed of the upper pressure head, the female mold (5), the mold core (4) and the ejector pin (9); the extrusion casting process is: pouring at 700±15°C , The mold temperature is 250±50°C. When the mold is closed, the pressure gradually rises for no more than 5 seconds. When it reaches 25MPa, the pressure is kept for 1 minute 30 seconds to 2 minutes. The necked flange casting of the present invention has few internal defects, compact structure and high mechanical properties. The squeeze casting process has strong applicability, wide range of material selection, simple process, good stability, high casting quality, and easy casting. Implement automation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

aluminum alloy ingot

The invention relates to an aluminum alloy ingot. The aluminum alloy ingot is prepared from, by weight percent, 7.2%-11.4% of Si, 1.2%-1.5% of Cu, 0.1%-0.3% of Mg, 0.2%-0.4% of Fe, 1.2%-1.4% of Zn, 0.2%-0.4% of Ni, 0.1%-0.3% of Sn, 1.2%-2.4% of Sr, 2.1%-2.4% of Ti, 2.1%-2.4% of B, 1.2%-1.4% of Sb, 0.3%-0.5% of As, 0.22%-0.44% of RE, 0.4%-1.4% of LaCe, 0.3%-0.5% of Pr and the balance Al and inevitable impurities, wherein the content of the impurities is not larger than 0.1%. The aluminum alloy ingot is good in comprehensive performance, resistant to corrosion and stable in performance.

Owner:肇庆南都再生铝业有限公司

Process for manufacturing aluminum alloy ingot

The invention discloses a process for manufacturing an aluminum alloy ingot, which is characterized by including the steps of a, proportioning raw materials according to the proportion of each element of the product, b, placing proportioned raw materials into a smelting furnace for smelting, c, sampling and assaying, and adding silicon metal according to the results of assay, d, adding a cooling material to reduce the temperature of an aluminum liquid, e, stirring for uniform composition, f, sampling and assaying, and adding aluminum strontium alloy, aluminum titanium boron alloy and nontoxic refining agent according to the results of assay, g, purification, refining and deaeration, h, still standing for 15 min to 25 min, i, drossing slags onto a slag car, j, sampling and assaying, and supplementing or diluting in case of incompliance with standard requirements on composition, k, filtering for improved cleanliness of the aluminum liquid, and l, casting a portable ingot. Ingots cast from the process have less cold laps and cracks, and are characterized by high tenacity and strength.

Owner:WUXI GREAT TECH

Aluminum alloy for auto parts and die-casting method for auto parts

The invention provides aluminum alloy for an automobile part. The aluminum alloy comprises the following components of Mg, Si, B, Ti, Cu, Cr, Zr, Fe, Sn, Co, Sc, Hf, and the balance Al and unavoidable impurities. Compared with the prior art, the Mg, Si, Cu, Cr and Zr elements are added into the aluminum alloy, so that the strength and toughness of the aluminum alloy are improved effectively; and through the Co, Sc, Hf, Ti and B elements added into the aluminum alloy, a die casting product can generate good grain refinement, the defect of casting cracks is overcome effectively, and the appearance of a casting and the surface quality of a cast ingot are improved. The invention further provides a die casting method for the automobile part, and the aluminum alloy for the automobile part is adopted. According to the aluminum alloy and the die casting method, the casting prepared through die casting, the defects such as pores or shrinkage cavities or misrun or unclear appearance outlines are overcome, and the product yield is high.

Owner:余姚市弘顺机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com