7xxx series aluminum alloy large-specification hollow cast ingot production device and process thereof

A hollow ingot and production device technology, which is applied in the field of 7xxx series aluminum alloy large-scale hollow ingot production device, can solve the problems of ring cracks, low controllability, radioactive cracks, etc. The effect of precise parameters and uniform distribution of temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

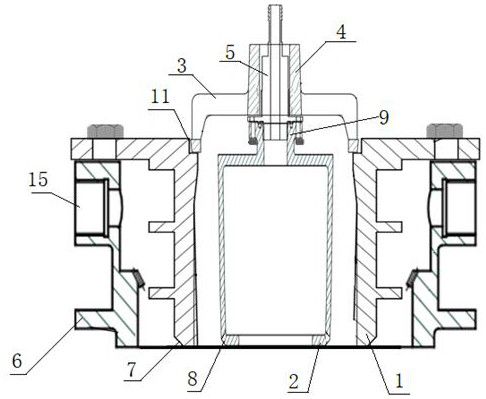

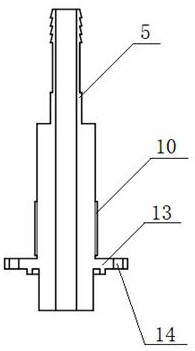

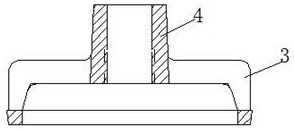

[0034] like Figures 1 to 5 As shown, a 7xxx series aluminum alloy large-scale hollow ingot production device includes a crystallizer 1, a water jacket 6, a core 2, and a core support 3. The crystallizer 1 is placed in the water jacket 6 and outside the crystallizer 1 A cooling water cavity is formed. The lower part of the crystallizer 1 is provided with a water outlet 7. The core 2 is placed in the crystallizer 1 and forms an annular casting cavity with the inner side of the crystallizer 1. The upper part of the core 2 is provided with a core water inlet 9. The lower part of the core 2 is provided with a core water eye 8, and the core support 3 is placed above the crystallizer 1 through the annular groove 11 provided on the top of the crystallizer 1, and the core support 3 is a circular frame and in the center The position is provided with a raised connecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com