Liquid extrusion forming method of steel ball

An extruded and liquid technology, applied in the field of wear-resistant steel balls, can solve problems such as poor quality, non-wear resistance, and waste of production materials, and achieve the effects of increasing service life, improving mechanical properties, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: make 6mn5si4cr5 wear-resistant steel ball.

[0031] The steps of the steel ball liquid extrusion forming method described in this embodiment are: smelting→liquid extrusion→waste heat treatment.

[0032] 1. The smelting process is as follows: the steel is smelted according to the chemical composition ratio of 6mn5si4cr5, and the molten steel is put into the heat preservation bag to be poured after the pre-furnace inspection and testing, and the composition is qualified.

[0033] 2. Liquid extrusion:

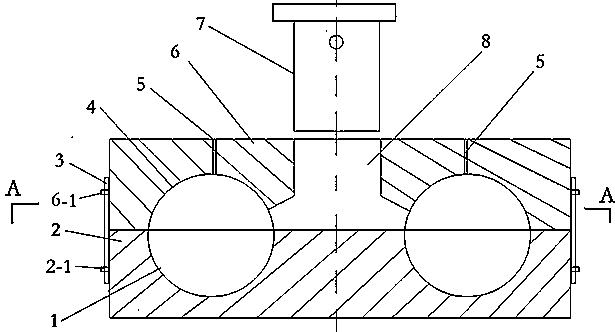

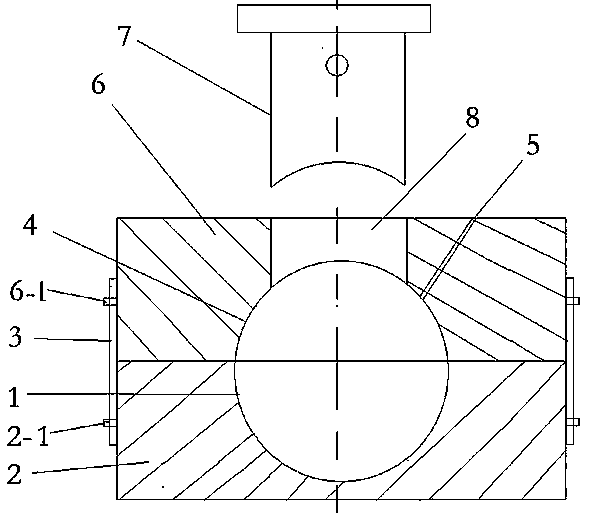

[0034] (1) Liquid extrusion die: see Figure 1-2 , 5, upper and lower molds 6, 2 are provided, and the upper and lower mold sides are provided with connecting locks: namely, the locking hook 3 is connected through the shaft 2-1 at the lower mold side, and the locking pin 6- is connected at the upper mold side. 1. When the upper and lower molds are closed, the lock hook 3 is hooked on the lock pin 6-1 to prevent movement between the upper and lower molds. ...

Embodiment 2

[0043] Embodiment two: making high chromium alloy wear-resistant steel balls.

[0044] The steps of the steel ball liquid extrusion forming method described in this embodiment are the same as those in Embodiment 1:

[0045] 1. Melting process: Melting the steel according to the chemical composition ratio of high chromium alloy. After inspection and testing before the furnace, after adjusting the composition, the molten steel is put into the heat preservation bag to be poured.

[0046] 2. Liquid extrusion:

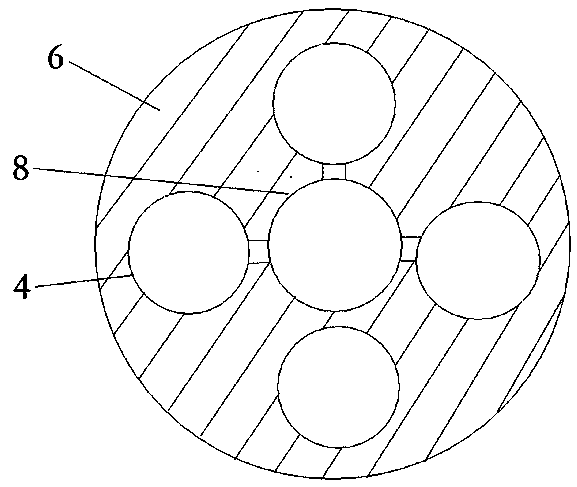

[0047] (1) Liquid extrusion die: see Figure 3-4 , 5. The mold is provided with upper and lower molds, and the sides of the upper and lower molds are provided with connecting locks: that is, the locking hook 3 is connected through the shaft 2-1 at the side of the lower mold, and the locking pin 6-1 is connected at the side of the upper mold. When the upper and lower dies are closed, the lock hook 3 is hooked on the lock pin 6-1 to prevent movement between the upper and lo...

Embodiment 3

[0052] Embodiment three: making low-chromium alloy wear-resistant steel balls.

[0053] The steps of the steel ball liquid extrusion forming method described in this embodiment are the same as those in Embodiment 1.

[0054] 1. Melting process: Melting the steel according to the chemical composition ratio of the low chromium alloy. After the inspection and testing before the furnace, the composition is adjusted and the molten steel is put into the heat preservation bag to be poured.

[0055] 2. Liquid extrusion:

[0056] (1) Liquid extrusion die: see Figure 1-2 , The mold is provided with upper and lower molds 6, 2, and the sides of the upper and lower molds are provided with connecting locks (same as Example 1). Four sets of opposite hemispherical inner cavities 4, 1 are respectively arranged on the opposite surfaces of the upper and lower molds, and the upper and lower opposite hemispherical inner cavities form a spherical liquid extrusion cavity; the hemispherical inner ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com