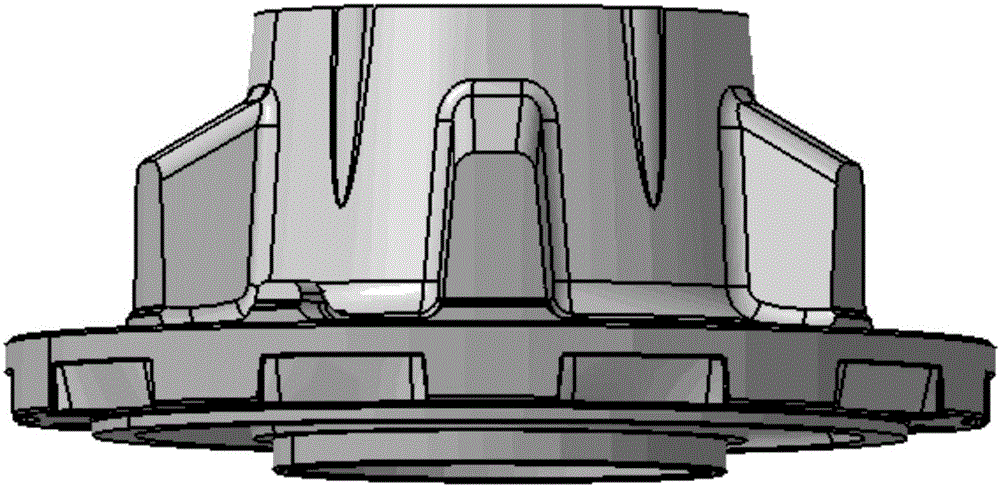

Liquid forging technology method for 6061 material commercial vehicle aluminum alloy shaft head

A technology of liquid die forging and aluminum alloy, which is applied in the field of liquid die forging process method of 6061 material commercial vehicle aluminum alloy shaft head, can solve the problem of no application of rare earth elements, etc., achieve obvious economic and social benefits, low process cost, good appearance The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

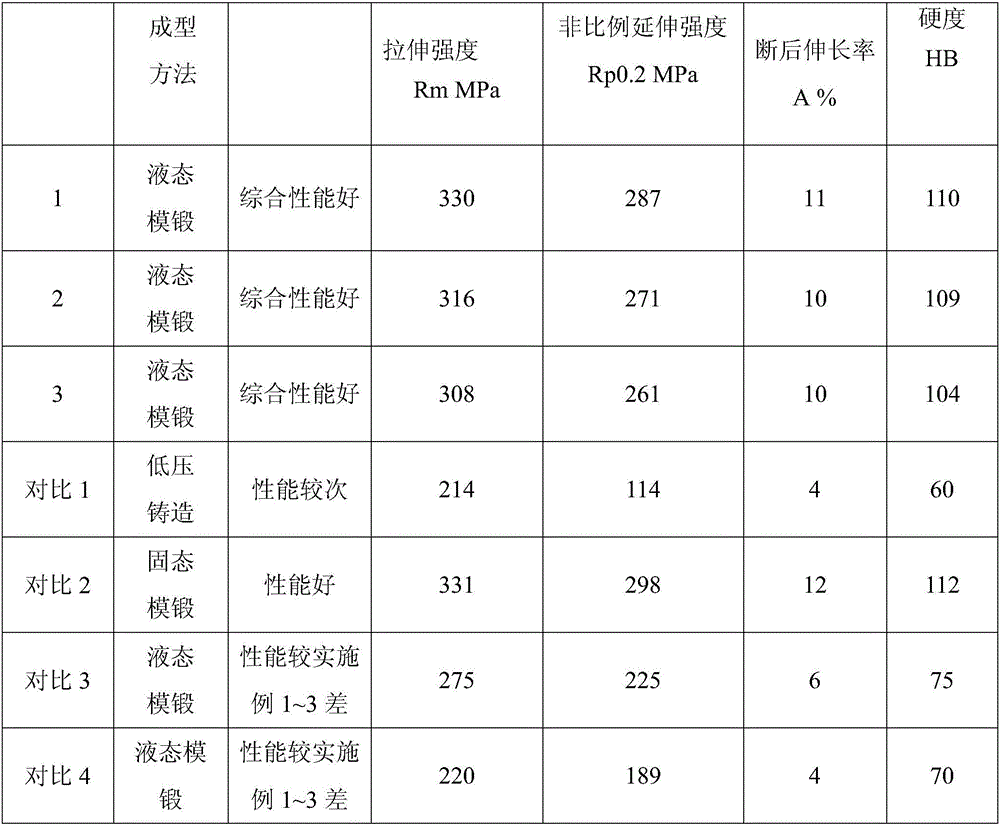

Embodiment 1

[0039](1) Alloy composition optimization: optimize the Mg / Si ratio and the ratio of other alloying elements in 6061 aluminum alloy, and control the mass content of impurity elements, including Si0.6 parts; Fe<0.25 parts; Cu0.2 parts; Mg1.0 parts ; Cr0.15 parts; Al97 parts, control other single impurities in 6061 aluminum alloy to less than 0.05 parts, then add elements Gd0.4 parts; Sm0.18 parts; Hf 0.5 parts, use Sr and Ti for modification and refinement treatment. In this step, it is necessary to strictly control the amount of Gd and Sm added, because adding too much will not only not improve the performance of the aluminum alloy, but also affect the normal use of the aluminum alloy, and even cause the scrap of the material;

[0040] (2) Melting;

[0041] (3) The melt obtained in step (2) is degassed and slag-removed in the furnace with a high-efficiency refining agent to make the melt clean and free of impurities; removing impurities and gases inside the aluminum alloy melt ...

Embodiment 2

[0053] (1) Alloy composition optimization: optimize the ratio of Mg / Si and other alloy elements in 6061 aluminum alloy, and control the mass content of impurity elements, including Si0.5 parts; Fe<0.1 parts; Cu0.15 parts; Mg0.80 parts ; Cr0.04 parts; Al95 parts, control other single impurities in 6061 aluminum alloy to less than 0.04 parts, then add elements Gd0.3 parts; Sm0.15 parts; Hf 0.3 parts, use Sr and Ti for modification and refinement treatment. In this step, it is necessary to strictly control the amount of Gd and Sm added, because adding too much will not only not improve the performance of the aluminum alloy, but also affect the normal use of the aluminum alloy, and even cause the scrap of the material;

[0054] (2) Melting;

[0055] (3) The melt obtained in step (2) is degassed and slag-removed in the furnace with a high-efficiency refining agent to make the melt clean and free of impurities; removing impurities and gases inside the aluminum alloy melt can further...

Embodiment 3

[0068] (1) Alloy composition optimization: optimize the Mg / Si ratio and other alloy element ratios in 6061 aluminum alloy, and control the mass content of impurity elements, including Si0.75 parts; Fe<0.1 parts; Cu0.25 parts; Mg1.10 parts ; Cr0.25 parts; Al98 parts, control other single impurities in 6061 aluminum alloy to less than 0.05 parts, then add elements Gd0.5 parts; Sm0.2 parts; Hf1 parts, use Sr and Ti for modification and refinement treatment. In this step, it is necessary to strictly control the amount of Gd and Sm added, because adding too much will not only not improve the performance of the aluminum alloy, but also affect the normal use of the aluminum alloy, and even cause the scrap of the material;

[0069] (2) Melting;

[0070] (3) The melt obtained in step (2) is degassed and slag-removed in the furnace with a high-efficiency refining agent to make the melt clean and free of impurities; removing impurities and gases inside the aluminum alloy melt can further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com