Continuously extruding method and extruding device of non-radial feeding

An extrusion method and technology of extrusion equipment, which are applied in the field of continuous extrusion with non-radial feed, can solve the problems of improper control, limited production efficiency, failure of extrusion tools, etc., so as to improve service life and improve production efficiency. , good effect of metallographic organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

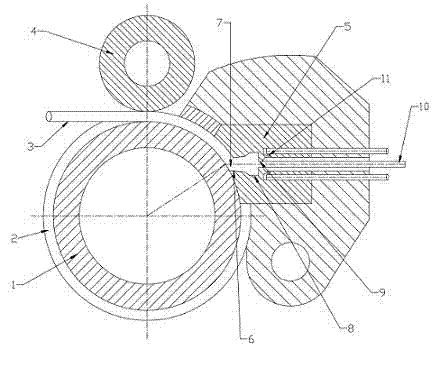

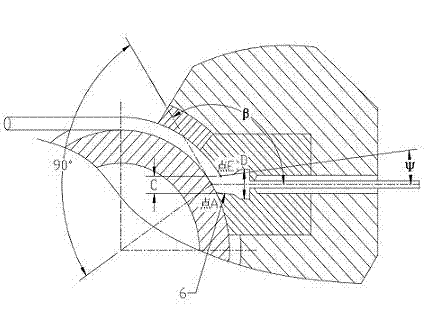

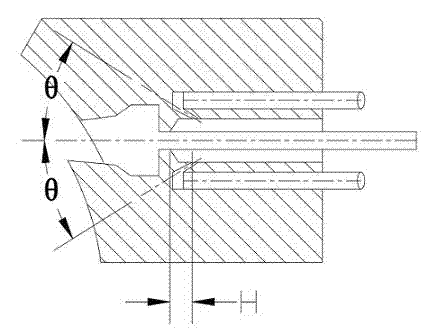

[0028] Such as figure 1 , figure 2 and image 3 As shown, the continuous extrusion method of non-radial feeding, the rotary extrusion wheel 1 has a groove 2 in the circumferential direction, and the billet 3 is pressed down by the compacting wheel 4, and between the billet 3 and the groove 2 of the extrusion wheel Driven by the frictional force, the billet 3 enters the extrusion tool 5, and when the billet 3 advances to the block 6, it enters the feed port 7 of the extrusion tool. There is a metal forming cavity 8 at the end of the feed port 7. A mold 9 is installed at the end of the metal cavity 8, and the product 10 is extruded through the mold 9 and rapidly cooled by a jet cooling device 11. figure 2 Among them, point A is the intersection point between the center line of the feed inlet and the extrusion wheel surface on the wheel surface, line B is the tangent line of the extrusion wheel surface passing through point A, and the β angle is the center line of the feed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com