Metal plate asynchronous rolling method

An asynchronous rolling and metal plate technology, applied in metal rolling, roll speed control, etc., can solve the problems of grain uniformity, compactness, strength defects, large metal plate grains, etc., to achieve fine grains, gold The effect of good phase organization and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

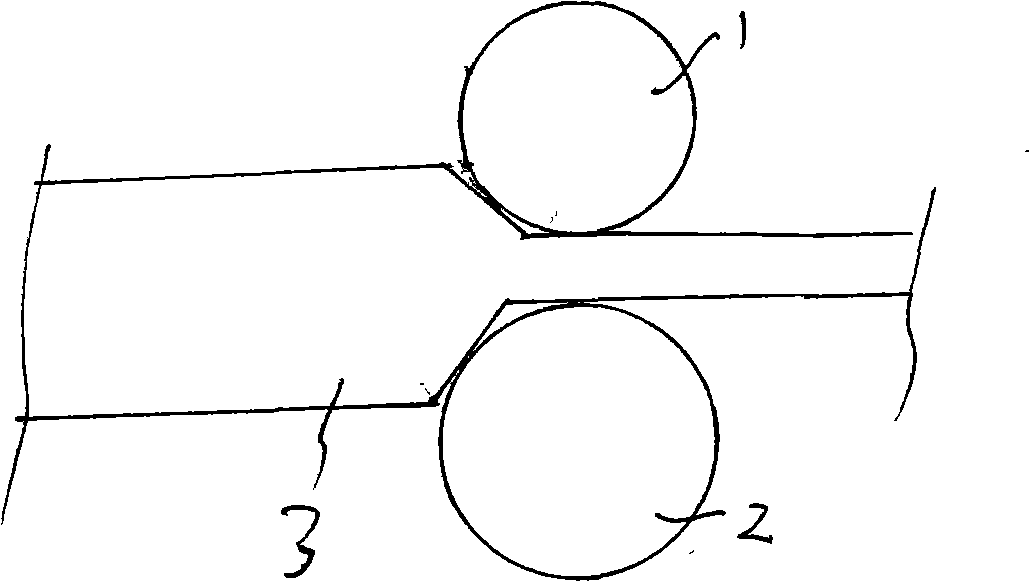

[0011] An asynchronous rolling method for a metal plate comprises rolling with a rolling pair of rolls. When the metal plate is rolled, the upper and lower rolling rolls 1 and 2 in the rolling pair of rolls adopt different linear speeds. (It can be that the rotating speeds of the upper and lower rolling rolls are the same and the roll diameters are different, or the roll diameters of the upper and lower rolling rolls are the same and the rotating speeds are different). There is also a metal plate 3 in the figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com