Perfluoropolyether modified polysiloxane coating aid, preparation method thereof and coating

A technology of polysiloxane and perfluoropolyether, which is applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve problems such as uneven spreading, shrinkage cavities, and cracked surfaces, and achieve Excellent hydrophobicity, oil repellency and antifouling effect, eliminate shrinkage cavity and lubrication, and ensure antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

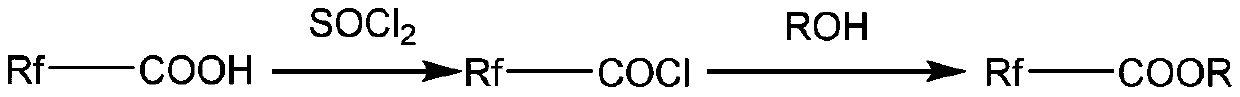

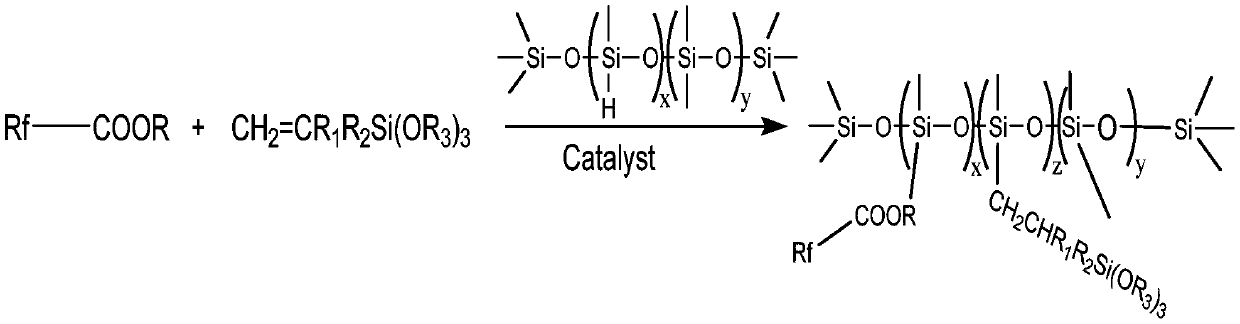

[0029] Embodiment 1: A kind of perfluoropolyether modified polysiloxane coating aid provided in this embodiment is made of perfluoropolyether acrylate, carbon-carbon double bond siloxane and hydrogen-containing silicone oil in the catalyst The molar ratio of the perfluoropolyether acrylate, carbon-carbon double bond-containing siloxane and hydrogen-containing silicone oil is 1-9:1-9:1. Among them, perfluoropolyether acrylate is obtained by reacting perfluoropolyether acid chloride with a molar ratio of 1:1-1.5 and a hydroxyl-containing acrylate compound; perfluoropolyether acid chloride is obtained by reacting a molar ratio of 3-8 : 1 Thionyl chloride and perfluoropolyether carboxylic acid react under the action of solvent to obtain; Catalyst is any one in metal catalyst such as rhodium, platinum, nickel or Lewis acid catalyst such as aluminum trichloride, iron trichloride or more; solvents are hydrofluoroether, hexafluorom-xylene, trifluorotrichloroethane, toluene, 1,4-dioxan...

Embodiment 2

[0043] Embodiment 2: a kind of perfluoropolyether modified polysiloxane coating aid provided by this embodiment and its preparation method, coating, it is basically the same as embodiment 1, the difference is:

[0044] Synthesize Rf-COOCH2CH2OC(O)C(CH3)=CH2(PFPE-HEMA) with reference to the method of Example 1: add perfluoropolyether acid chloride ( RfCOCl, Mw=3000, 15g, 0.005mol) and hydroxyethyl methacrylate (HOCH2CH2OCOC(CH3)=CH2), Mw=130.14, 0.6767g, 0.0052mol) and stirred at 30°C for 12h under nitrogen protection; washed with ethanol Remove unreacted acrylate, and remove the ethanol solvent under reduced pressure to obtain perfluoropolyether acrylate.

[0045] Test analysis: in the FTIR analysis, there is a peak associated with the ester group of Rf-C(O)OCH2- (-1794cm -1 ) and the peak associated with CH2OCOCH=CH2 α, β unsaturated ester group (-1735cm -1 ). Store the product sealed for later use.

[0046] With reference to the method of Example 1: under nitrogen protec...

Embodiment 3

[0047] Embodiment 3: a kind of perfluoropolyether modified polysiloxane coating aid provided by this embodiment and its preparation method, coating, it is basically the same as embodiment 1, embodiment 2, difference is:

[0048] Synthesize Rf-COOCH2CH2OC(O)C(CH3)=CH2(PFPE-HEMA) according to the method of Example 2, prepare perfluoro Polyether polysiloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com