Patents

Literature

109 results about "Nitride phosphor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

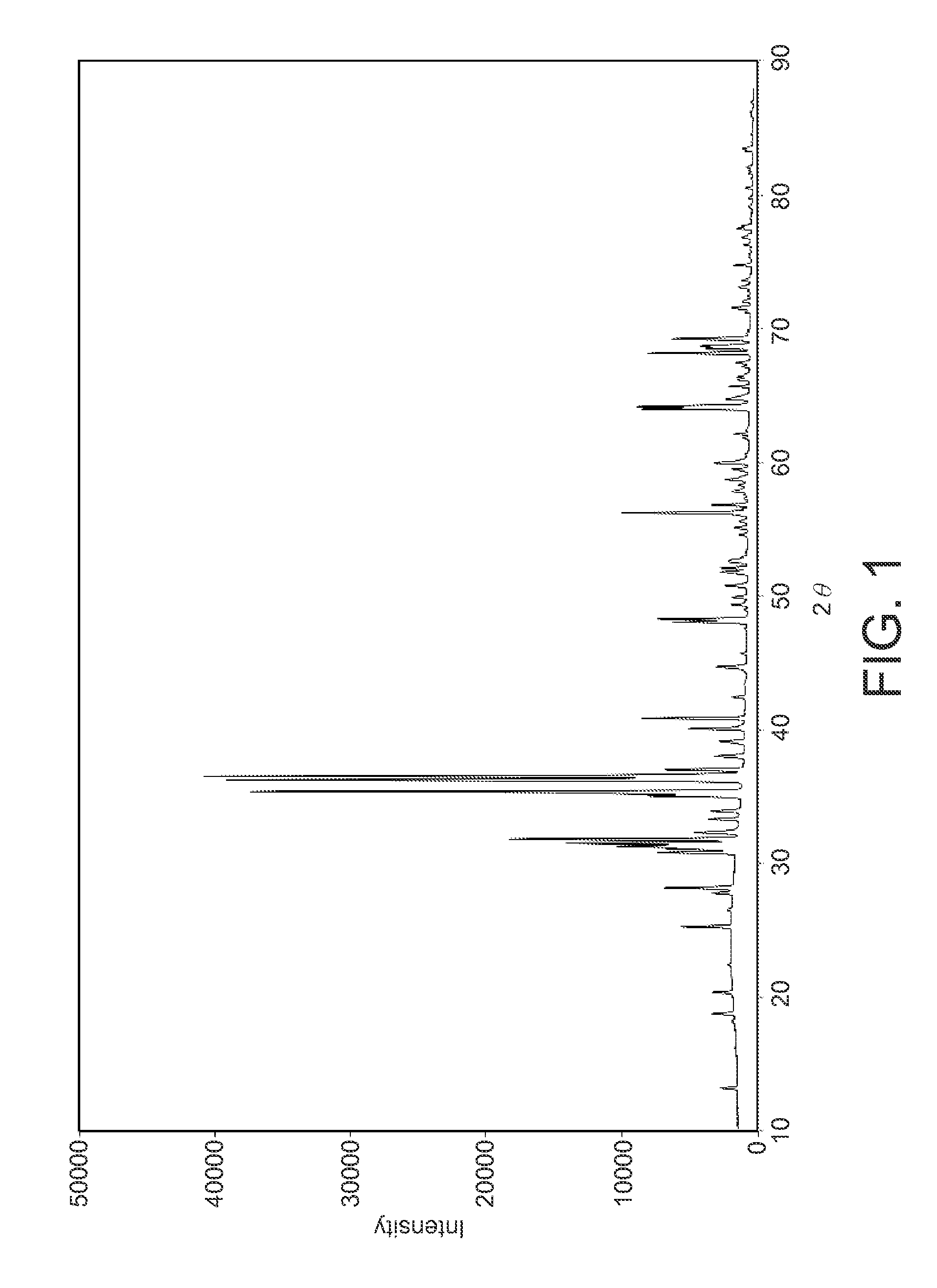

Red Nitride Phosphor and Production Method Thereof

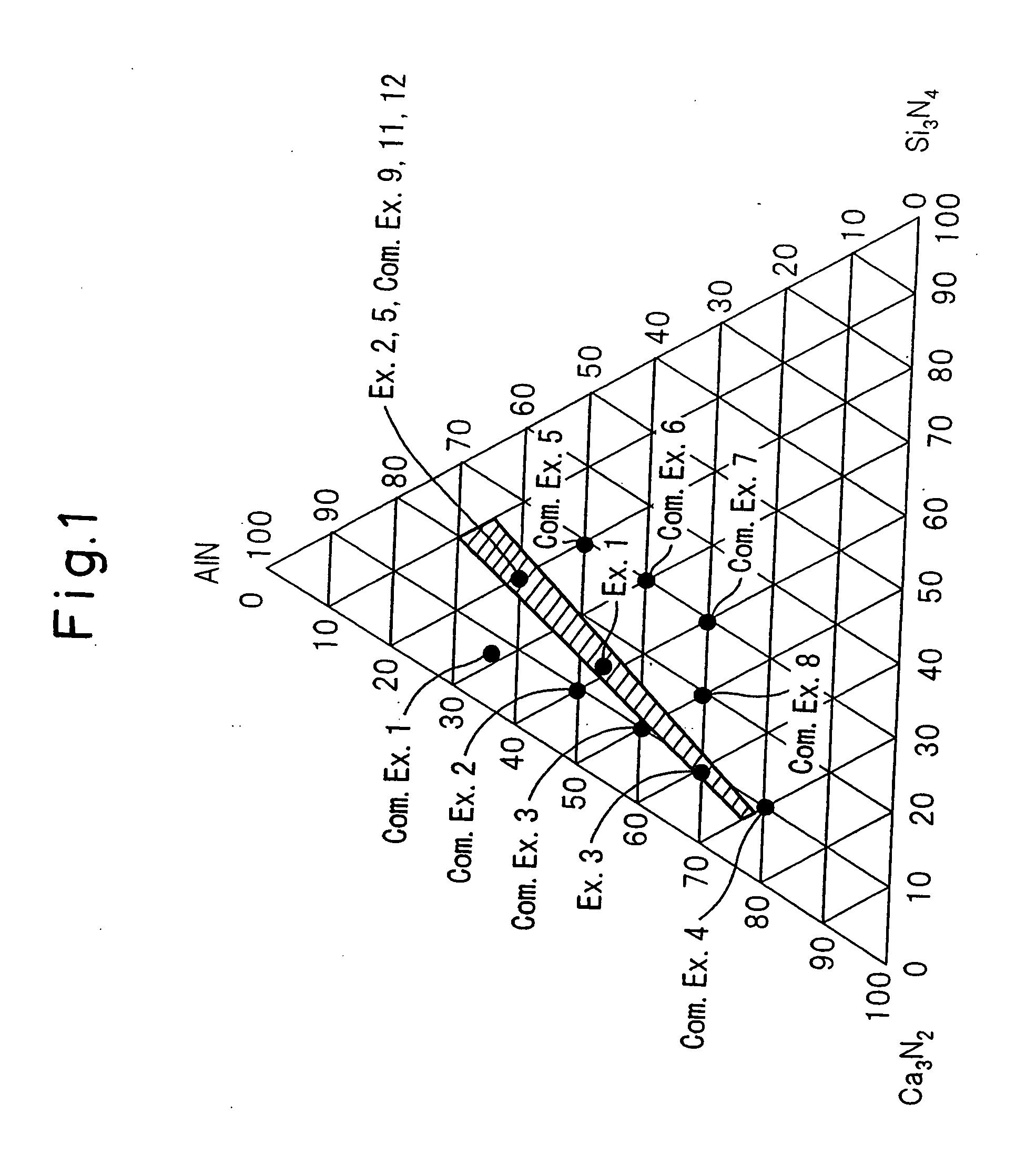

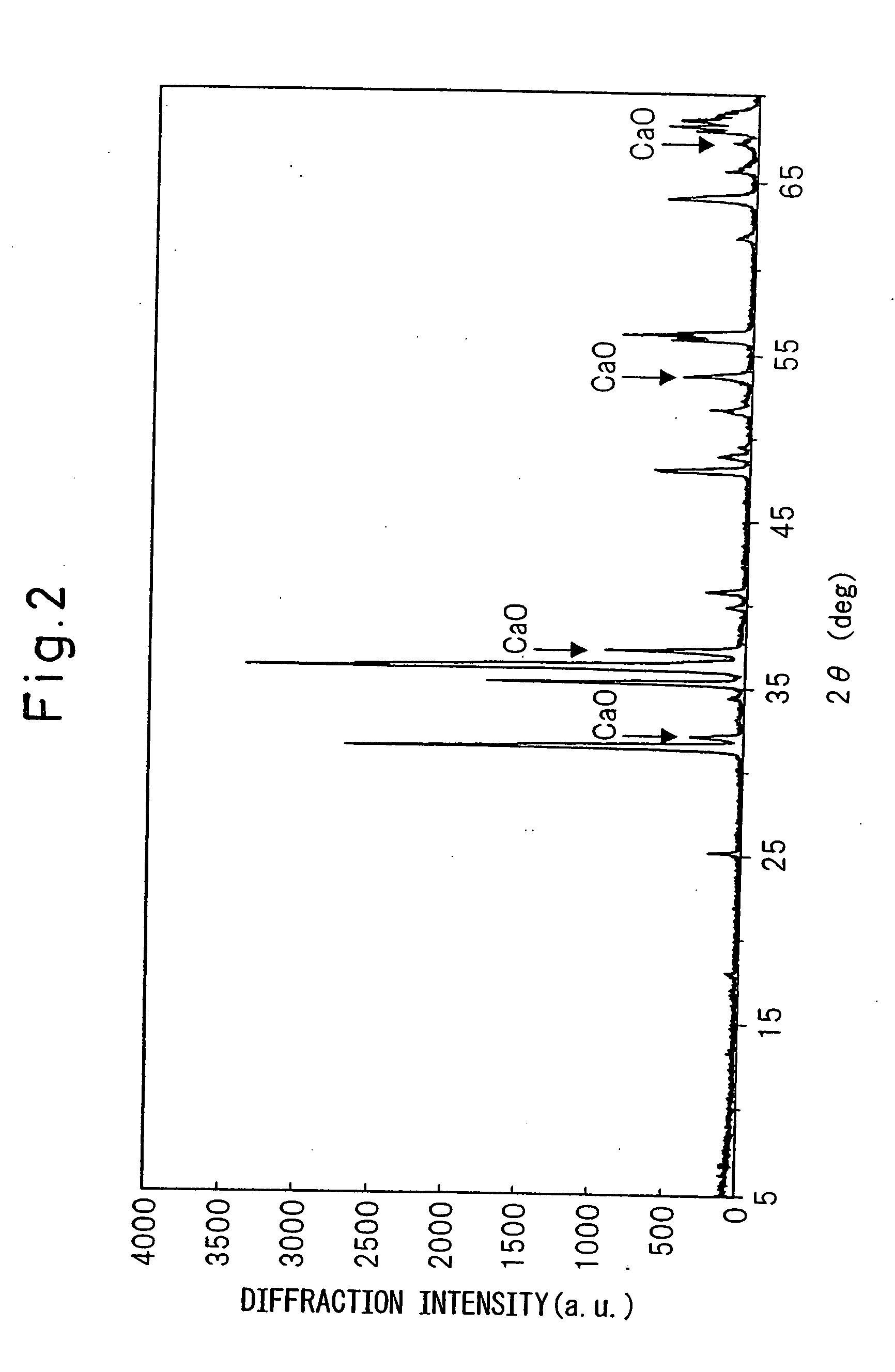

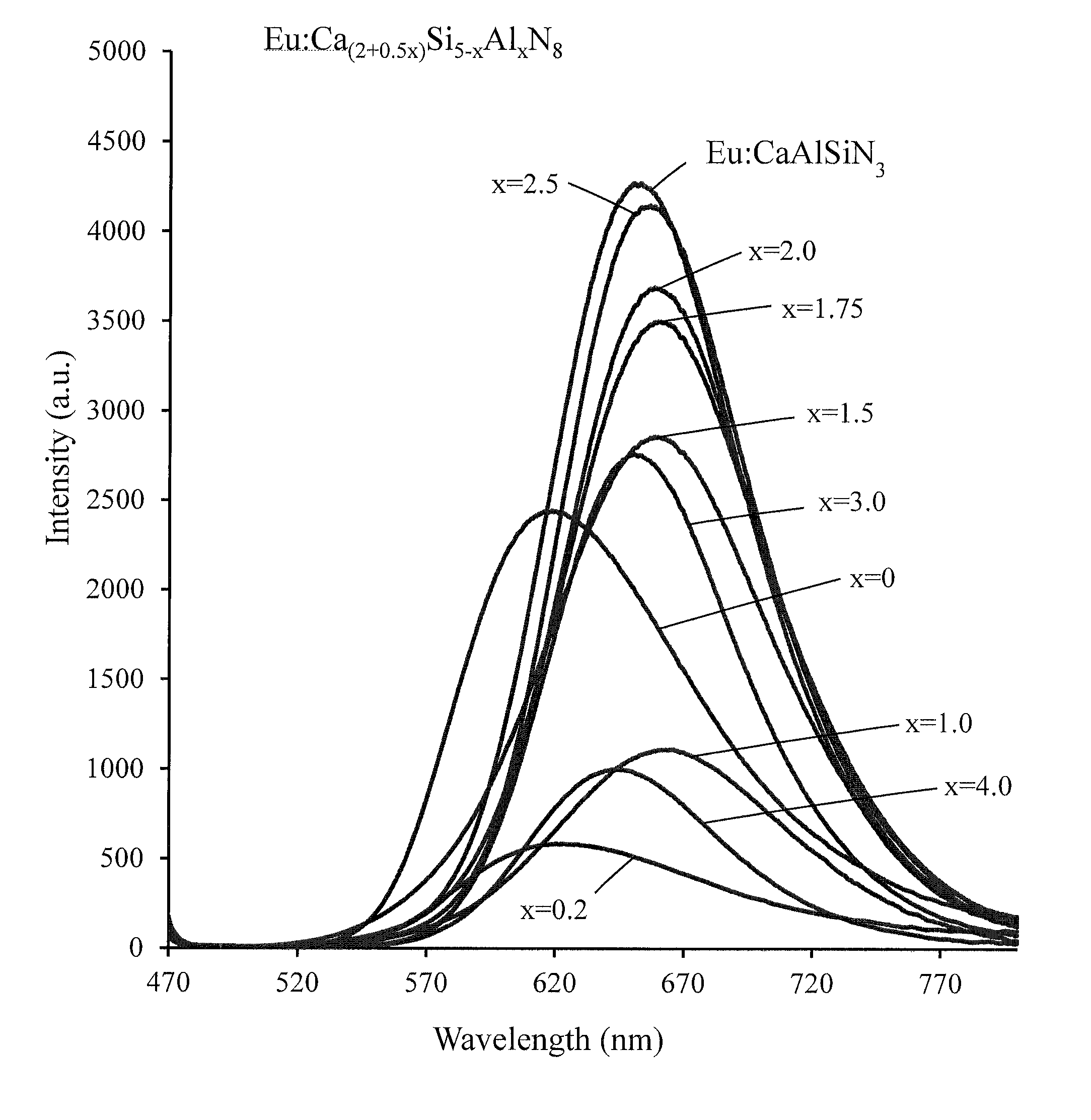

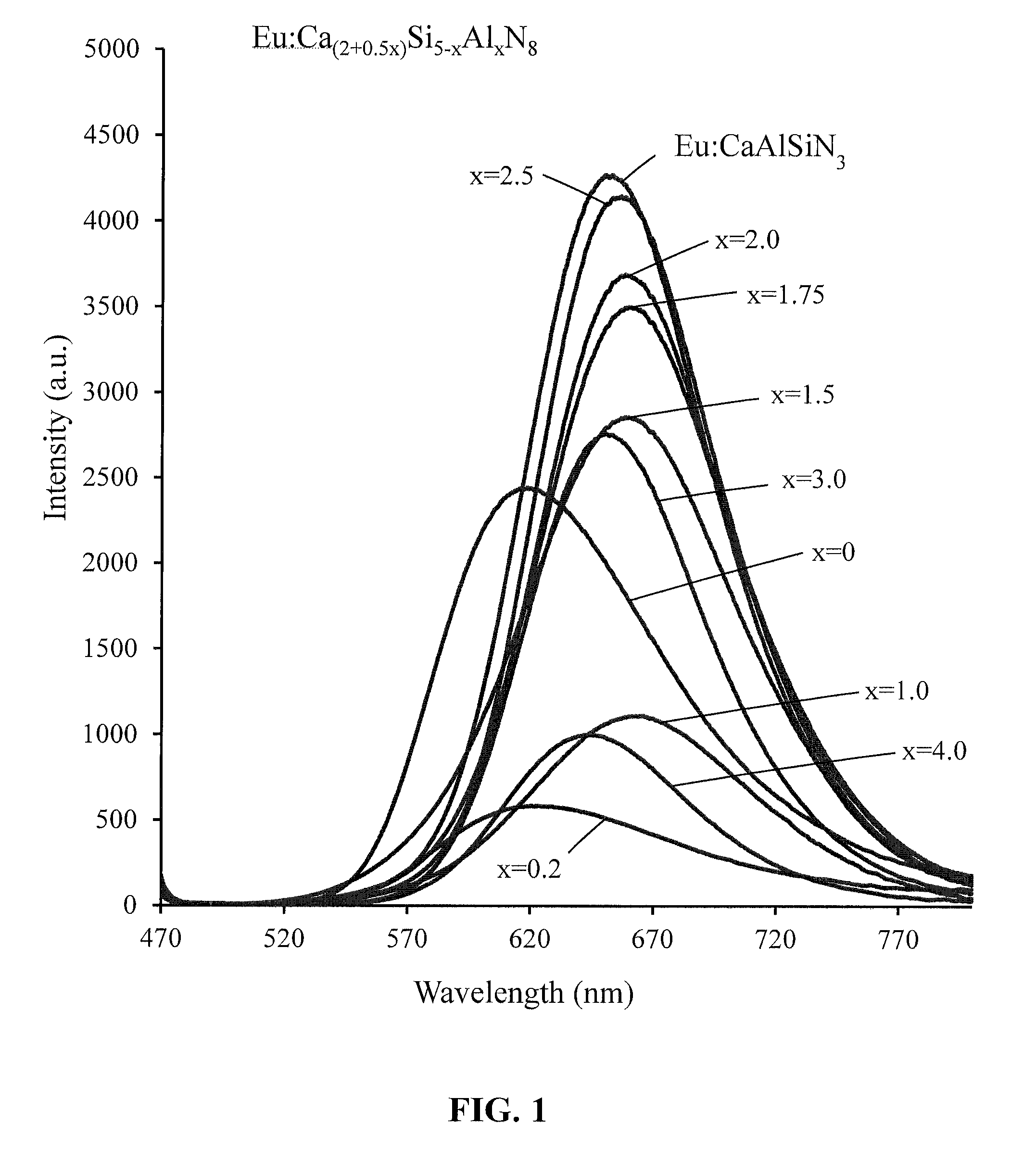

A red phosphor where the crystal phase constituting the phosphor is monoclinic Eu-activated CaAlSiN3. A red phosphor which is Eu-activated CaAlSiN3 powder having an average particle diameter of 10 μm or less as measured in the non-pulverized state by the laser scattering particle size distribution analysis. A light-emitting device comprising a blue light-emitting element, a yellow phosphor capable of converting the blue light emitted from the blue light-emitting element into yellow light, and the above-described red phosphor capable of converting the blue light emitted from the blue light-emitting element into red light. A method for producing Eu-activated CaAlSiN3, comprising firing a raw material powder comprising Ca3N2, AlN, Si3N4 and EuN at 1,400 to 2,000° C. in a nitrogen-containing atmosphere, the Ca3N2, AlN and Si3N4 giving a composition falling in the region surrounded by a straight line connecting the following four points A to D in the composition diagram of FIG. 1 and EuN being contained in an amount of 0.01 to 10 parts by weight as Eu per 100 parts by weight in total of Ca3N2, AlN and Si3N4.

Owner:UBE IND LTD

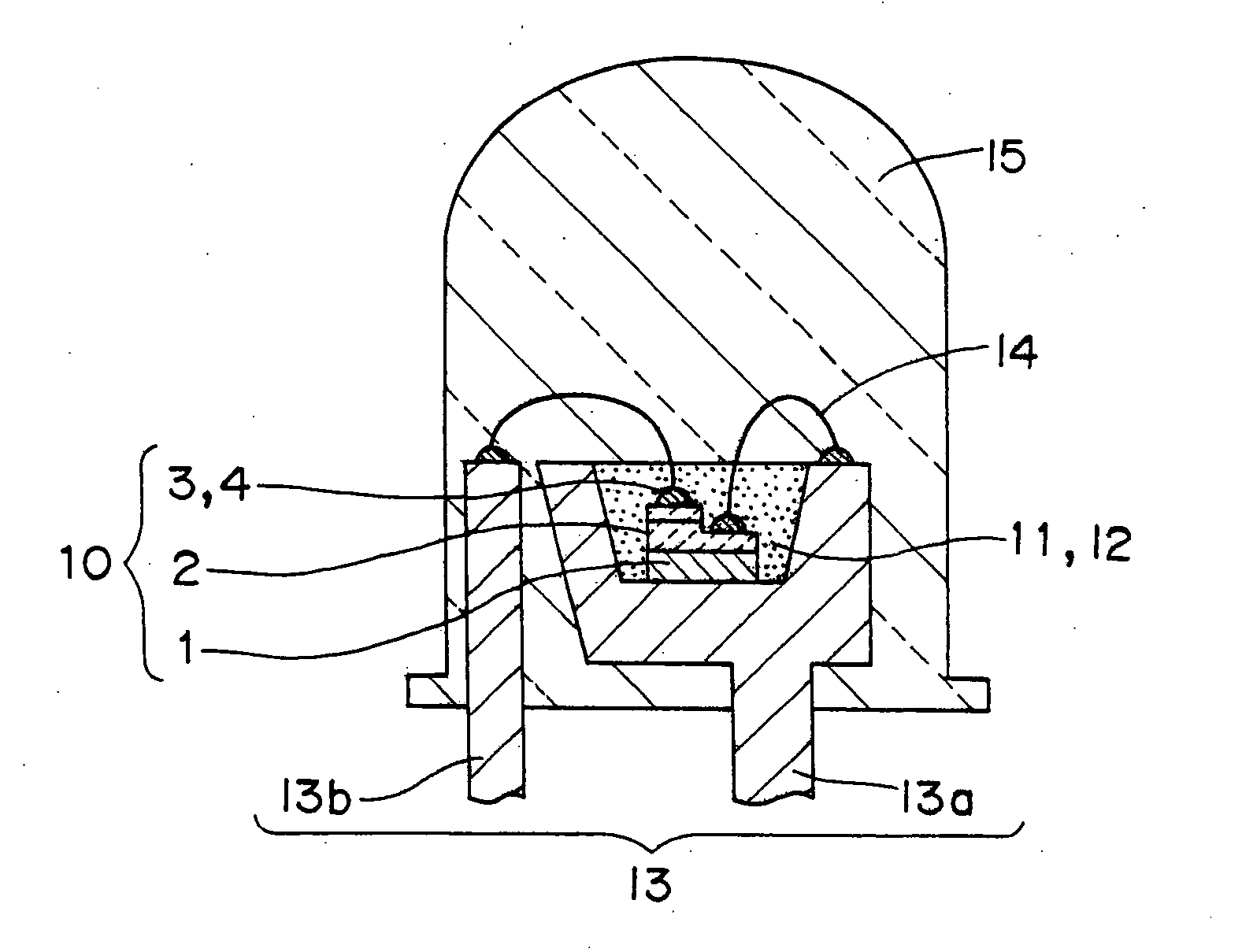

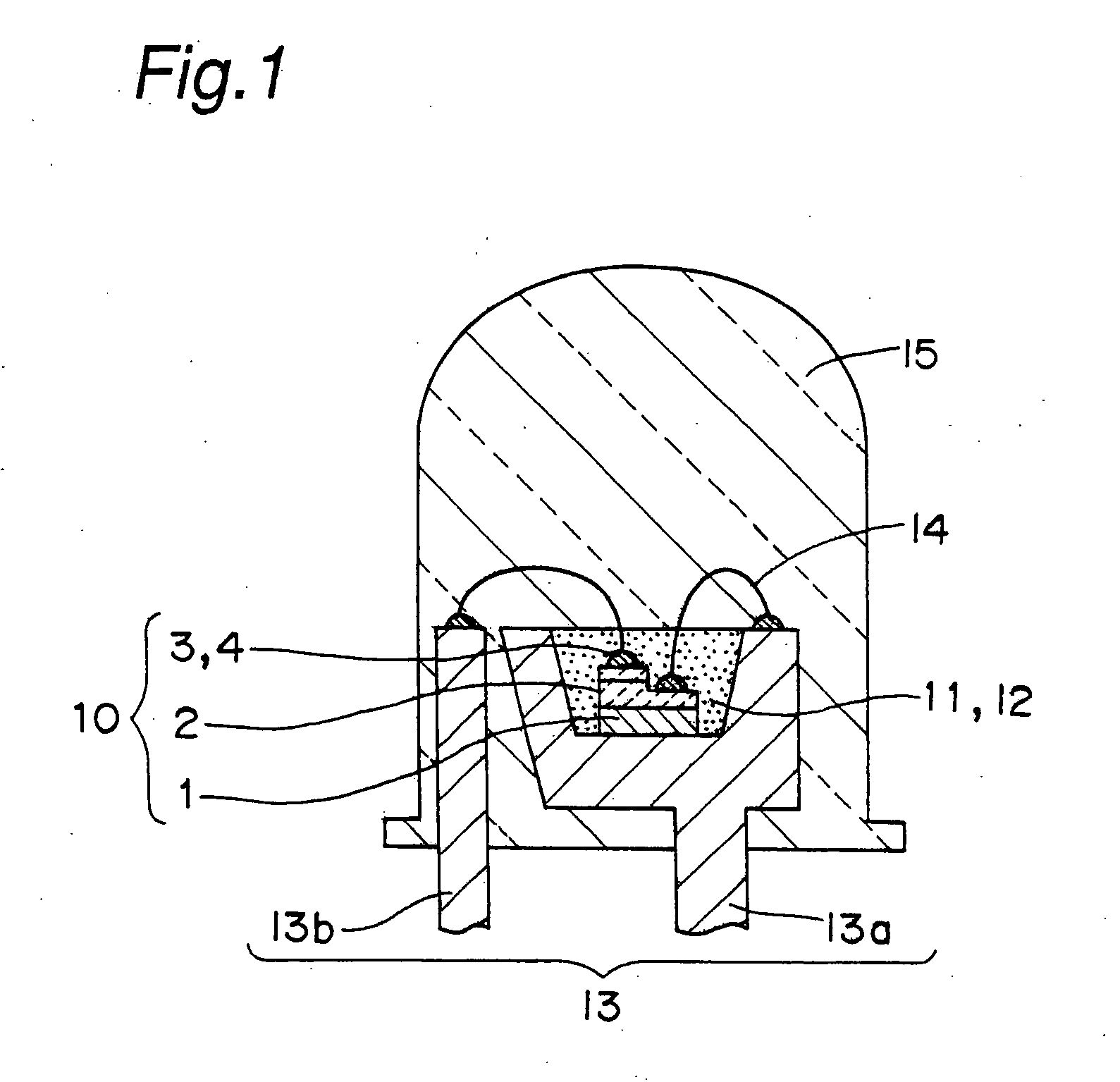

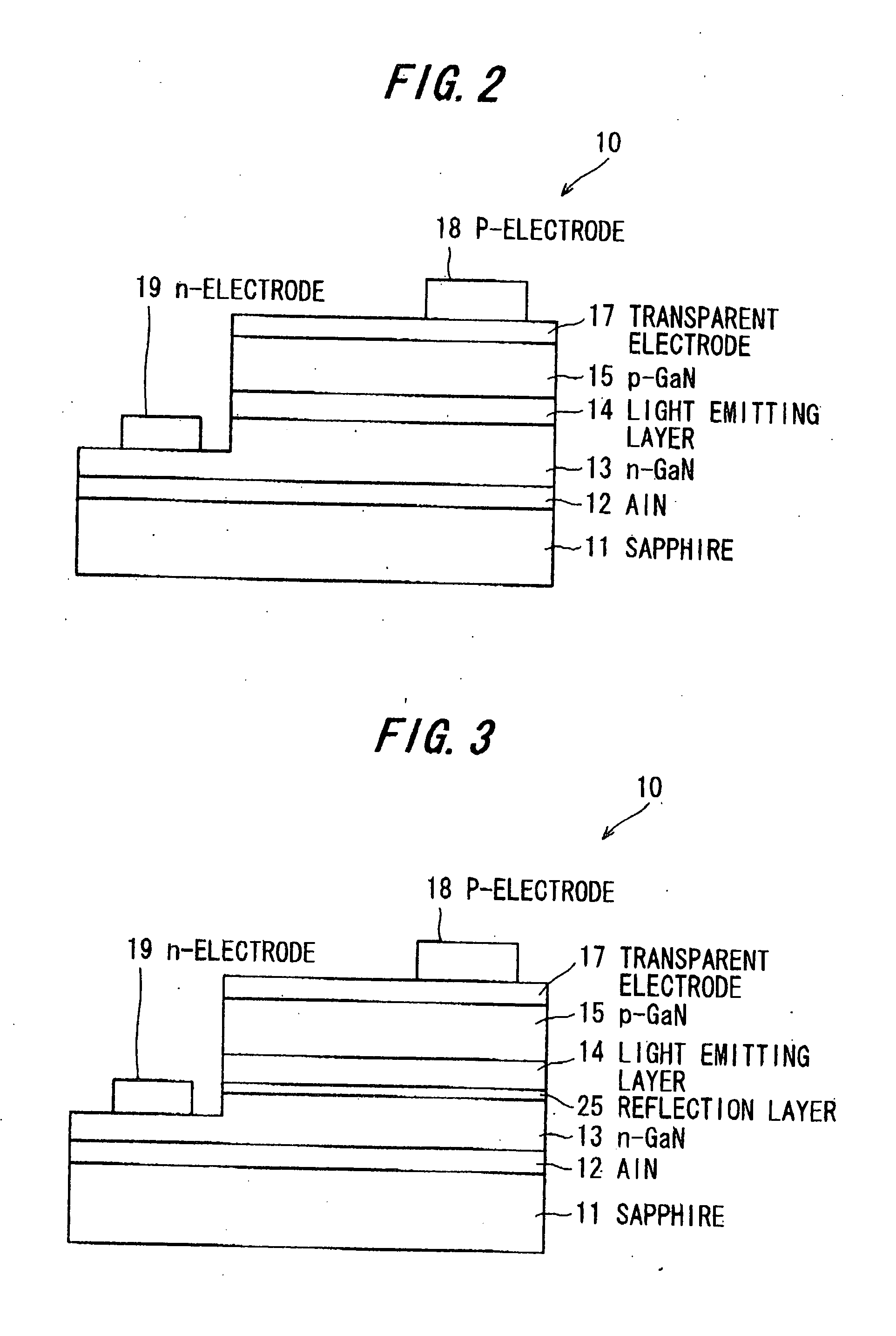

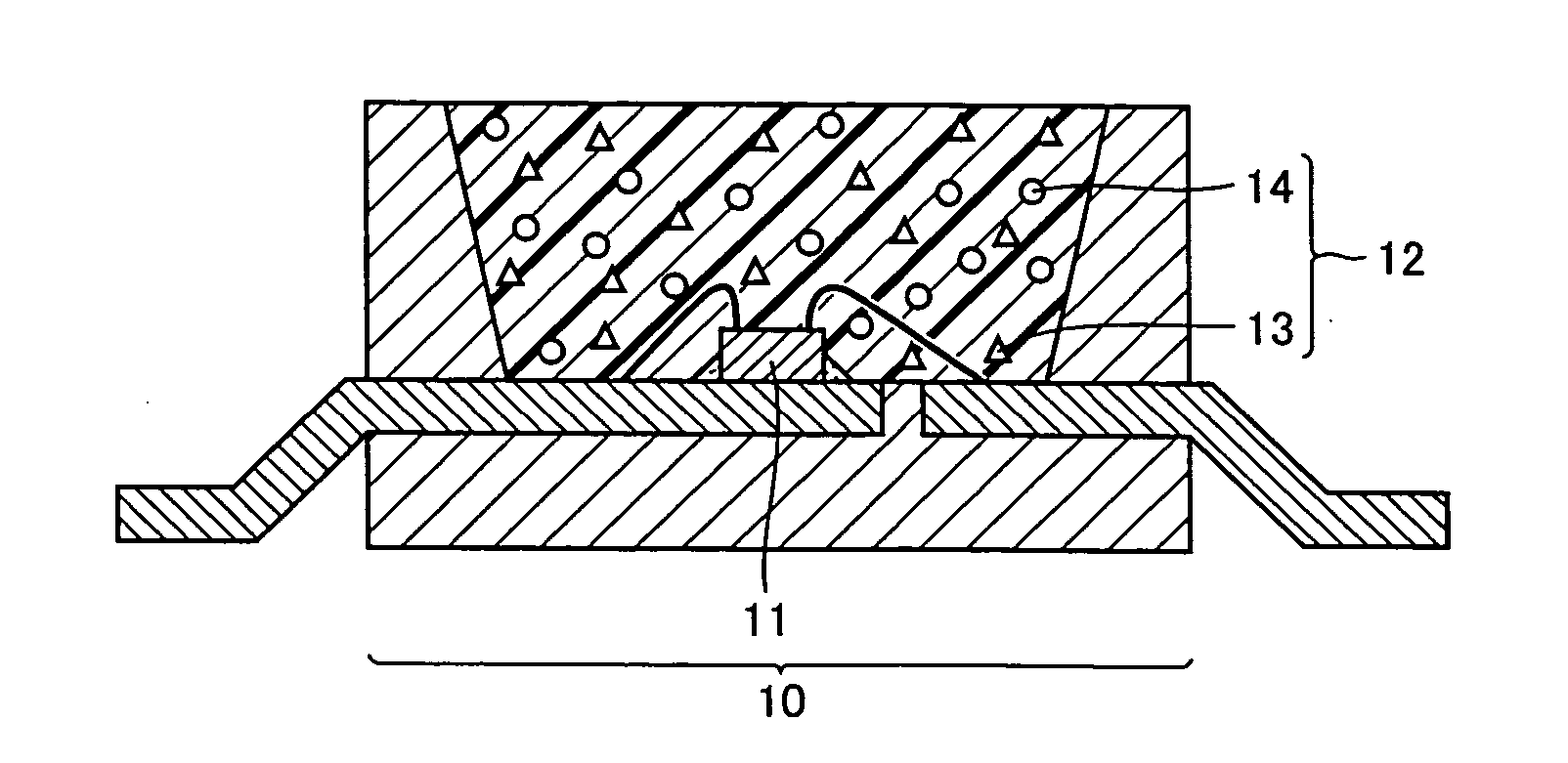

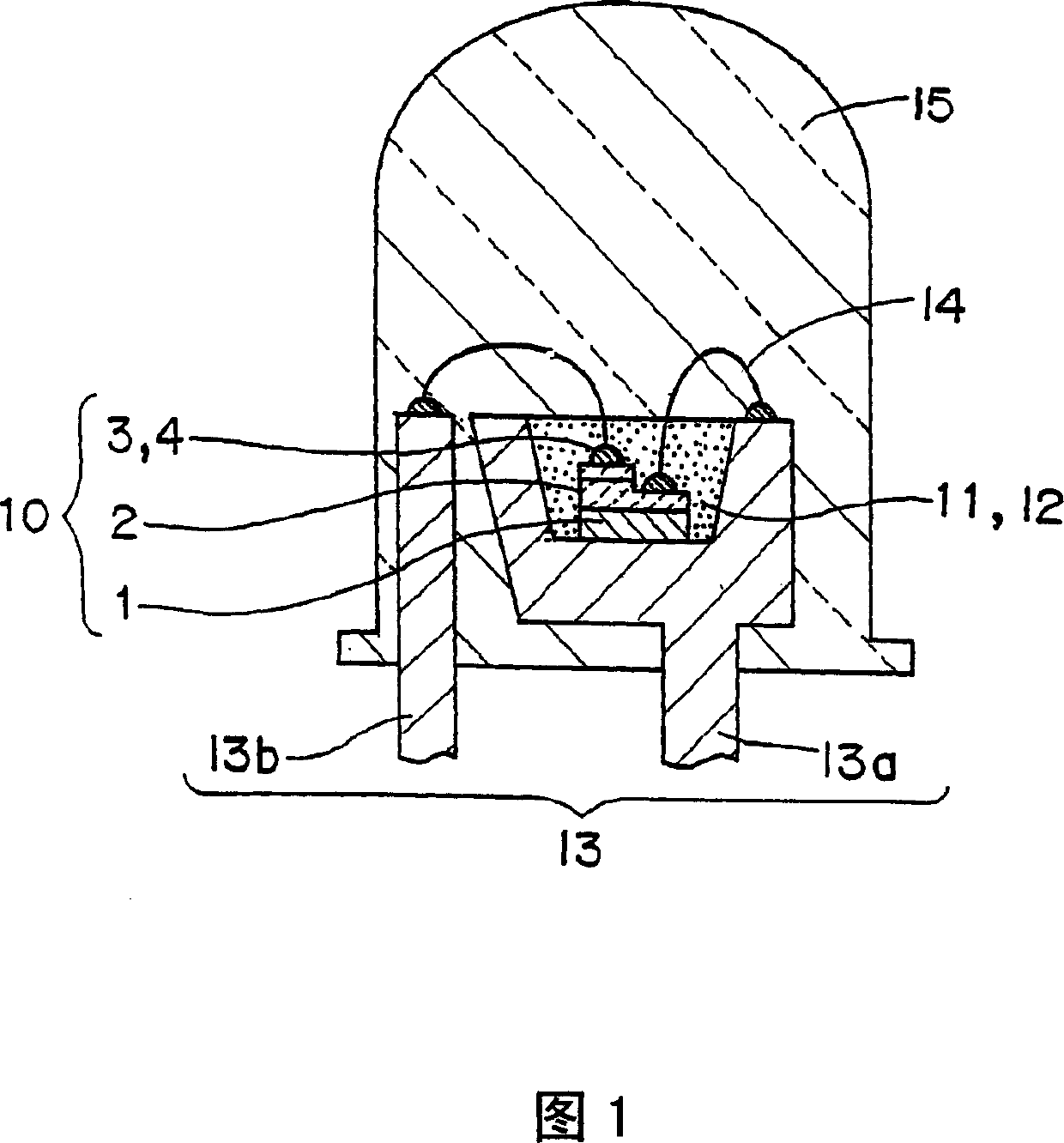

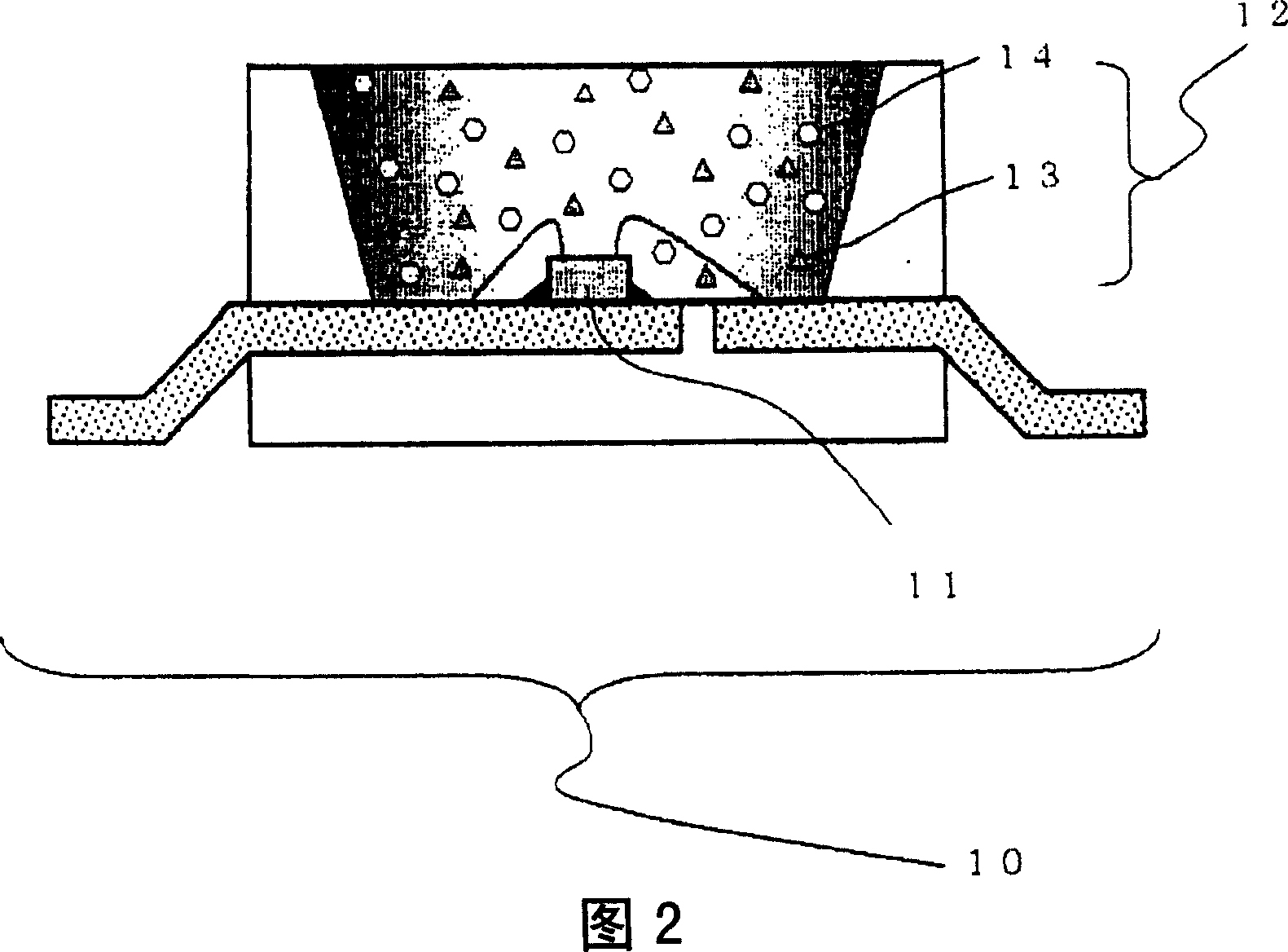

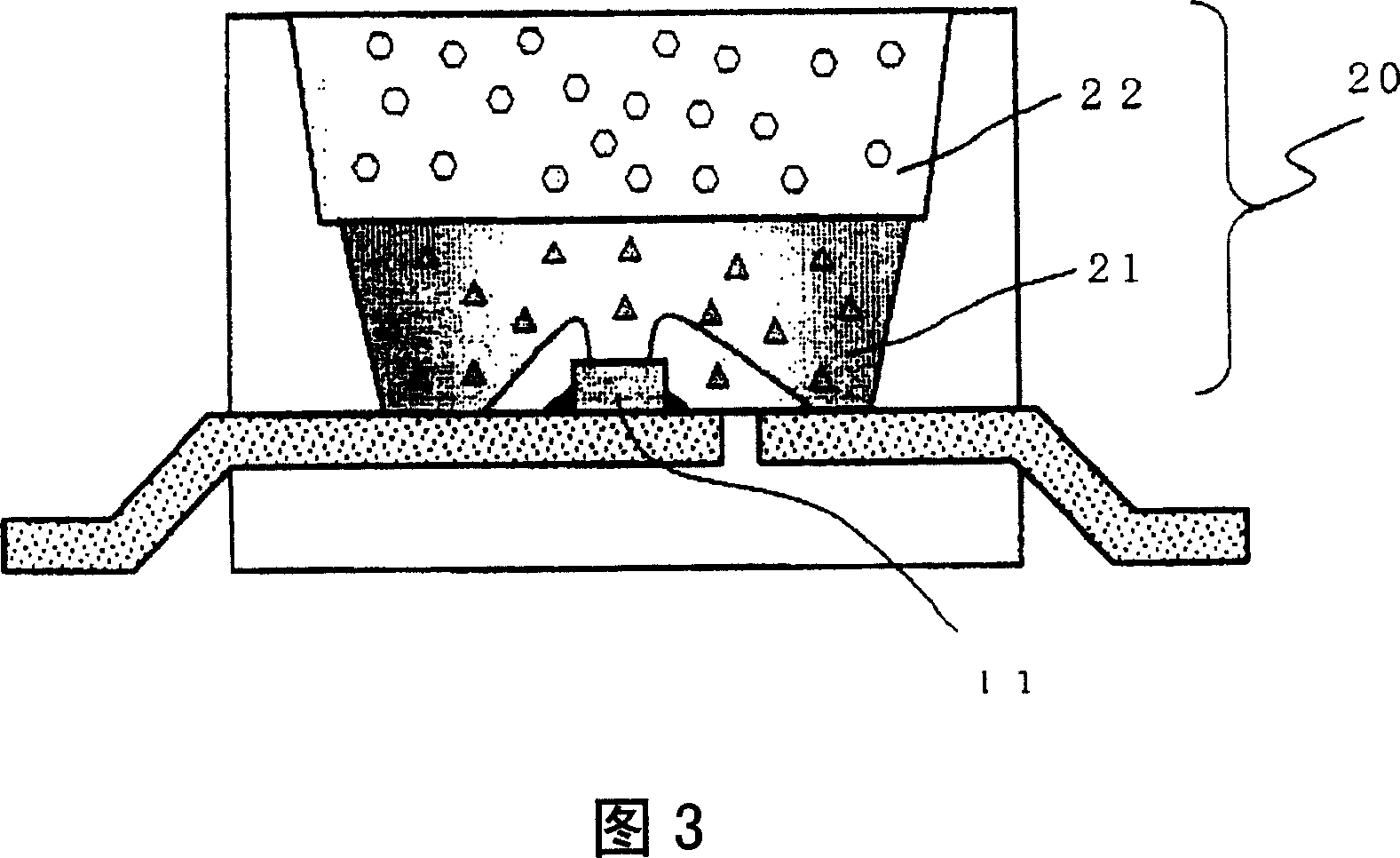

Nitride phosphor and method for preparation thereof, and light emitting device

InactiveUS7258816B2High luminous efficiencyDifficult to generateDischarge tube luminescnet screensNitrogen compoundsRare-earth elementNitride phosphor

Owner:NICHIA CORP

Charge compensated nitride phosphors for use in lighting applications

ActiveUS7262439B2Solid-state devicesNatural mineral layered productsPhosphoric acidPhysical chemistry

Disclosed are phosphor compositions having the formulas Ca1−a−bCeaEubAl1+aSi1−aN3, where 0<a≦0.2, 0≦b≦0.2; Ca1−c−dCecEudAl1−c(Mg,Zn)cSiN3, where 0<c≦0.2, 0≦d≦0.2; Ca1−2e−fCee(Li,Na)eEufAlSiN3, where 0≦e≦0.2, 0≦f≦0.2, g+h>0; and Ca1−g−h−iCeg(Li,Na)hEuiAl1+g−hSi1−g+hN3 where 0≦g≦0.2, 0<h≦0.4, 0≦i≦0.2,g+i>0. When combined with radiation from a blue or UV light source, these phosphors can provide light sources with good color quality having high CRI over a large color temperature range. Also disclosed are blends of the above phosphors and additional phosphors.

Owner:GE LIGHTING SOLUTIONS LLC

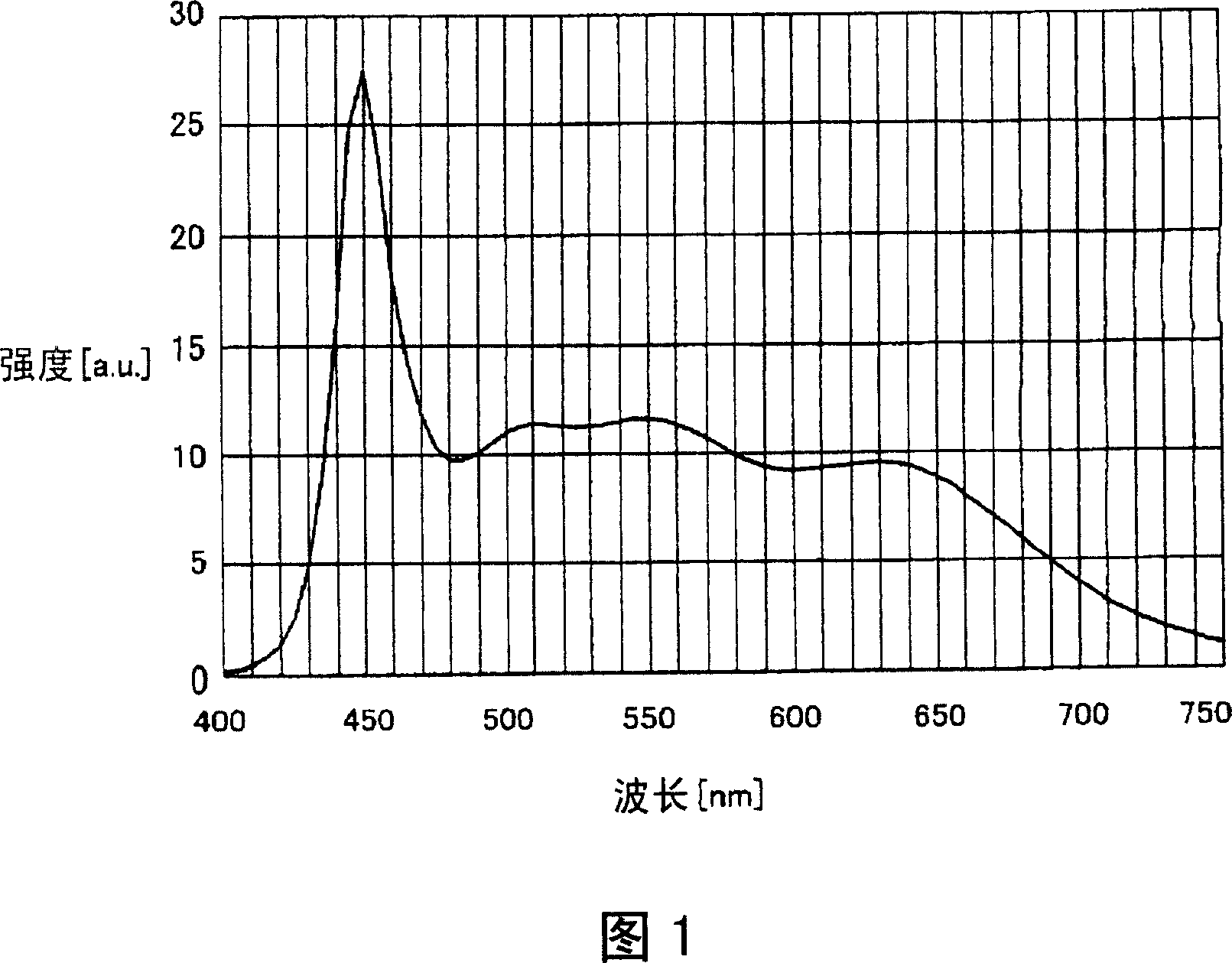

Nitride phosphor and production process thereof, and light emitting device

InactiveUS20060038477A1High luminous brightnessImprove luminous performanceDischarge tube luminescnet screensNitrogen compoundsRare-earth elementNitride phosphor

To provide a phosphor containing a comparatively much red component and having high light emitting efficiency, high brightness and further high durability, the nitride phosphor is represented by the general formula LXMYN((2 / 3)X+(4 / 3)Y):R or LXMYOZN((2 / 3)X+(4 / 3)Y−(2 / 3)Z):R (wherein L is at least one or more selected from the Group II Elements consisting of Mg, Ca, Sr, Ba and Zn, M is at least one or more selected from the Group IV Elements in which Si is essential among C, Si and Ge, and R is at least one or more selected from the rare earth elements in which Eu is essential among Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er and Lu.); contains the another elements.

Owner:NICHIA CORP

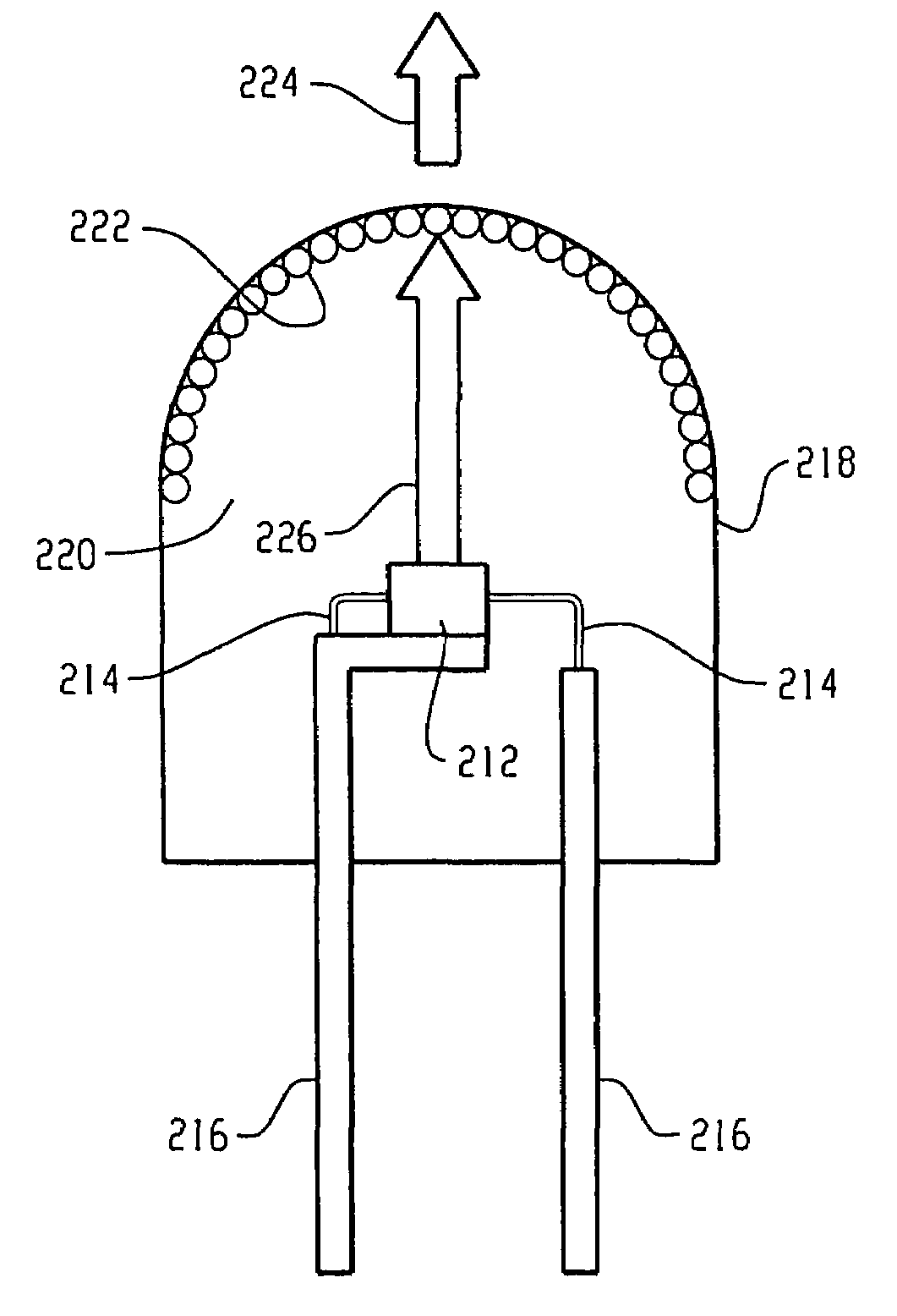

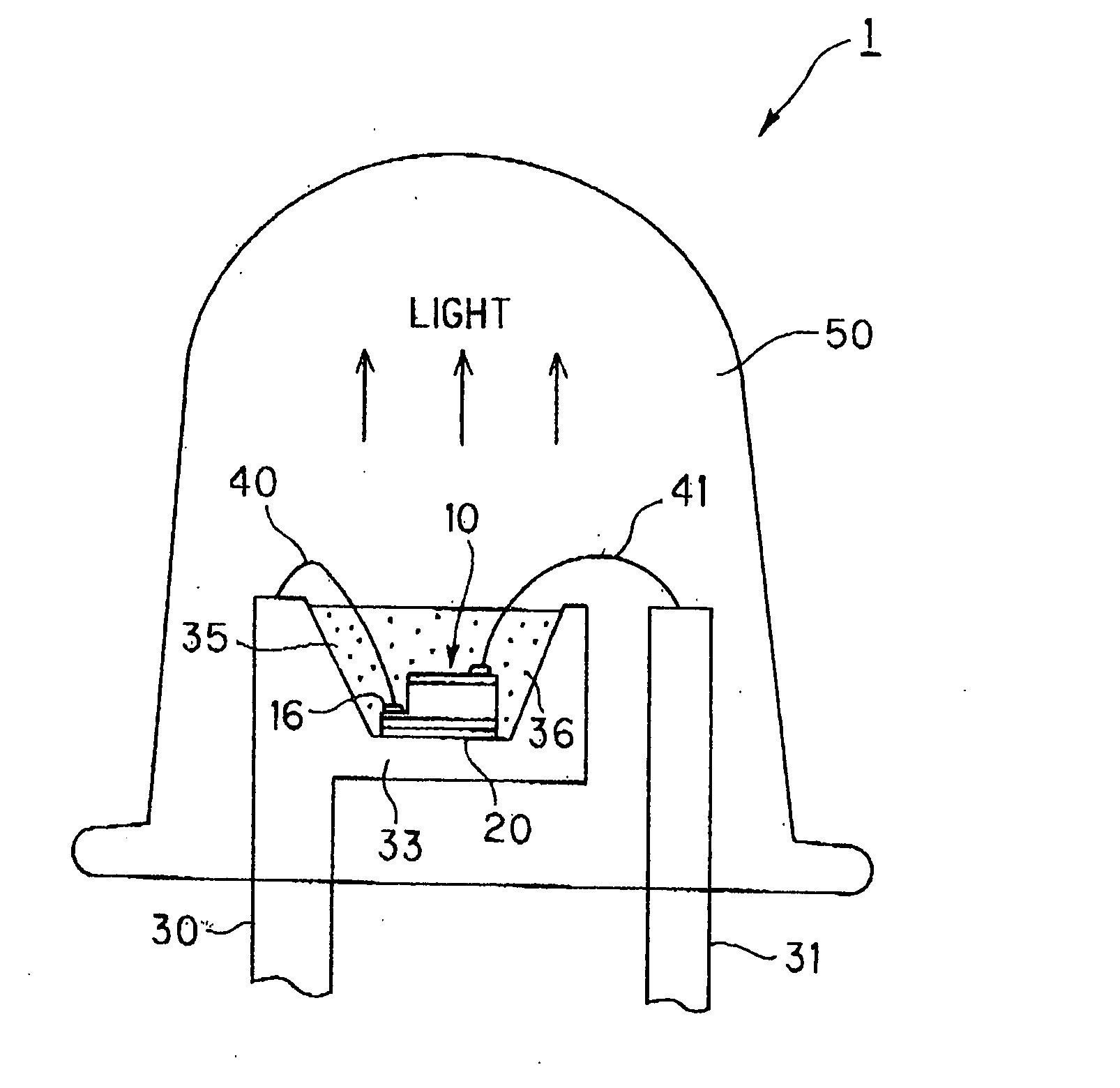

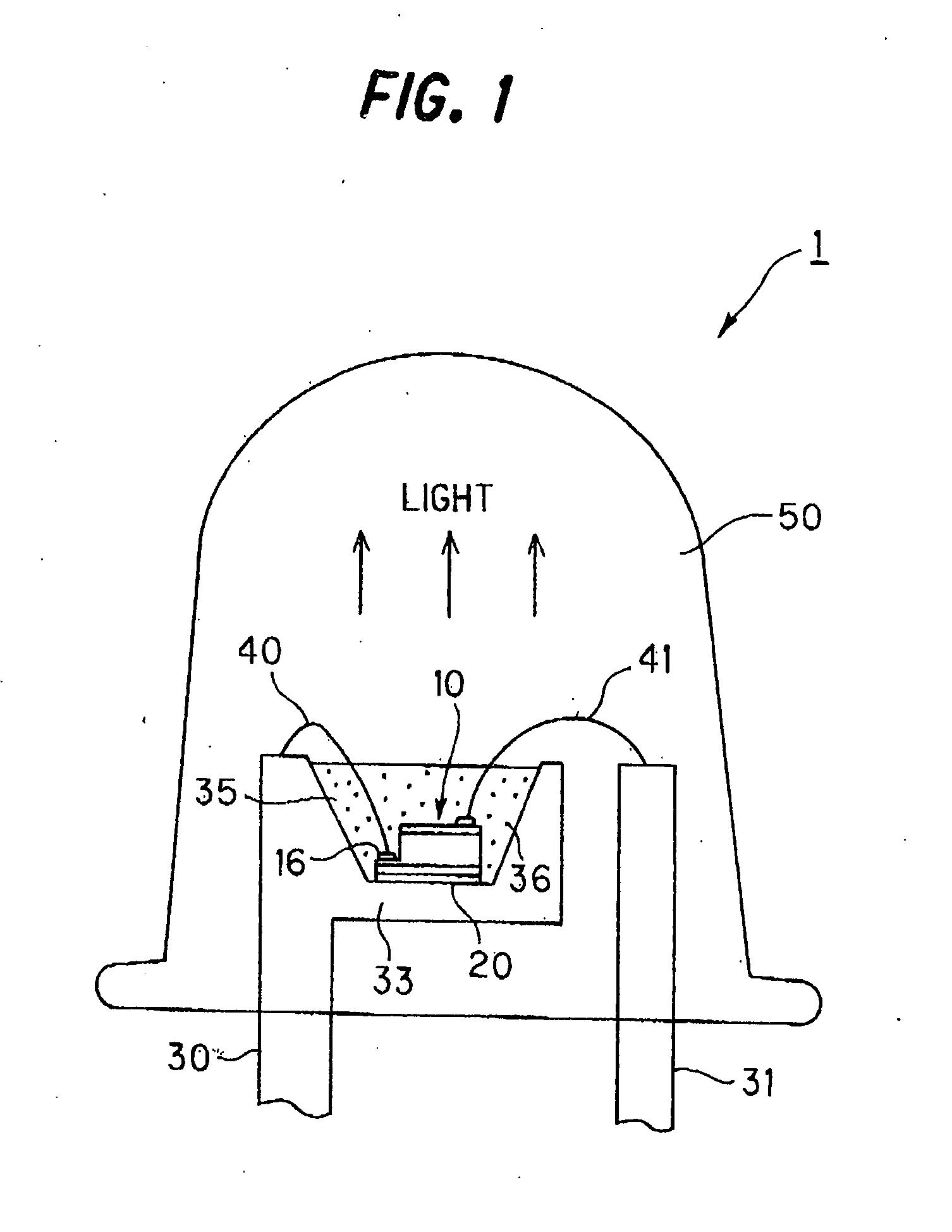

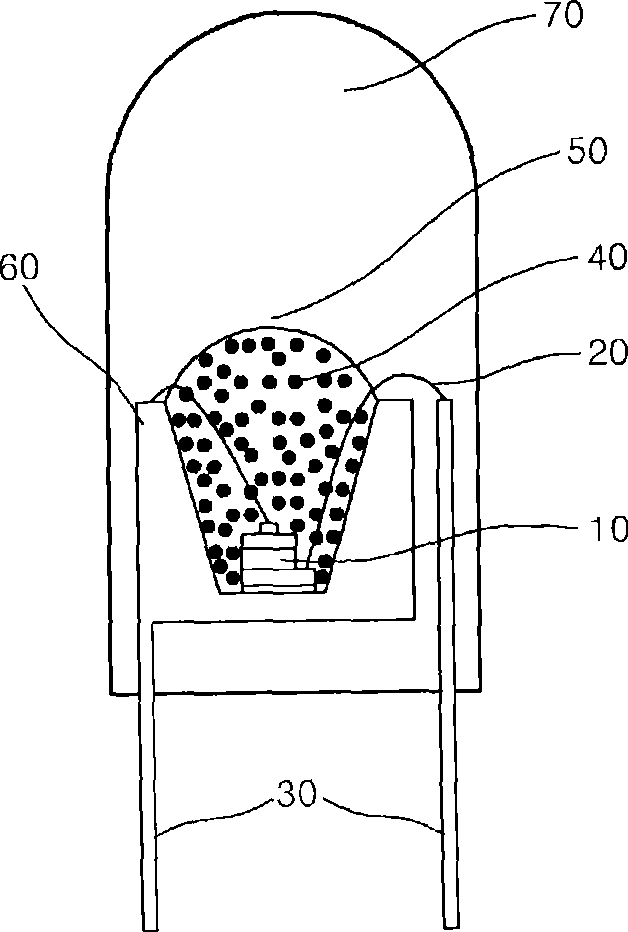

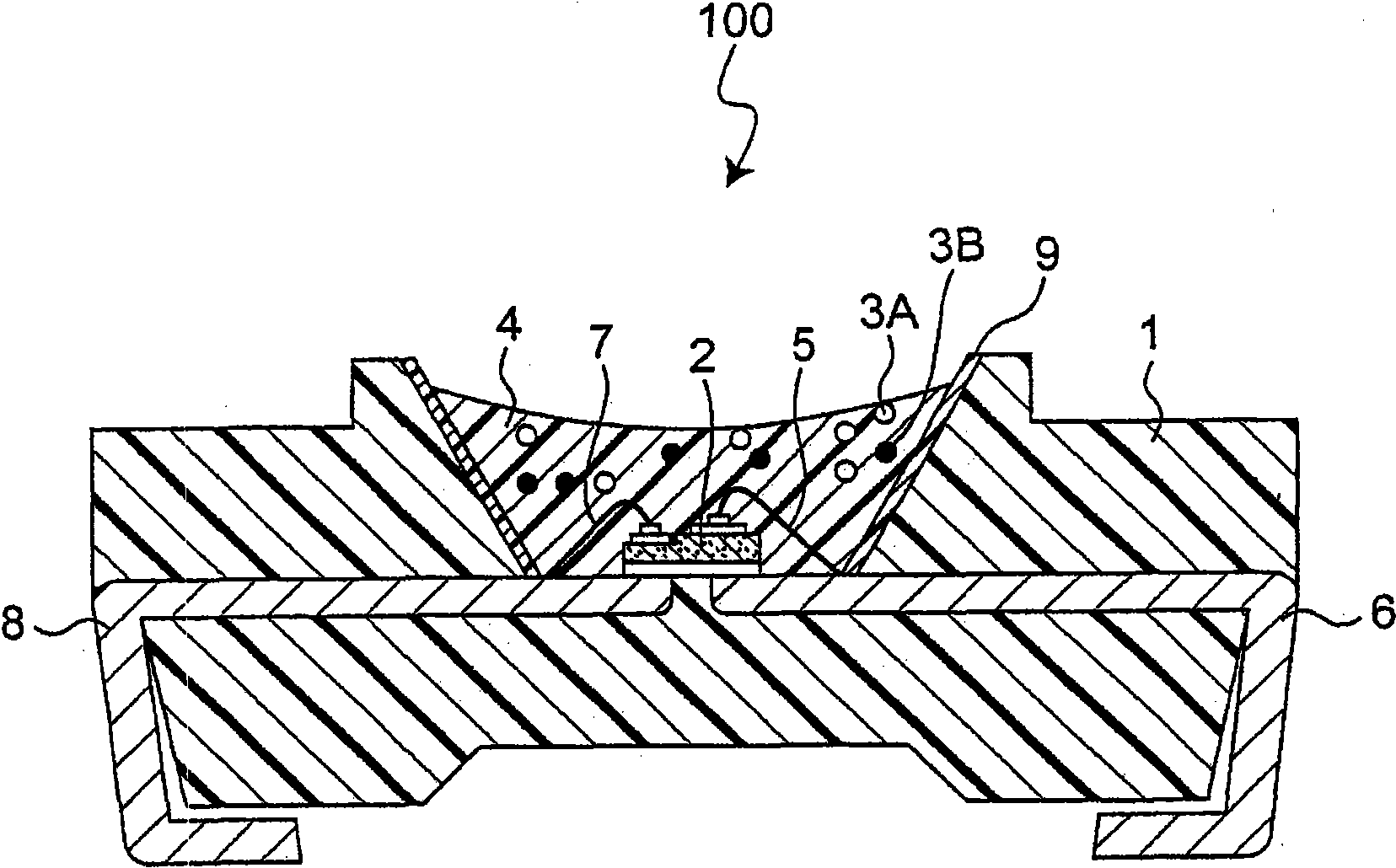

Light emitting apparatus and light emitting method

ActiveUS20070164308A1Improve propertiesIncrease brightnessDischarge tube luminescnet screensLamp detailsFluorescenceDoped oxide

A light emitting apparatus has a light emitting element with an emission wavelength in the range of 360 to 550 nm and a rare-earth element doped oxide nitride phosphor or cerium ion doped lanthanum silicon nitride phosphor. Part of light radiated from the light emitting element is wavelength-converted by the phosphor. The light emitting apparatus radiates white light generated by a mixture of the wavelength-converted light and the other part of light radiated from the light emitting element.

Owner:TOYODA GOSEI CO LTD

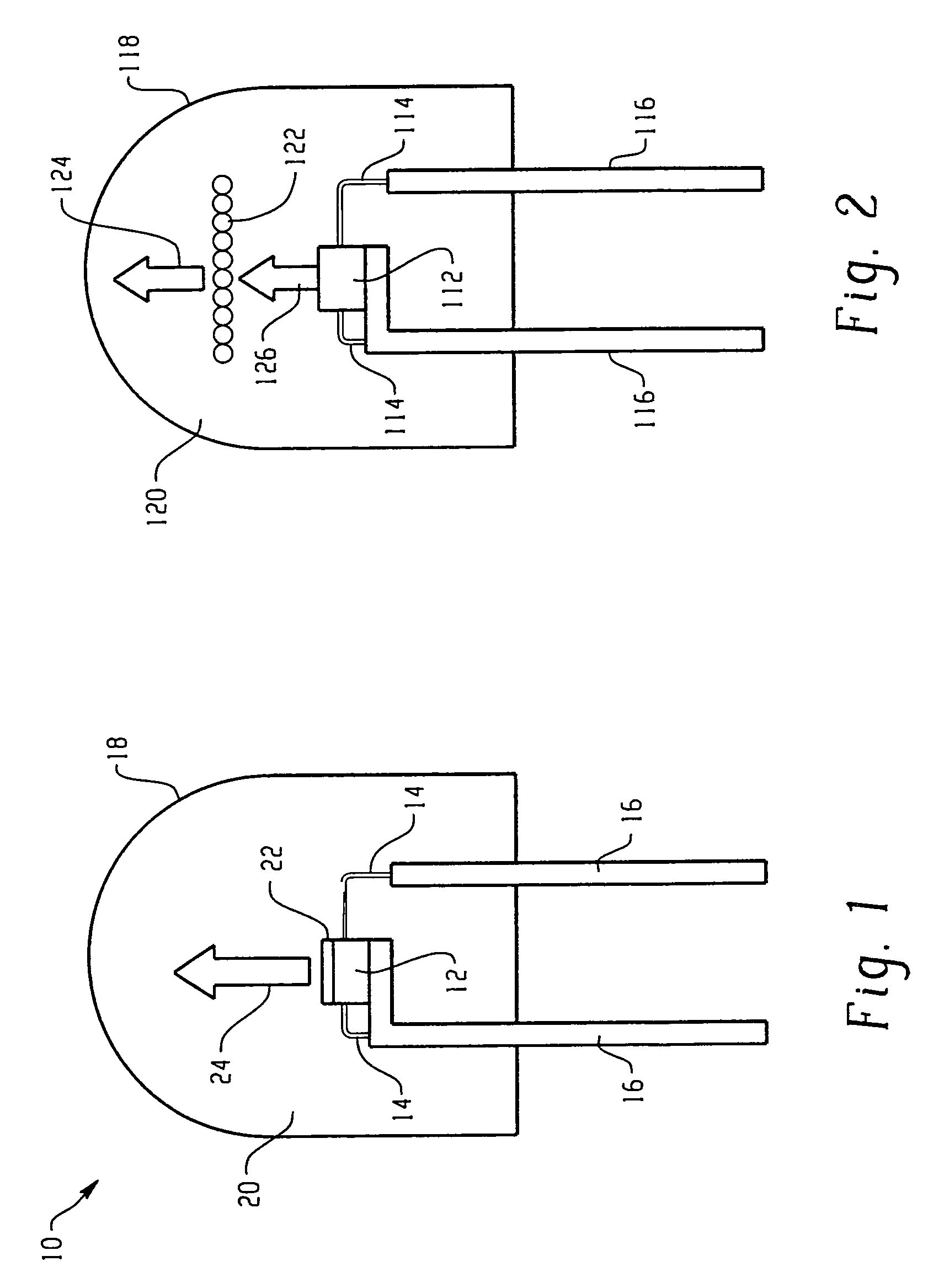

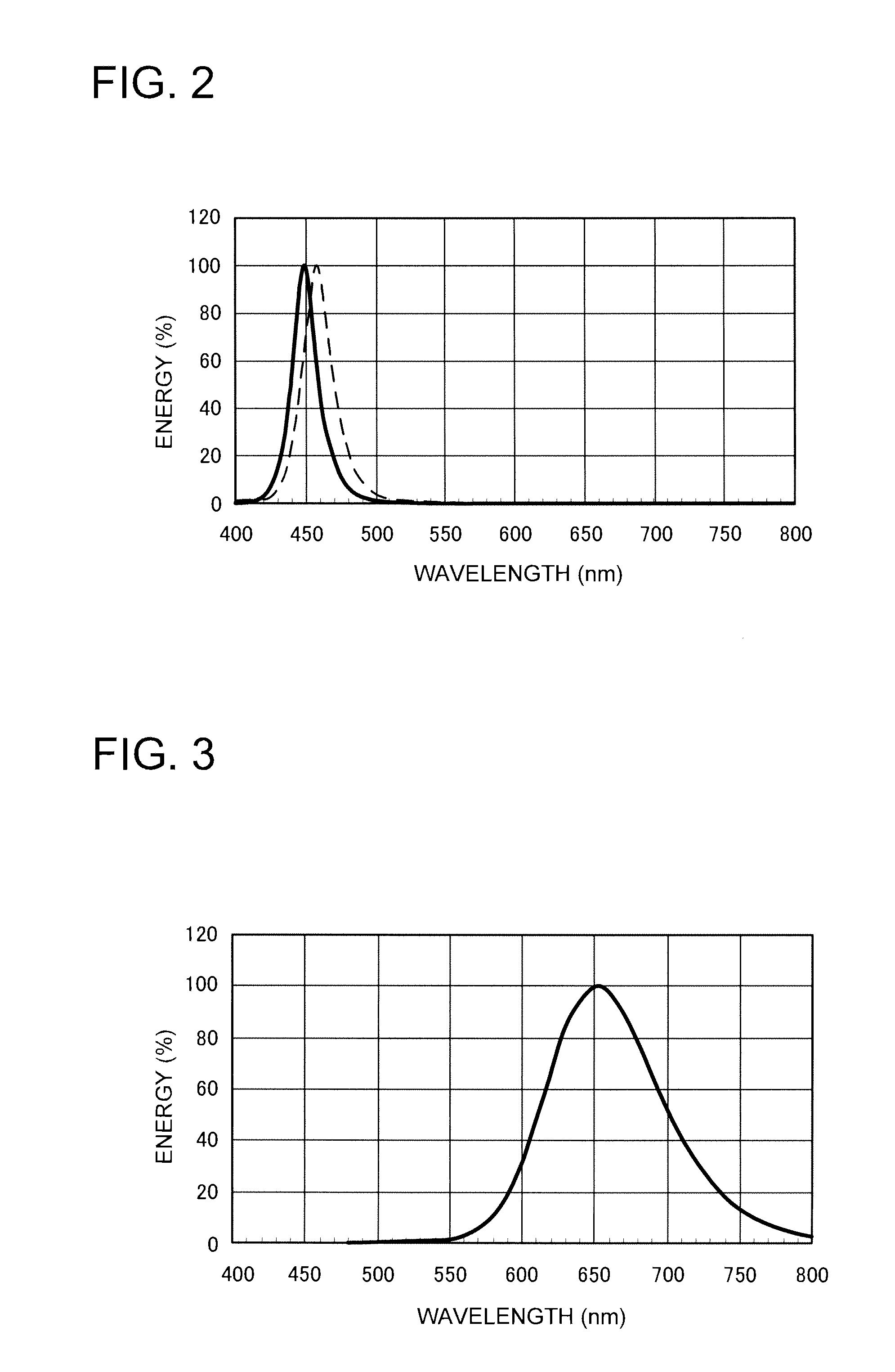

Light-emitting device

InactiveUS20070052342A1Improve efficiencyGood colorDischarge tube luminescnet screensElectroluminescent light sourcesCeriumLength wave

A light-emitting device includes a light-emitting element emitting primary light and a wavelength conversion portion absorbing a part of the primary light and emitting secondary light having a wavelength equal to or longer than the wavelength of the primary light. The wavelength conversion portion includes a plurality of green or yellow light-emitting phosphors and a plurality of red light-emitting phosphors. The green or yellow light-emitting phosphor is implemented by at least one selected from a specific europium (II)-activated silicate phosphor (A-1) and a specific cerium (III)-activated silicate phosphor (A-2). The red light-emitting phosphor is implemented by a specific europium (II)-activated nitride phosphor (B). The light-emitting device emitting white light at efficiency and color rendering property higher than in a conventional example can thus be provided.

Owner:SHARP KK

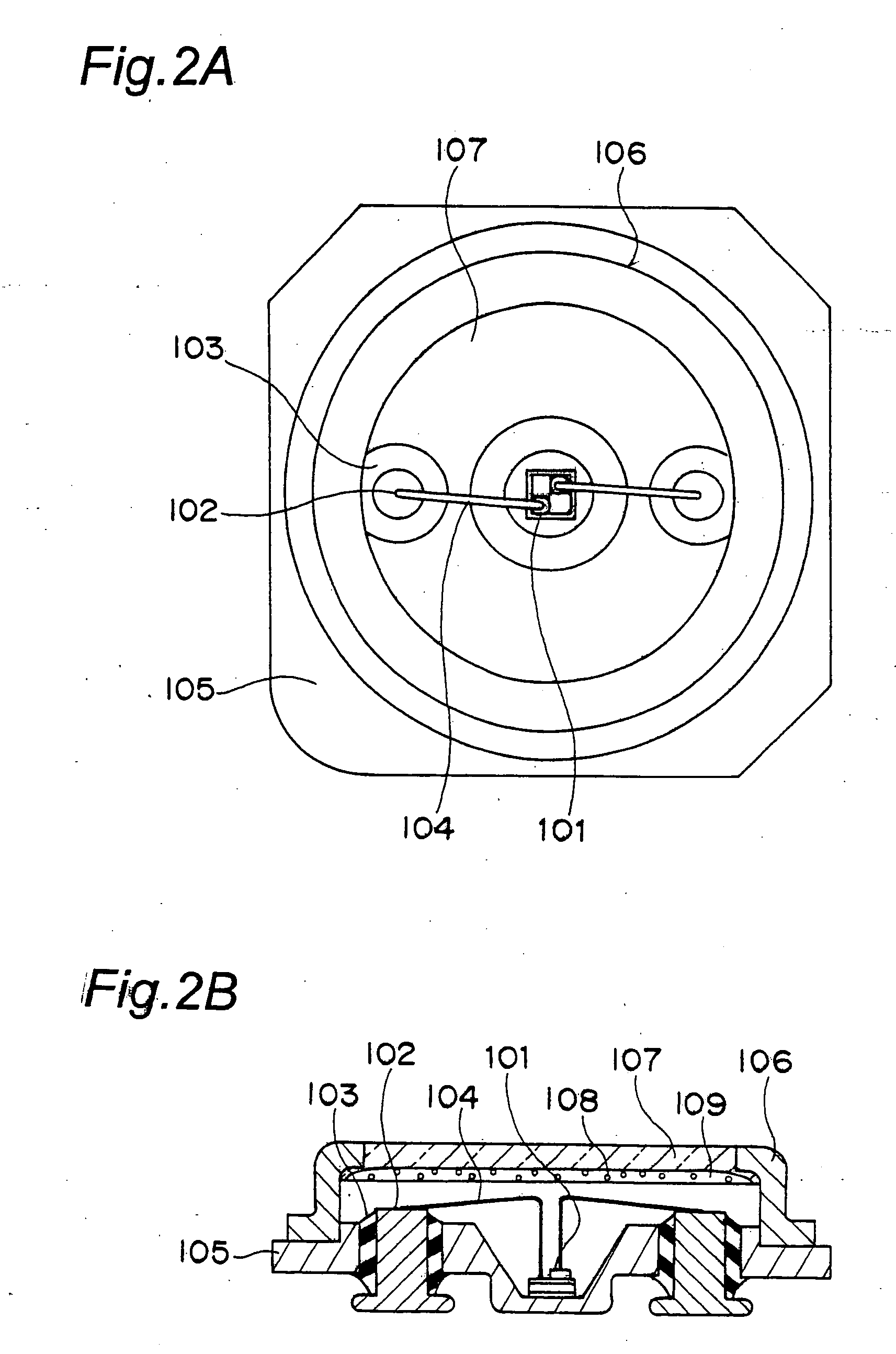

Phosphor, method of producing the same, and light emitting apparatus

ActiveUS20080258602A1Improve efficiencyStable characteristicsMaterial nanotechnologyDischarge tube luminescnet screensLength waveNitride phosphor

There are provided a phosphor which is a divalent europium-activated oxynitride phosphor substantially represented by General formula (A): EuaSibAlcOdNe, a divalent europium-activated oxynitride phosphor substantially represented by General formula (B): MIfEugSihAlkOmNn or a divalent europium-activated nitride phosphor substantially represented by General formula (C): (MIIl-pEup)MIIISiN3, having a reflectance of light emission in a longer wavelength region of visible light than a peak wavelength of 95% or larger, and a method of producing such phosphor; a nitride phosphor and an oxynitride phosphor which emit light efficiently and stably by the light having a wavelength ranging from 430 to 480 nm from a semiconductor light emitting device by means of a light emitting apparatus using such phosphor, and a producing method of such phosphor; and a light emitting apparatus having stable characteristics and realizing high efficiency.

Owner:DENKA CO LTD +1

Nitride phosphor and production process thereof, and light emitting device

InactiveUS7297293B2High luminous efficiencyDifficult to generateDischarge tube luminescnet screensNitrogen compoundsRare-earth elementNitride phosphor

To provide a phosphor containing a comparatively much red component and having high light emitting efficiency, high brightness and further high durability, the nitride phosphor is represented by the general formula LXMYN((2 / 3)X+(4 / 3)Y):R or LXMYOZN((2 / 3)X+(4 / 3)Y−(2 / 3)Z):R (wherein L is at least one or more selected from the Group II Elements consisting of Mg, Ca, Sr, Ba and Zn, M is at least one or more selected from the Group IV Elements in which Si is essential among C, Si and Ge, and R is at least one or more selected from the rare earth elements in which Eu is essential among Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er and Lu.); contains the another elements.

Owner:NICHIA CORP

Light emitting apparatus

ActiveUS20110031874A1Spread evenlyReduce uneven distributionDischarge tube luminescnet screensLamp detailsNitride phosphorMaterials science

A red nitride phosphor of formula (I) or (II), and two green phosphors of formulas (III) and / or (IV) are included.MwAlxSiyBzN((2 / 3)w+x+(4 / 3)y+z):Eu2+ (I)M is any of Mg, Ca, Sr and Ba, and 0.5≦w≦3, x=1, 0.5≦y≦3 and 0≦z≦0.5,MpSiqN((2 / 3)p+(4 / 3)q):EU2+ (II)1.5≦p≦2.5 and 4.5≦q≦5.5,MxMgSizOaXb:Eu2+ (III)M is any of Ca, Sr, Ba, Zn and Mn, X is any of F, Cl, Br and I, and 6.5≦x≦8.0, 3.7≦z≦4.3, a=x+1+2z−b / 2 and 1.0≦b≦1.9,SicAldOfNg:Eu2+ (IV)c+d=6, 5.0≦c<6, 0<d≦1.0, 0.001<f≦1, 7≦g<8.

Owner:NICHIA CORP

Nitride phosphor and production process thereof, and light emitting device

PROBLEM TO BE SOLVED: To provide a white-emitting phosphor excellent in light-emitting characteristics, and to provide a phosphor exhibiting light-emitting characteristics featured in high luminance in a extremely high yield.SOLUTION: The method for manufacturing a nitride phosphor comprising as an essential constituent element at least nitrogen and represented by L<SB>x< / SB>M<SB>y< / SB>N(2 / 3X+4 / 3Y):Z, which has at least one second emission spectrum obtained by converting at least a part of a first emission spectrum within a region different from a region of the first emission spectrum, comprises a step for calcination in an ammonia atmosphere. In the formula, L is selected among Be, Mg, Ca, Sr, Ba, Zn, Cd and Hg; M is selected among C, Si, Ge, Sn, Ti, Zr and Hf; and Z is an activator.

Owner:NICHIA CORP

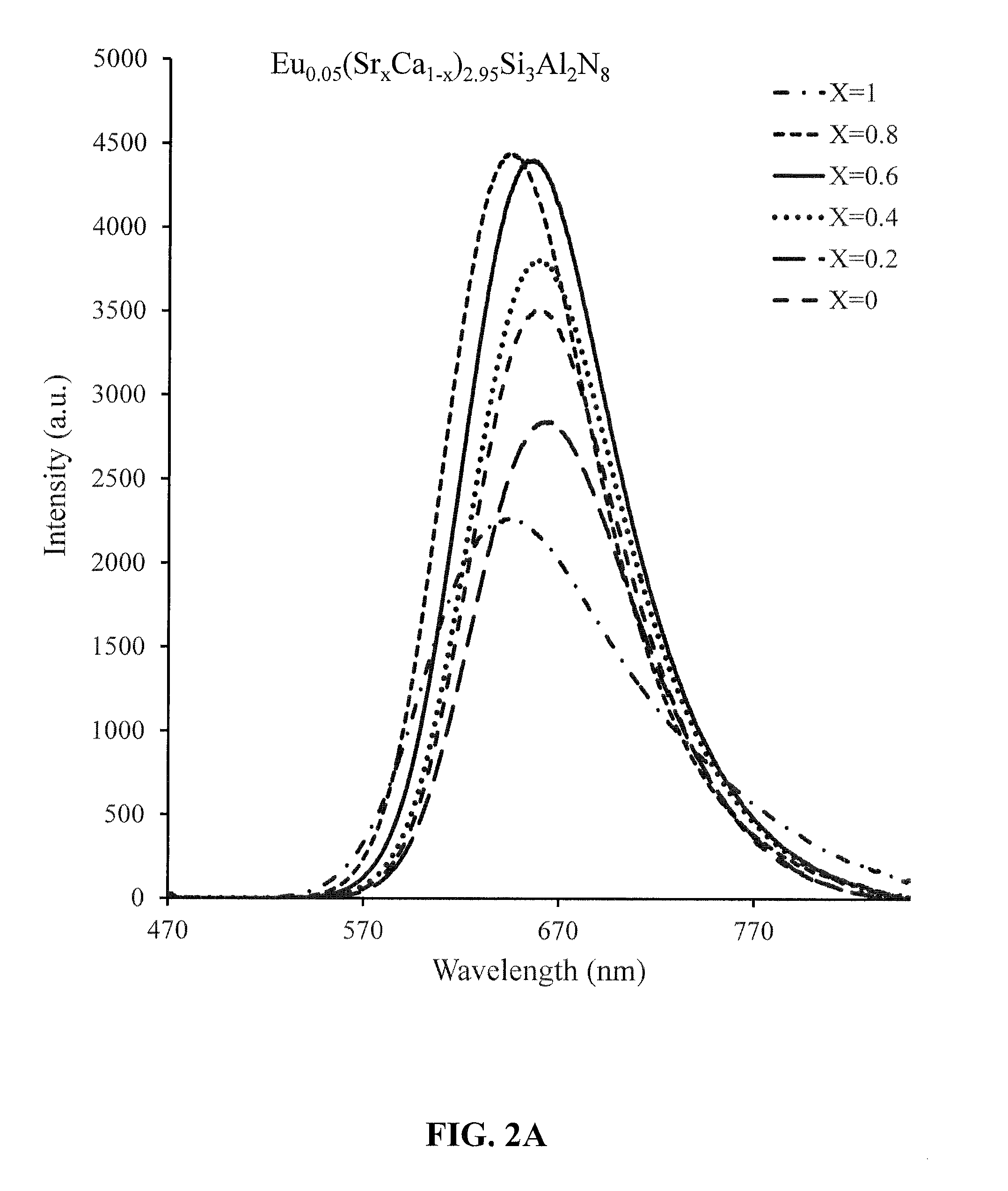

Nitride phosphors with interstitial cations for charge balance

Phosphors comprising a nitride-based composition represented by the chemical formula: M(x / v)(M′aM″b)Si(c-x)AlxNd:RE, wherein: M is a divalent or trivalent metal with valence v; M′ is at least one divalent metal; M″ is at least one trivalent metal; 2a+3b+4c=3d; and RE is at least one element selected from the group consisting of Eu, Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho, Er, Tm, Yb. Furthermore, the nitride-based composition may have the general crystalline structure of M′aM″bSicNd, where Al substitutes for Si within the crystalline structure and M is located within the crystalline structure substantially at the interstitial sites.

Owner:INTEMATIX

(Oxy) Nitride phosphor, white light-emitting device and method of preparing phosphor

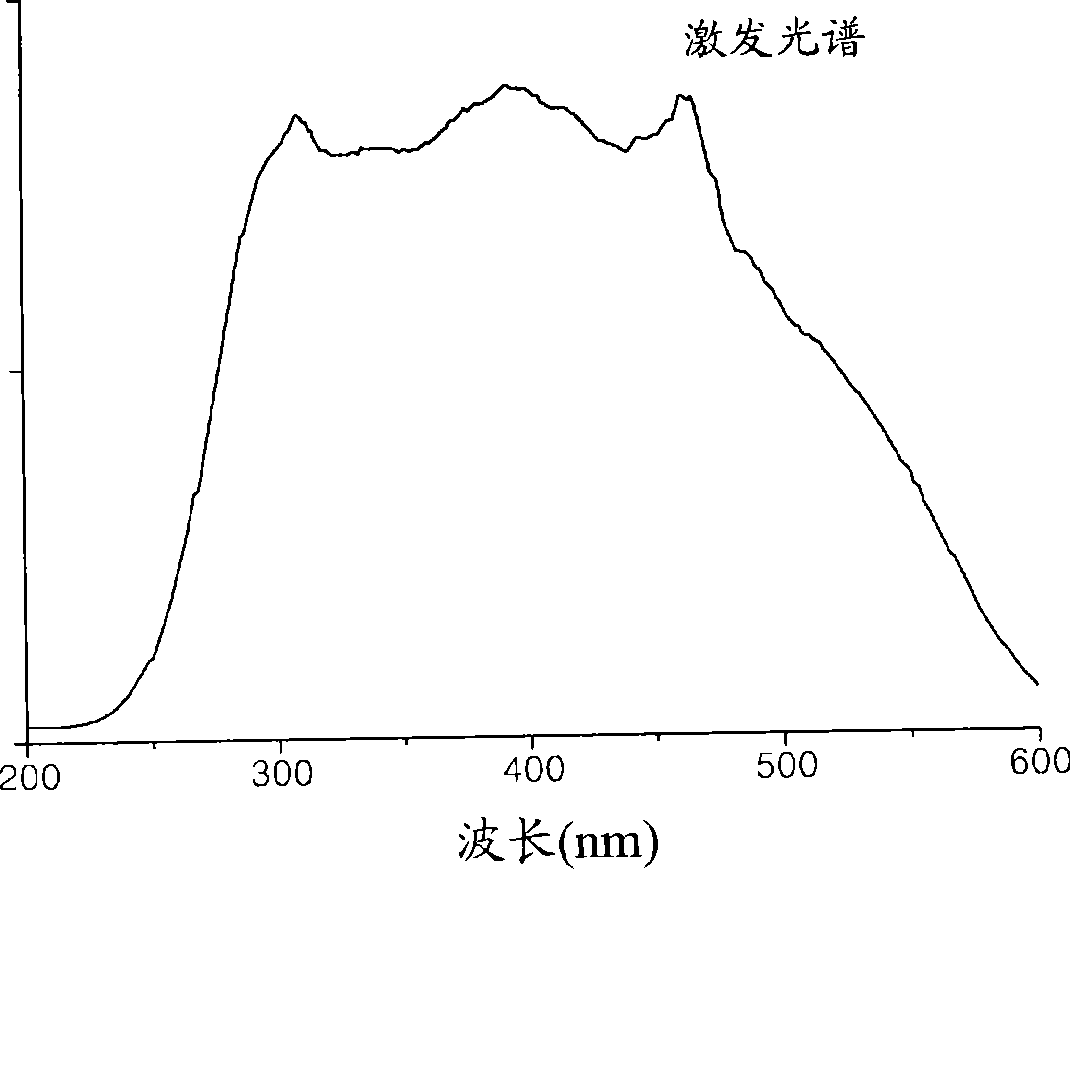

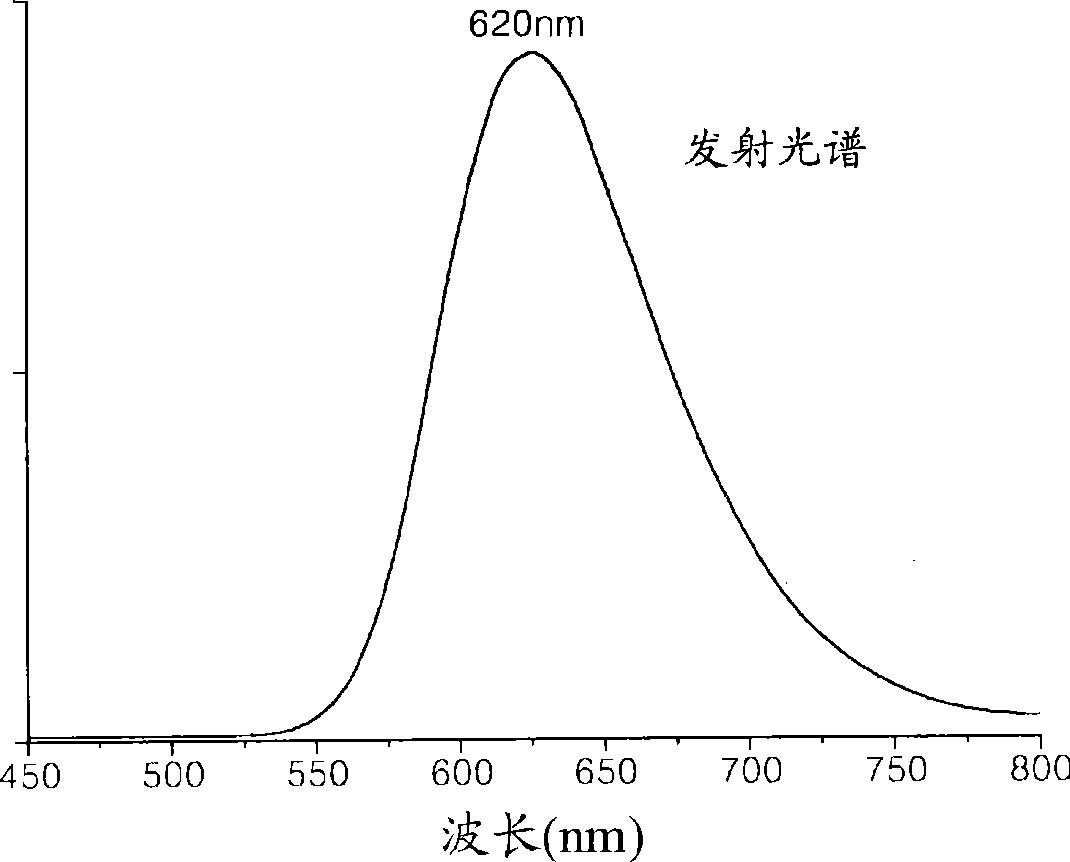

The invention provides an (oxy) nitride phosphor, a white light emitting device comprising the (oxy) nitride phosphor, a method for preparing the (oxy) nitride phosphor and the nitride phosphor prepared by the method. The (oxy)nitride phosphor is the compound represented by the formula 1; M is the alkaline-earth metal; furthermore x is more than 1 and less than 1; a is more than 1.8 and less than 2.2; b is more than 4.5 and less than 5.5; c is more than or equal to 0 and less than 8; d is more than 0 and less than or equal to 8; c+d is more than 0 and less than or equal to 8. The (oxy) nitride phosphor produces red light suitable for use in UV-LED and blue-LED type white light-emitting devices and achieves good efficiency.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Nitride phosphor and manufacturing method thereof, and light emitting device using the same

ActiveUS20120126687A1Increase brightnessIncrease color rendering property and color saturationDischarge tube luminescnet screensElectroluminescent light sourcesNitride phosphorPhysical chemistry

A phosphor and a manufacturing method thereof, and the light emitting device using the same are provided, wherein the composition formula of the phosphor is Ii-Mm-Aa-Bb—Ot—Nn:Zr, wherein I is selected from the group consisting of Li, Na, and K, M is selected from the group consisting of Ca, Sr, Mg, Ba, Be, and Zn, A is selected from the group consisting of Al, Ga, In, Sc, Y, La, Gd, and Lu, B is selected from the group consisting of Si, Ge, Sn, Ti, Zr, and Hr, and Z is selected from the group consisting of Eu and Ce; m+r=1, 0<i<0.25, 0<a<1, 0<b<2, 1.15<b / a<1.4, 0≦t≦0.7, 2.1≦n≦4.4, and 0.001≦r≦0.095.

Owner:DENKA CO LTD

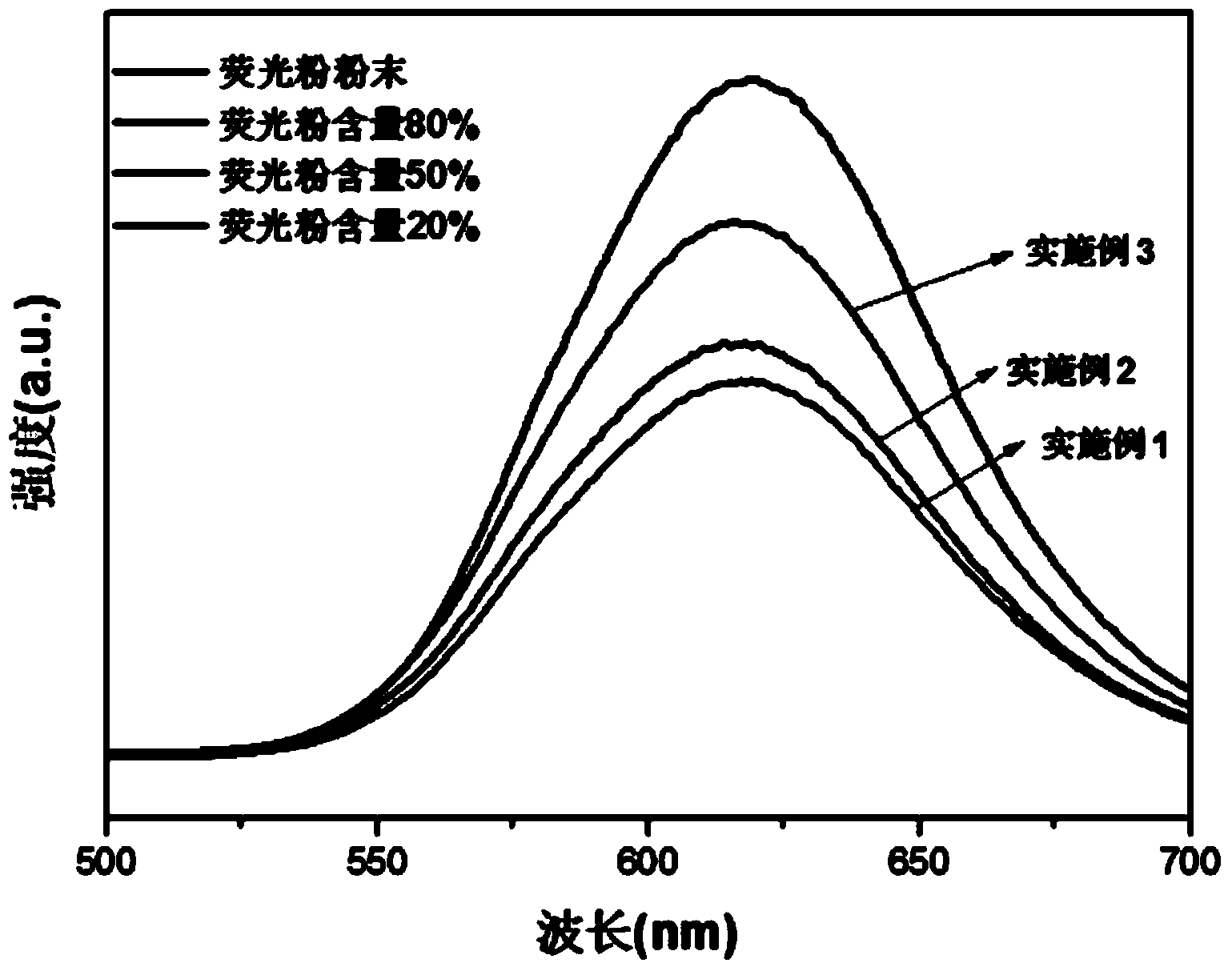

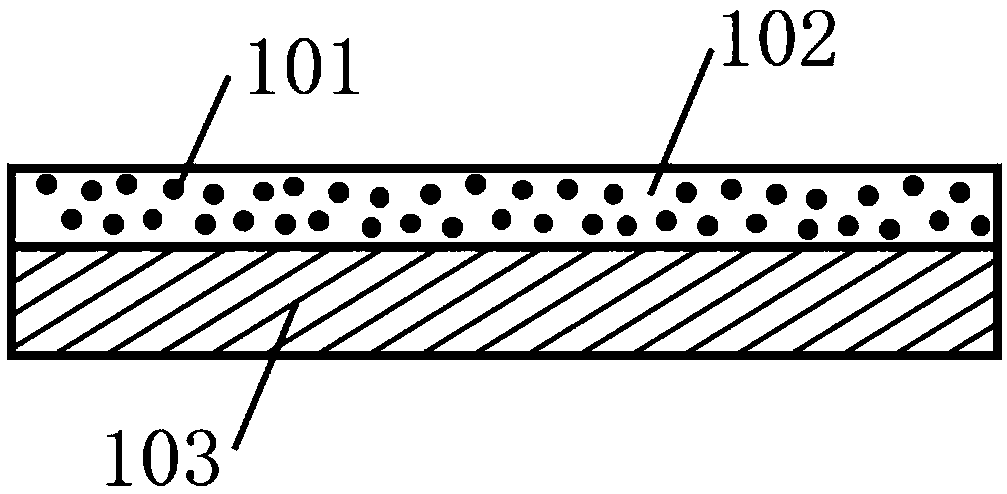

Preparation method for nitride phosphor/glass composite luminescent sheet layer

The invention relates to a preparation method for a nitride phosphor / glass composite luminescent sheet layer. The preparation method comprises the steps of mixing glass components uniformly, melting to obtain a molten glass liquid, wherein the glass components comprise, by mass, 60-70% % of Bi2O3, 20-30% of B2O3, 6-8% of ZnO and 2-4% of Al2O3; water quenching, drying, grinding and screening to obtain glass powder; mixing phosphor powder and the glass powder uniformly to obtain mixed powder; then spreading the mixed powder on a mold; tabletting; carrying out heat treatment for 0.5-1.5 h at a temperature of 500-600 DEG C; and cooling to obtain the nitride phosphor / glass composite luminescent sheet layer. The preparation method is simple, and has low requirements for equipment. The phosphor / glass composite luminescent sheet layer provided by the invention has the advantages of high luminescent intensity, good heat stability and good mechanical strength. Besides, the phosphor / glass composite luminescent sheet layer is simple in preparation, and has good application prospects in laser phosphor display (LPD) display.

Owner:DONGHUA UNIV

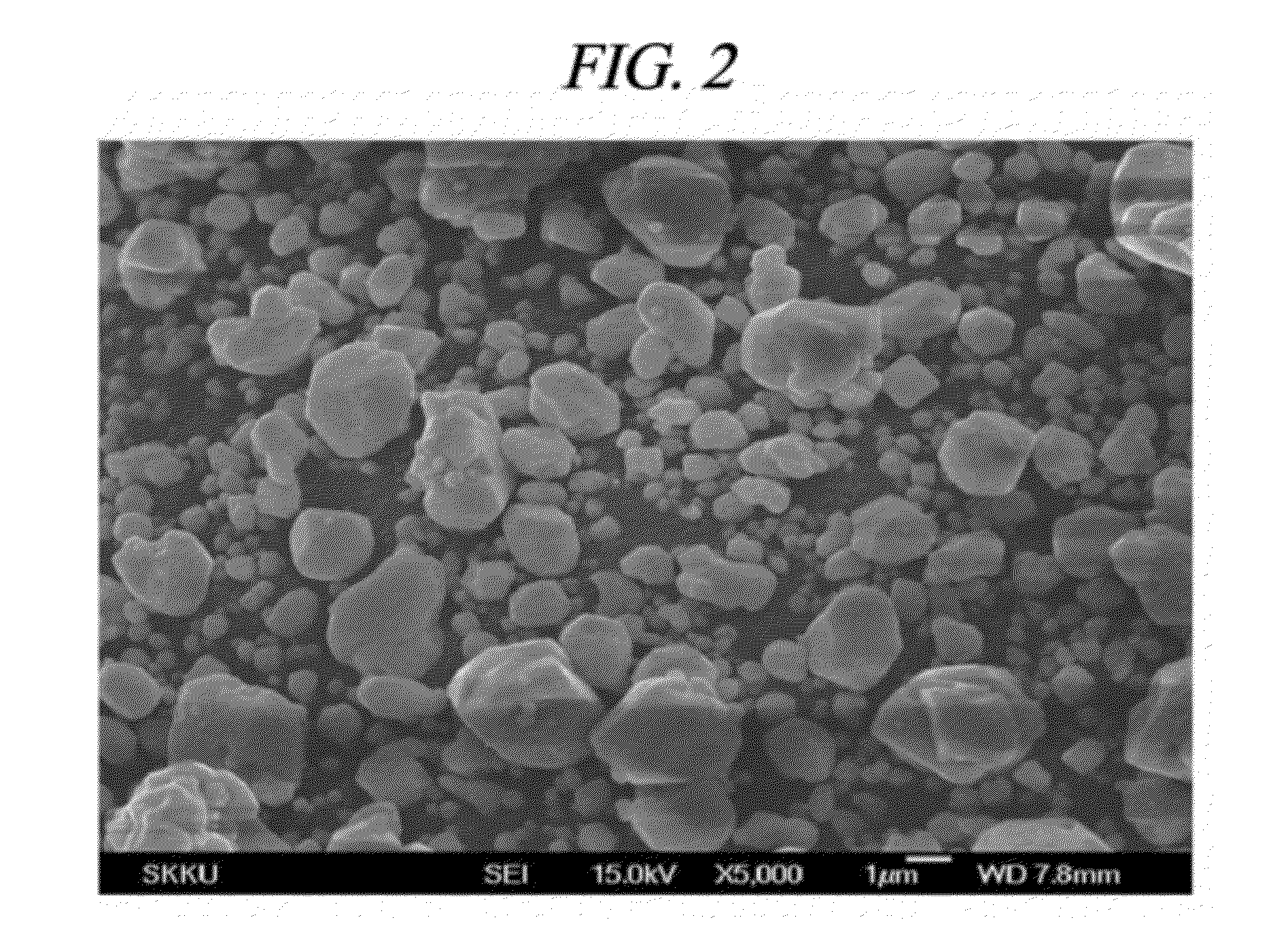

Oxynitride phosphor powder, nitride phosphor powder and a production method therefor

InactiveCN102625820ASolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceDisplay device

The present invention relates to a production method for oxynitride and nitride phosphor powders which can be used in displays such as vacuum fluorescent displays (VFDs), field emission displays (FEDs) and LED display devices, or in lighting devices such as cold cathode fluorescent lamps (CCFL) and LED lamps, or in light-emitting apparatuses such as backlights, wherein the production method for phosphor powders comprises the step of subjecting part or all of a metal oxide to nitriding by calcining in an atmosphere containing nitrogen, using a fine carbon substance.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV +1

Oxynitride phosphor powder, nitride phosphor powder, and a production method therefor

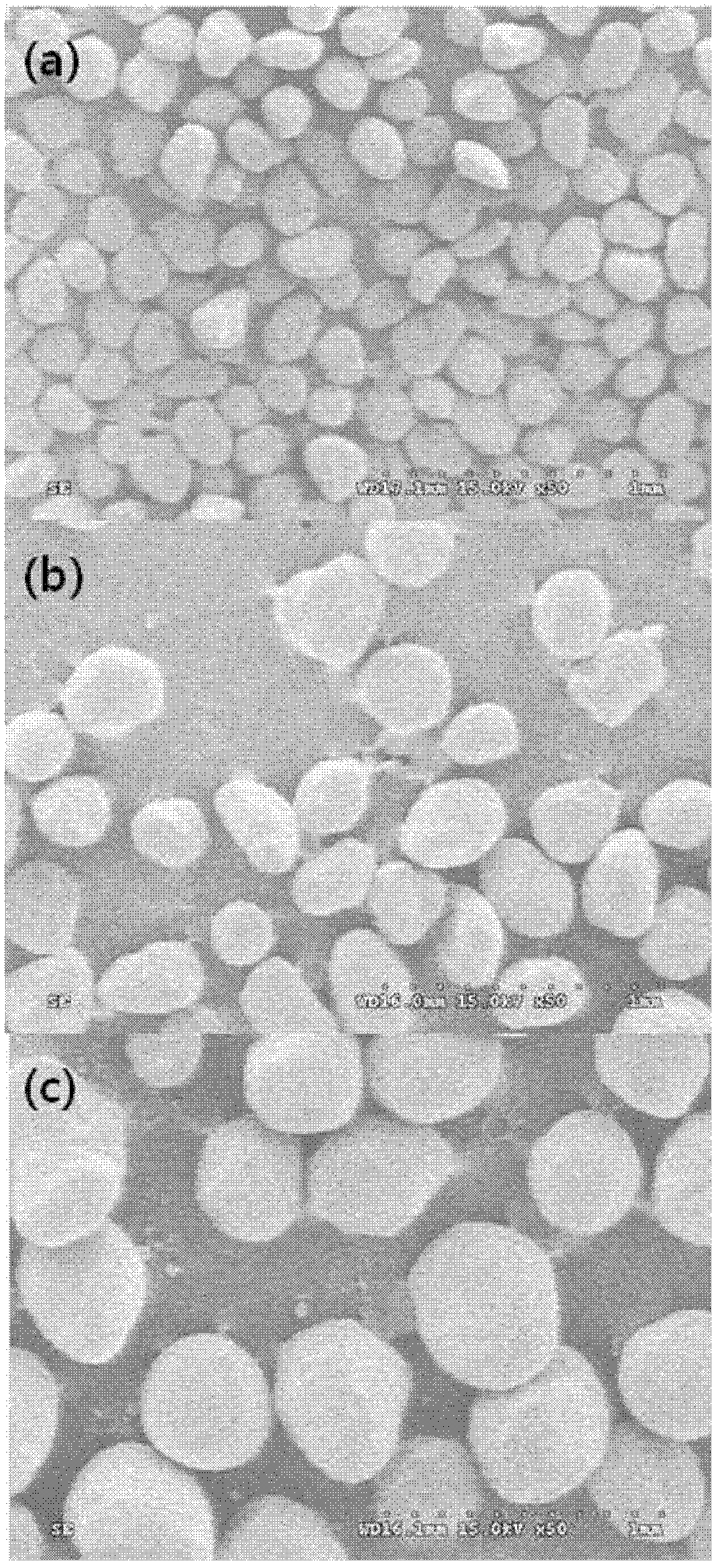

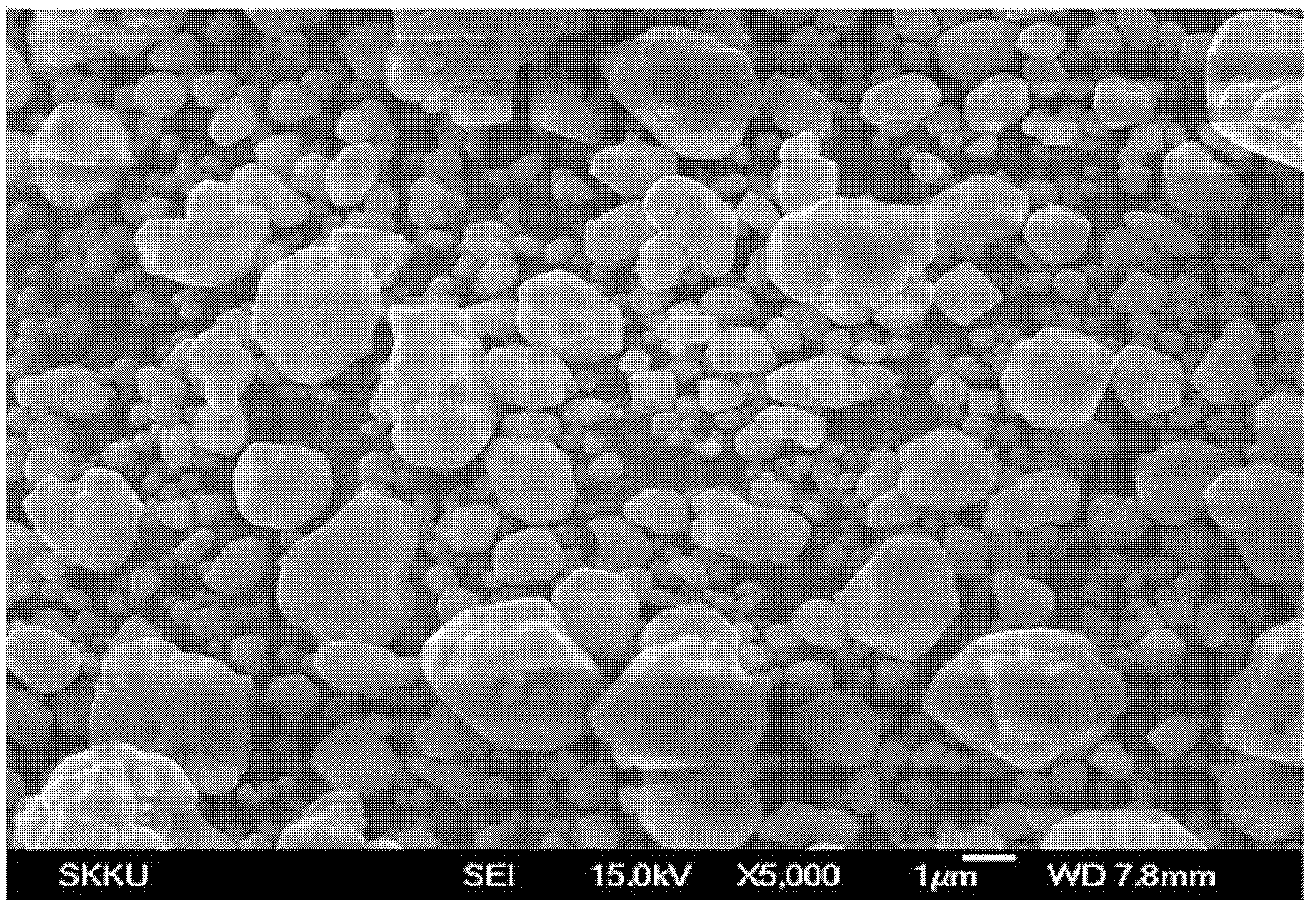

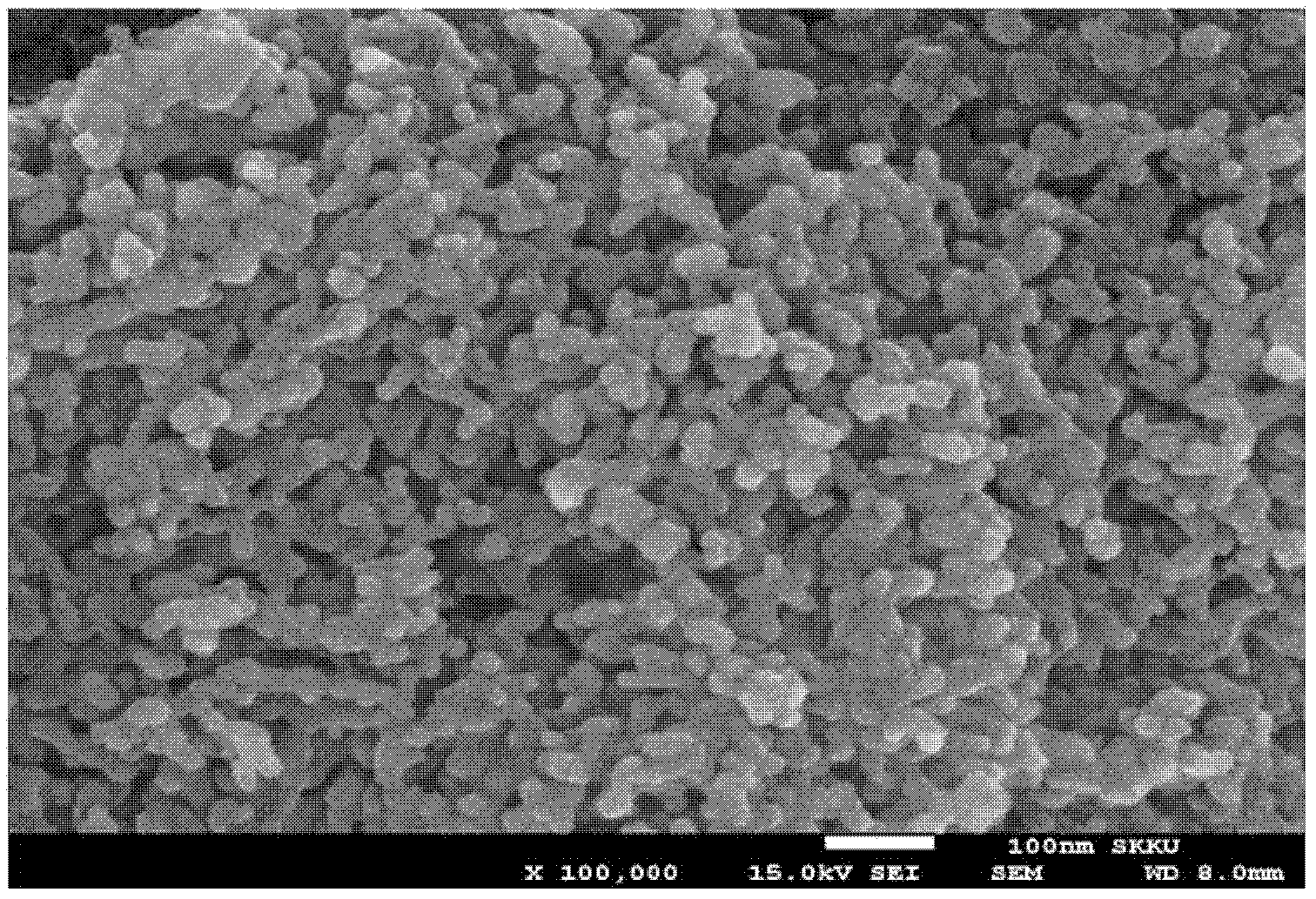

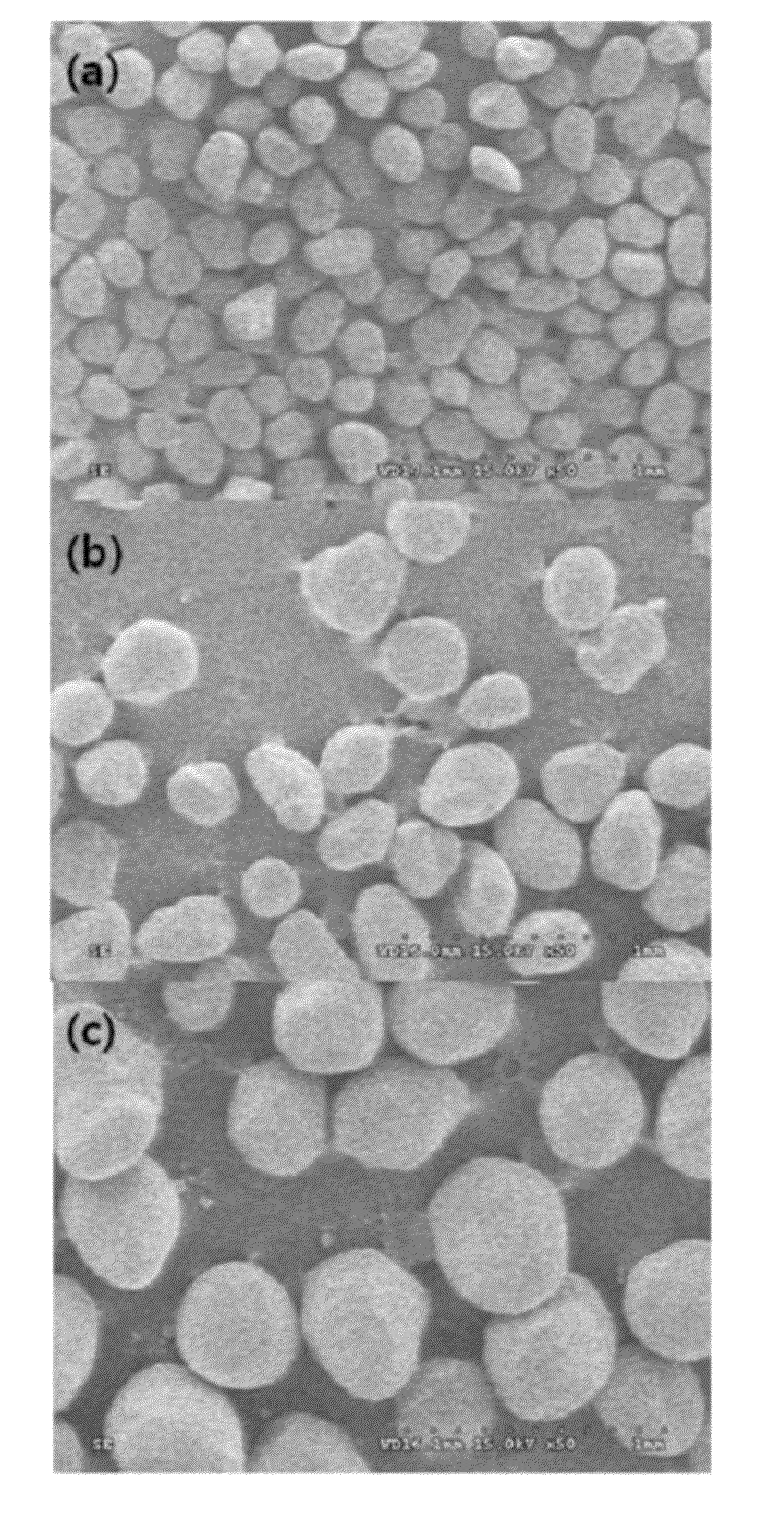

InactiveUS20120187339A1Good temperature characteristicsImprove light emission efficiencyLuminescent compositionsElectric discharge lampsFluorescenceDisplay device

The present disclosure relates to a producing method for oxynitride or nitride phosphor powders which can be used in displays such as vacuum fluorescent display (VFD), field emission display (FED) and LED display devices, or in lighting devices such as cold cathode fluorescent lamps (CCFL) and LED lamps, or in light-emitting apparatuses such as back-lights, wherein the producing method for phosphor powders comprises the step of subjecting part or all of a metal oxide to nitriding by calcining in an atmosphere containing nitrogen, using a fine carbon substance.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV +1

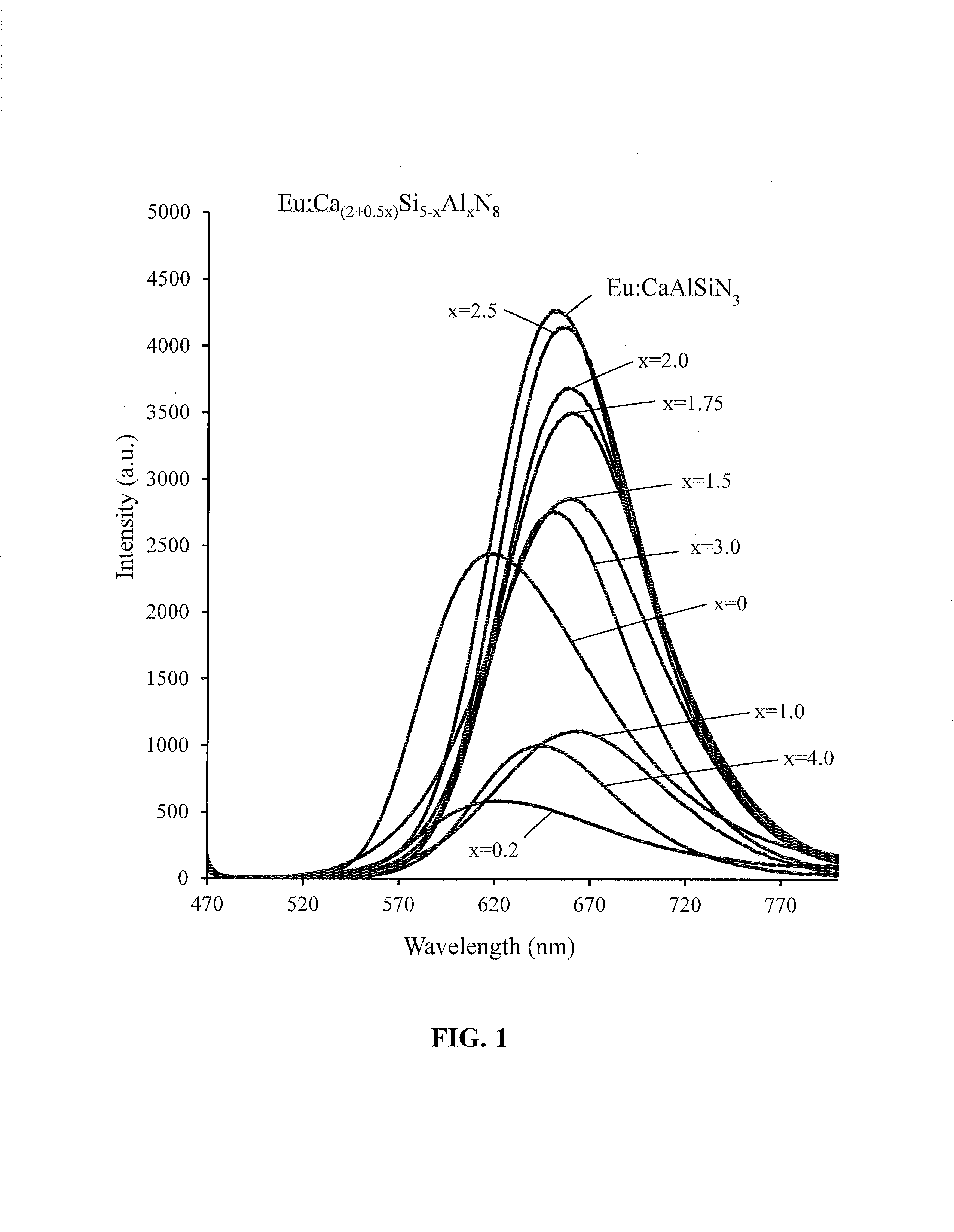

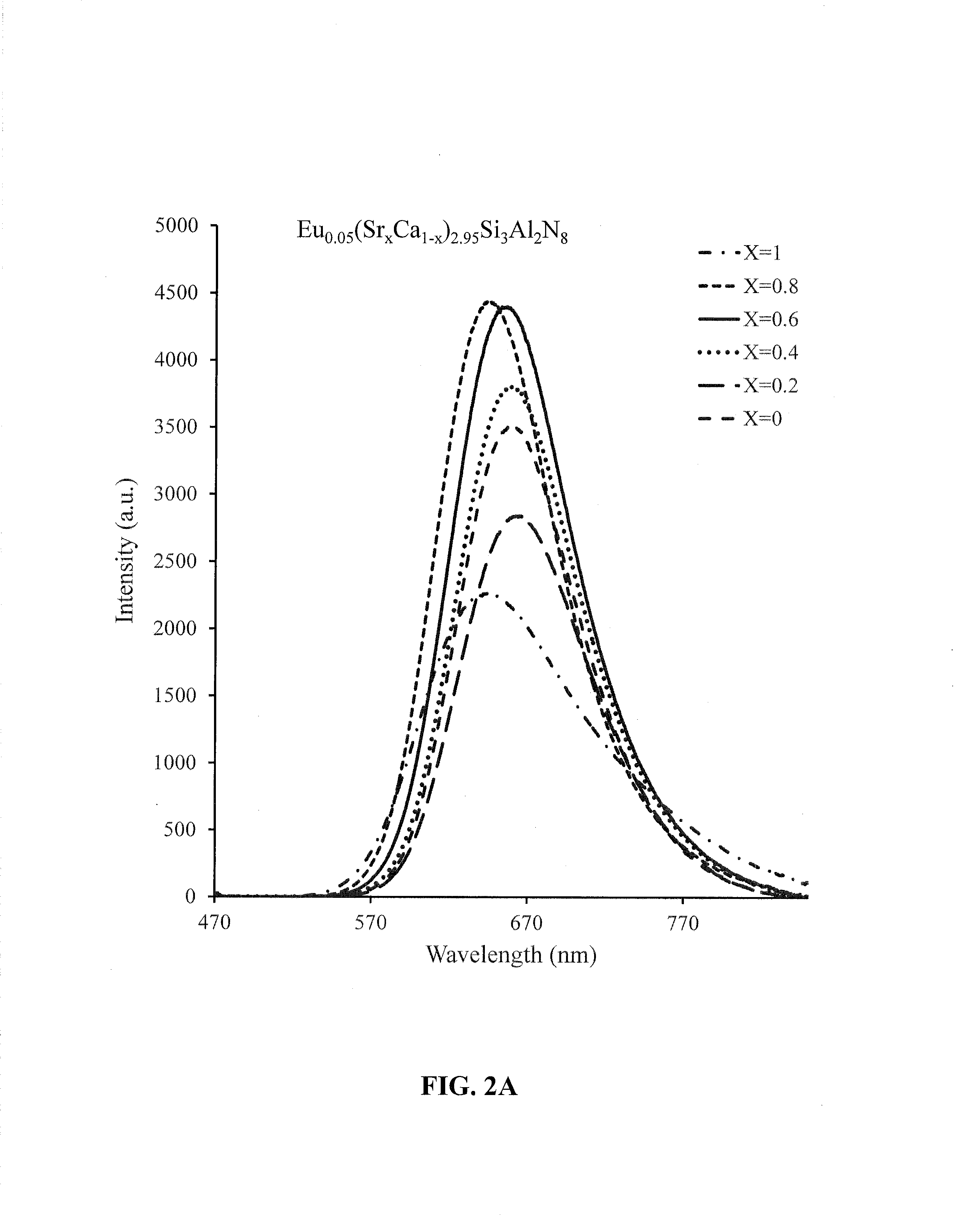

Nitride phosphor material and preparation method thereof

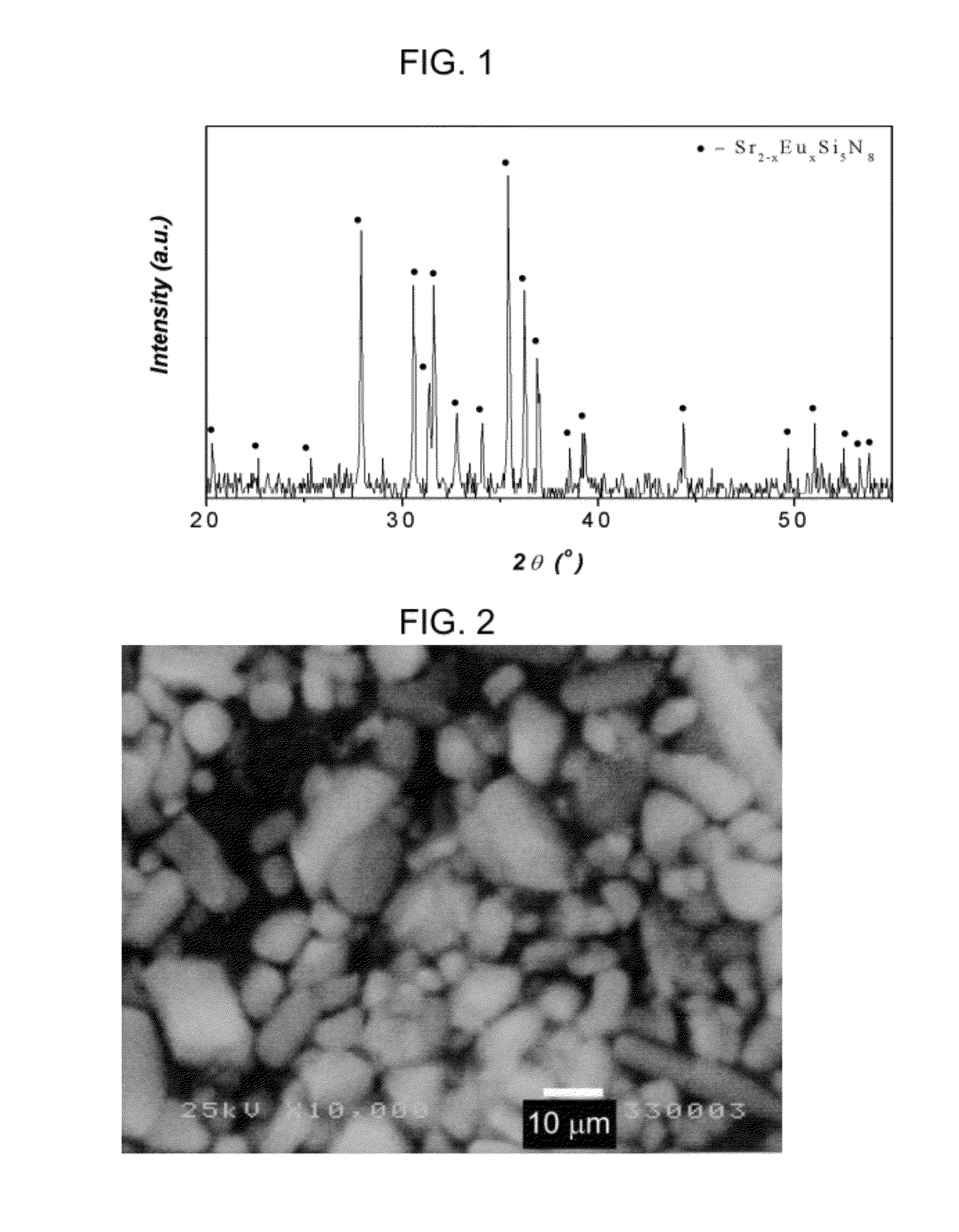

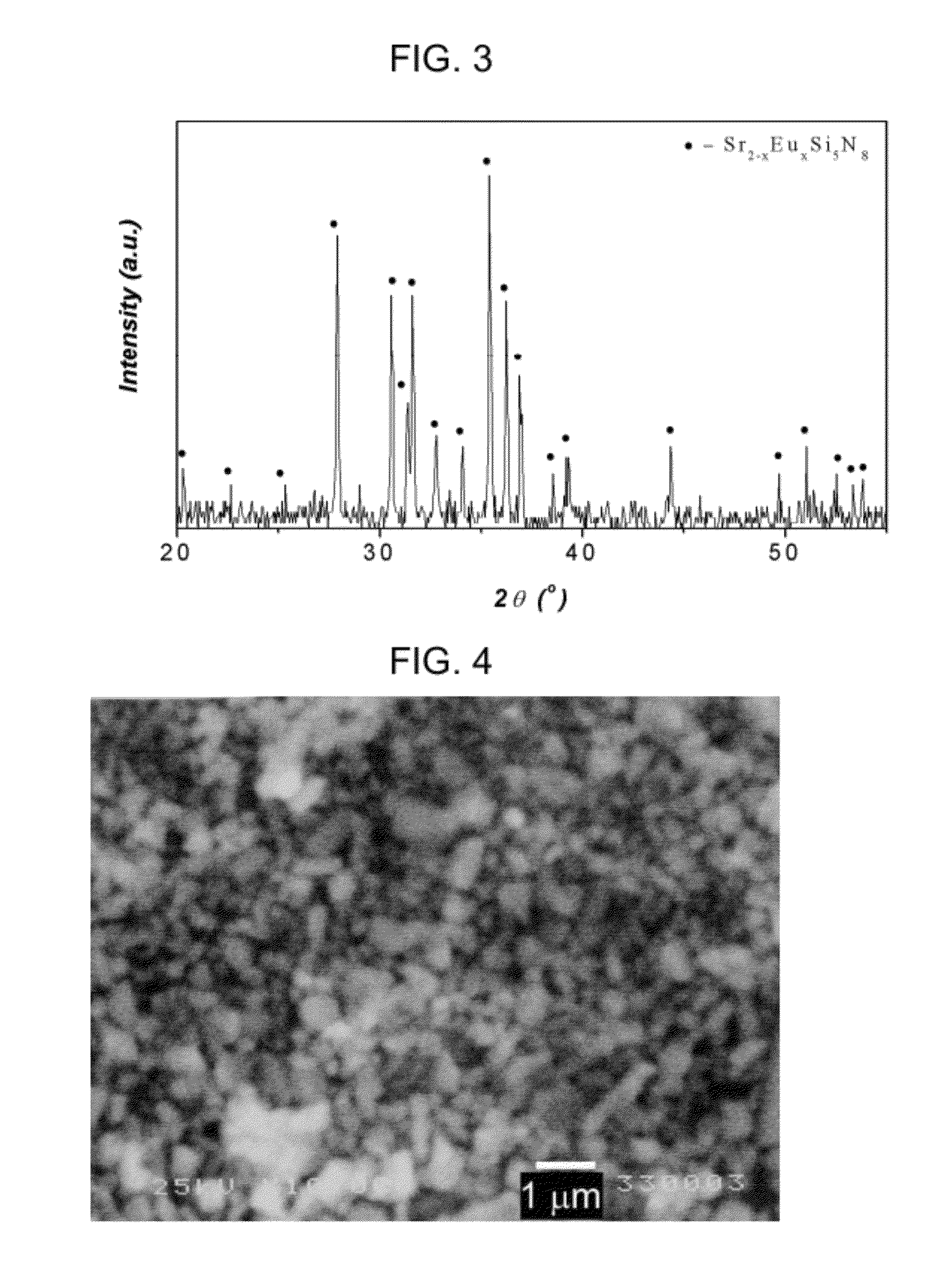

InactiveCN101798510AImprove quantum efficiencyPhysicochemically stableLuminescent compositionsAlkaline earth metalMaterial synthesis

The invention provides a nitride phosphor material and a preparation method thereof. The nitride phosphor material is characterized in that the general chemical formula is M2-xSi5-yZyN8:xEu, wherein M is one or a combination of two of the alkaline-earth metals including Mg, Ca, Sr and Ba, and Z is one of Al and Ge; x is not less than 0.01 and not more than 0.3; and y is not less than 0 and not more than 1.0. The nitride phosphor material has low-price synthetic raw materials, stable performance and simple synthesis technology and is suitable for industrialized volume production.

Owner:IRICO

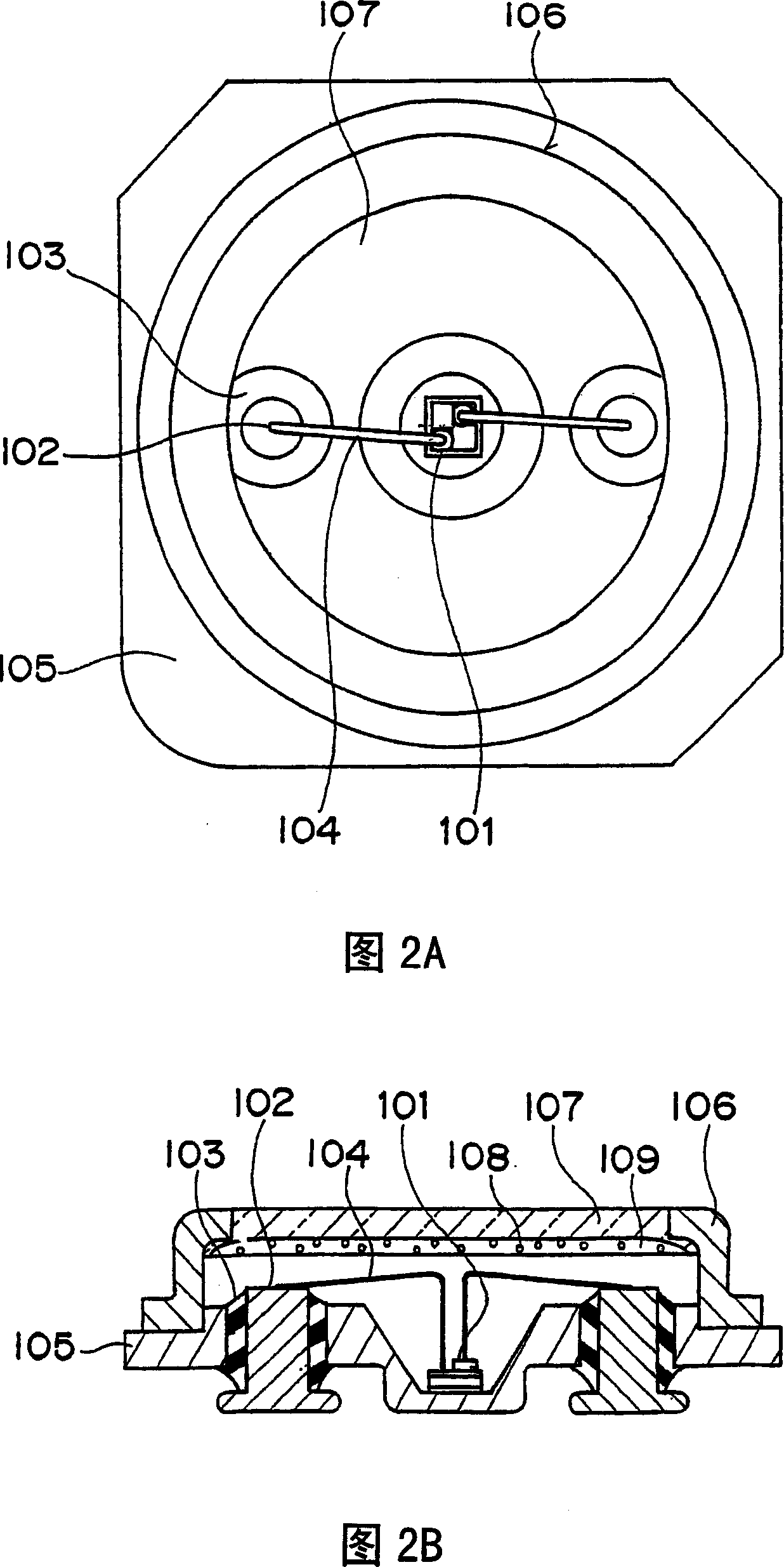

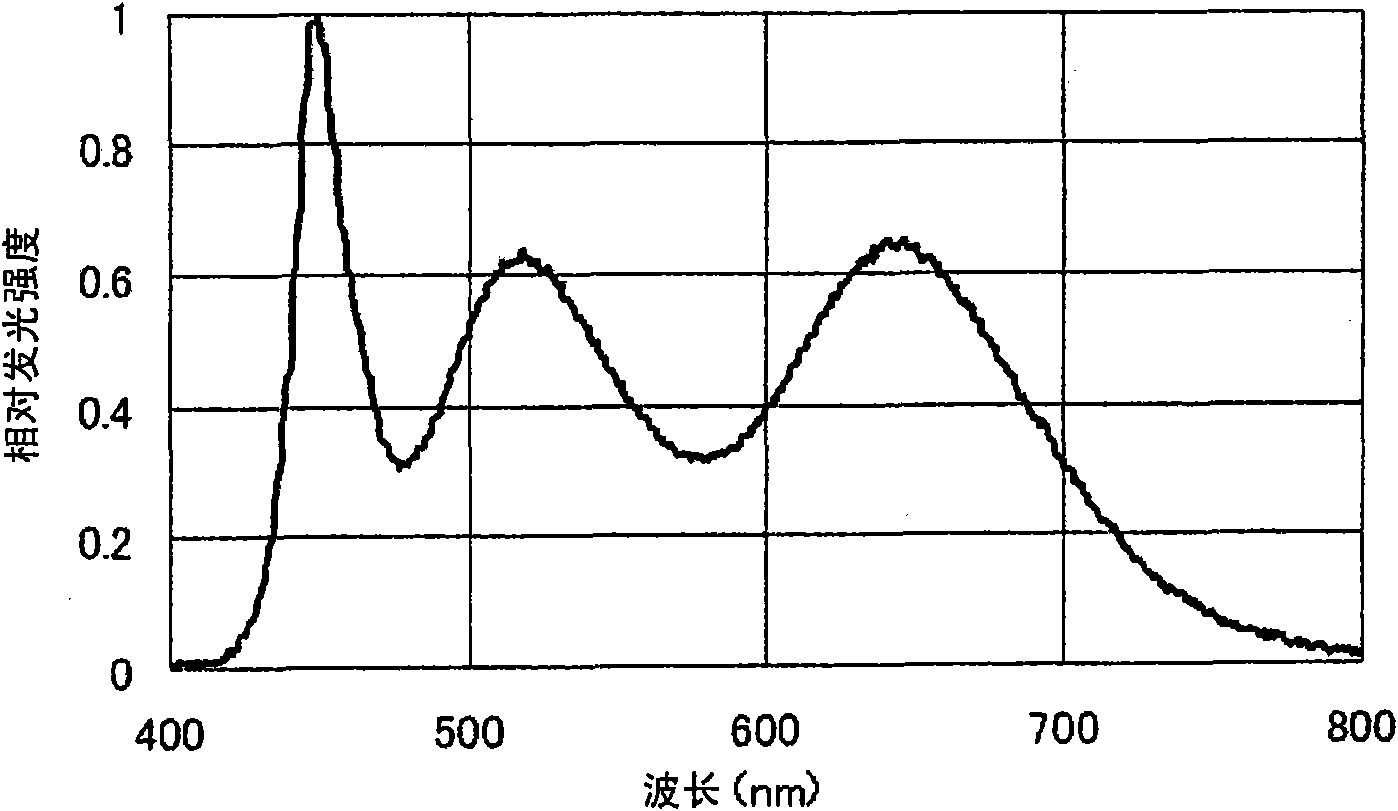

Light emitting device

ActiveCN101785120AHigh color reproductionElectroluminescent light sourcesSolid-state devicesLuminous intensityNitride phosphor

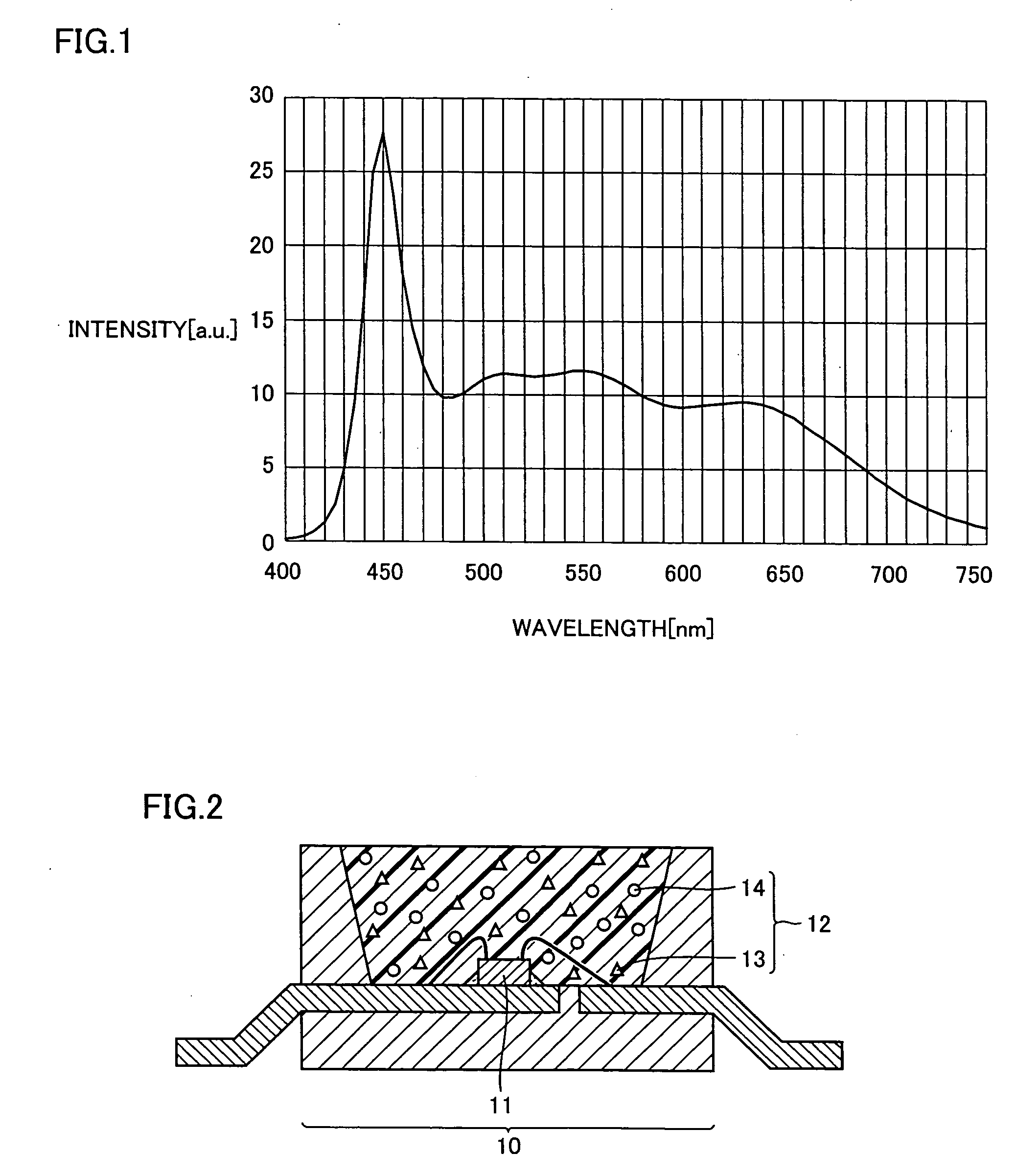

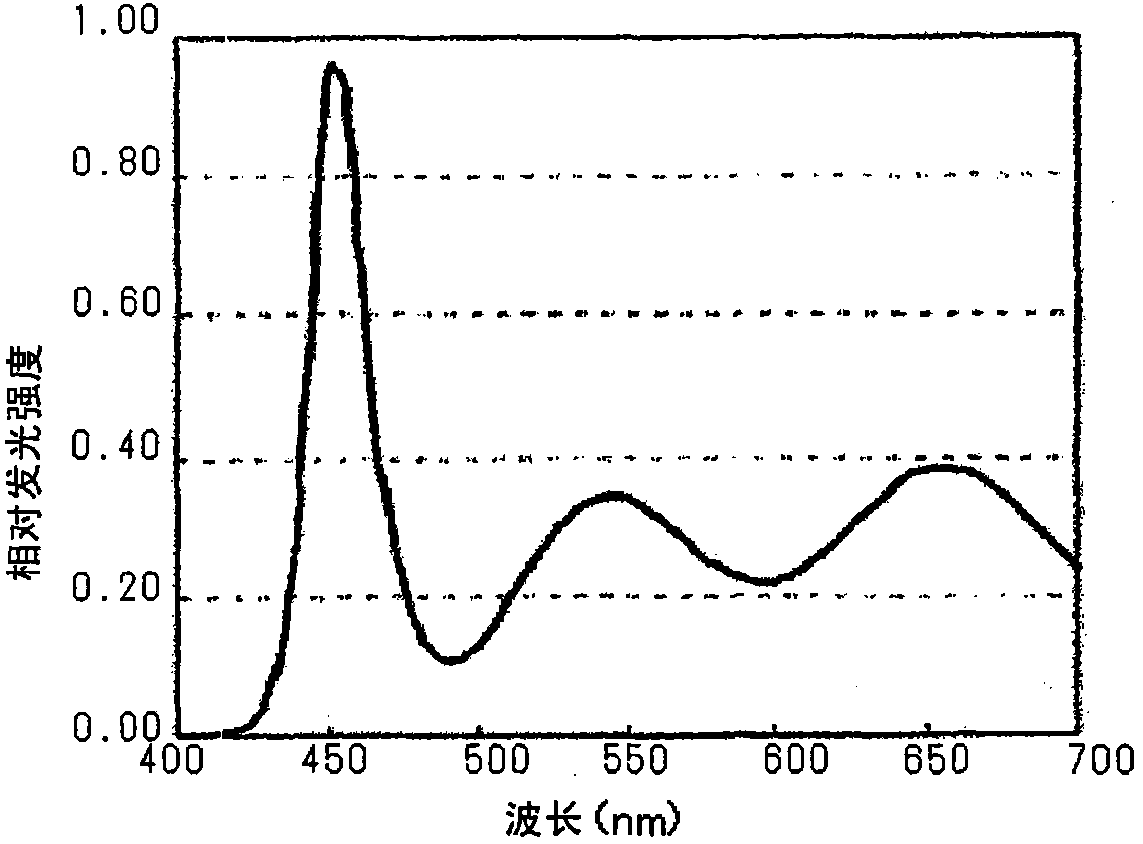

Provided is a light emitting device having excellent color reproducing performance. The light emitting device has a light emitting element, a red phosphor composed of a nitride phosphor, and a green phosphor composed of halosilicate. The emission spectrum has a first peak wavelength of 440nm or more but not more than 470nm, a second peak wavelength of 510nm or more but not more than 550nm, and a third peak wavelength of 630nm or more but not more than 670nm. The lowest relative emission strength value between the second peak wavelength and the third peak wavelength is 80% of the lower value of either the relative emission intensity value at the second peak wavelength or the relative emission intensity at the third peak wavelength or is lower than 80% of such value.

Owner:NICHIA CORP

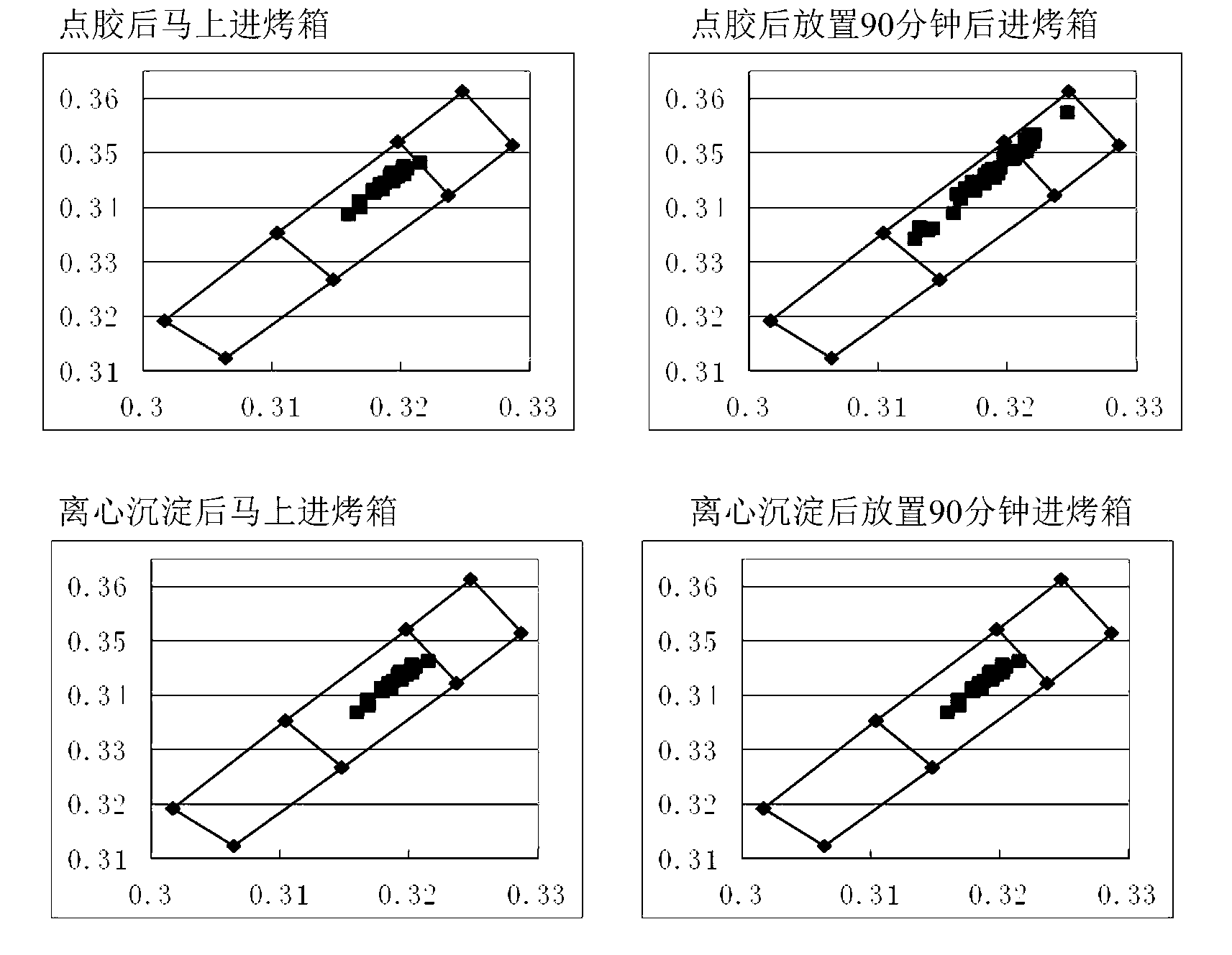

Packaging process for white light-emitting diodes (LEDs)

ActiveCN103311406AGood colorImprove luminous efficiencySemiconductor devicesAluminateRefractive index

The invention discloses a packaging process for white light-emitting diodes (LEDs). The packaging process comprises the following steps of blending silica gel A, silica gel B, a brightening agent, an anti-settling agent, aluminate phosphor and nitride phosphor according to a mass proportion of 0.4:1.6:0.01:0.01:0.73:0.08 to prepare fluorescent gel, wherein the model number of the silica gel A is 1520A, and the model number of the silica gel B is 1520B; dispensing the prepared fluorescent gel into blue LED chips to be packaged, placing the blue LED chips to be packaged on the inner wall of a revolving drum of a centrifugal machine in batches, and revolving the revolving drum for 160 to 200 seconds at revolving speed of 1,800 to 2,200 revolutions per minute; and placing the centrifugally precipitated LEDs into an oven, baking the LEDs for 50 to 70 minutes at 70 to 90 DEG C, and baking the LEDs for 110 to 130 minutes at 140 to 160 DEG C. The emission wavelengths of the LED chips are matched with the excitation wavelength of the phosphor, so that an optimal color rendering property is achieved; a refractive index after the silica gel A and the silica gel B are blended can reach 1.53, so that the luminous efficiency can be improved, and radiation can be improved; a centrifugal precipitation mode is adopted, the fluorescent gel can be precipitated at the bottom of an LED support, and residual light on the lateral surfaces of the chips can be totally reflected, so that the luminous efficiency can be improved by 5 to 10 percent; and the spectroscopical BIN-based targeting rate of a centrifugal precipitation process is greatly increased.

Owner:DONGGUAN SINOWIN OPTO ELECTRONICS

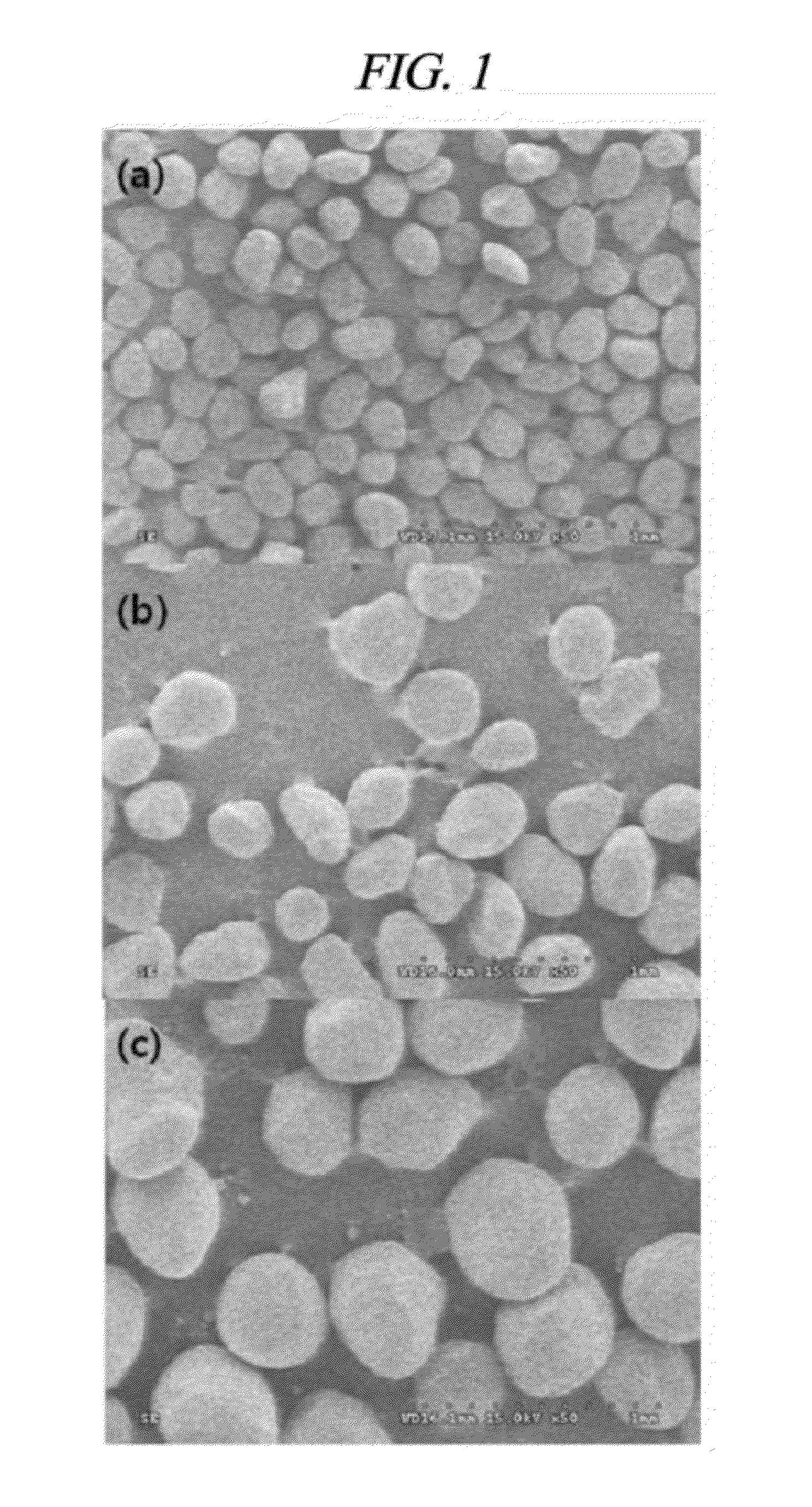

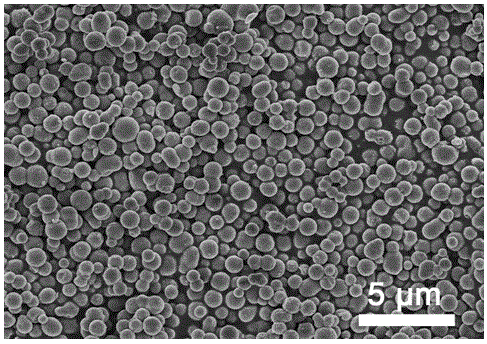

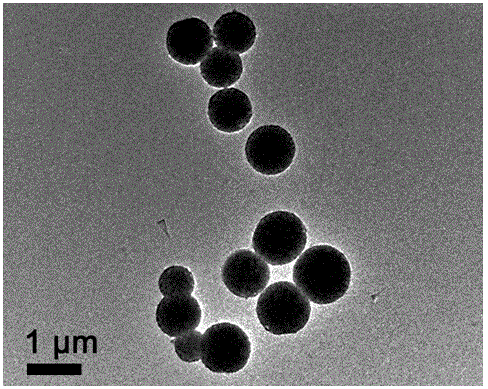

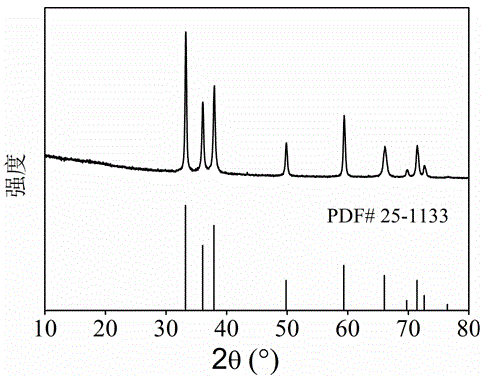

Novel aluminum nitride microsphere powder preparation method

The present invention discloses aluminum nitride microsphere powder, which has a diameter of 20 nm-10 [mu]m. According to the preparation method, a metal inorganic salt is adopted as a precursor and a sol-gel method and a gas nitriding reducing method are combined to prepare the aluminum nitride microsphere powder at the low heat treatment temperature. According to the present invention, the method has characteristics of simple preparation process, simple operation, short preparation process period, low heat treatment temperature, substantial energy consumption reducing, low raw material cost and low equipment cost, and is suitable for industrial mass production; and the prepared ALN microspheres have characteristics of regular shape, adjustable particle size, uniform size distribution, good crystallinity, high purity and the like, can be used for producing circuit packaging materials, ultraviolet photoelectric detectors, pressure sensors, thermal radiation sensors, field effect transistors, light emitting diodes, transparent ceramics, nitride phosphor and the like, and is further the material with the excellent performances such as high temperature resistance, corrosion resistance and anti-oxidation property.

Owner:ZHEJIANG UNIV

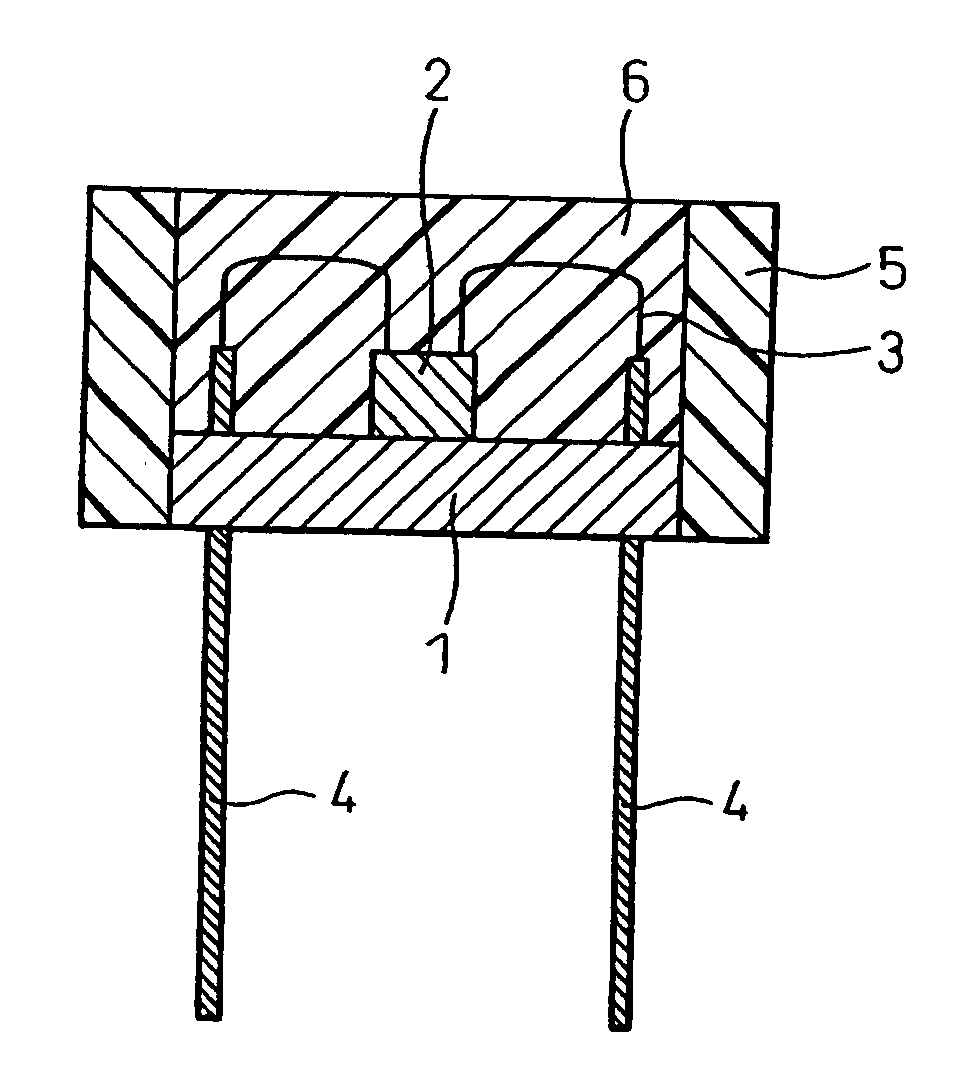

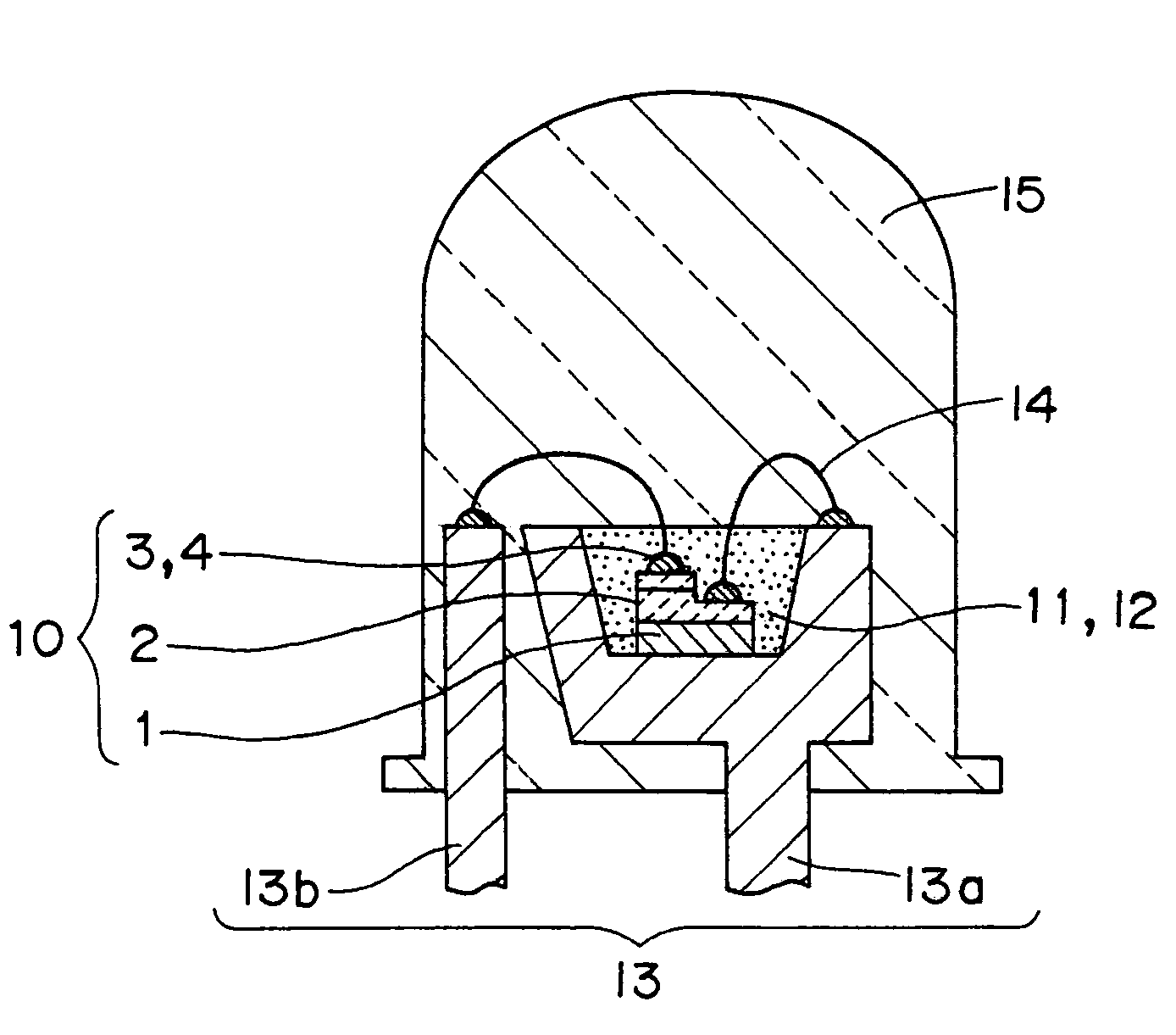

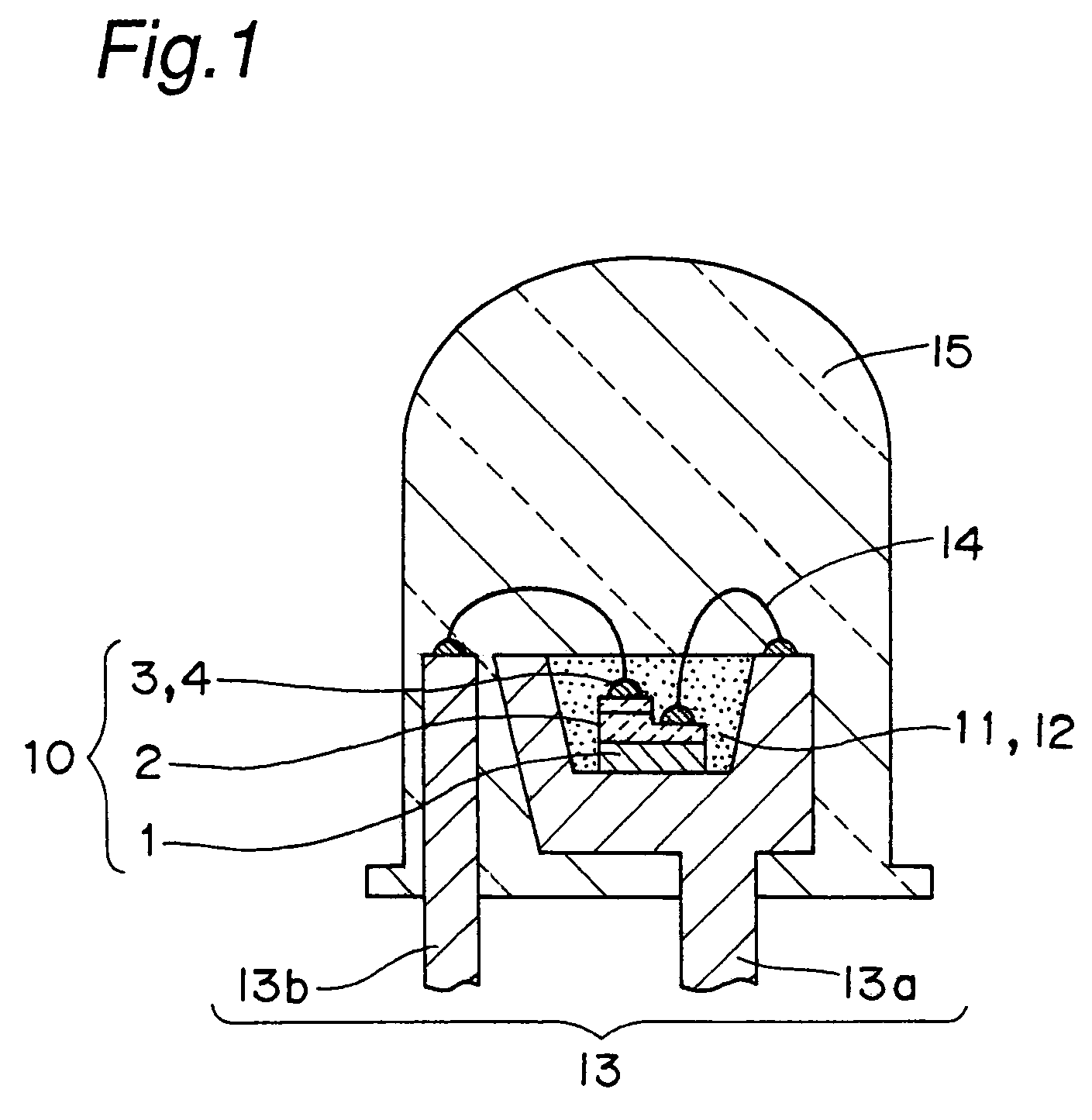

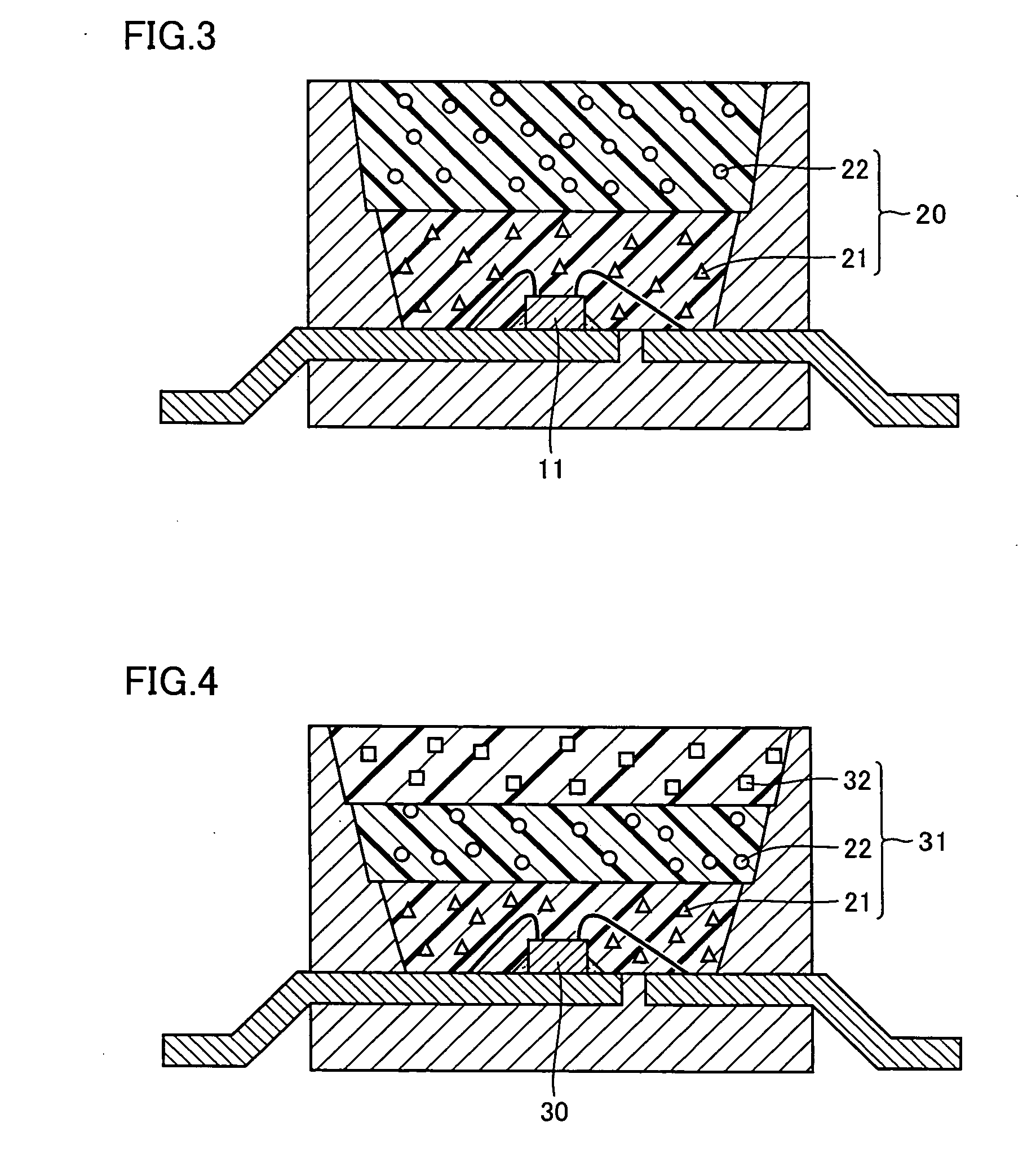

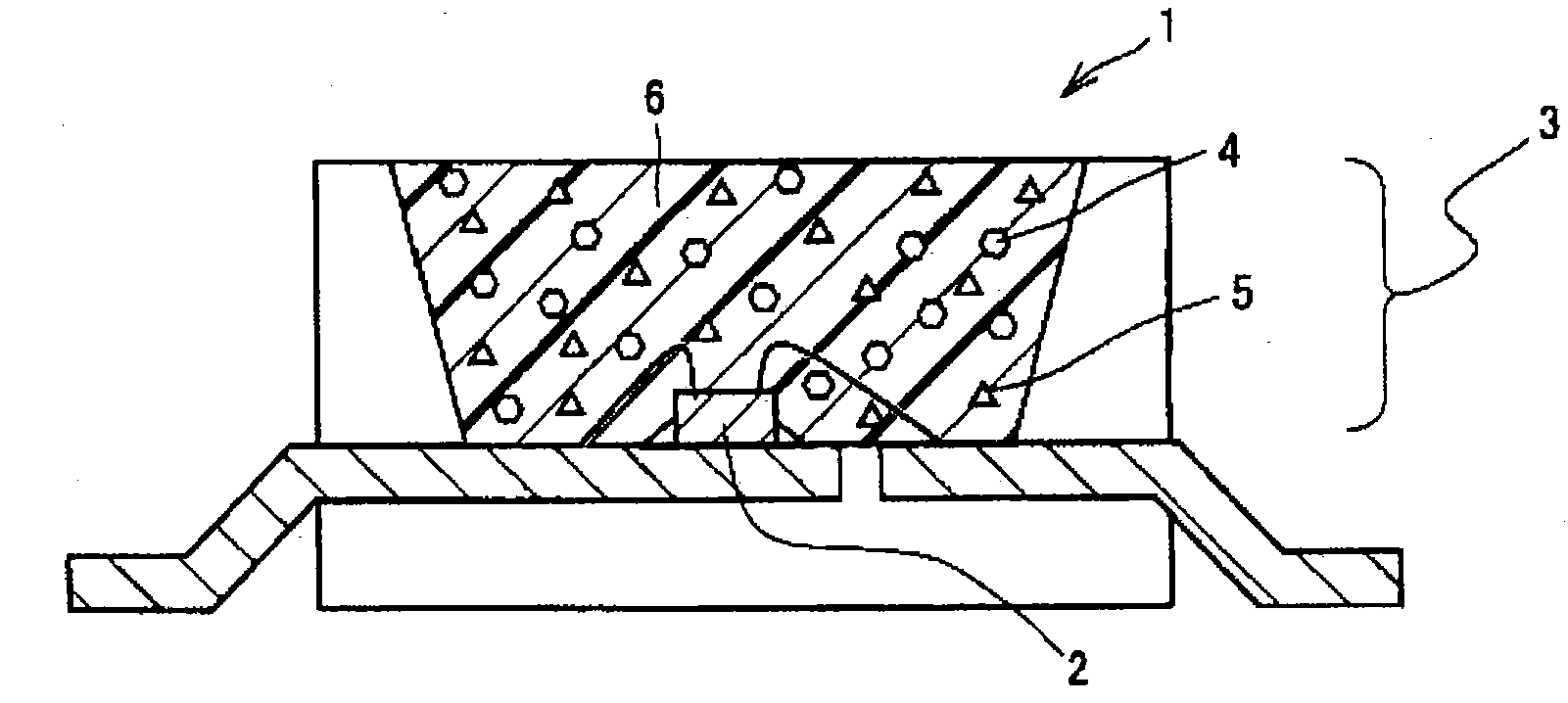

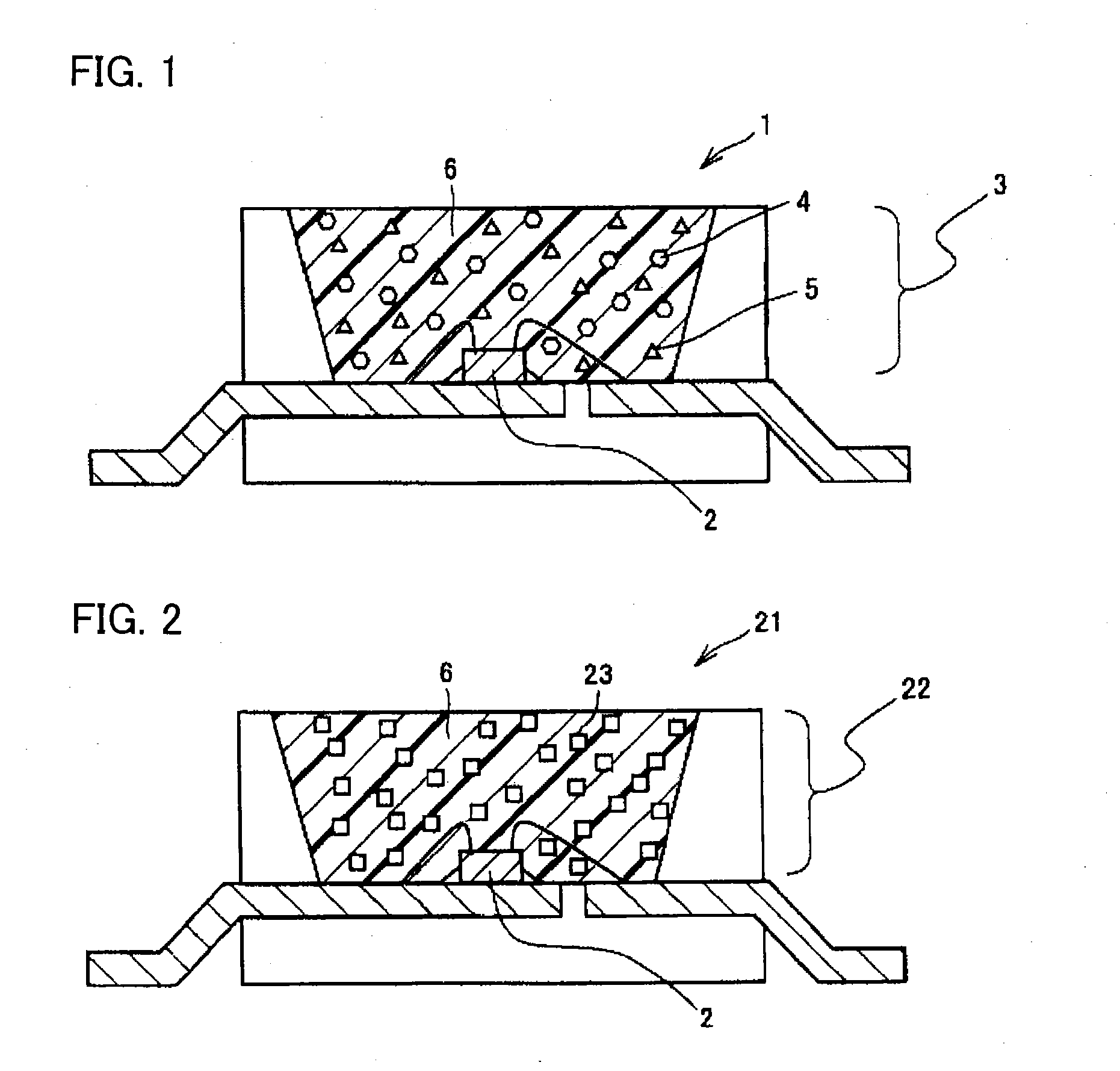

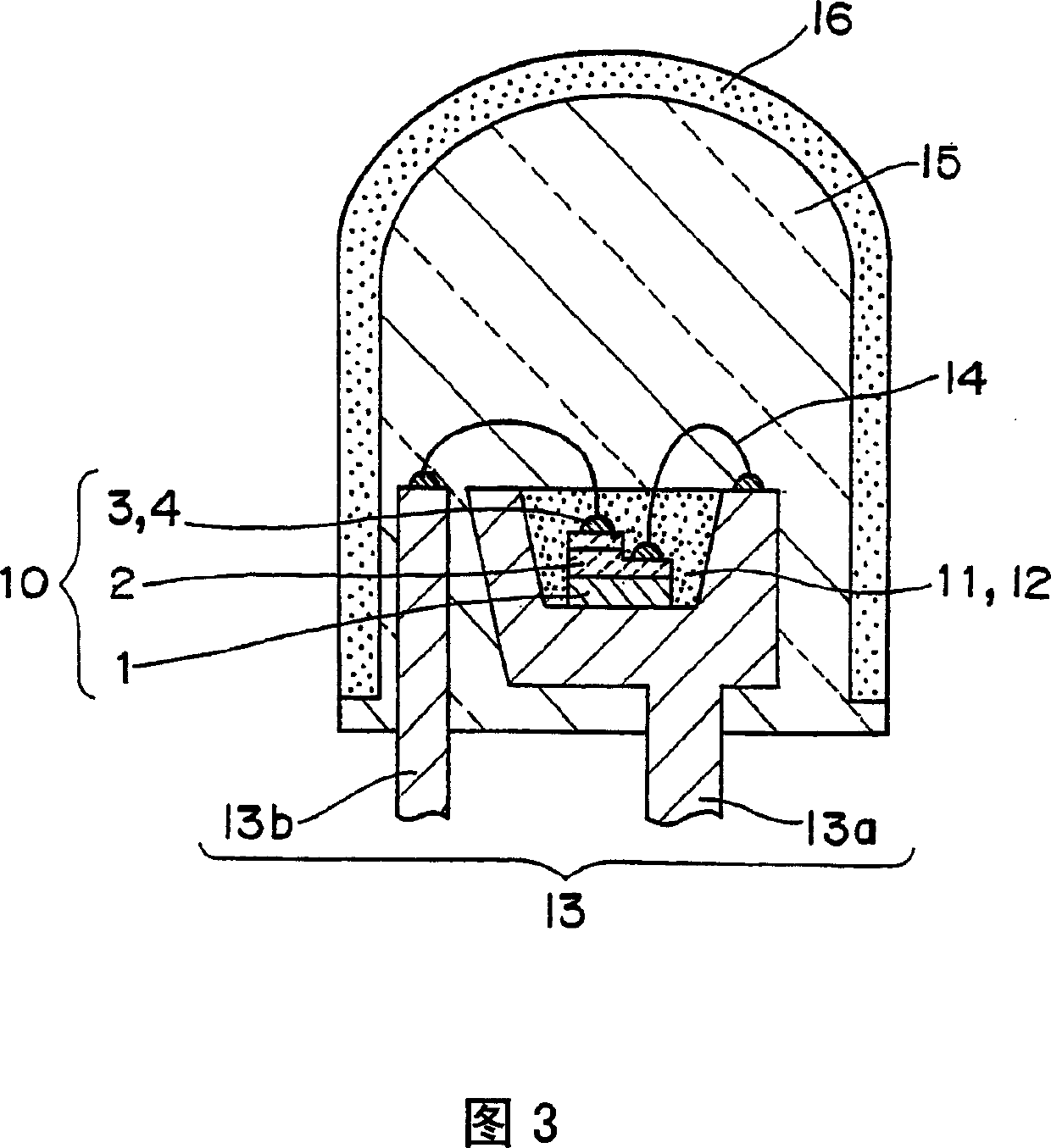

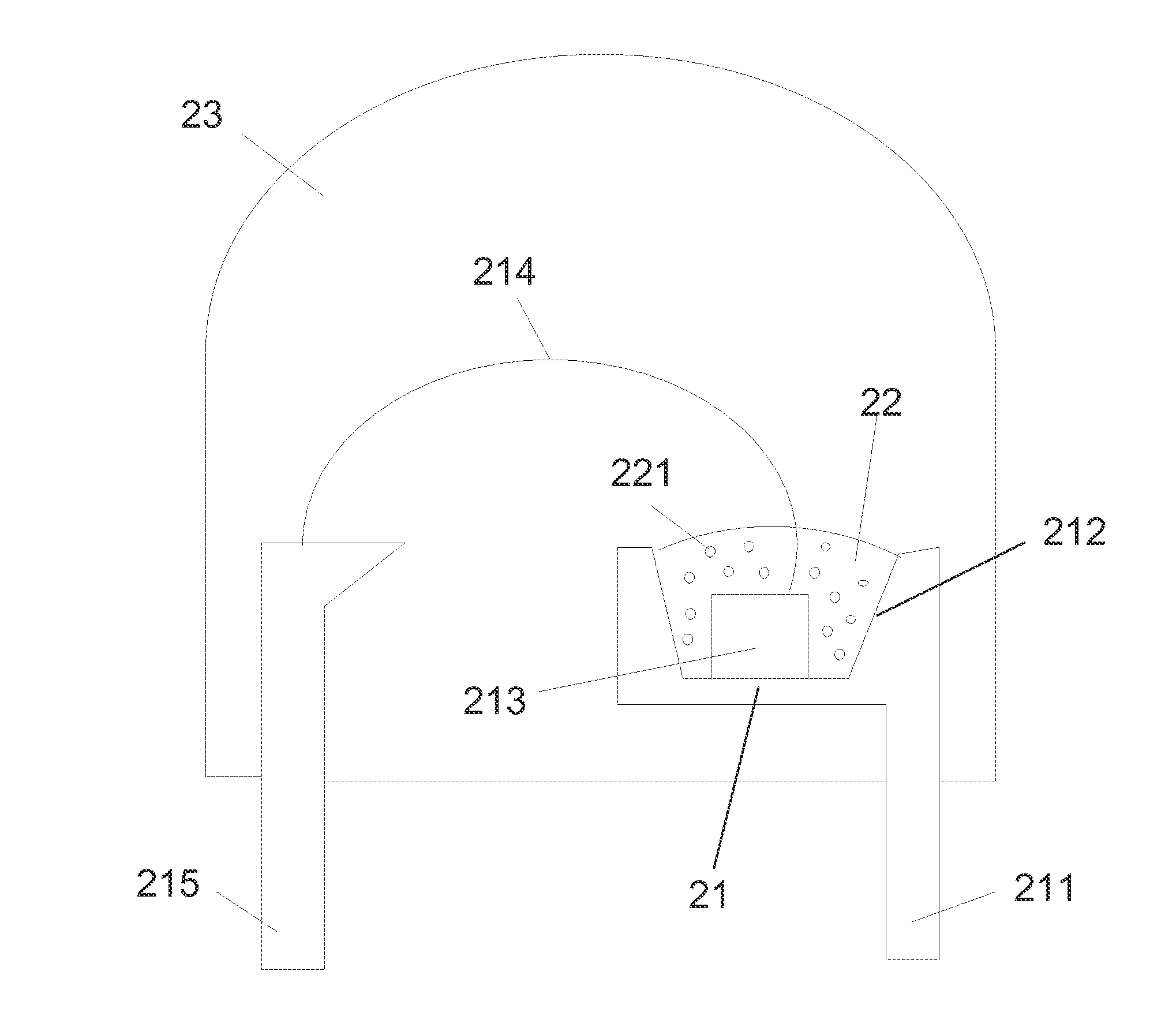

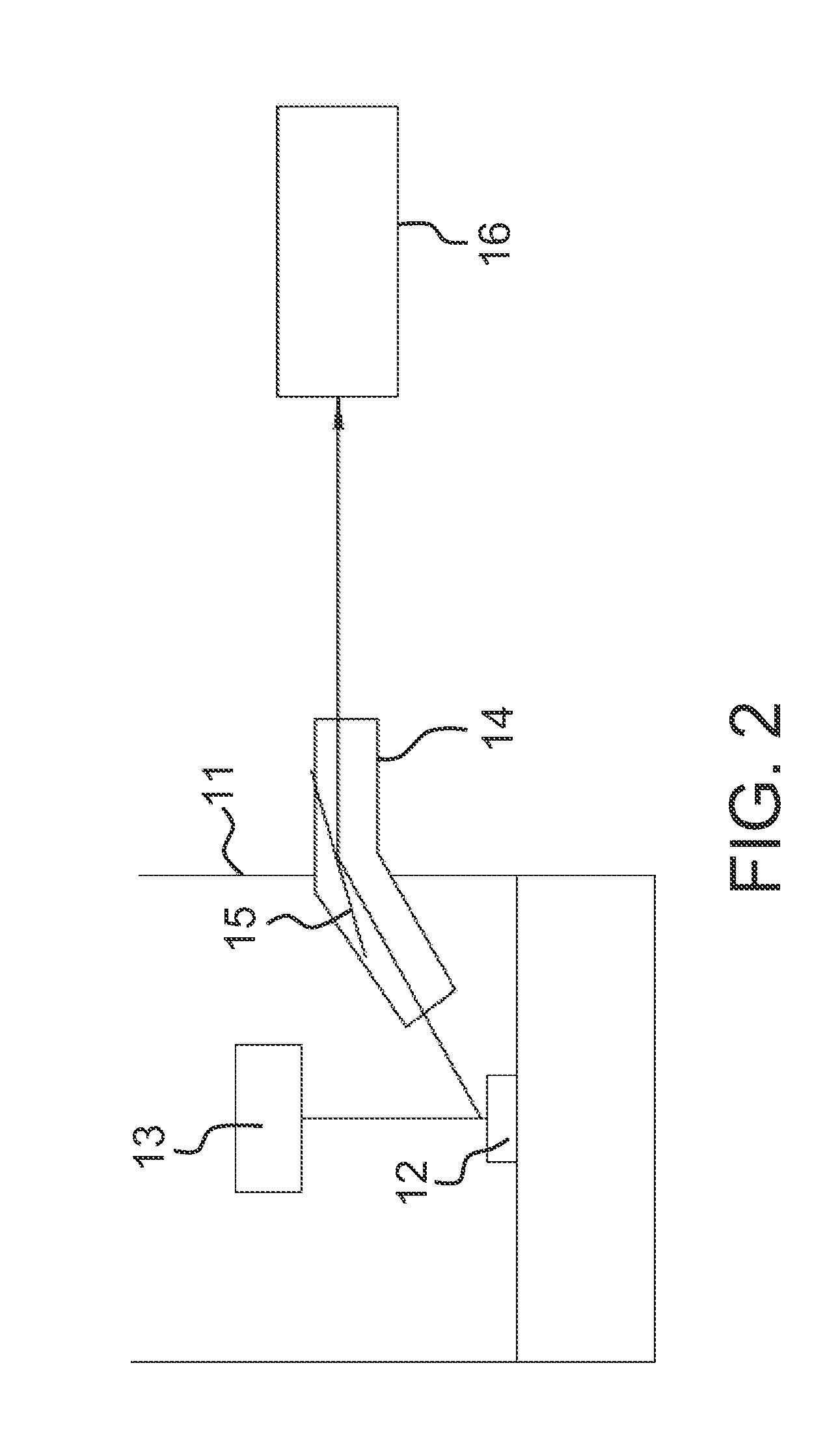

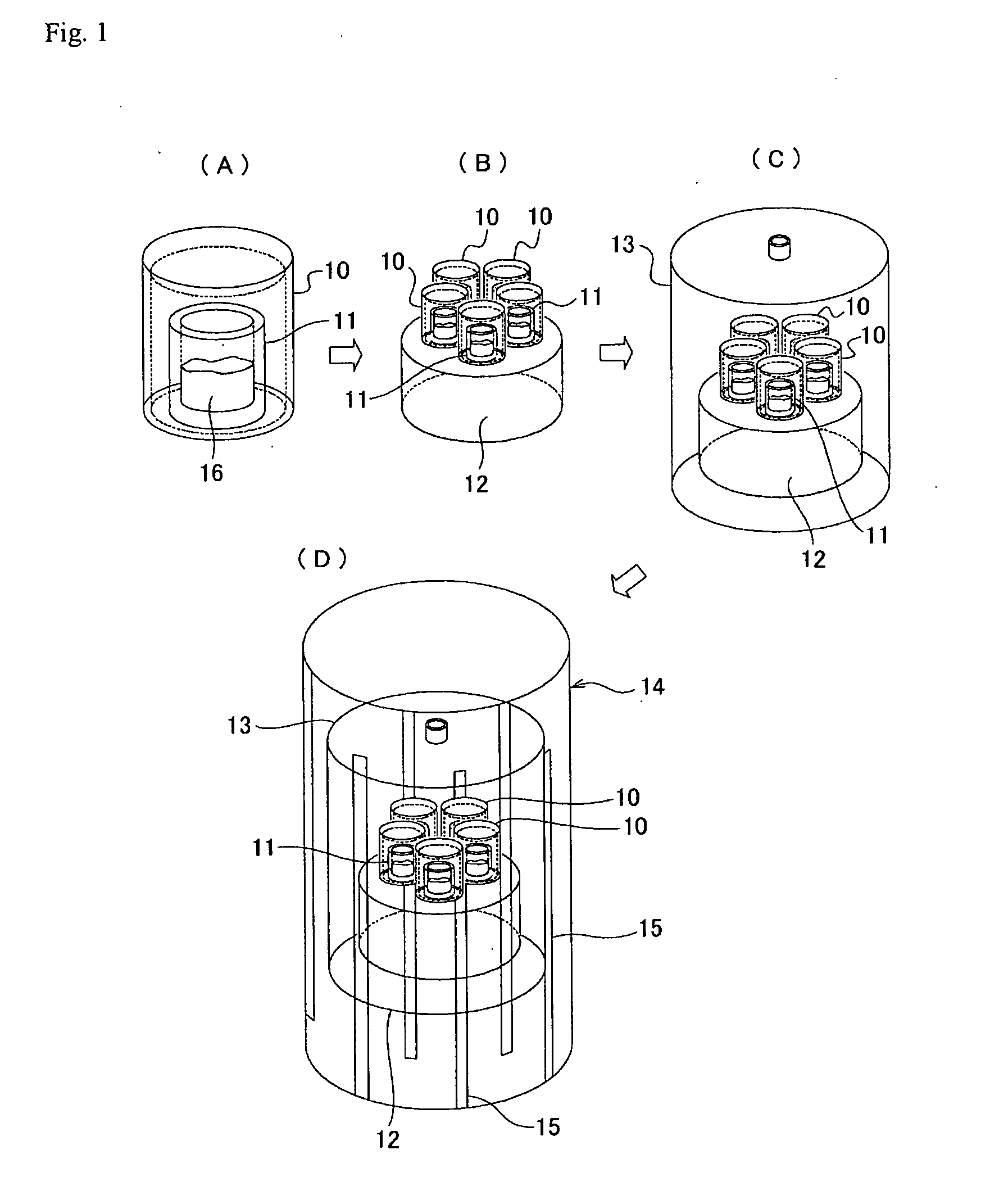

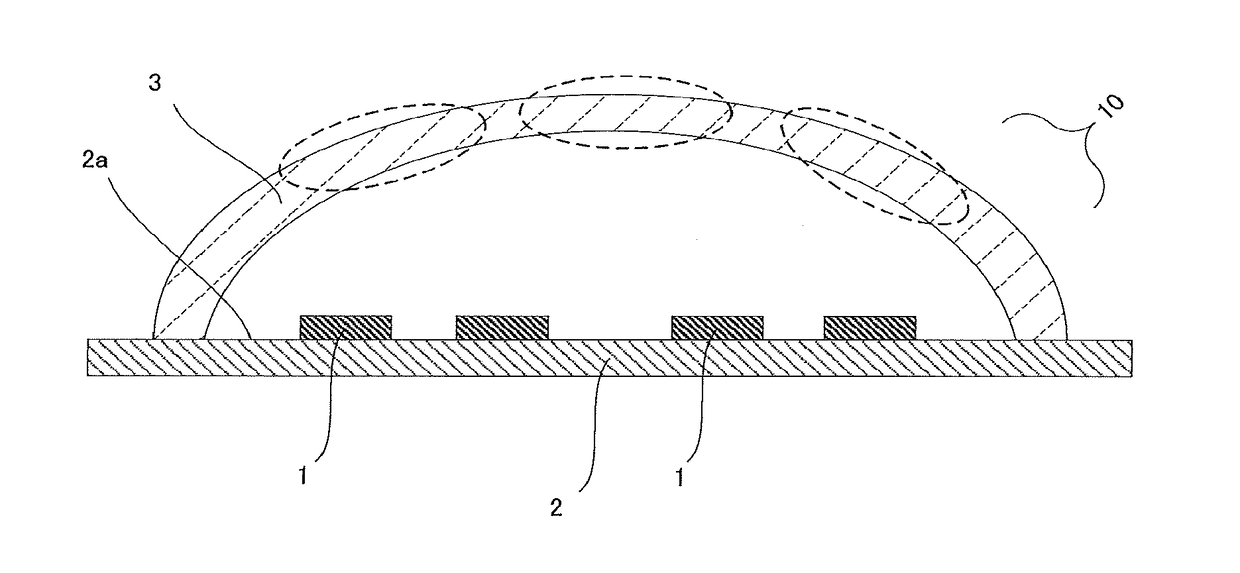

Manufacturing method of nitride phosphor or oxynitride phosphor

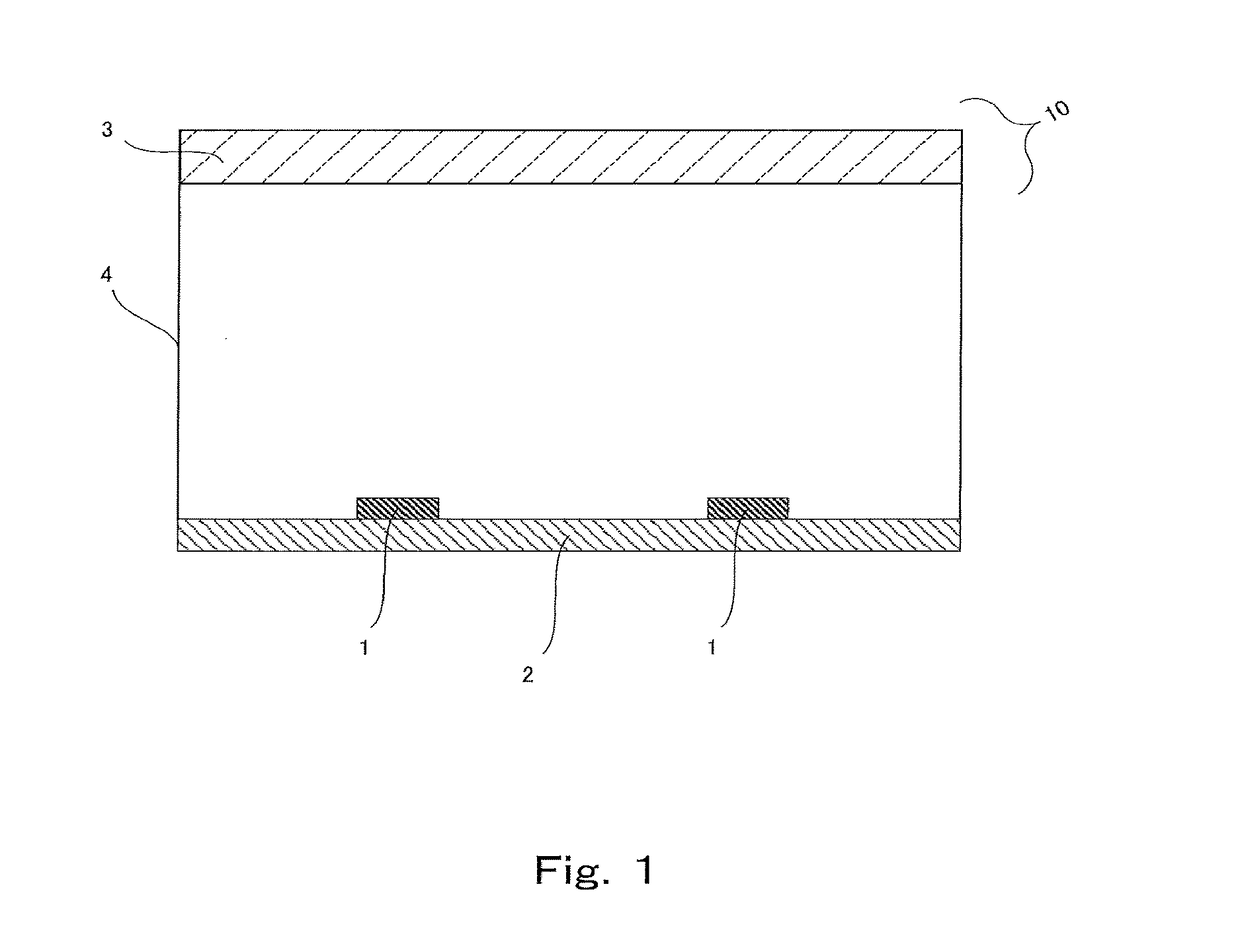

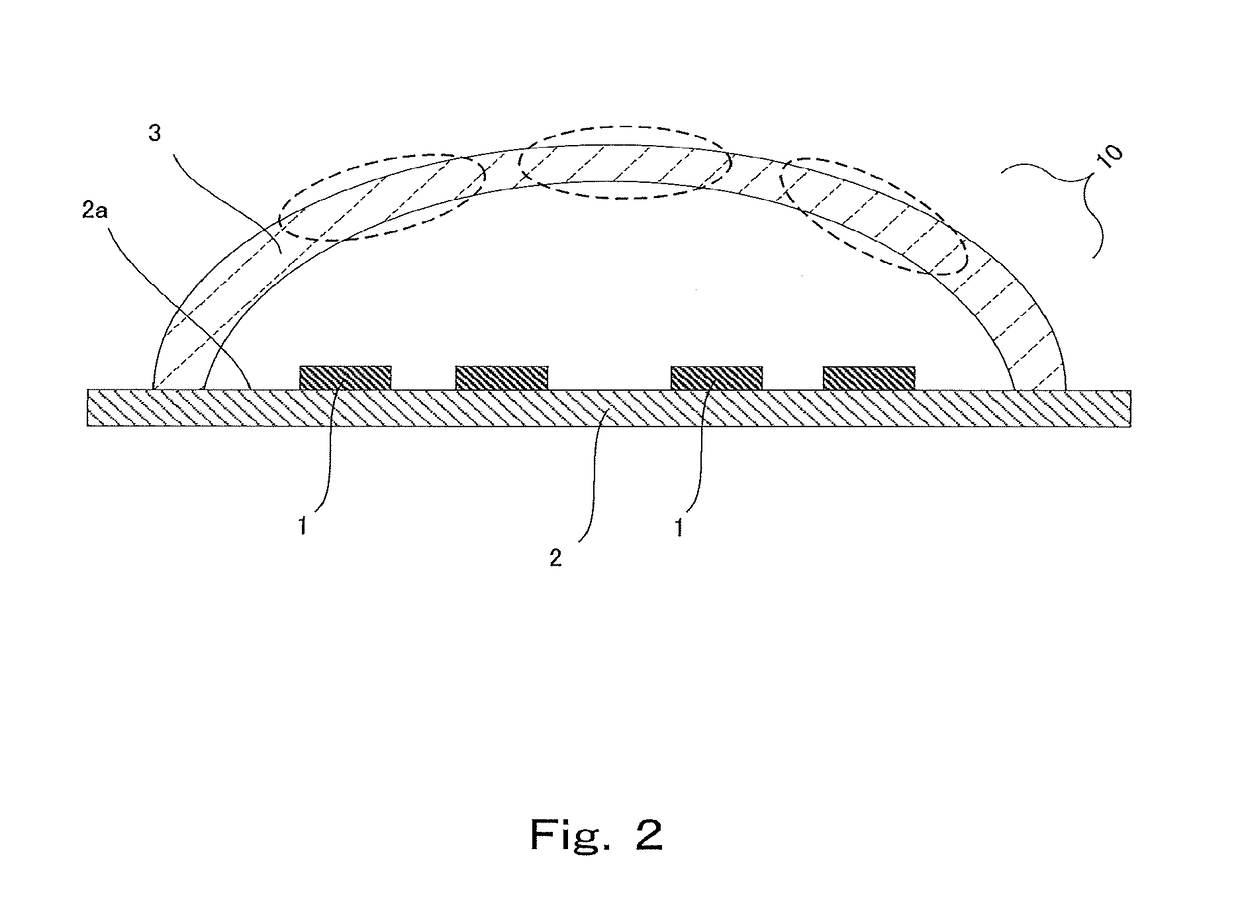

ActiveUS20100001234A1Accelerate emissionsImprove emission efficiencyLuminescent compositionsNitrogen oxidesCrucible

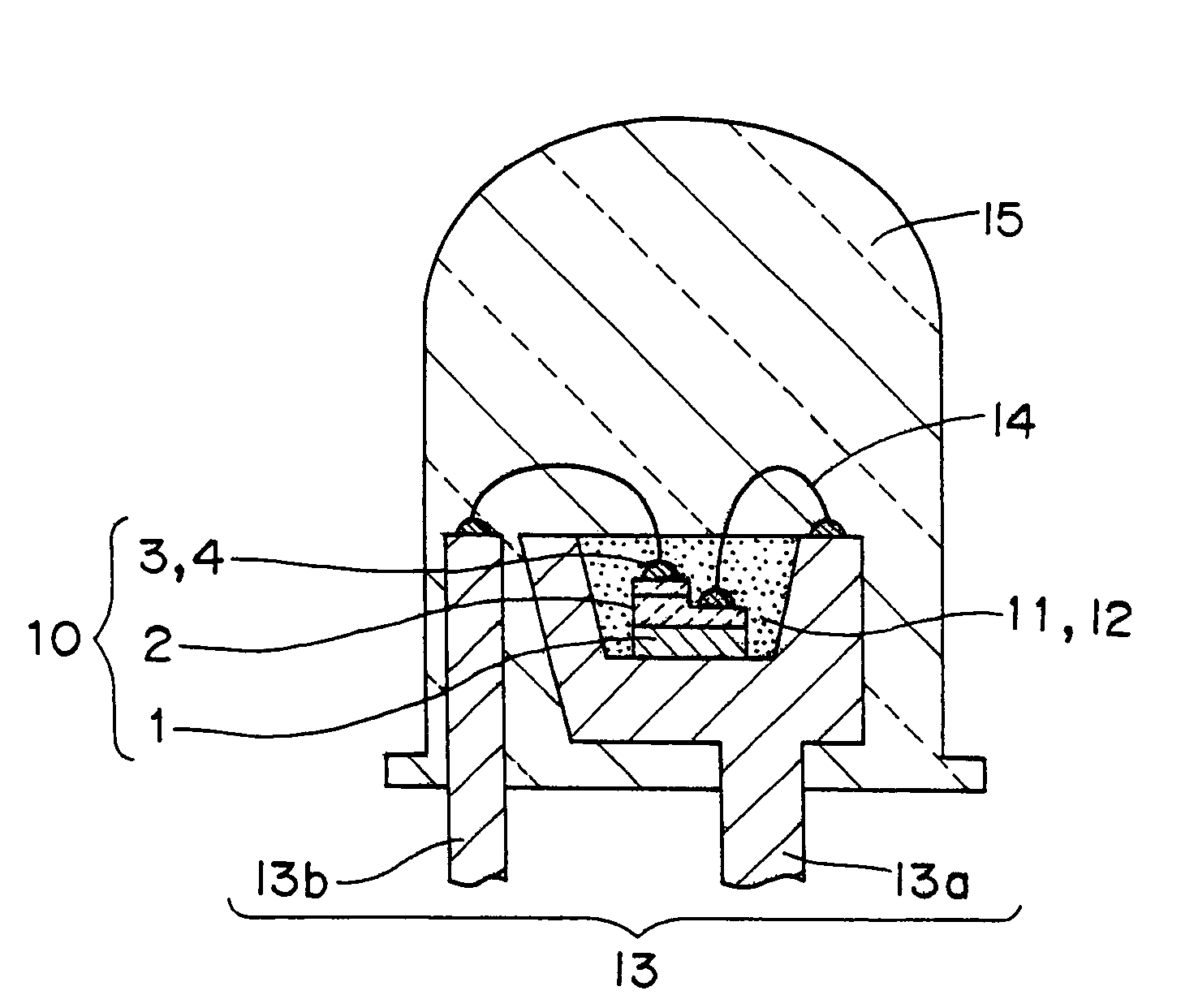

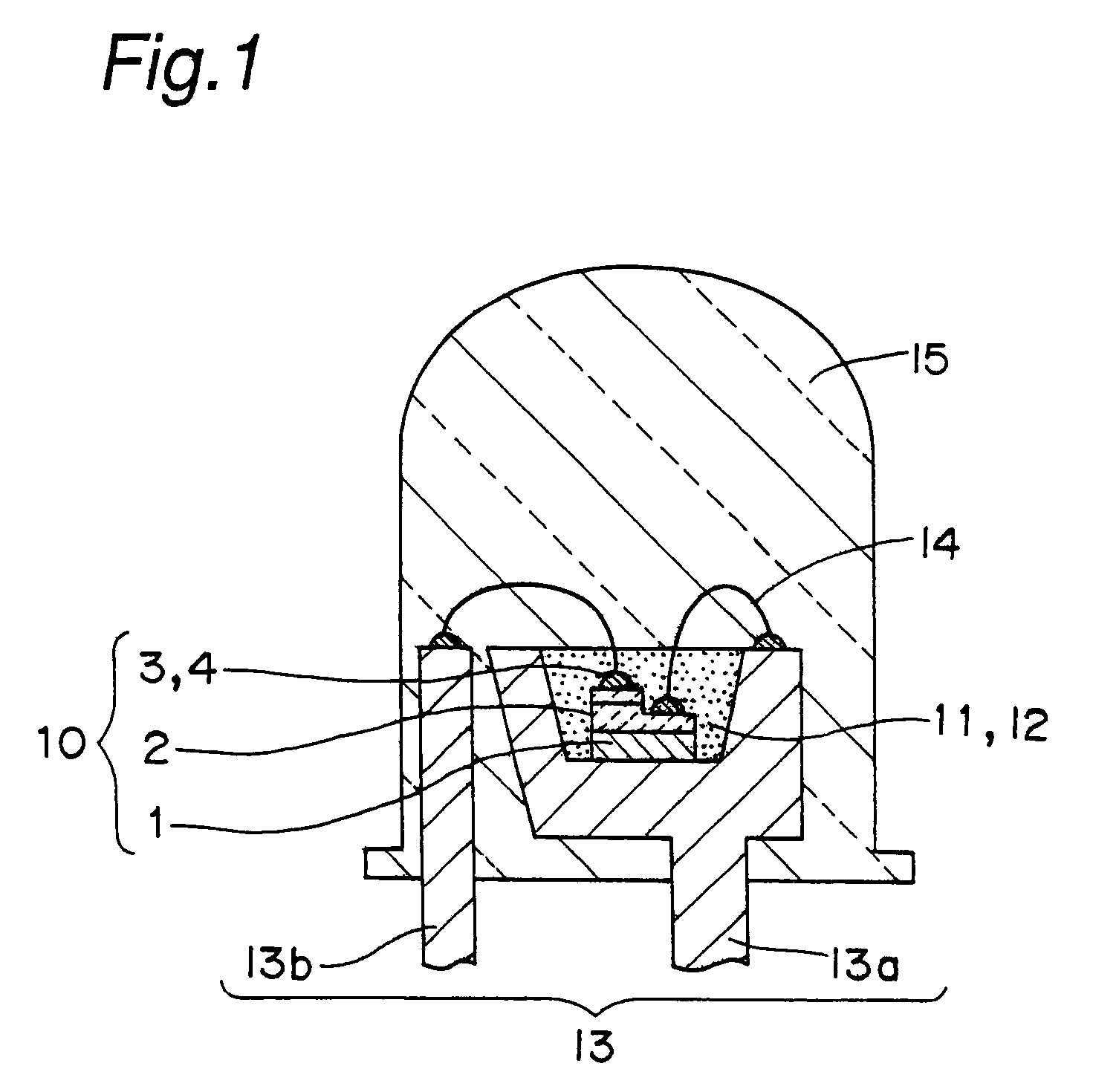

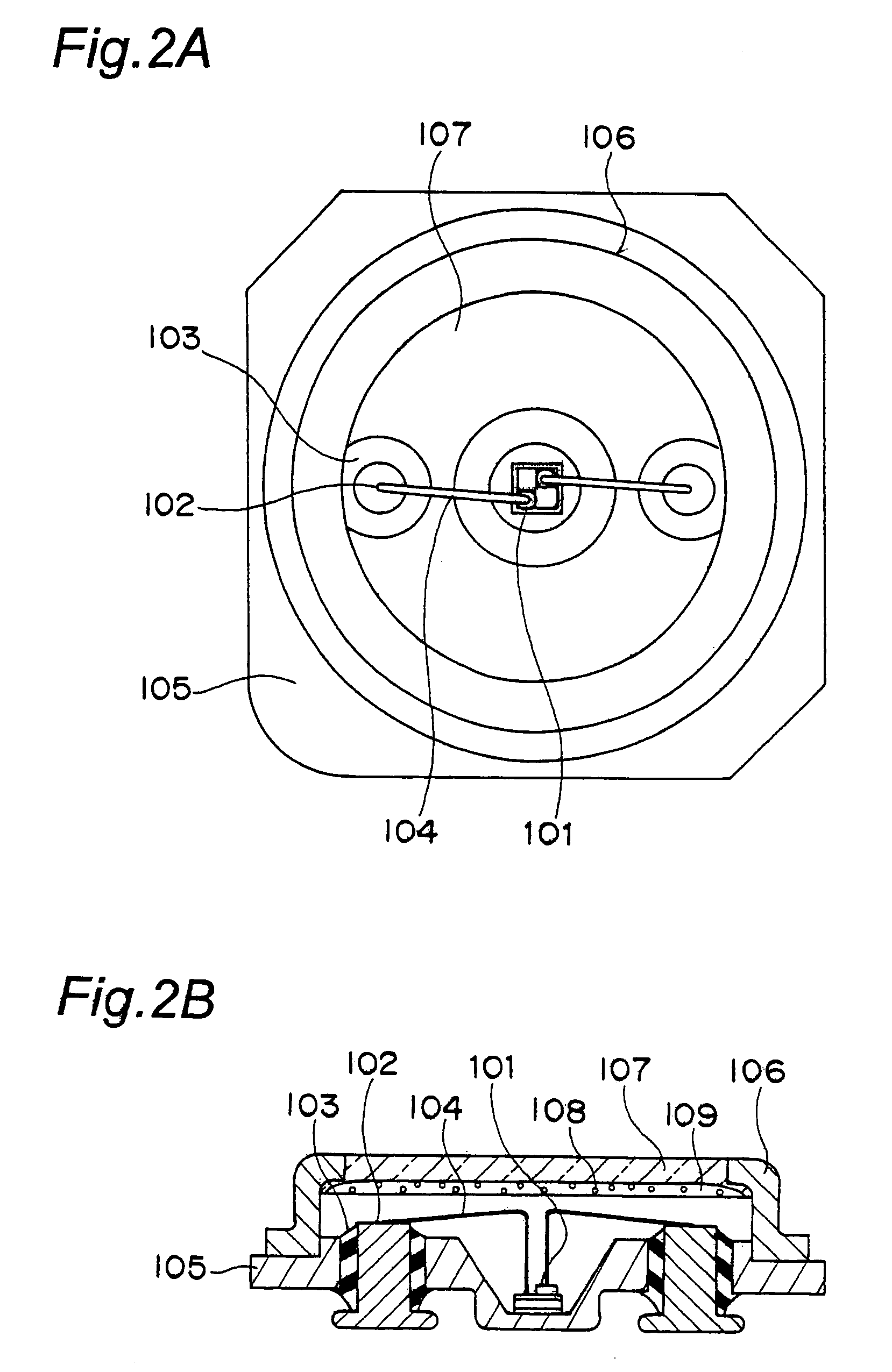

To reduce impurity contents of carbon and oxygen not contributing to light emission, then suppress deterioration of emission intensity of a phosphor, and improve emission efficiency of this phosphor. Therefore, there is provided a firing method of nitride or oxynitride phosphors, wherein a crucible 11 made of nitride is used as a firing container, and firing is performed, with this crucible covered with a lid (container 10), to manufacture the phosphor. The phosphor is expressed by a general composition formula MABOoN3-2 / 3O:Z in which element M is one or more kinds of elements having bivalent valency, element A is one or more kinds of elements having tervalent valency, element B is one or more kinds of elements having tetravalent valency, O is oxygen, N is nitrogen, and element Z is an activating agent, satisfying o≧0.

Owner:NICHIA CORP +1

Phosphor, method of producing the same, and light emitting apparatus

ActiveUS8663498B2Improve efficiencyStable characteristicsMaterial nanotechnologyDischarge tube luminescnet screensLength waveNitride phosphor

Owner:DENKA CO LTD +1

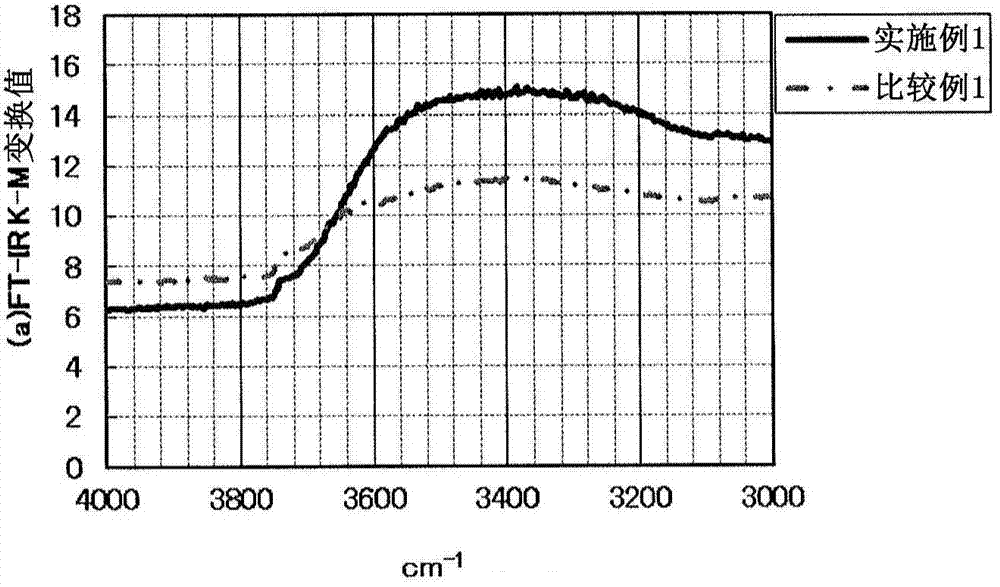

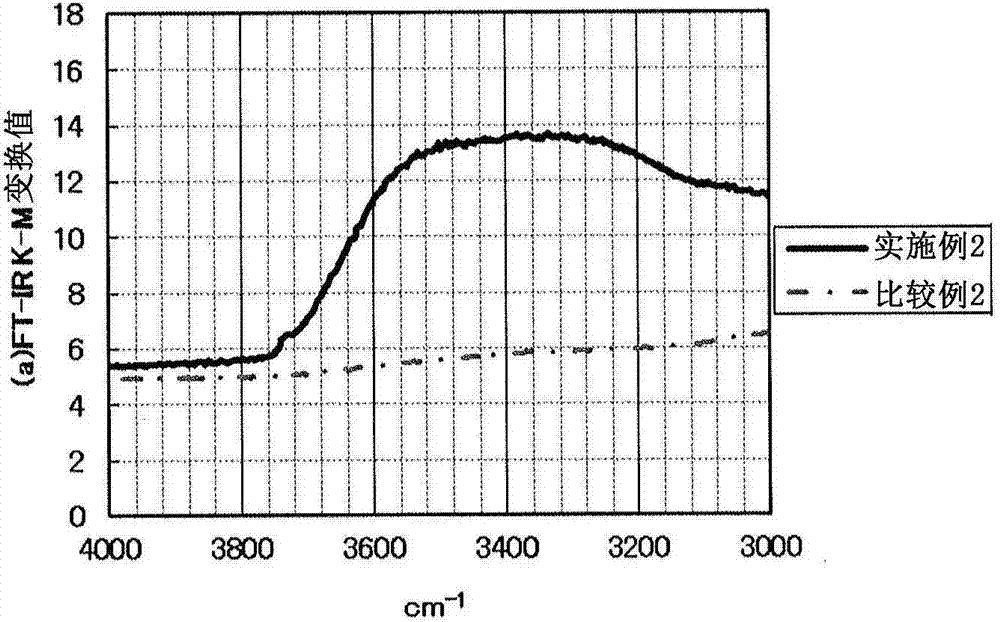

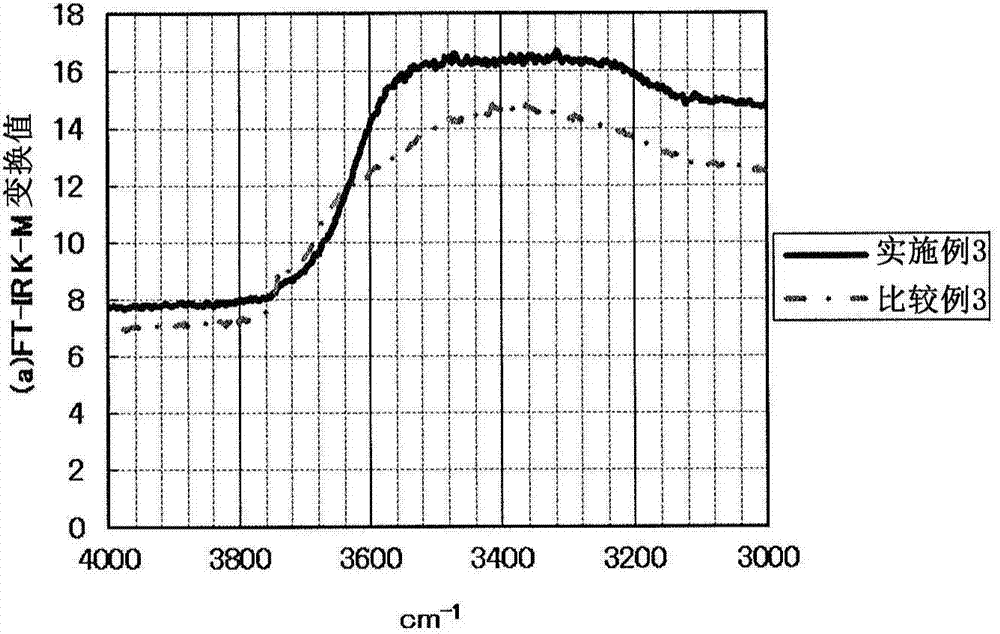

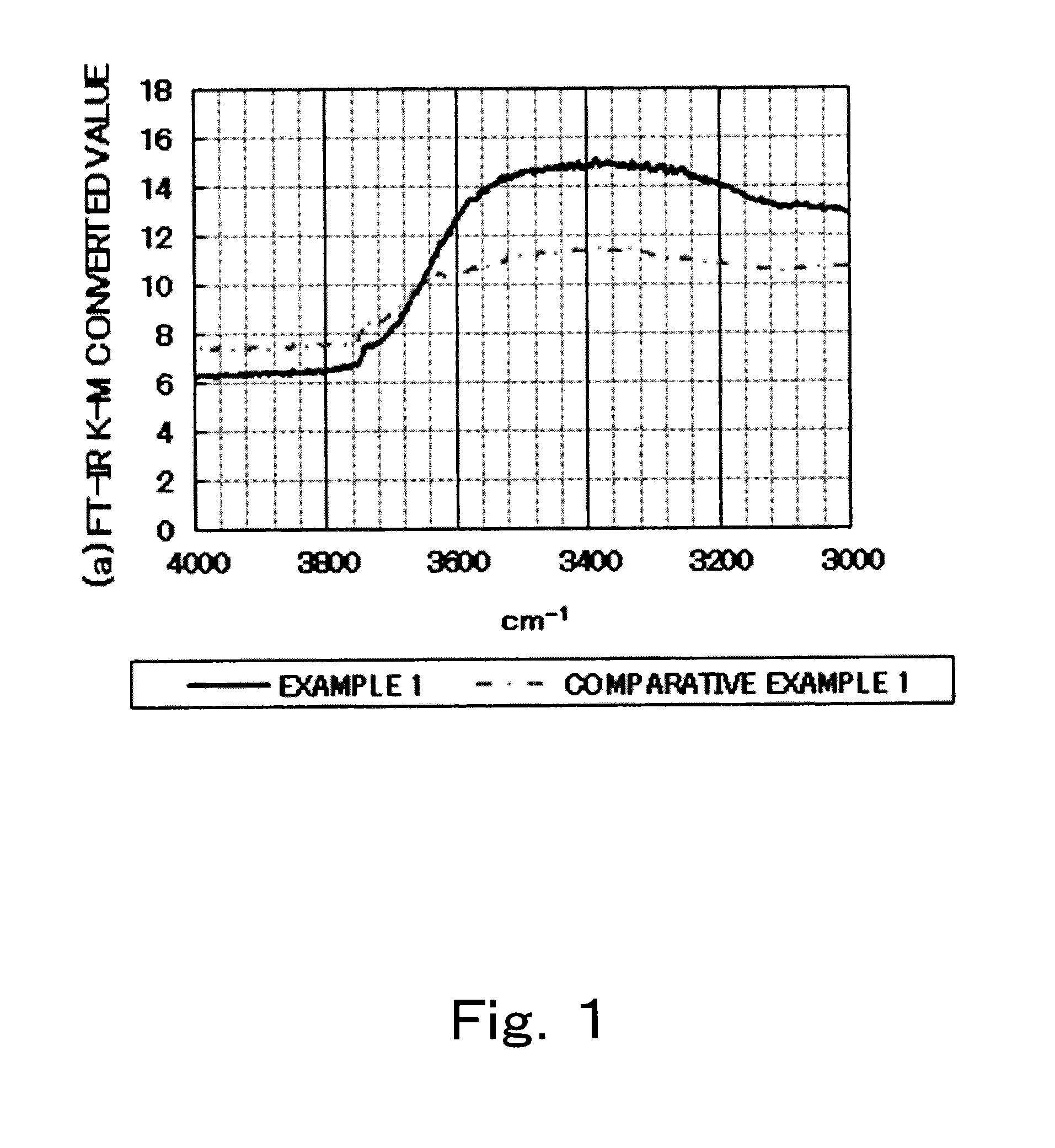

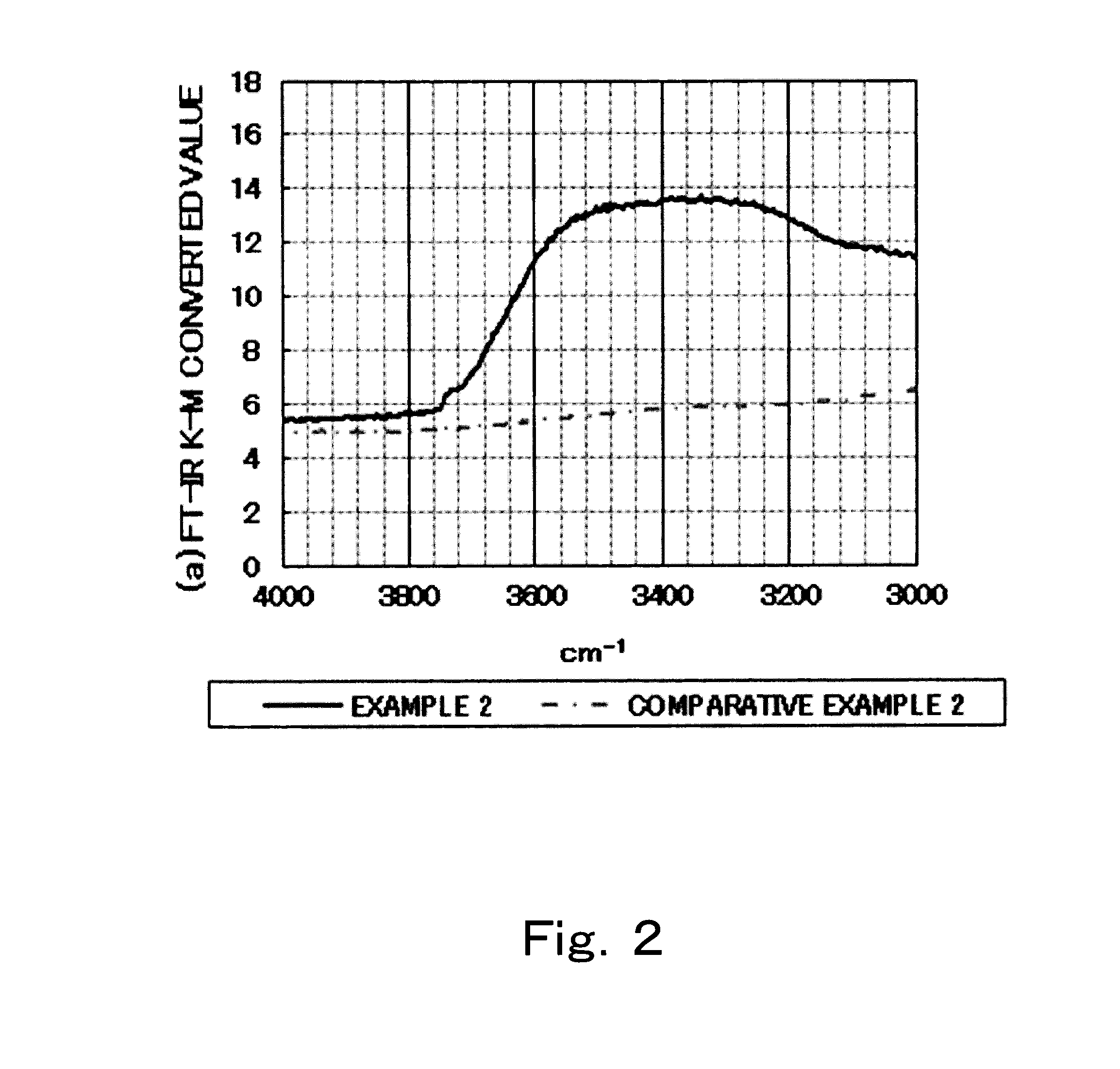

Nitride phosphor and method of producing same

InactiveCN103946340AIncrease brightnessImprove internal quantum efficiencyLuminescent compositionsRare-earth elementQuantum efficiency

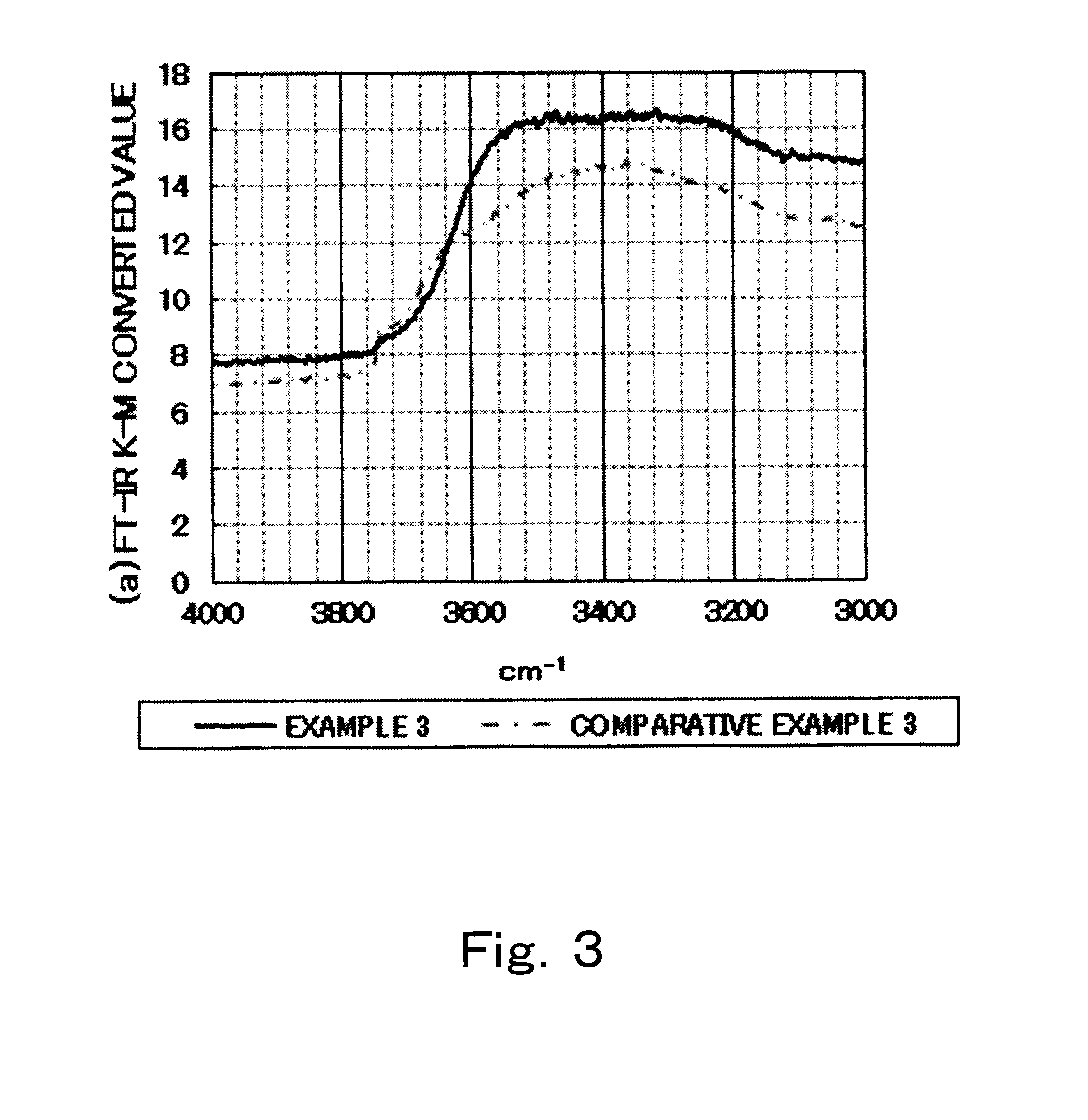

The purpose of the present invention is to provide a nitride phosphor with higher-than-conventional brightness, internal quantum efficiency, and external quantum efficiency. This nitride phosphor is represented by general formula (1) below, and is characterized in that the infrared absorption spectrum, measured by the diffuse reflection method with at least a 2cm-1 or lower measurement interval, satisfies prescribed conditions. LnxSiyNn:Z (1) (In general formula (1), Ln is a rare earth element excluding elements used as activators, Z is an activator, x satisfies 2.7<= x<= 3.3, y satisfies 5.4 <= y <= 6.6, and n satisfies 10 <= n <= 12.)

Owner:MITSUBISHI CHEM CORP

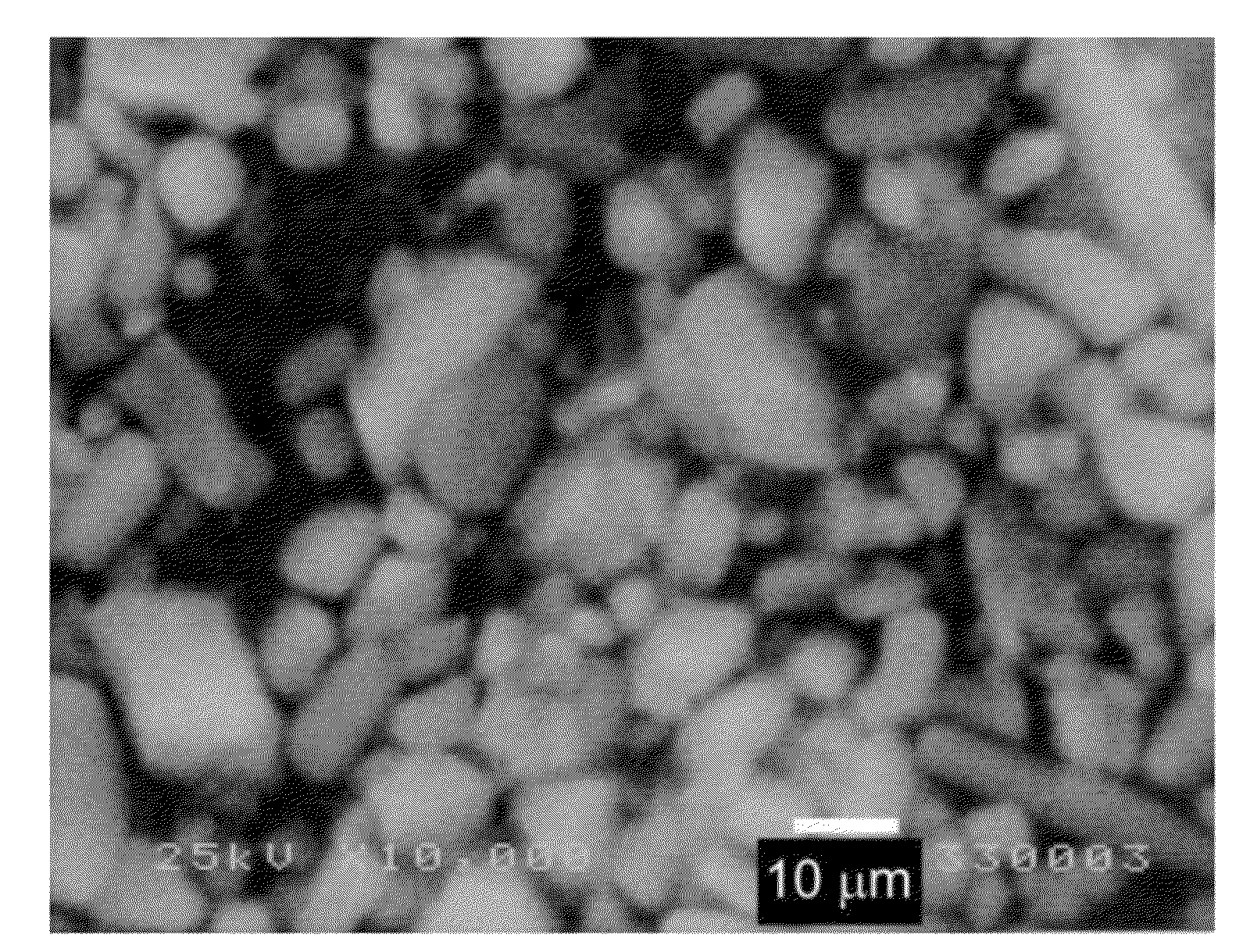

Nitride phosphor and method for manufacturing the same

InactiveUS20140246623A1Improve internal quantum efficiencySolve low luminous efficiencyBleaching apparatusElectrostatic spraying apparatusQuantum efficiencyRare-earth element

Problem to be solved is to provide a nitride phosphor having enhanced luminance, internal quantum efficiency and external quantum efficiency compared to those of conventional nitride phosphors. The nitride phosphor is represented by the general formula (1) shown below and it is characterized in that the infrared spectroscopy measured by the diffuse reflection method at the measurement intervals of 2 cm−1 or lower, satisfies predetermined conditions:LnxSiyNn:Z (1)(In the general formula (1), Ln represents rare earth element excluding the element to be used as an activator, Z represents an activator, x satisfies the condition of 2.7≦x≦3.3, y satisfies the condition of 5.4≦y≦6.6, and n satisfies the condition of 10≦n≦12.)

Owner:MITSUBISHI CHEM CORP

Nitride phosphor, reaction mixture and method production and light emitting device comprising such a phosphor

InactiveUS20120228550A1Improve efficiencyLow priceSolid-state devicesSemiconductor lamp usageDisplay deviceRare earth

Provided are a method for preparing a rare-earth doped alkaline-earth silicon nitride phosphor powder having the composition of Me2-xRxSi5N8-yF3y (0<x<1.0, 0≦y<0.5) within seconds at ambient temperature; the nitride phosphor prepared therefrom; and a light emitting device comprising the phosphor.Such silicon nitride based phosphors having small particle size, large surface area and improved chemical properties can strongly absorb UV and blue light and efficiently convert it into orange-red light, so that they can be used as an effective phosphor to form a smooth layer without sedimentation in a LED package, and as light sources and displays. Especially for applying the fine particles to a LED package, cost reduction can be achieved with respect to the weight ratio.

Owner:ELLIM ADVANCED MATERIALS

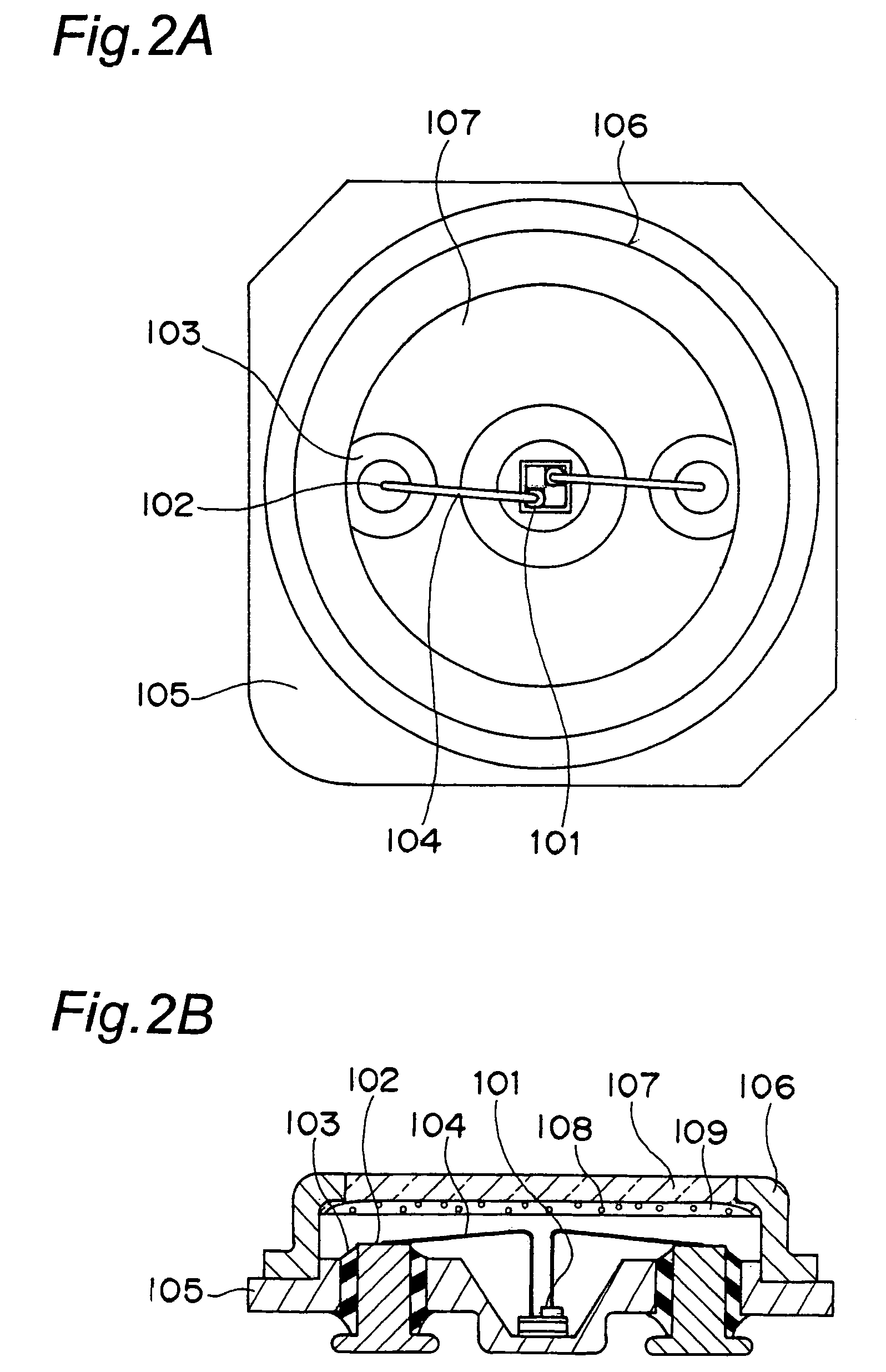

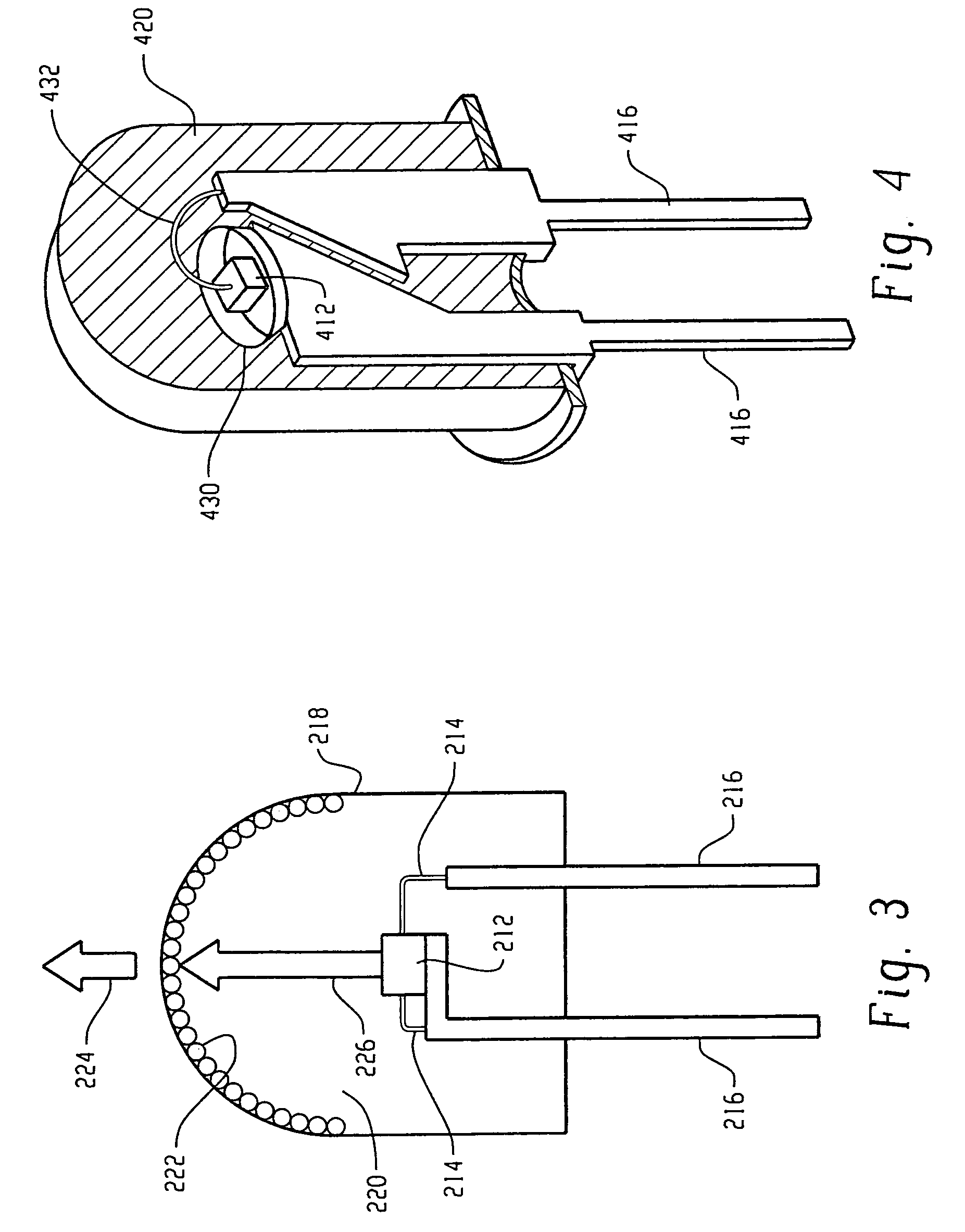

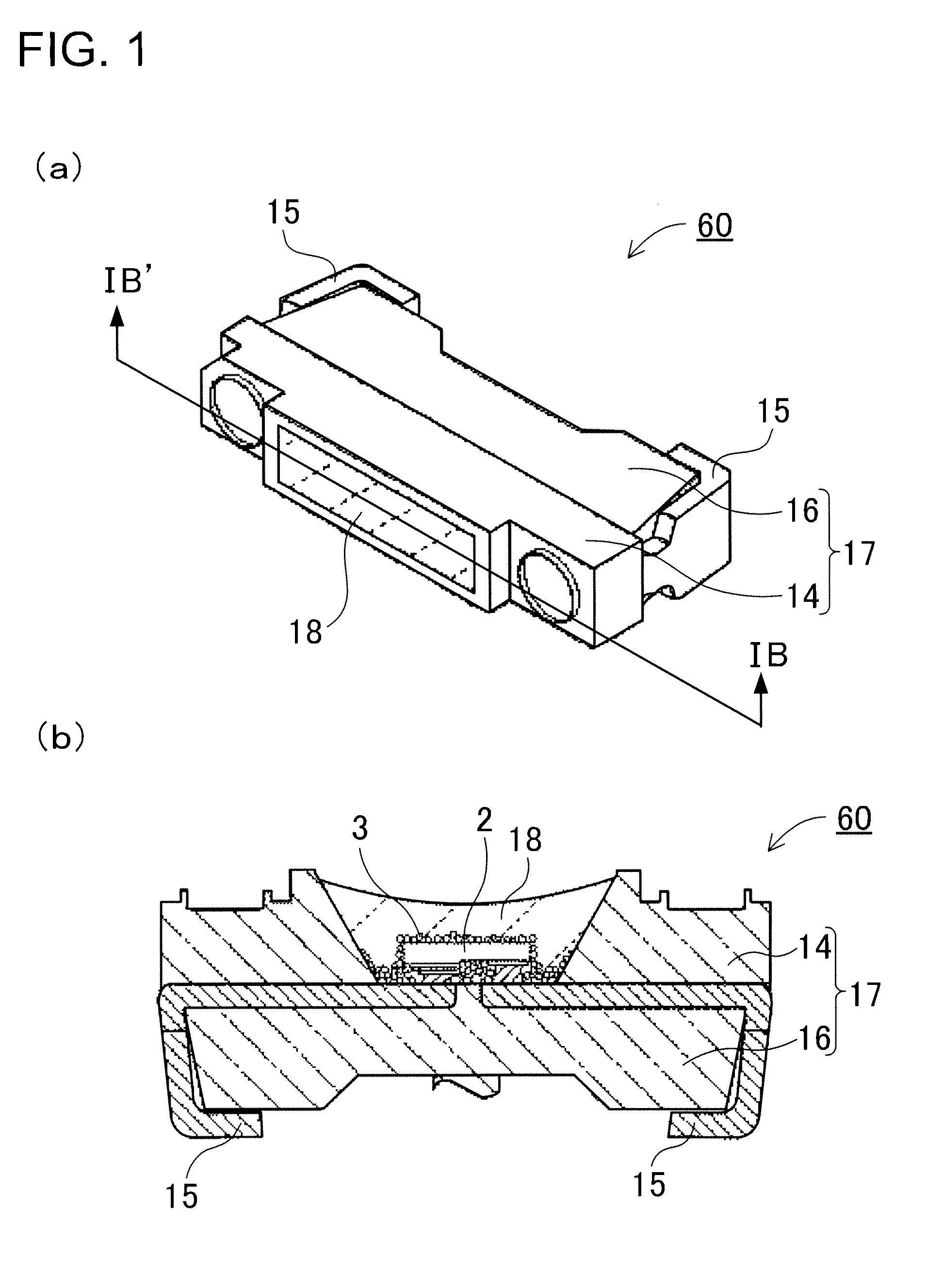

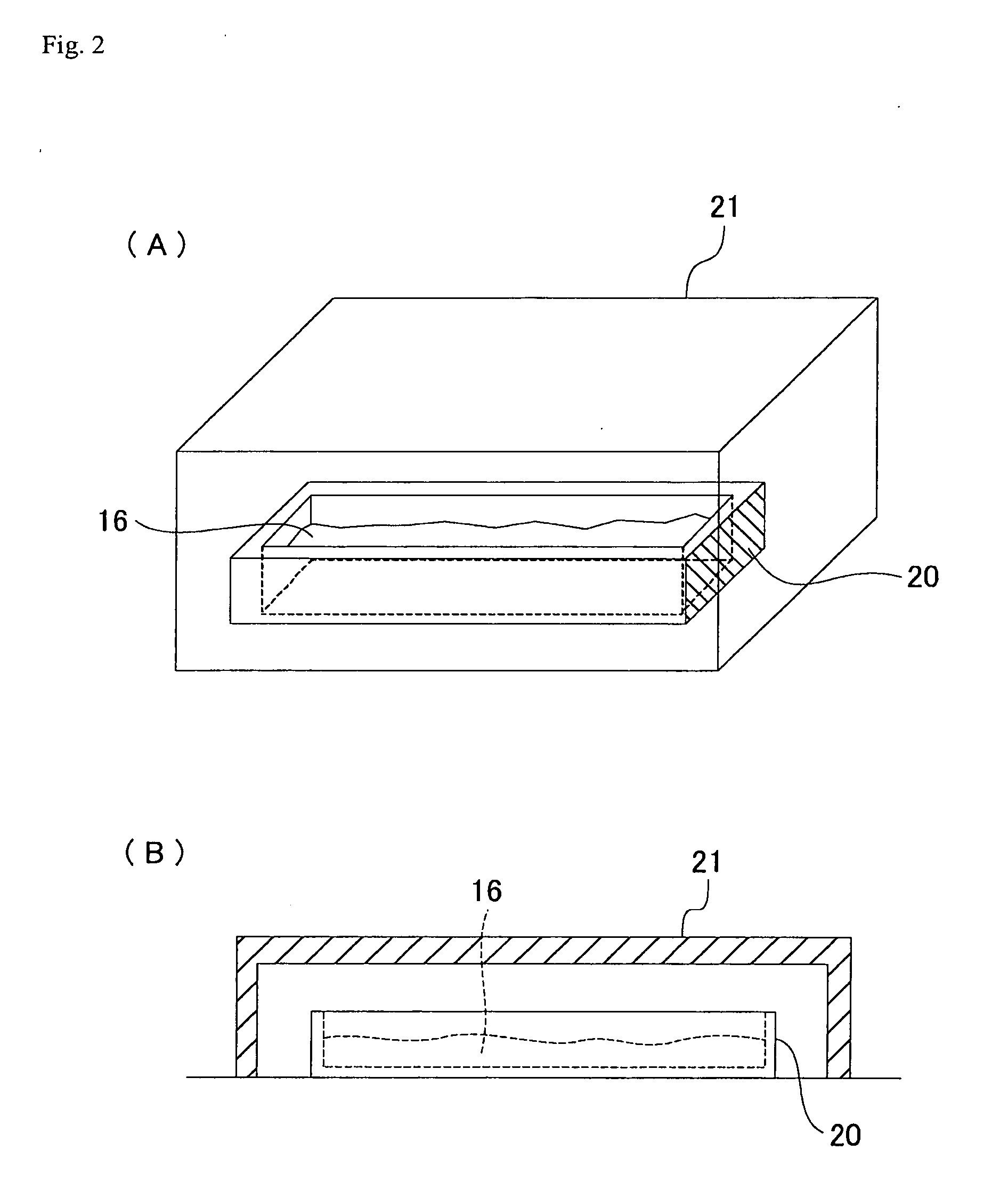

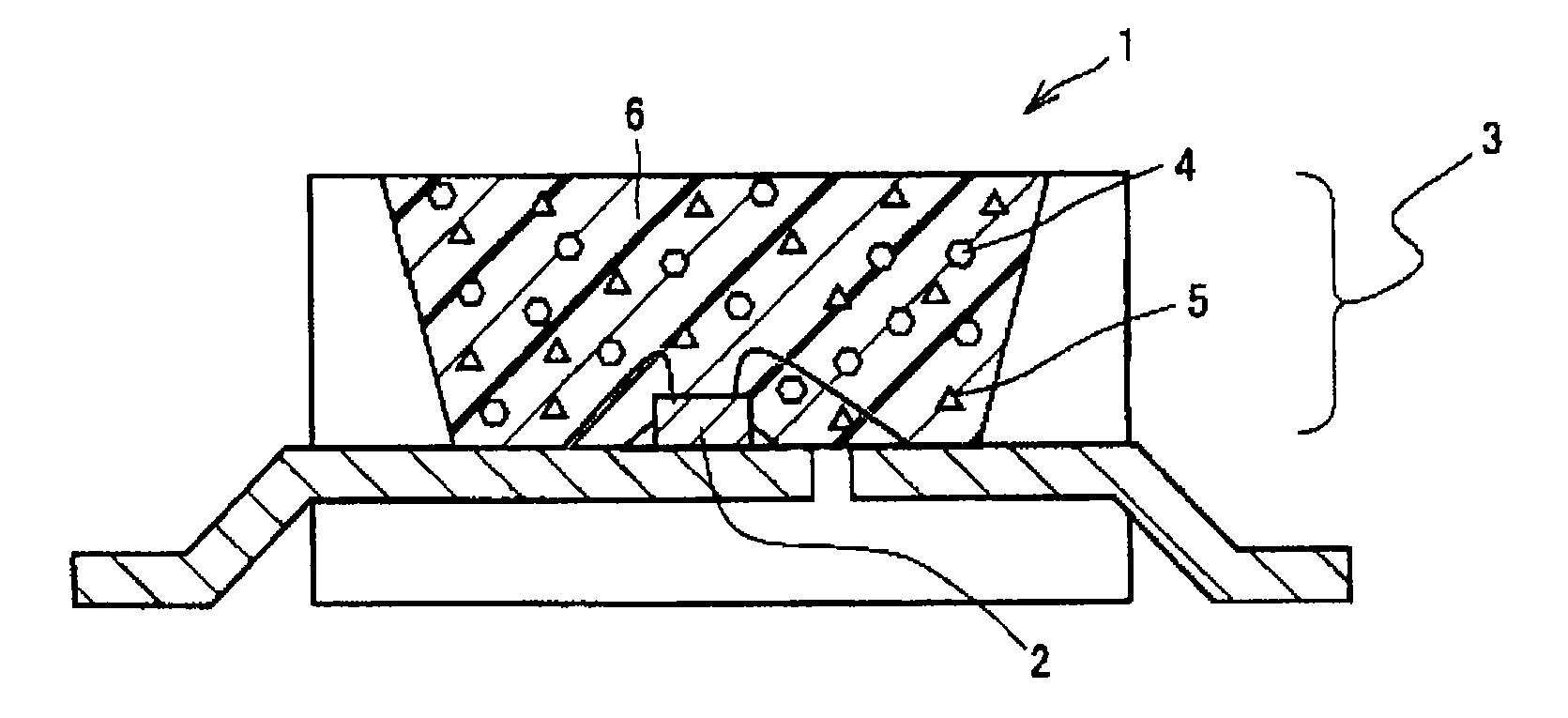

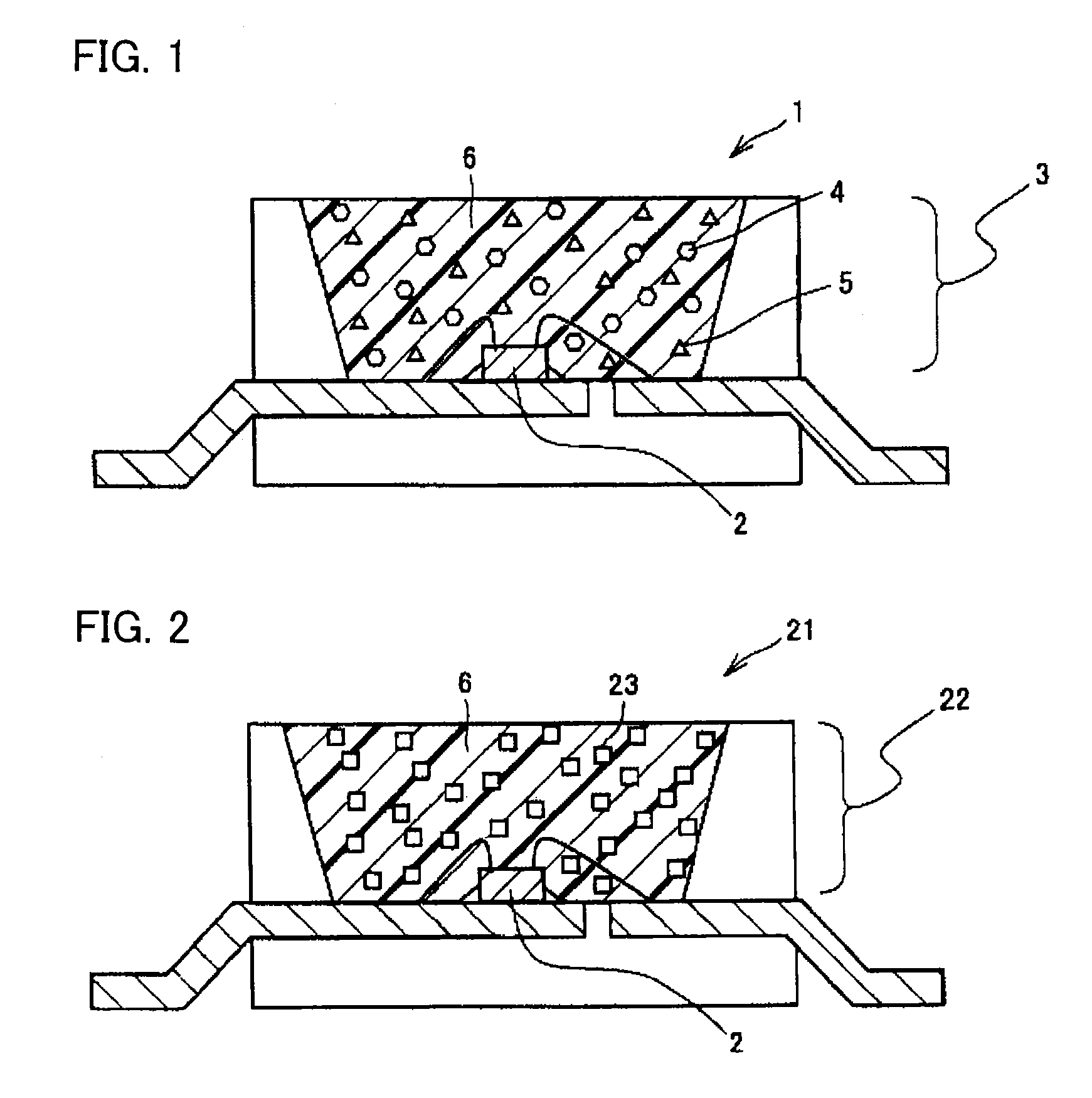

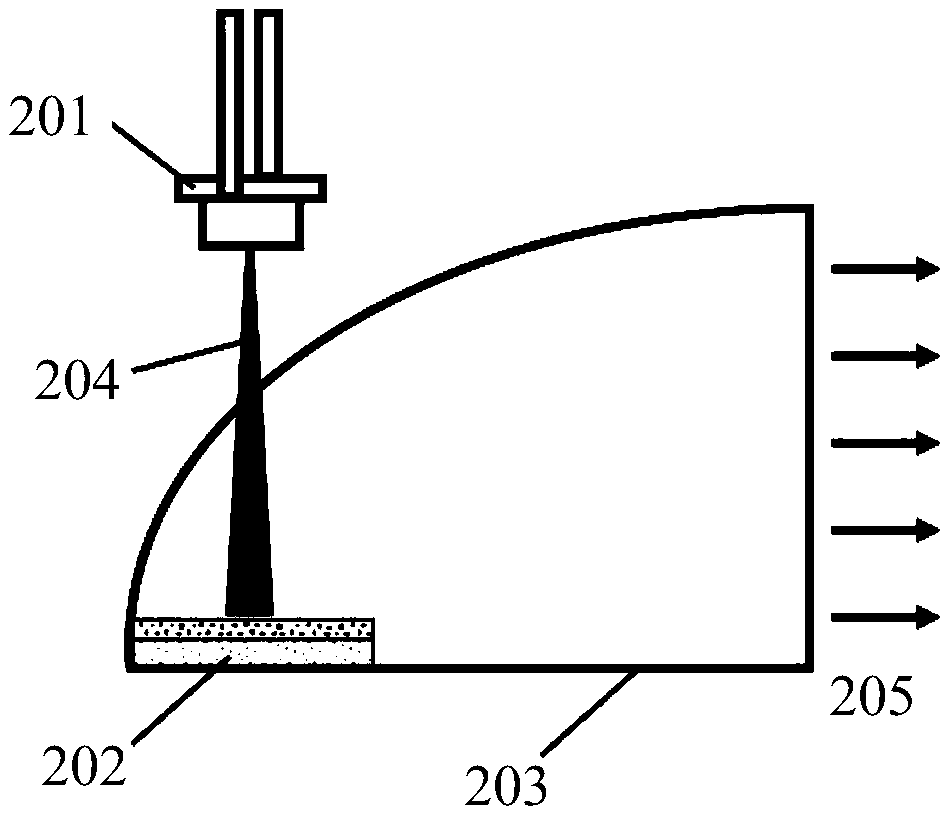

Sintered phosphor, light emitting device, illumination device, vehicle headlamp, and method for manufacturing sintered phosphor

ActiveUS20170321866A1Improve heat resistanceReduce Brightness VariationsVehicle headlampsOptical signallingFluorescenceMaterials science

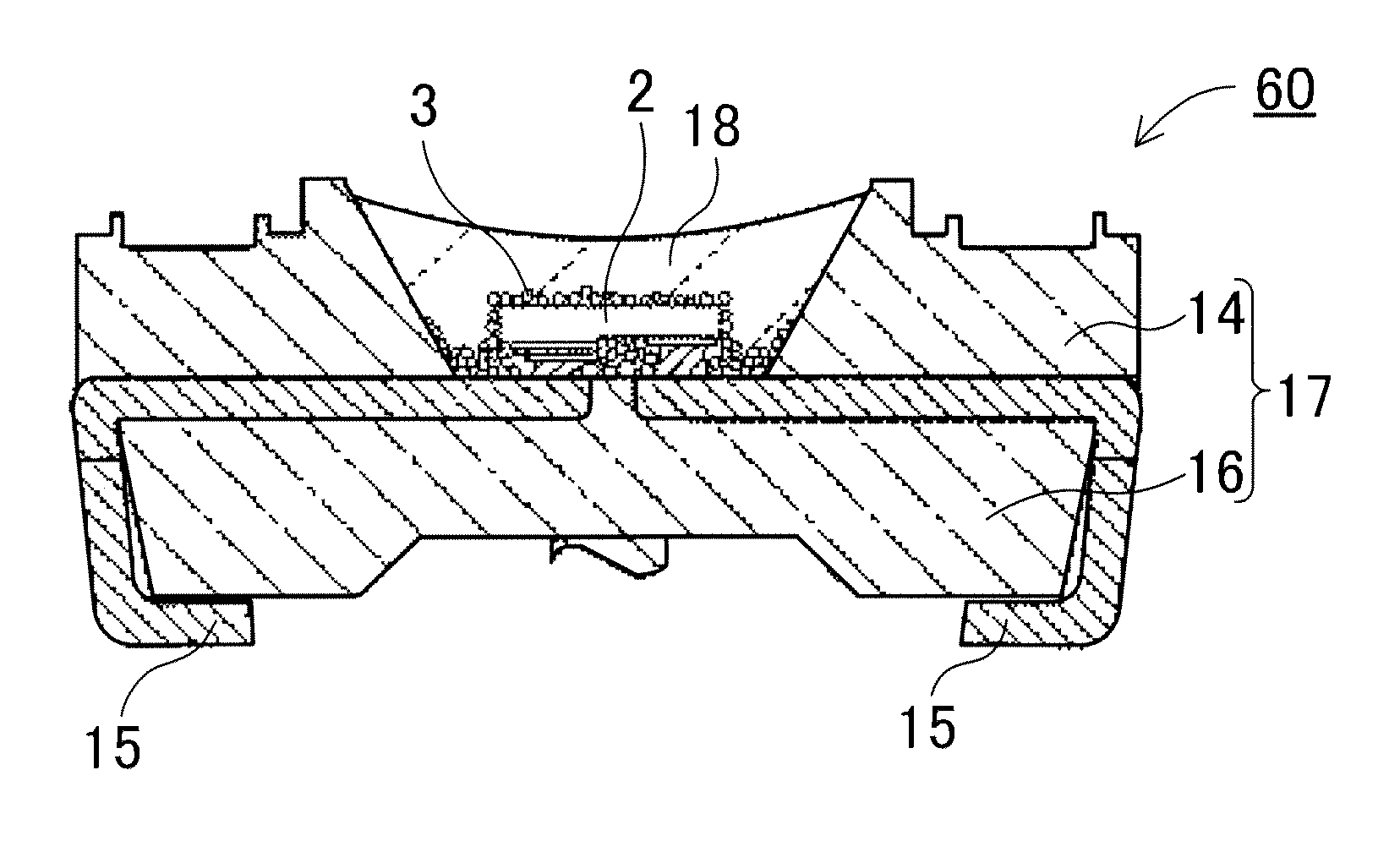

Provided is a sintered phosphor-composite for an LED, having high heat resistance, high thermal conductivity, high luminance, and high conversion efficacy. In addition, there are provided: a light-emitting apparatus which uses the sintered phosphor-composite; and an illumination apparatus and a vehicular headlamp which use the light-emitting apparatus. The sintered phosphor-composite includes a nitride phosphor and a fluoride inorganic binder. The sintered phosphor-composite preferably has an internal quantum efficiency of 60% or more when excited by blue light having a wavelength of 450 nm. Further, the sintered phosphor-composite preferably has a transmittance of 20% or more at a wavelength of 700 nm.

Owner:MITSUBISHI CHEM CORP

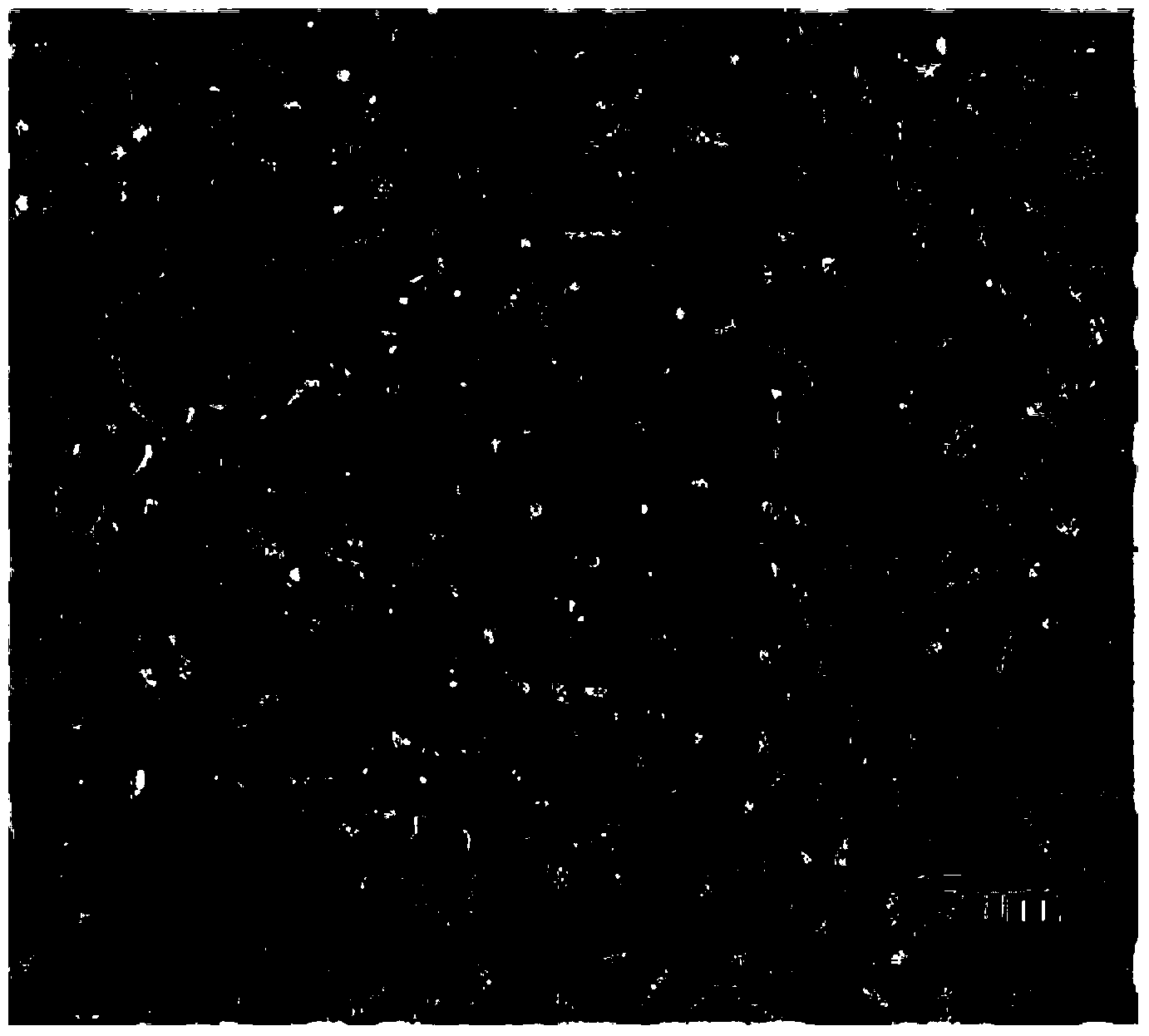

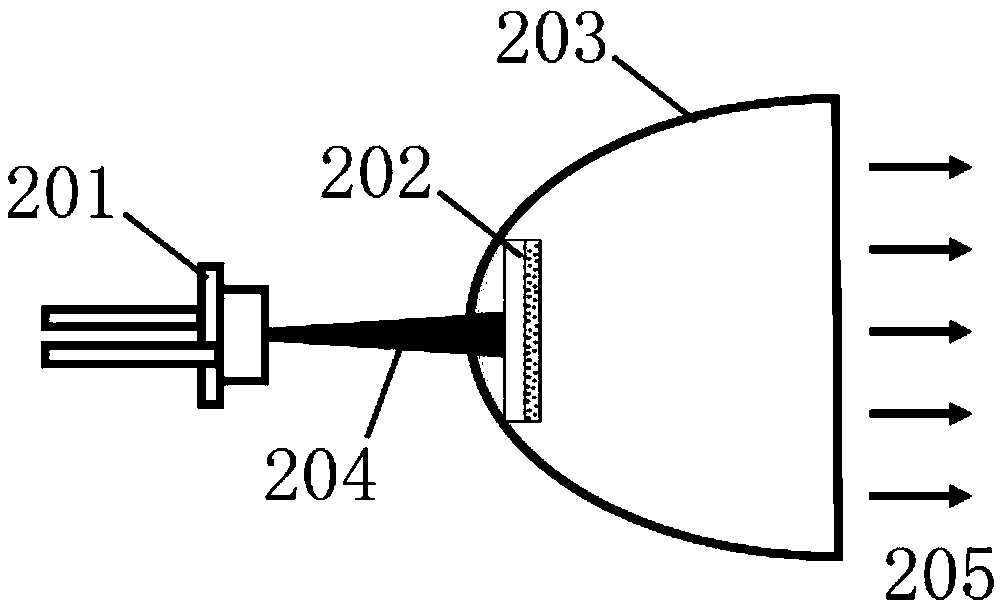

Nitride phosphor/glass composite optical conversion kit for laser illumination and preparation thereof

InactiveCN108895314AImprove quantum efficiencyExcellent thermal quenching performanceSemiconductor devices for light sourcesGlass compositesSlurry

The invention relates to a nitride phosphor / glass composite optical conversion kit for laser illumination and a preparation thereof, which relates to light conversion components. Nitride phosphor / glass composite optical conversion kit for laser illumination comprises a nitride phosphor / glass composite coating and a high thermal conductivity ceramic substrate, the nitride phosphor / glass composite coating is closely grown on the high thermal conductivity ceramic substrate. The preparation of phosphor slurry: the nitride phosphor / glass composite optical conversion kit is prepared for laser illumination. The nitride phosphor / glass composite optical conversion kit can be used in laser illumination. The luminous efficiency above 280 lm / W can be obtained by coupling the provided nitride phosphor / glass composite optical conversion kit for laser illumination with a laser source with emission wavelength about 450 nanometers.

Owner:XIAMEN UNIV

Light-emitting device

ActiveCN1924427AGood colorSmall deviation of black trackLight source combinationsGas discharge lamp usageFluorescenceCerium

A light-emitting device includes a light-emitting element emitting primary light and a wavelength conversion portion absorbing a part of the primary light and emitting secondary light having a wavelength equal to or longer than the wavelength of the primary light. The wavelength conversion portion includes a plurality of green or yellow light-emitting phosphors and a plurality of red light-emitting phosphors. The green or yellow light-emitting phosphor is implemented by at least one selected from a specific europium (II)-activated silicate phosphor (A-1) and a specific cerium (III)-activated silicate phosphor (A-2). The red light-emitting phosphor is implemented by a specific europium (II)-activated nitride phosphor (B). The light-emitting device emitting white light at efficiency and color rendering property higher than in a conventional example can thus be provided.

Owner:SHARP KK

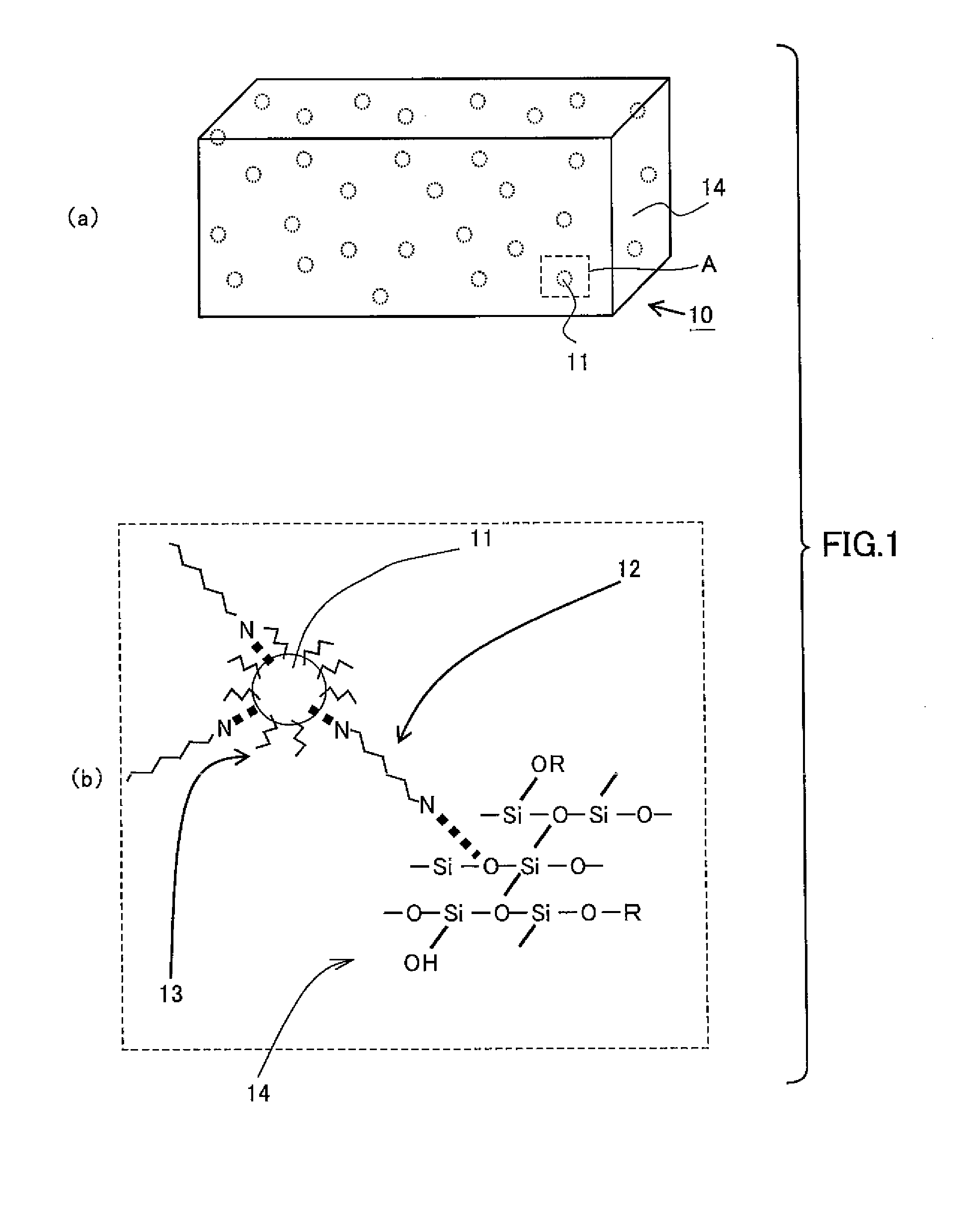

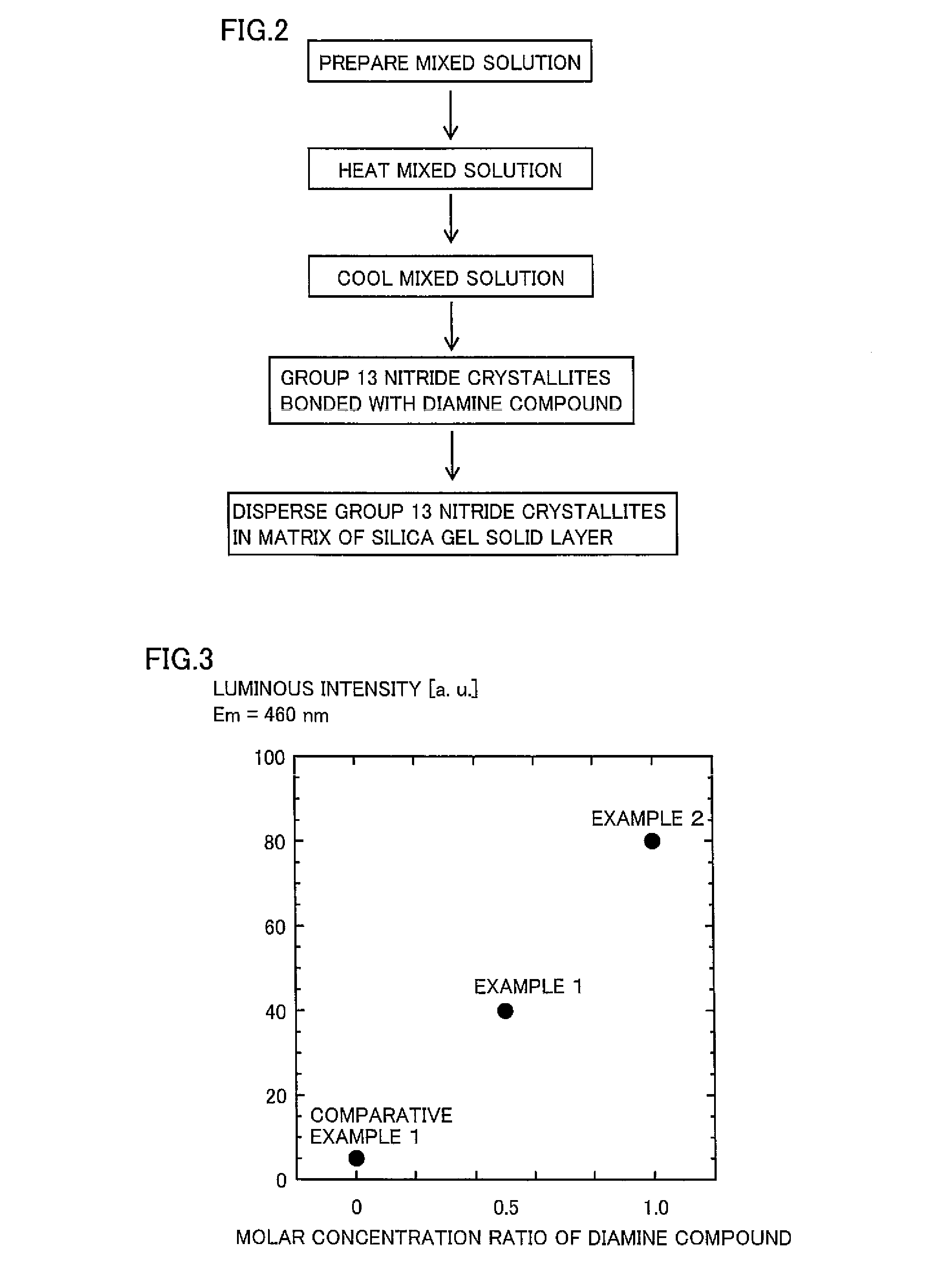

Group 13 nitride phosphor and method of preparing the same

InactiveUS20080283801A1Synthetic is simpleHigh luminous intensityConductive materialOxide conductorsLuminous intensitySilica gel

Provided are a group 13 nitride phosphor having high luminous intensity and excellent reliability obtained by preparing group 13 nitride crystallites homogeneously dispersible in a solid matrix by capping surface defects and homogeneously dispersing the group 13 nitride crystallites in the solid matrix and an efficient method of preparing the same. The present invention relates to a group 13 nitride phosphor consisting of group 13 nitride crystallites having a group 13 element dispersed in a matrix of a silica gel solid layer, with a diamine compound bonded to the surfaces of the group 13 nitride crystallites and the silica gel solid layer, and a method of preparing the same.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com