(Oxy) Nitride phosphor, white light-emitting device and method of preparing phosphor

A nitride phosphor, oxynitride technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve problems such as red phosphors that have not yet been developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

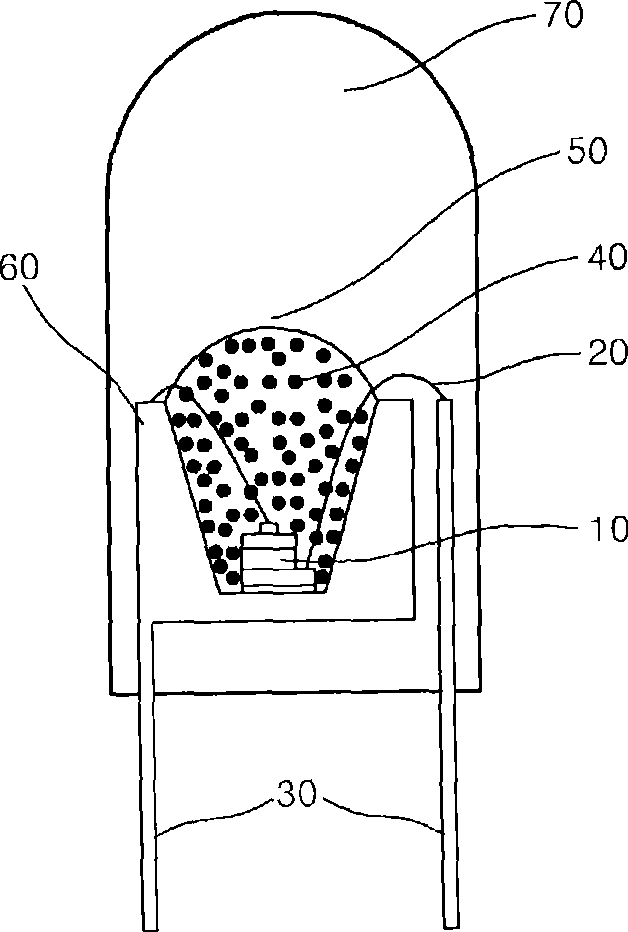

[0055] According to an exemplary embodiment, there is provided a white light emitting device including a UV-LED and the above-mentioned (oxy)nitride phosphor. The (oxy)nitride phosphor has pores.

[0056] The UV-LED is an excitation source emitting electromagnetic radiation in the ultraviolet or near ultraviolet region of the electromagnetic spectrum.

[0057] In the white light emitting device, the excitation wavelength of the UV-LED ranges from about 390 to about 460 nm.

[0058] According to an exemplary embodiment, the white light emitting device may further include at least one phosphor selected from blue phosphors, green phosphors, or a combination including at least one of blue phosphors or green phosphors.

[0059] The blue phosphor can be (Sr, Ba, Ca) 5 (PO 4 ) 3 Cl:Eu 2+ ;BaMg 2 al 16 o 27 :Eu 2+ ;Sr 4 al 14 o 25 :Eu 2+ ;BaAl 8 o 13 :Eu 2+ ;(Sr, Mg, Ca, Ba) 5 (PO 4 ) 3 Cl:Eu 2+ ; BaMgAl 10 o 17 : Eu 2+ ;Sr 2 Si 3 o 8 2SrCl 2 :Eu 2+ ; or a ...

Embodiment 1

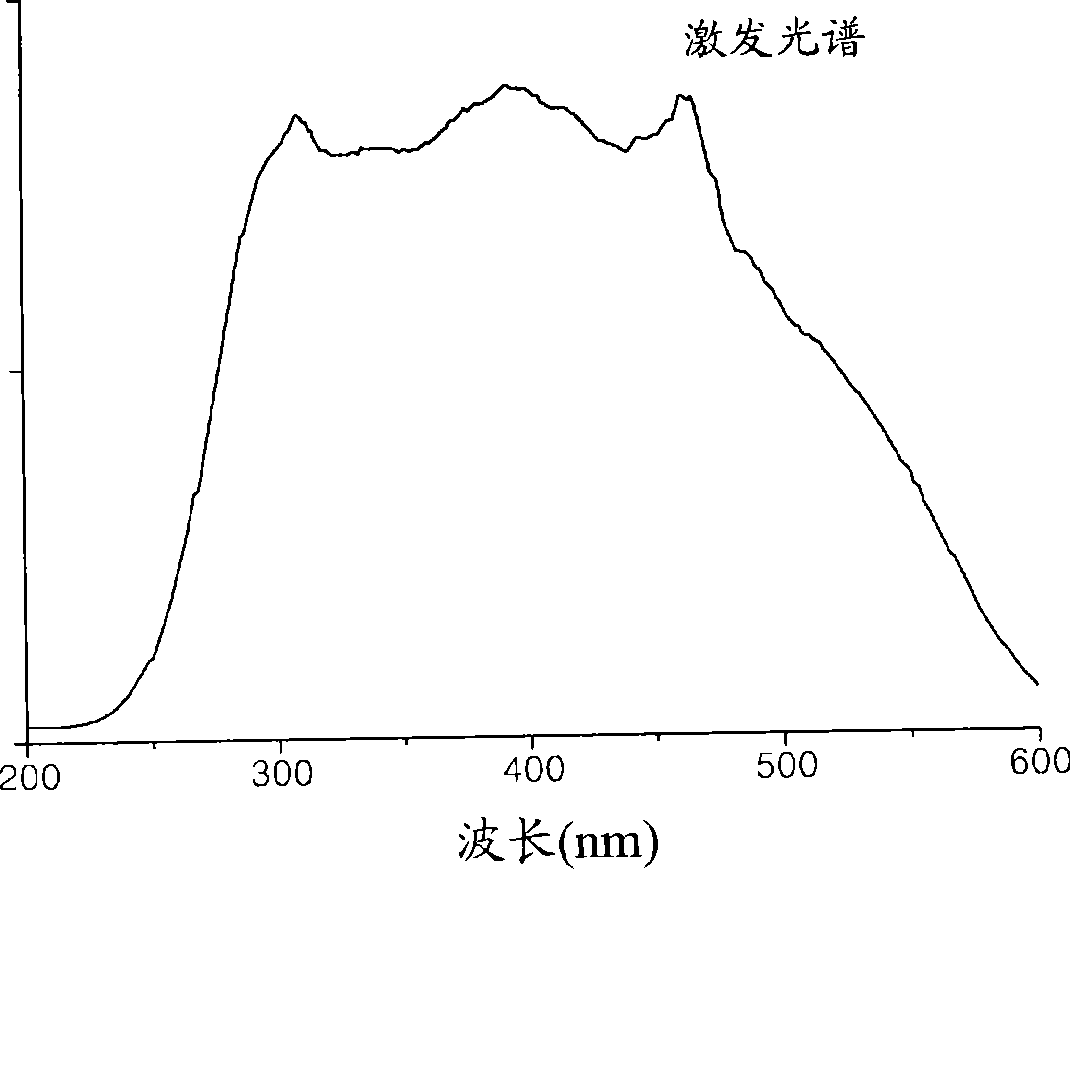

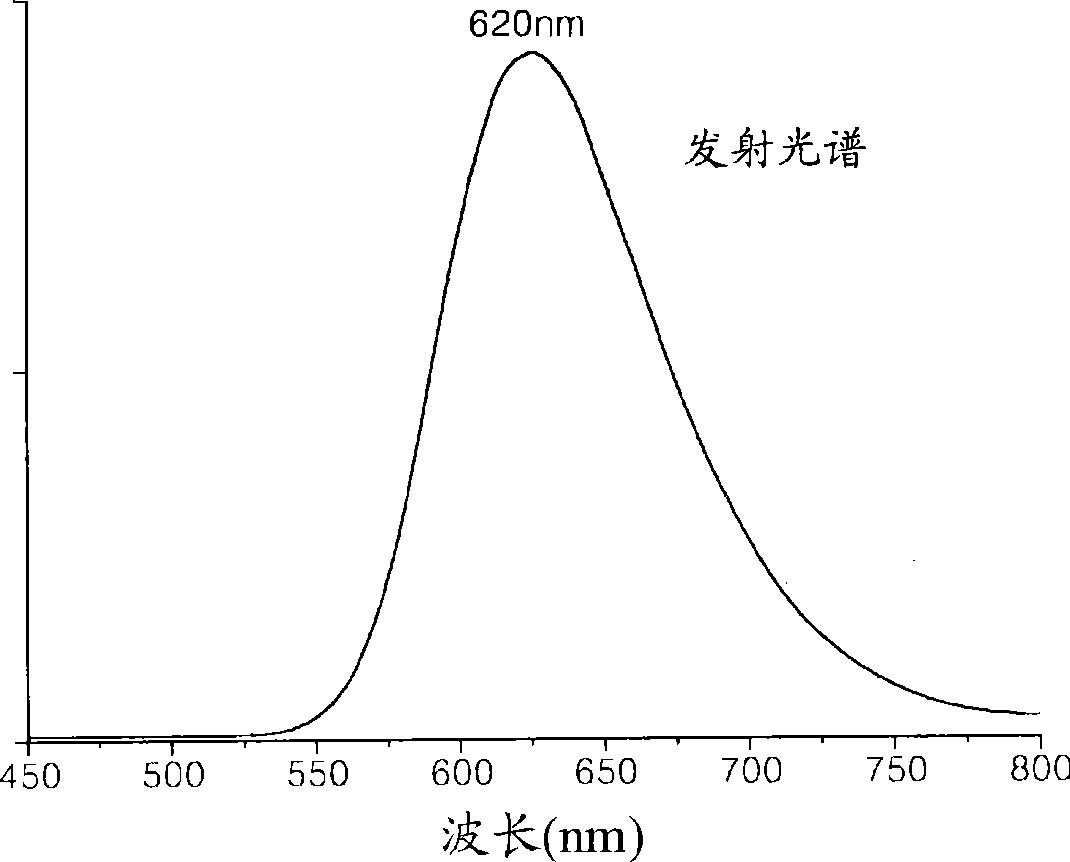

[0114] 5.0g SrCO 3 and 0.06g Eu 2 o 3 Dissolve in 100cc 10% nitric acid, then add 4.0g Si to it 3 N 4 . This mixed solution was mixed with 4.8 g of citric acid, and the resulting solution was dried. The dried product was initially sintered at 700° C. for 1 hour in an air atmosphere. The sintered product was pulverized into powder using an agate mortar. This powder is made into a pellet. Put the pellets in the crucible, and put the crucible in the electric furnace. Pellets and carbon together in an electric furnace in NH 3 Heated under atmosphere up to 1100°C for 3 hours, then in 5% H 2 and 95% of N 2 Heated under atmosphere up to 1600°C for 5 hours. Carbon is included to avoid oxidation of the nitride starting material. The resulting sintered product is pulverized into powder, and the powder is washed with distilled water, and dried in an oven to obtain a powder having the formula ((Sr 0.99 Eu 0.01 ) 2 Si 5 N 8 ) phosphor sample 1.

Embodiment 2

[0116] Preparation in the same manner as in Example 1 has the formula ((Sr 0.98 Eu 0.02 ) 2 Si 5 N 8 ) of the phosphor sample 2, except that 5.0 g of SrCO will be used as the starting material 3 and 0.12g Eu 2 o 3 Dissolve in 100cc of 10% nitric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com