Novel aluminum nitride microsphere powder preparation method

An aluminum nitride and microsphere technology, applied in the field of aluminum nitride microsphere powder and its preparation, can solve the problems of unsuitable industrial production, high reaction temperature, expensive and complicated equipment, etc., and achieves low cost of raw materials and equipment, high heat treatment temperature Low effect and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) According to the mass ratio of crystalline aluminum chloride: ethanol: deionized water: 1,2-propylene oxide = 1:1.15:1.06:1.54, weigh crystalline aluminum chloride, ethanol, deionized water and 1,2-cyclo Oxypropane;

[0021] 2) Under the condition of constant temperature water bath at 40°C, fully dissolve crystalline aluminum chloride in the mixed solution of deionized water and ethanol, then add 1,2-propylene oxide, stir for 10 seconds and then stand still to obtain a white gel;

[0022] 3) Dry the gel at a constant temperature of 60°C for 5 hours, then grind and disperse it, keep it in an ammonia atmosphere at 1200°C for 2 hours, and obtain AlN microsphere powder after cooling.

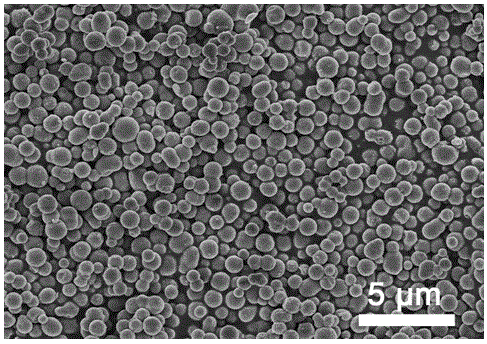

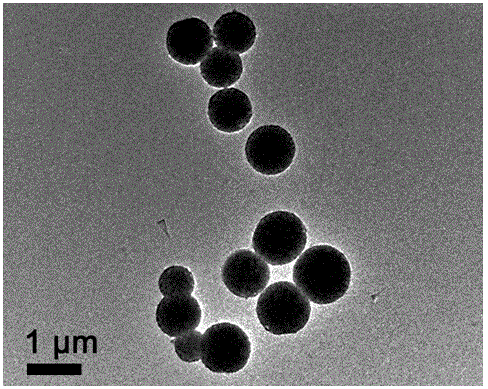

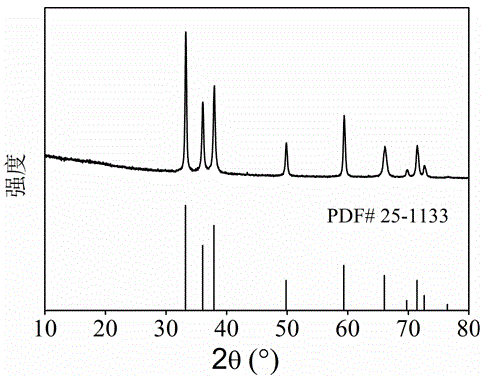

[0023] The scanning electron microscope photo of the AlN microsphere powder is shown in figure 1 , it can be seen from the figure that the AlN microspheres have the characteristics of regular shape and uniform size distribution. Its transmission electron microscope pictures are shown in ...

Embodiment 2

[0025] 1) According to the mass ratio of crystalline aluminum chloride: polyethylene oxide: ethanol: deionized water: formamide: 1,2-propylene oxide = 1: 0.02: 0.35: 1.45: 0.10: 1.45, weigh crystalline aluminum chloride, Polyethylene oxide, ethanol, deionized water, formamide and 1,2-propylene oxide;

[0026] 2) Under the condition of a constant temperature water bath at 40°C, fully dissolve crystalline aluminum chloride and polyethylene oxide in a mixed solution of deionized water, formamide and ethanol, then add 1,2-propylene oxide, stir for 10 seconds and then statically placed, a white gel was obtained;

[0027] 3) Dry the gel at a constant temperature of 70°C for 4 hours, then grind and disperse it, keep it at 1100°C for 5 hours under an ammonia atmosphere, and obtain AlN microsphere powder after cooling, with a microsphere diameter distribution of 0.6~3.2 μm, regular shape, uniform size distribution.

Embodiment 3

[0029] 1) According to the mass ratio of crystalline aluminum chloride: polyethylene glycol: ethanol: deionized water: formamide: 1,2-propylene oxide = 1: 0.1: 1.32: 0.88: 0.10: 0.77, weigh the crystalline aluminum chloride , polyethylene oxide, ethanol, deionized water, formamide and 1,2-propylene oxide;

[0030] 2) Under the condition of a constant temperature water bath at 40°C, fully dissolve crystalline aluminum chloride and polyethylene glycol in a mixed solution of deionized water, formamide and ethanol, then add 1,2-propylene oxide, and stir for 10 seconds Stand still, obtain white gel;

[0031] 3) Dry the gel at a constant temperature of 80°C for 3 hours, then grind and disperse it, keep it in an ammonia atmosphere at 1300°C for 3 hours, and obtain AlN microsphere powder after cooling, the diameter distribution of the microspheres is 0.8~2.8 μm, regular shape, uniform size distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com