Nitride phosphor and method of producing same

A manufacturing method and phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as brightness reduction, and achieve the effect of improving internal quantum efficiency and external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

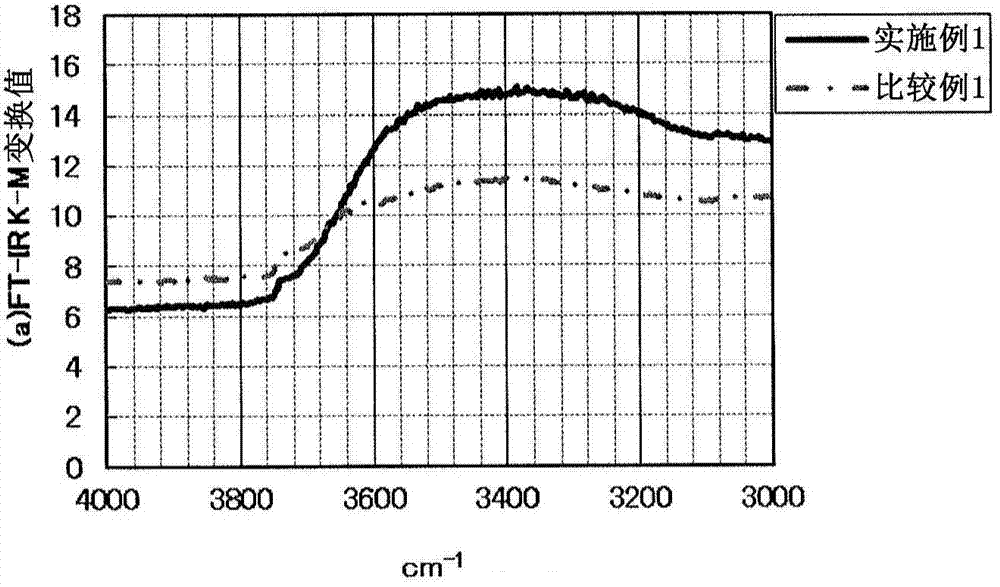

Embodiment 1

[0220] (blending of raw materials)

[0221] With La:Si=3:6 (molar ratio) and CeF 3 / (alloy+Si 3 N 4 )=6wt% mode weighing La:Si=1:1 (molar ratio) alloy, Si 3 N 4 , CeF 3 . After mixing the weighed raw materials with a ball mill, pass through the sieve holes of the nylon sieve to blend the raw materials. It should be noted that the work from weighing to blending was carried out in a glove box with an oxygen concentration of 1% or less in a nitrogen atmosphere, and the double-duty process of putting a plastic tank filled with nitrogen into an airtight container also filled with nitrogen was carried out. In the state of the container, the ball mill was carried out in the atmosphere. As the media (balls) of the ball mill, nylon-coated iron balls were used.

[0222] (Firing process)

[0223]The prepared raw materials were filled into a Mo crucible and placed in an electric furnace. After vacuuming the device, raise the temperature in the furnace to 120°C, and after confirm...

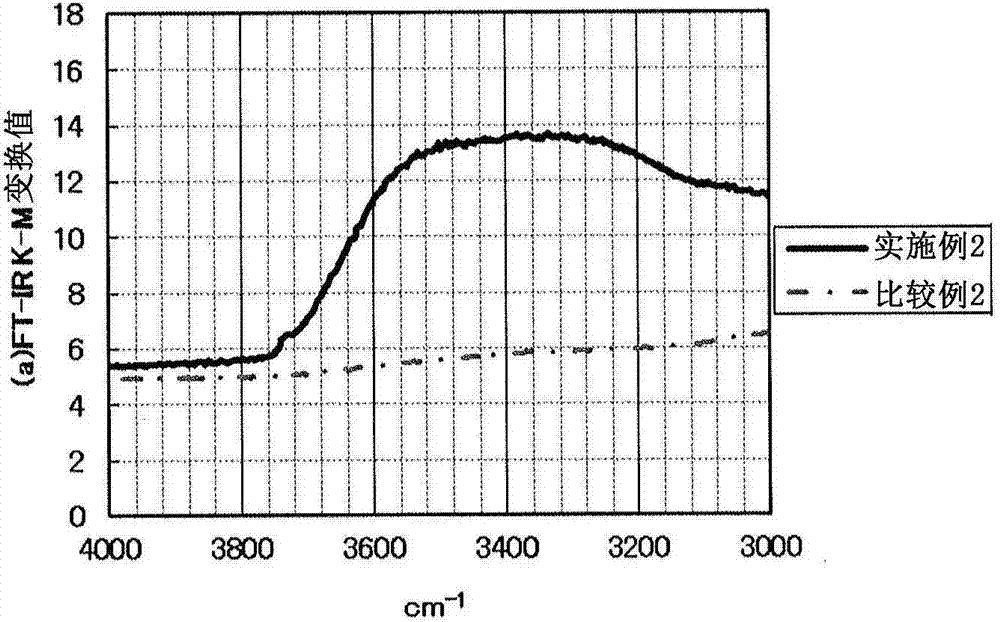

Embodiment 2

[0229] Phosphor 2 was obtained in the same manner as in Example 1 except that the time for pulverizing the fired phosphor in the cleaning step was changed to obtain the particle diameters shown in Table 1. Table 1 shows the chromaticity coordinates, luminance, and particle diameters of the obtained phosphors. In addition, the value obtained by converting the obtained infrared absorption spectrum into the Kubelka-Munck function is shown in figure 2 .

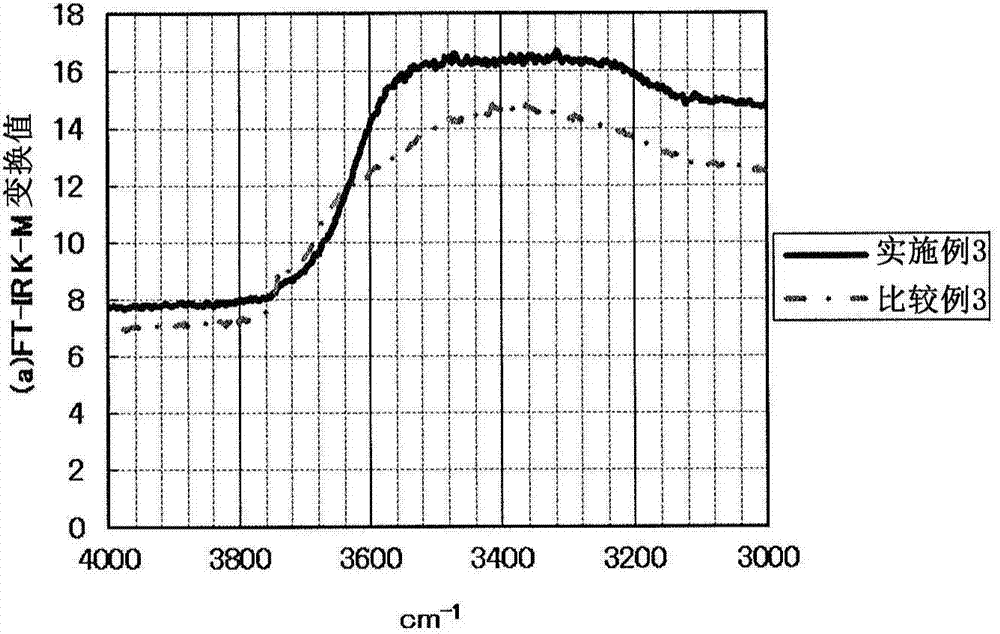

Embodiment 3

[0231] In the mixing with a ball mill in the preparation of raw materials, the medium was changed to zirconia balls, and the time for pulverizing the fired phosphor in the cleaning process was changed to obtain the particle diameters shown in Table 1, except Other than that, it carried out similarly to Example 1, and obtained the phosphor 3. Table 1 shows the chromaticity coordinates, luminance, and particle diameters of the obtained phosphors. In addition, the value obtained by converting the obtained infrared absorption spectrum into the Kubelka-Munck function is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com