Oxynitride phosphor powder, nitride phosphor powder and a production method therefor

A technology of nitrogen oxides and manufacturing methods, which is applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, cold cathode manufacturing, etc., can solve the problems of easy vitrification of precursors, formation of massive particles, and particle coarsening, etc., to achieve Effect of excellent temperature characteristics or luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0195] Manufacture of CaAlSiN Nitride Using Second Precursor 3 :Eu 2+

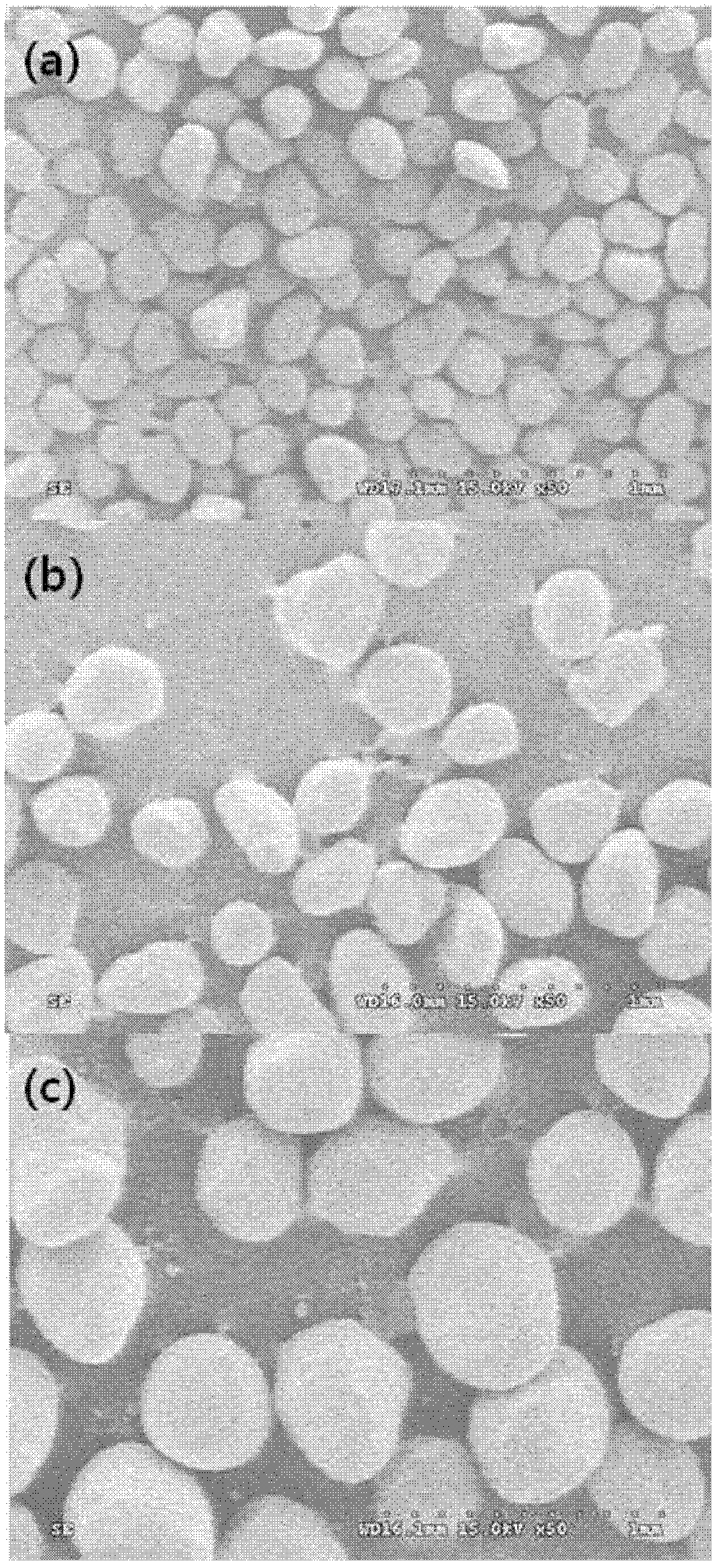

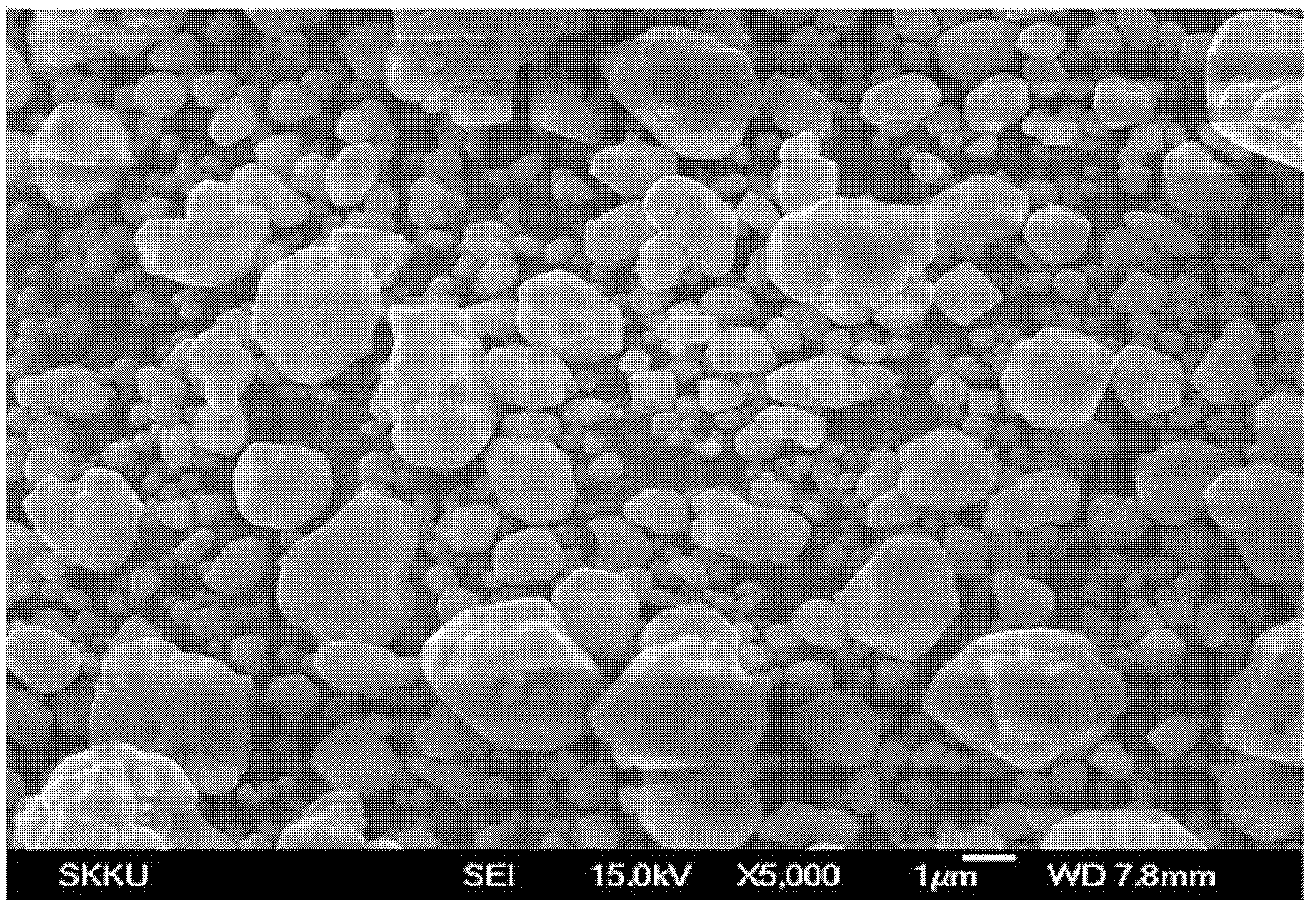

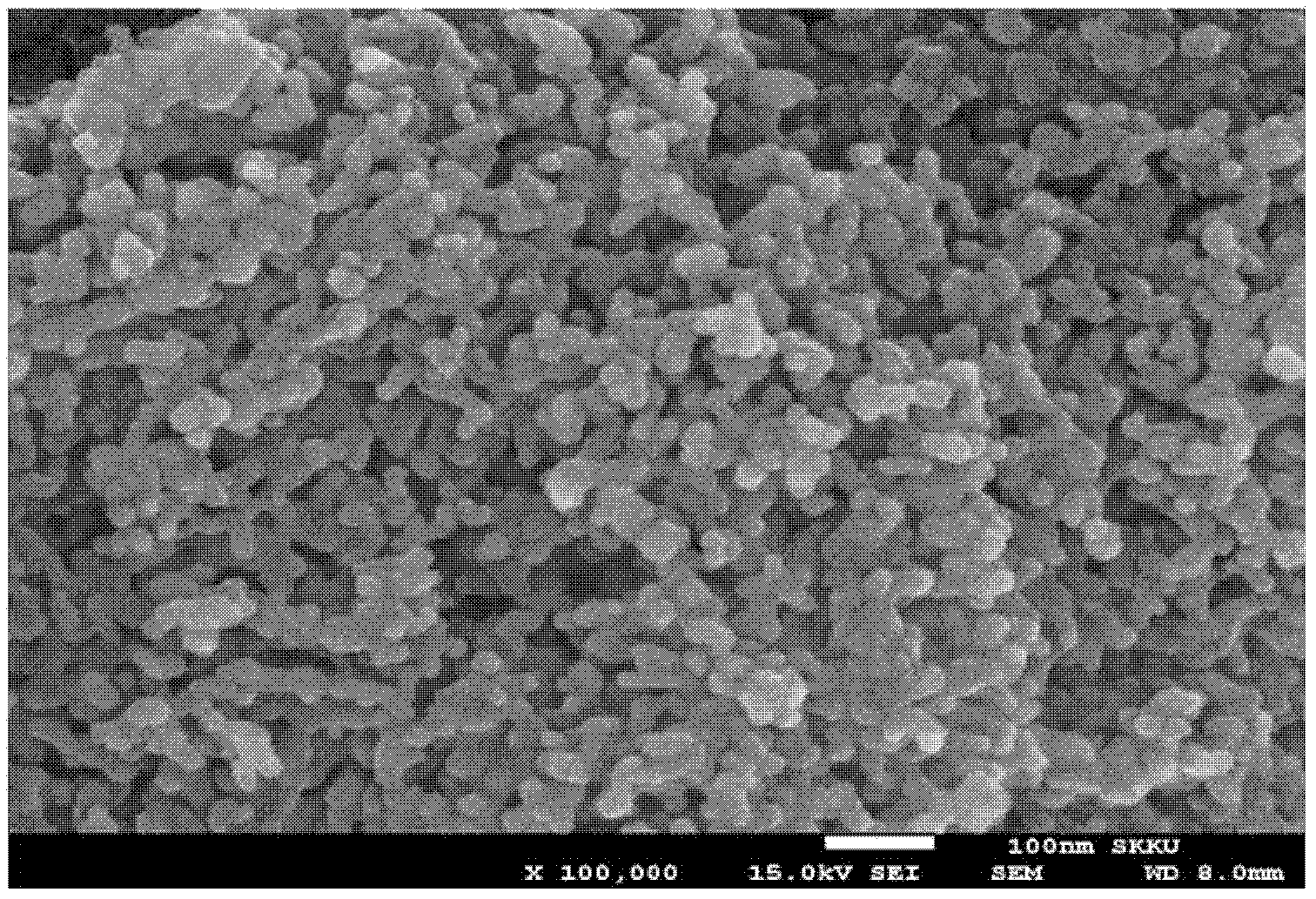

[0196] As the metal source aqueous solution, in order to use Ca 0.92 Eu 0.08 AlSiN 3 Synthesize 5g of phosphors, using dissolved in deionized water (Deionized water, D.I water) to include 17.22gCa(NO 3 ) 2 30 (weight)% aqueous solution, 25.67gAl(NO 3 ) 3 9H 2 50 (weight)% aqueous solution of O, 10.00gSiO 2 (sol) of 20 (weight)% aqueous solution and 3.16gEuCl 3 ·6H 2 A solution of 30% by weight O in water. The solution was impregnated in 12.26g of crystalline cellulose powder to obtain the first precursor, and then fired at a temperature of 300°C in air to obtain a particle size of The second precursor of ( image 3 ). After cooling at normal temperature, it was placed in a horizontal tube electric furnace in which nitrogen flowed at 1 cm / s, and fired at a temperature of 1600° C. for 5 hours. Figure 4 It is the nitride phosphor CaAlSiN obtained by this example 3 :Eu 2+ The XRD pattern. T...

Embodiment 2

[0198] Manufacture of Oxynitride Ca-α-SiAlON:Eu Using the First Precursor 2+

[0199] Using the nitriding method of the first precursor, as a metal salt solution, in order to use Ca 0.8 Eu 0.05 al 2.4 Si 9.6 o 0.7 N 15.3 5g of phosphors were obtained, the metal salt was dissolved in deionized water (Deionized water, D.I water) and each metal salt solution was used: 3.65gCa(NO 3 ) 2 30 (weight)% metal salt solution, 15.02gAl (NO 3 ) 3 9H 2 50 (weight)% metal salt solution of O, 23.40gSiO 2 (sol) of 20 (weight)% metal salt solution and 0.48gEuCl 3 ·6H 2 O in a 30% by weight aqueous metal salt solution. The mixed solution was impregnated in 15.48 g of cellulose powder. Now, according to the following reaction formula, utilize the carbon contained in the cellulose powder to determine the usage amount of the cellulose:

[0200] Reaction formula: Ca 0.8 Eu 0.05 al 2.4 Si 9.6 o 23.675 +22.975C (required carbon) +7.65N 2

[0201] → Ca 0.8 Eu 0.05 al 2.4 Si 9....

Embodiment 3

[0204] Manufacture of Oxynitride β-SiAlON:Eu Using Second Precursor 2+

[0205] Synthesize 5gEu with the method identical with embodiment 2 0.05 Si 5 al 0.95 o 10.5 N 6.95 , using 12.38gAl(NO 3 ) 3 9H 2 50 (weight)% of O, 25.38g of SiO 2 (sol) of 20 (weight)% and 1.00g of EuCl 3 ·6H 2 30% by weight of O. The mixed solution was impregnated in 14.61 g of cellulose powder. The firing in the nitrogen-containing gas and the environment in which the gas flows at a fixed speed in the above-mentioned embodiment is firing at 1600° C. for 5 hours at a linear flow rate of 1 cm / s in a nitrogen atmosphere. Synthesized β-SiAlON:Eu 2+ By XRD analysis ( Figure 8 ) to confirm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com