Light emitting device

A technology of light-emitting devices and light-emitting elements, which is applied in the direction of light-emitting materials, lighting devices, electroluminescent light sources, etc., and can solve problems such as insufficient color reproducibility of backlights, insufficient color reproducibility of images, and insufficient NTCS ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

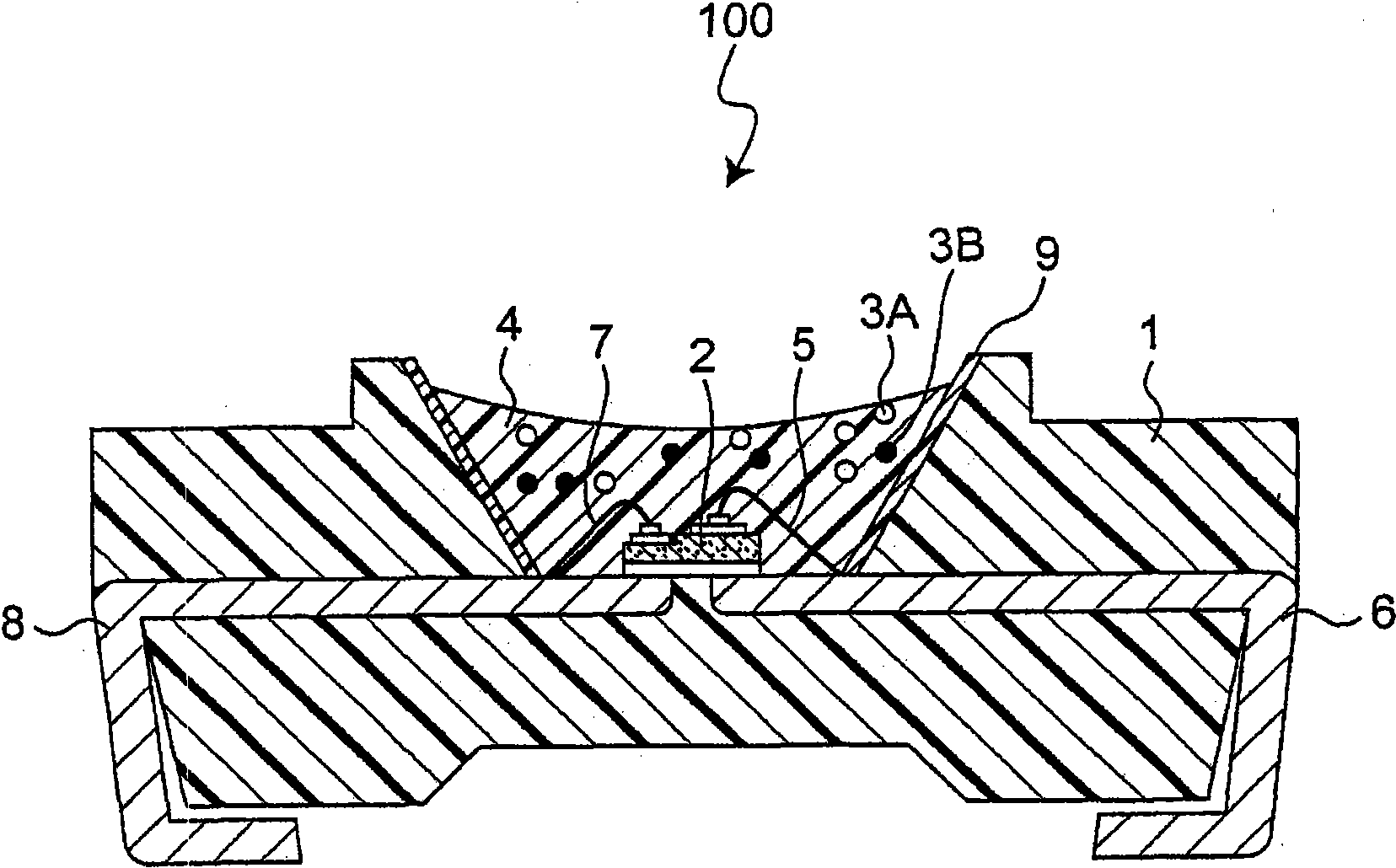

[0155] Melted polyphenolimide resin is poured into the mold in which the positive and negative pair of external electrodes 6 and 8 are inserted and confined, and hardened to form the frame body 1 . The housing 1 has an opening (recess) in which the light emitting element 2 can be accommodated. The frame body 1 and the external electrodes 6 and 8 are integrally molded by cooling the mold.

[0156] On the bottom surface of the concave portion of the frame body 1 formed in this way, a light emitting element (LED chip) 2 having a peak wavelength of 455 nm is chip-mounted with epoxy resin, and then the external electrode 6 and the light emitting element 2 are electrically connected with a conductive bonding wire 5. For connection, the external electrode 8 and the light emitting element 2 are electrically connected with the conductive bonding wire 7 .

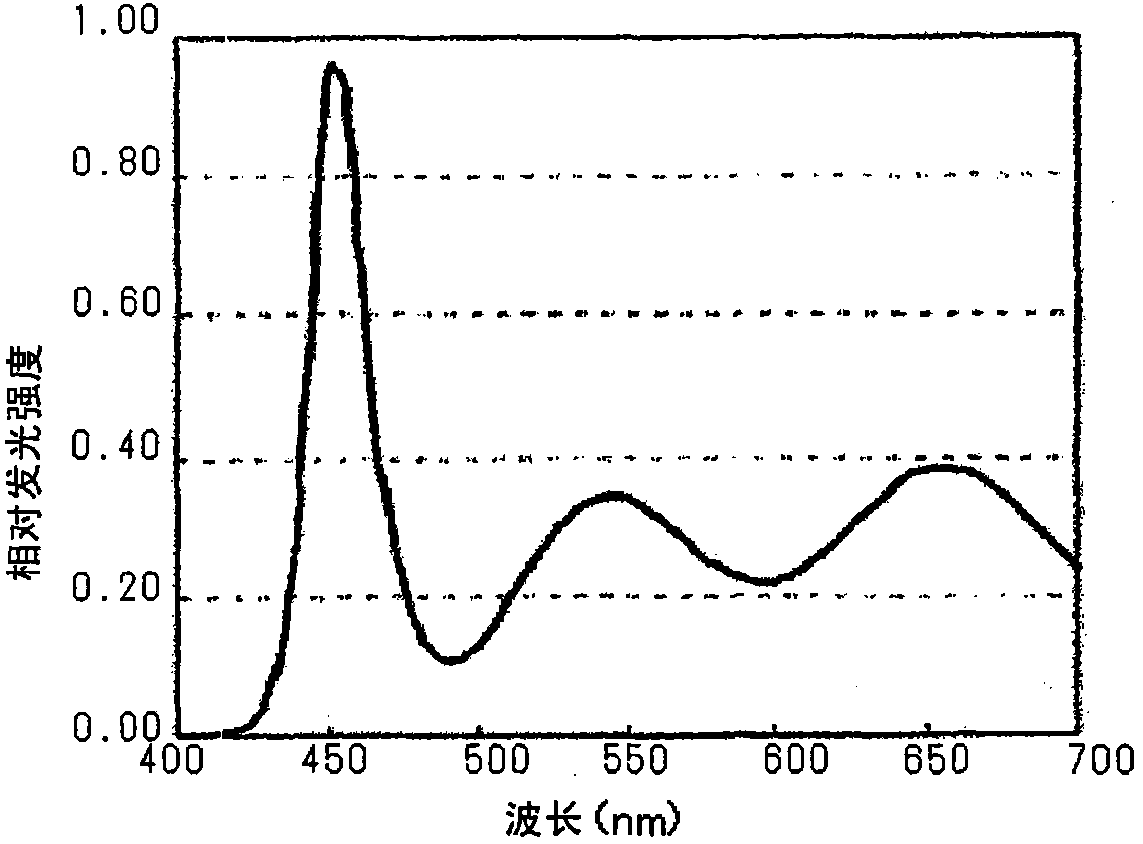

[0157] Then, to the silicone resin composition 3 g was added and mixed: a halosilicate Ca having a peak wavelength around 525 nm ...

Embodiment 2

[0164] To the silicone resin composition 3g was added and mixed: halosilicate Ca having a peak wavelength around 520nm 8 MgSi 4 o 16 Cl 2 :Eu((Ca 7.6 , Eu 0.4 )MgSi 4 o 16 Cl 2 ) about 0.3g, and a YAG-based phosphor (Y 2.95 (Al 0.8 , Ga 0.2 ) 5 o 12 : Ce 0.05 )0.1g, and a nitride phosphor CaAlSiBN with a peak wavelength around 660nm 3 :Eu((Ca 0.97 , Eu 0.03 )AlSiBN 3 ) about 0.11g, except that, the light-emitting device 100 was fabricated in the same manner as in Example 1.

[0165] In this embodiment, the difference between the peak wavelength of the green phosphor and the peak wavelength of the YAG-based phosphor is 20 nm, and the addition amount of the YAG-based phosphor is about 20% of the addition amount of all the phosphors.

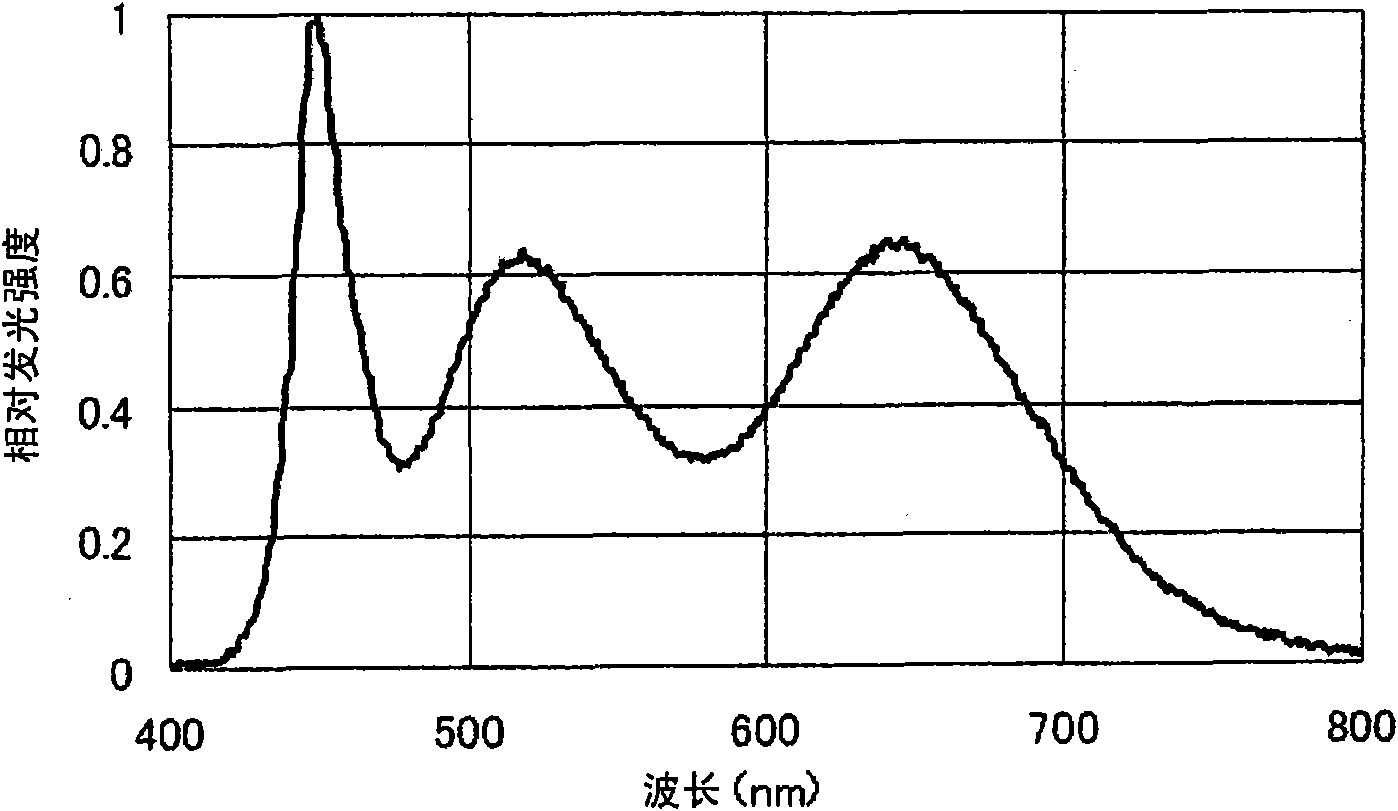

[0166] image 3 is the emission spectrum of the obtained light-emitting device 100 .

[0167] The first peak wavelength is around 450nm, the second peak wavelength is around 520nm, and the third peak wavelength is around 650nm. ...

Embodiment 3

[0171] To the silicone resin composition 3g was added and mixed: halosilicate Ca having a peak wavelength around 520nm 8 MgSi 4 o 16 Cl 2 :Eu((Ca 7.6 , Eu 0.4 )MgSi 4 o 16 Cl 2 ) about 0.3g, and a YAG-based phosphor (Y 2.95 (Al 0.8 , Ga 0.2 ) 5 o 12 : Ce 0.05 )0.15g, and a nitride phosphor CaAlSiBN with a peak wavelength around 660nm 3 :Eu((Ca 0.97 , Eu 0.03 )AlSiBN 3 ) about 0.11g, except that, the light-emitting device 100 was fabricated in the same manner as in Example 1.

[0172] In this example, the difference between the peak wavelength of the green phosphor and the peak wavelength of the YAG-based phosphor was 20 nm, and the added amount of the YAG-based phosphor was about 27% of the added amount of all the phosphors.

[0173] Figure 4 is the emission spectrum of the obtained light-emitting device 100 .

[0174] The first peak wavelength is around 450nm, the second peak wavelength is around 520nm, and the third peak wavelength is around 640nm.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com