Packaging process for white light-emitting diodes (LEDs)

A packaging process and white light technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as uneven distribution of phosphors, reduced light extraction efficiency, and photon loss, so as to improve light extraction efficiency, increase light extraction efficiency, and increase light extraction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A packaging process for white light LEDs, the steps of which are as follows:

[0018] In the step of preparing fluorescent glue, A silica gel, B silica gel, brightening agent, anti-precipitation agent, aluminate phosphor and nitride phosphor are blended into fluorescent glue according to the mass ratio of 0.4:1.6:0.01:0.01:0.73:0.08, Among them, the models of A silica gel and B silica gel are 1520A and 1520B respectively;

[0019] In the centrifugal precipitation step, the prepared fluorescent glue is dotted on the blue LED chips to be packaged, and then loaded into the inner wall of the drum of the centrifuge in batches. The axis of the drum is horizontal, and the centrifuge is started to make the drum rotate at 1800 Rotate at a speed of 200 seconds per minute;

[0020] In the baking step, put the centrifuged LED into the oven, bake at 70°C for 70 minutes, and then turn it to 140°C for 130 minutes.

Embodiment 2

[0022] A packaging process for white light LEDs, the steps of which are as follows:

[0023] In the step of preparing fluorescent glue, A silica gel, B silica gel, brightening agent, anti-precipitation agent, aluminate phosphor and nitride phosphor are blended into fluorescent glue according to the mass ratio of 0.4:1.6:0.01:0.01:0.73:0.08, Among them, the models of A silica gel and B silica gel are 1520A and 1520B respectively;

[0024] In the centrifugal precipitation step, the prepared fluorescent glue is dotted on the blue LED chips to be packaged, and then loaded into the inner wall of the drum of the centrifuge in batches. Rotate at a speed of 160 seconds per minute;

[0025] In the baking step, put the centrifuged LED into the oven, bake at 90°C for 50 minutes, and then turn it to 160°C for 110 minutes.

Embodiment 3

[0027] A packaging process for white light LEDs, the steps of which are as follows:

[0028] In the step of preparing fluorescent glue, A silica gel, B silica gel, brightening agent, anti-precipitation agent, aluminate phosphor and nitride phosphor are blended into fluorescent glue according to the mass ratio of 0.4:1.6:0.01:0.01:0.73:0.08, Among them, the models of A silica gel and B silica gel are 1520A and 1520B respectively;

[0029] In the centrifugal precipitation step, the prepared fluorescent glue is dotted on the blue LED chips to be packaged, and then loaded into the inner wall of the drum of the centrifuge in batches. The axis of the drum is horizontal, and the centrifuge is started to make the drum rotate at 2000 Rotation speed per minute rotates for 180 seconds;

[0030] In the baking step, put the centrifuged LED into the oven, bake at 80°C for 60 minutes, and then turn it to 150°C for 120 minutes.

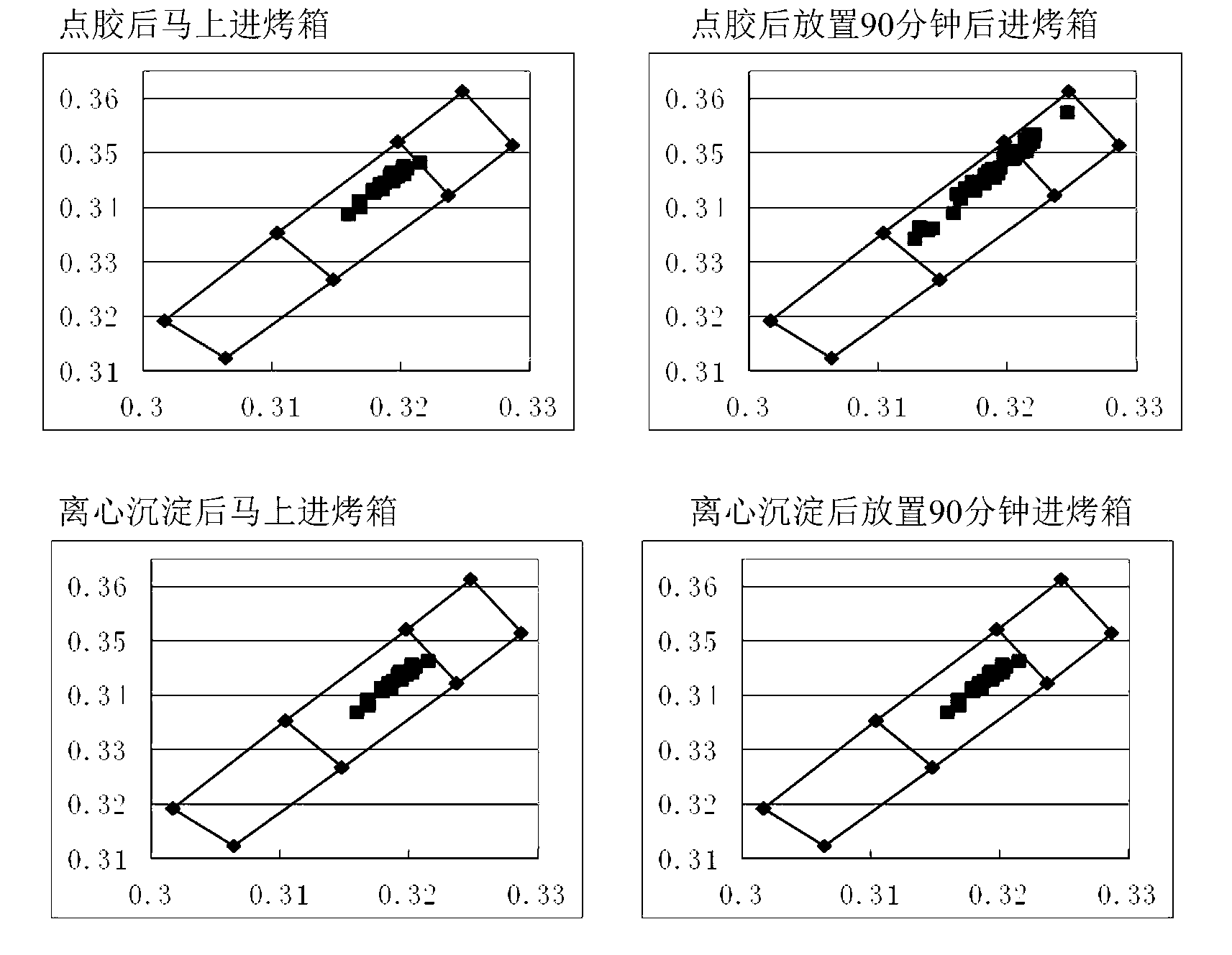

[0031] At the same time, 20 pieces of LEDs were dispensed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com