Lithium-based concrete sealing solidifying agent

A technology for sealing curing agent and concrete, applied in the field of chemical building materials, can solve the problems of low performance, easy generation of dust, rapid strength decline, etc., to improve compressive strength and wear resistance, reduce cumbersome processes, and reduce adverse reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

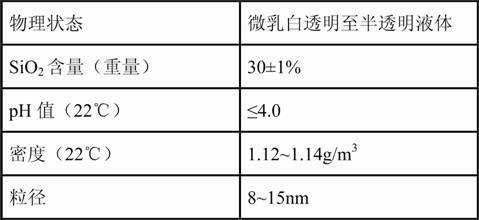

Image

Examples

Embodiment 1

[0036] A lithium-based concrete sealing and curing agent, its formula is:

[0037] Table 2 Lithium-based concrete sealant curing agent A formula

[0038]

[0039] Dissolve lithium hydroxide monohydrate in water, put it into the reaction kettle and stir for 15 minutes, then add the silica sol in two steps, first add half of it in 15 minutes, then stir for 10 minutes, then add the remaining half in 20 minutes, Stirring continued for more than 3 hours to obtain a lithium silicate sol with a modulus of about 16. Add FSJ, 2-3168, BS1306, and propylene glycol sequentially under stirring. When one component is dispersed or dissolved evenly, the next component can be added. When all components are evenly dispersed, continue stirring for 60 to 90 minutes to obtain Lithium based concrete sealer in composition A. The reaction temperature is controlled at 40°C±3°C.

Embodiment 2

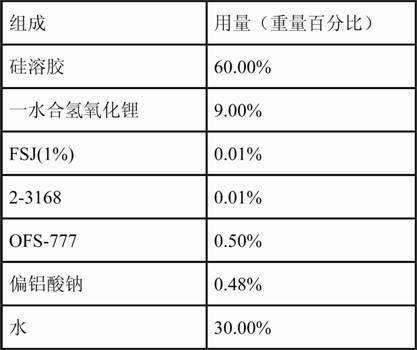

[0041] A lithium-based concrete sealing and curing agent, its formula is:

[0042] Table 3 Formula of Lithium-based Concrete Sealing and Curing Agent B

[0043]

[0044] First put water and lithium hydroxide monohydrate into the reaction kettle, start stirring and heat to 60°C to dissolve the lithium hydroxide completely, then add the silica sol dropwise within 1.5 hours, and continue to keep stirring for more than 3 hours after the dropwise addition, to obtain Lithium silicate sol with a modulus of about 2.8. Then add FSJ, 2-3168, OFS-777, and sodium metaaluminate sequentially under stirring. When one component is dispersed or dissolved evenly, the next component can be added. When all components are evenly dispersed, add 1000~ Keep stirring at a speed of 1500rpm for 60-90 minutes to obtain the lithium-based concrete sealing and curing agent in composition B. The reaction temperature was controlled at 60°C±3°C.

Embodiment 3

[0046] A lithium-based concrete sealing and curing agent, its formula is:

[0047] Table 4 Lithium-based concrete sealant curing agent C formula

[0048]

[0049] First put the silica sol into the reaction kettle, start stirring and keep the temperature of the reaction kettle at 20±5°C, drop the lithium hydroxide solution dissolved in water by lithium hydroxide monohydrate within 2 hours, and continue to keep warm after the addition is completed After stirring for more than 3 hours, a lithium silicate sol with a modulus of about 4.2 was obtained. Then add Tegopren 5878, 2-3168, BS1306 and triethanolamine in sequence under stirring. When one component is dispersed or dissolved evenly, the next component can be added. When all components are evenly dispersed, continue stirring for 60~90 minutes , to obtain the lithium-based concrete sealing and curing agent in composition C. The reaction temperature was controlled at 20±5°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com