Method for casting end cap of non-transmission end of traction motor on subway locomotive

A technology for traction motors and locomotives, which is applied to casting molding equipment, casting molds, and casting mold components. It can solve the problems of high labor intensity for workers, non-dense internal structure, and large amount of self-setting resin, so as to save time and manpower. The effect of eliminating internal shrinkage and reducing the amount of resin sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

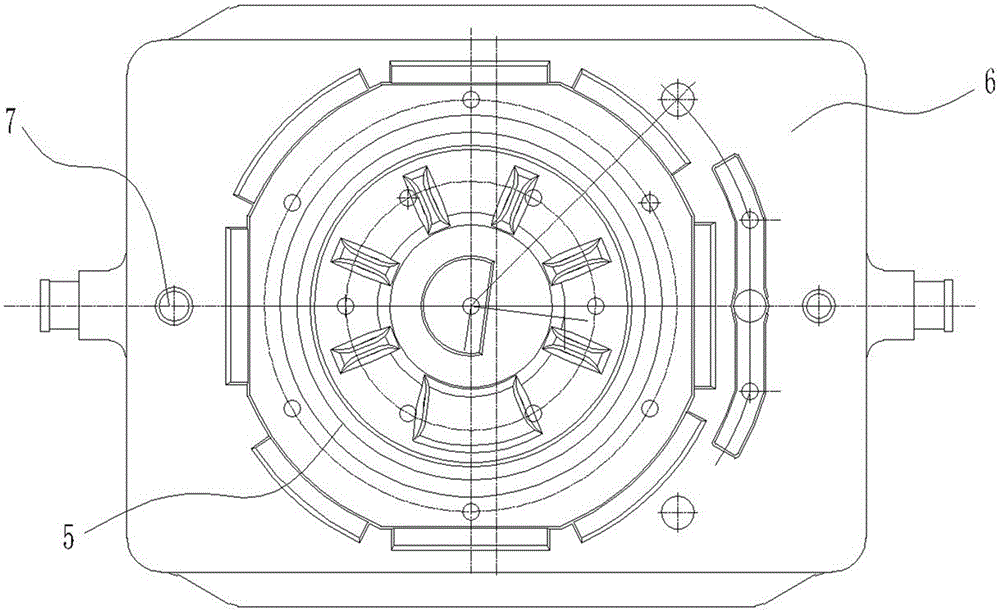

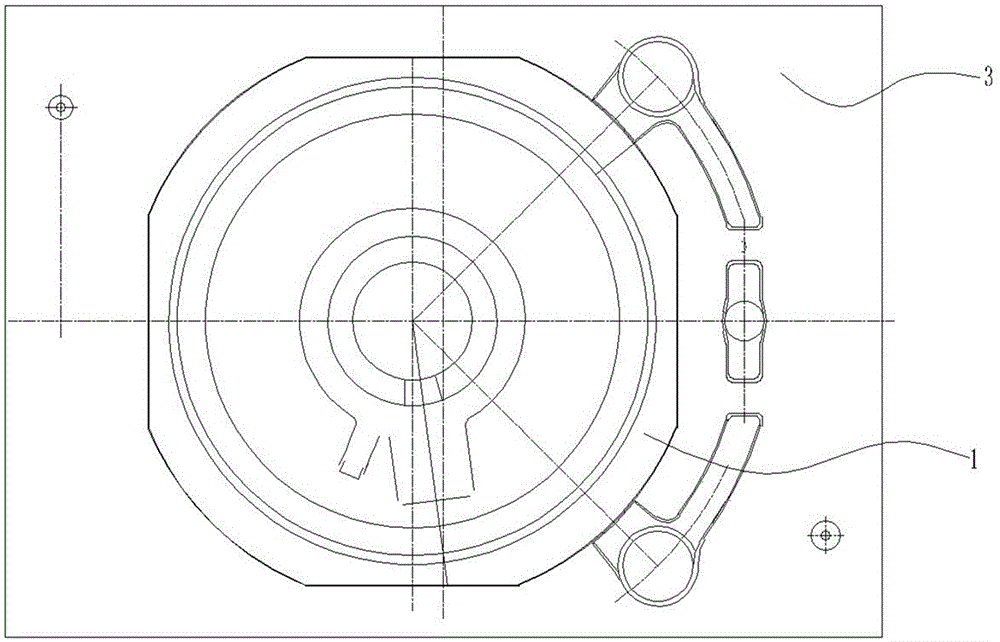

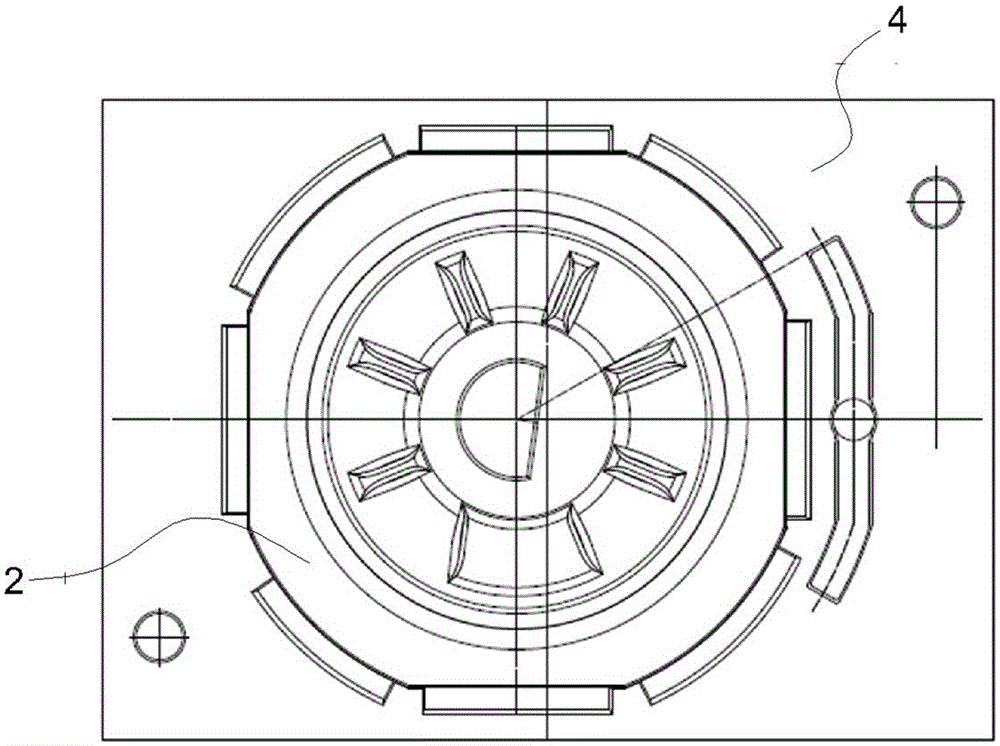

[0036] A casting method for the non-transmission end cover of the traction motor on a subway locomotive. The casting method adopts an iron mold sand-covering process for casting. The specific steps are as follows: (1) Design a set of non-transmission end cover shape of the traction motor on the subway locomotive The completely consistent model is used as a master mold, and the master mold includes a tooling mold for designing and manufacturing the non-drive end cover of the traction motor on the subway locomotive, a pouring system, a heating plate and a base. Such as figure 2 , Figure 8 , Figure 9 As shown, the upper mold plate 3 is provided with a non-drive end cover upper mold 1, and the non-drive end cover upper mold 1 is provided with a cavity for the external structure of the non-drive end cover. Such as image 3 , Figure 10 , Figure 11 As shown, the lower mold plate 4 is provided with a non-drive end cover lower die 2, and the non-drive end cover lower die 2 is...

Embodiment 2

[0039] A casting method for the non-transmission end cover of the traction motor on a subway locomotive. The casting method adopts an iron mold sand-covering process for casting. The specific steps are as follows: (1) Design a set of non-transmission end cover shape of the traction motor on the subway locomotive The completely consistent model is used as a master mold, and the master mold includes a tooling mold for designing and manufacturing the non-drive end cover of the traction motor on the subway locomotive, a pouring system, a heating plate and a base. Such as figure 2 , Figure 8 , Figure 9 As shown, the upper mold plate 3 is provided with a non-drive end cover upper mold 1, and the non-drive end cover upper mold 1 is provided with a cavity for the external structure of the non-drive end cover. Such as image 3 , Figure 10 , Figure 11 As shown, the lower mold plate 4 is provided with a non-drive end cover lower die 2, and the non-drive end cover lower die 2 is...

Embodiment 3

[0042] A casting method for the non-transmission end cover of the traction motor on a subway locomotive. The casting method adopts an iron mold sand-covering process for casting. The specific steps are as follows: (1) Design a set of non-transmission end cover shape of the traction motor on the subway locomotive The completely consistent model is used as a master mold, and the master mold includes a tooling mold for designing and manufacturing the non-drive end cover of the traction motor on the subway locomotive, a pouring system, a heating plate and a base. Such as figure 2 , Figure 8 , Figure 9 As shown, the upper mold plate 3 is provided with a non-drive end cover upper mold 1, and the non-drive end cover upper mold 1 is provided with a cavity for the external structure of the non-drive end cover. Such as image 3 , Figure 10 , Figure 11 As shown, the lower mold plate 4 is provided with a non-drive end cover lower die 2, and the non-drive end cover lower die 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com