Process for producing electronic aluminium alloy from recycled aluminium

A production process and technology of aluminum alloy, applied in the field of metallurgy, can solve the problem of difficult to recycle aluminum to process high-end aluminum alloy products, and achieve the effect of improving ecological effect, reducing microscopic defects, and reducing hair and columnar crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

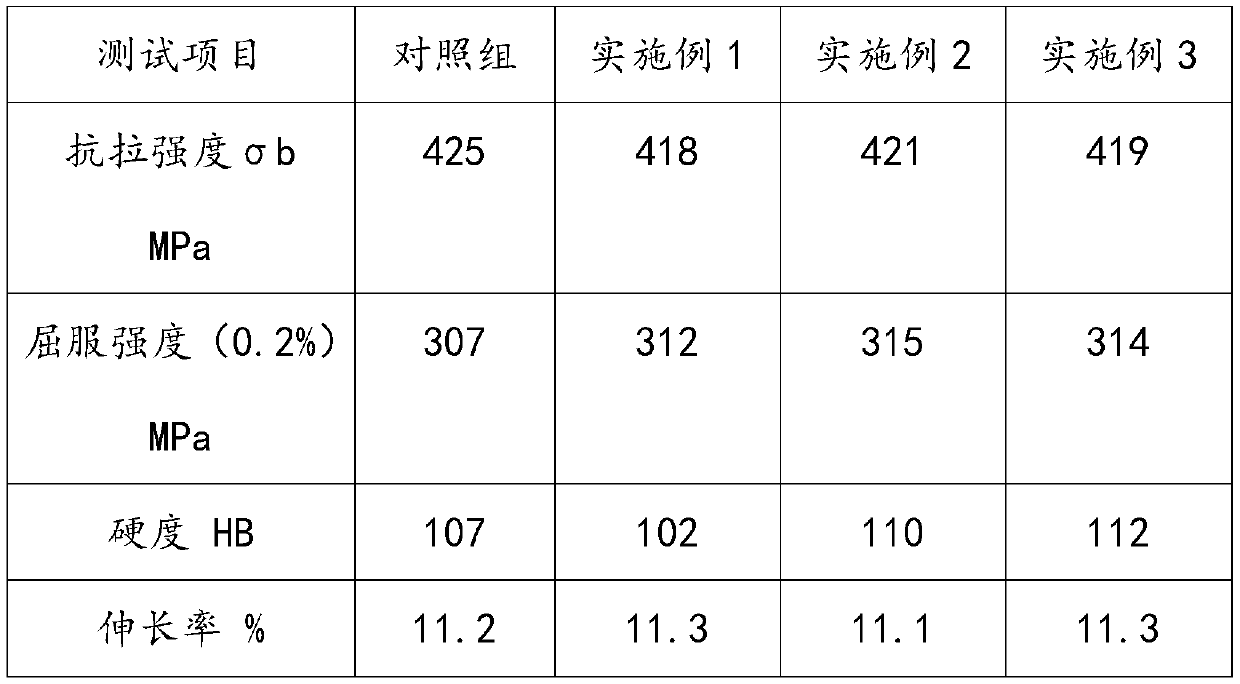

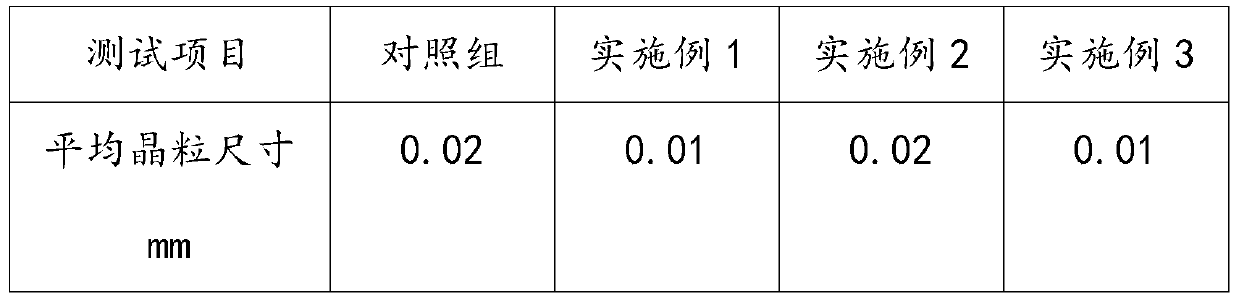

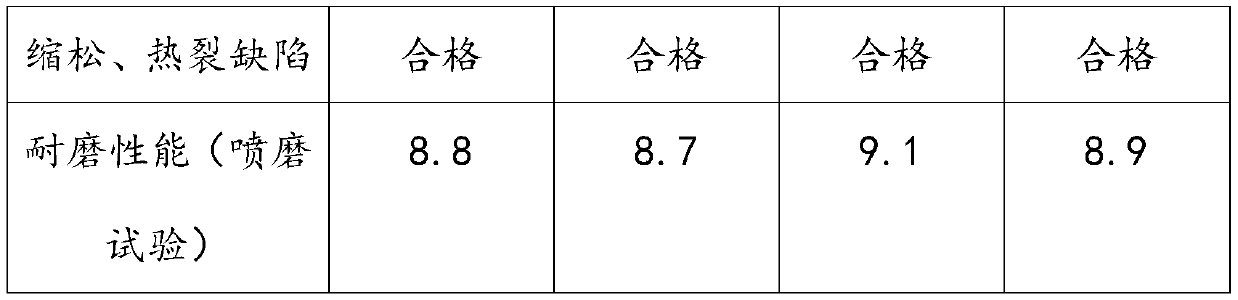

Examples

Embodiment 1

[0033] A production process for producing electronic aluminum alloys by using recycled aluminum, comprising the following steps:

[0034] (1) Smelting: raise the temperature of the furnace to 690°C, put recycled aluminum and aluminum processing waste into the furnace for melting;

[0035] (2) Stirring and slag removal: continue to increase the temperature in the furnace to 825°C, stir for 13 minutes, and then stir again after standing for 8 minutes, stirring in a cycle-stand still for not less than 3 times, and then remove the scum on the surface of the aluminum liquid;

[0036] (3) Stand still: discharge the molten aluminum in the smelting furnace into the standing furnace, lower the temperature of the molten aluminum to 735°C, and let stand for 30 minutes;

[0037] (4) Sampling and testing: Sampling and analyzing the molten aluminum, and calculating the elements or intermediate alloys that need to be added according to the composition formula of the target aluminum alloy;

...

Embodiment 2

[0053] A production process for producing electronic aluminum alloys by using recycled aluminum, comprising the following steps:

[0054] (1) Smelting: raise the temperature of the furnace to 800°C, put recycled aluminum and aluminum processing waste into the furnace for melting;

[0055] (2) Stirring and slag removal: continue to increase the temperature in the furnace to 840°C, stir for 15 minutes, and then stir again after standing for 10 minutes, stirring in a cycle - standing for no less than 3 times, and then remove the scum on the surface of the aluminum liquid;

[0056] (3) Stand still: discharge the molten aluminum in the smelting furnace into the standing furnace, lower the temperature of the molten aluminum to 760°C, and let stand for 30 minutes;

[0057] (4) Sampling and testing: Sampling and analyzing the molten aluminum, and calculating the elements or intermediate alloys that need to be added according to the composition formula of the target aluminum alloy;

...

Embodiment 3

[0073] A production process for producing electronic aluminum alloys by using recycled aluminum, comprising the following steps:

[0074] (1) Smelting: raise the temperature of the furnace to 730°C, put recycled aluminum and aluminum processing waste into the furnace for melting;

[0075] (2) Stirring and slag removal: Continue to increase the temperature in the furnace to 830°C, stir for 14 minutes, and then stir again after standing still for 9 minutes. Stir in a cycle-stand still not less than 3 times, and then remove the scum on the surface of the aluminum liquid;

[0076] (3) Stand still: discharge the molten aluminum in the smelting furnace into the standing furnace, lower the temperature of the molten aluminum to 750°C, and let stand for 30 minutes;

[0077] (4) Sampling and testing: Sampling and analyzing the molten aluminum, and calculating the elements or intermediate alloys that need to be added according to the composition formula of the target aluminum alloy;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com