Patents

Literature

81 results about "7075 aluminium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

7075 aluminium alloy is an aluminium alloy, with zinc as the primary alloying element. It has excellent mechanical properties, and exhibits good ductility, high strength, toughness and good resistance to fatigue. It is more susceptible to embrittlement than many other aluminium alloys because of microsegregation, but has significantly better corrosion resistance than the 2000 alloys. It is one of the most commonly used aluminium alloy for highly stressed structural applications, and has been extensively utilized in aircraft structural parts.

3D printing 7xxx aluminum alloy and preparation method thereof

ActiveCN108330344AImprove mechanical propertiesImprove liquidityAdditive manufacturing apparatusIncreasing energy efficiency7075 aluminium alloyMaterials science

The invention discloses a 3D printing 7xxx aluminum alloy and a preparation method thereof. The 7xxx aluminum alloy comprises, by mass, 0.1-6.0% of Si, 0-6.0% of Fe, 1.2-6.0% of Cu, 0.1-6.3% of Mn, 2.1-6.9% of Mg, 0.18-0.68% of Cr, 5.1-10.1% of Zn, 0-6.2% of Ti, 0-6.0% of Zr, 0-1% of Sc, and the balance Al. An aluminum alloy workpiece subjected to 3D printing is smooth in surface and free of cracks. Moreover, 7075 aluminum alloy powder is low in price. By adopting the 3D printing workpiece prepared from the 7xxx aluminum alloy powder prepared through the preparation method, the production costcan be saved greatly.

Owner:CENT SOUTH UNIV

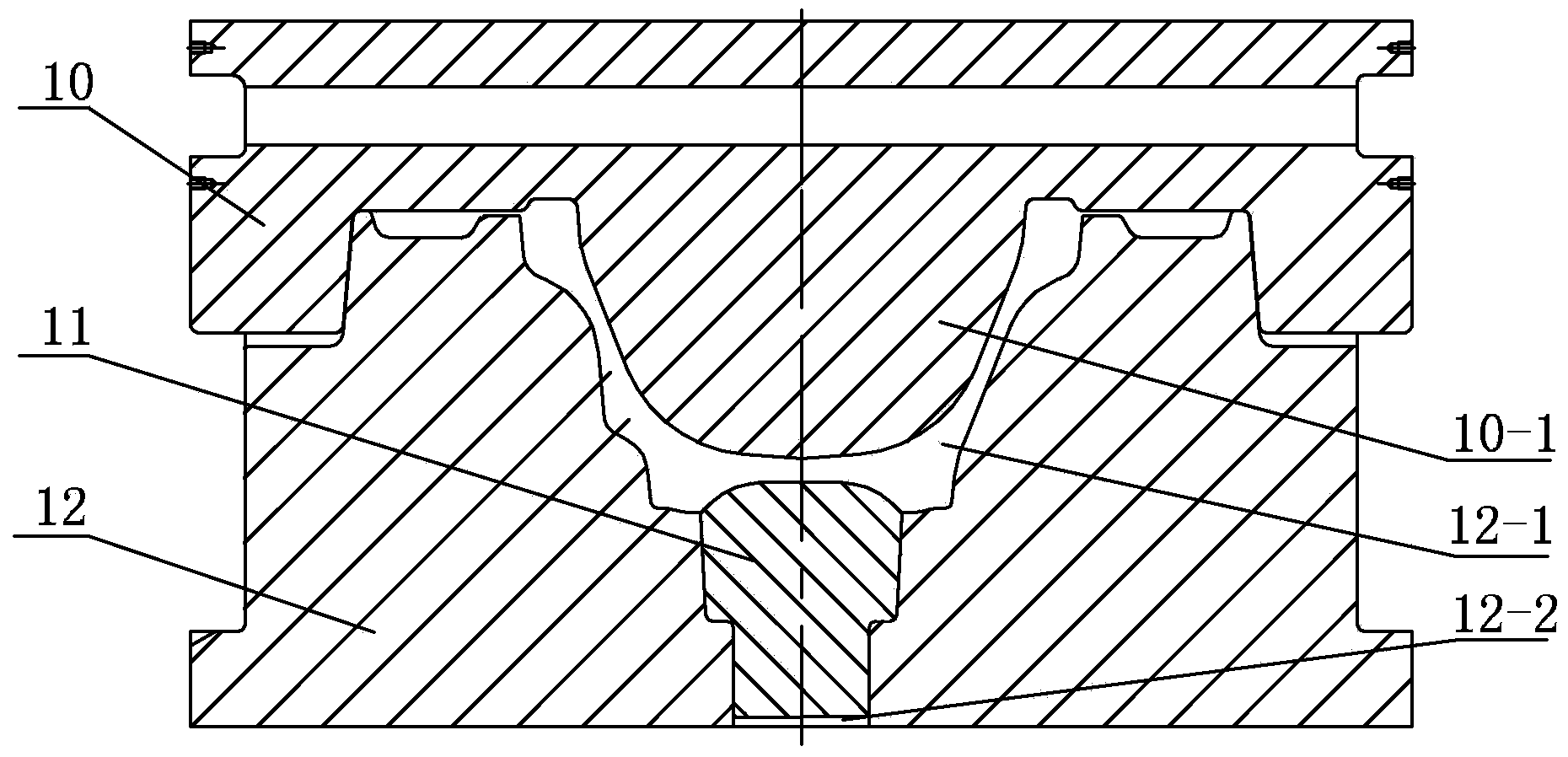

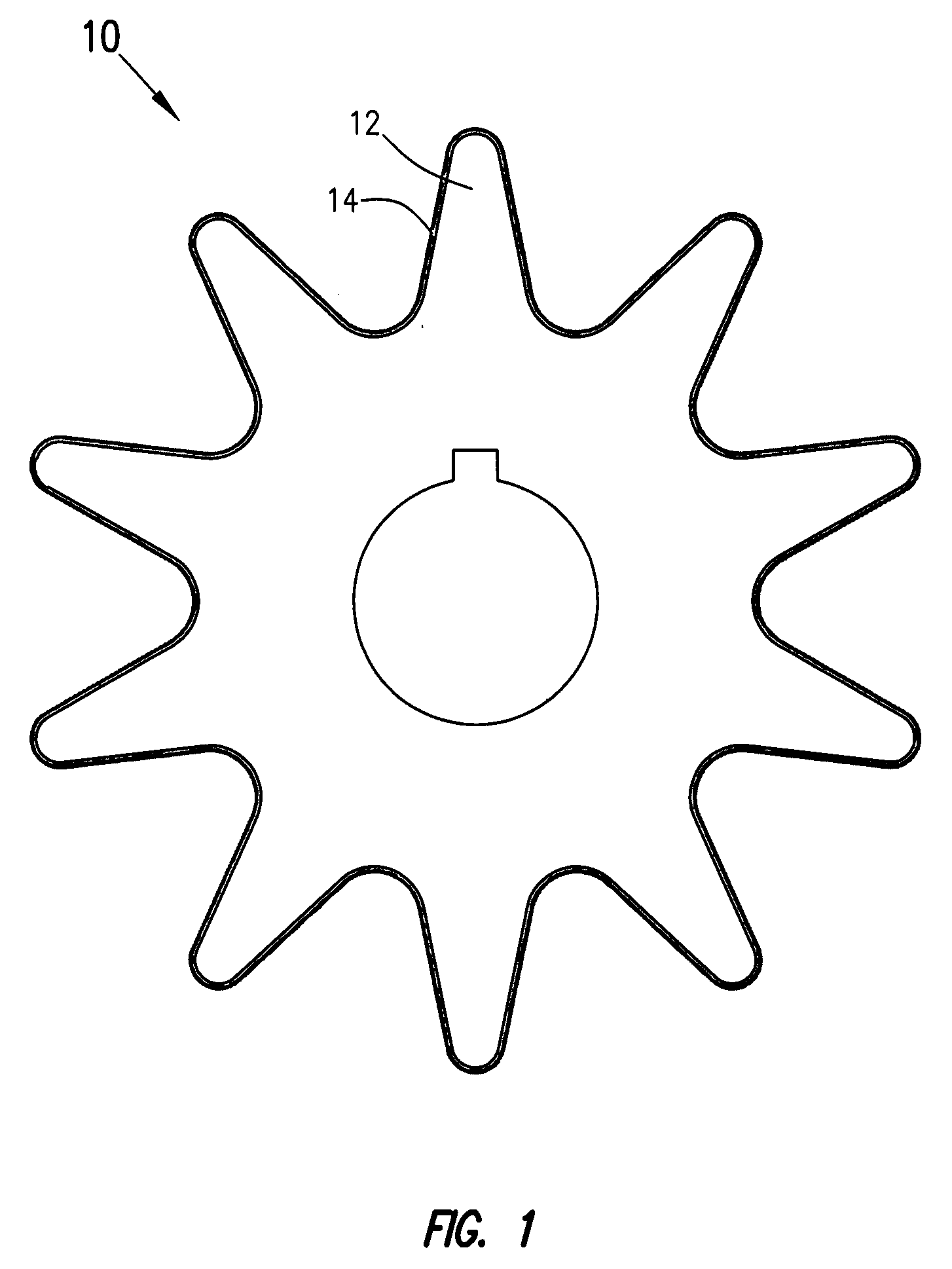

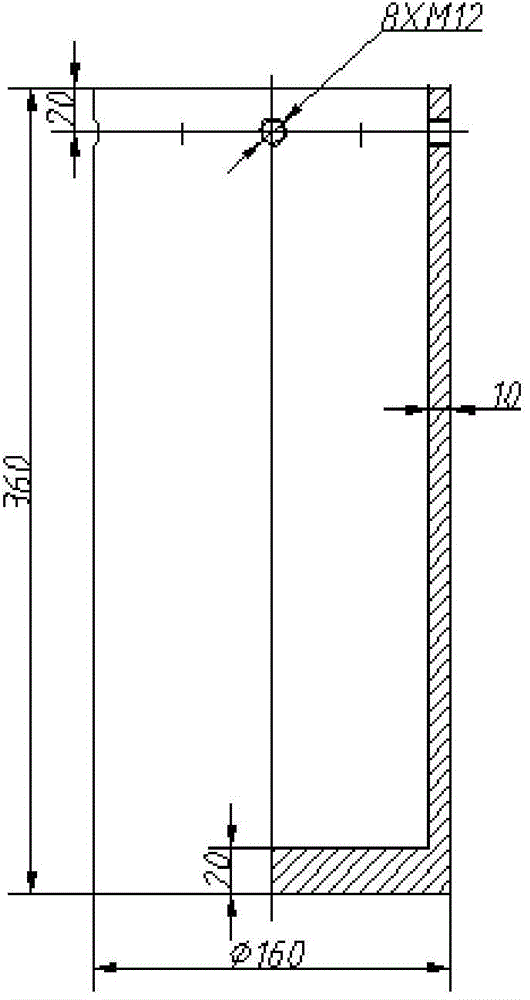

Isothermal forging forming die and method for 7075 aluminum alloy tapered casing

ActiveCN103406482ALow volume productionQuality improvementForging/hammering/pressing machinesGraphite7075 aluminium alloy

The invention discloses an isothermal forging forming die and method for 7075 aluminum alloy tapered casing and relates to an aluminum alloy part forming die and method to solve the problems of folding, streamline disorders, surface coarse grain defects and forming difficulties in manufacturing of 7075 aluminum alloy tapered casing in the prior art. The method comprises main steps of first, blank making, wherein a cylindrical 7075 aluminum alloy blank material is subjected to flat drilling upsetting to be manufactured into a formed blank; second, pre-forging, wherein the blank is placed in a female die of a pre-forging die for pre-forging forming to be produced into a formed pre-forged part; third, primary finish forging, wherein the primary finish forging is performed to manufacture a formed primary finished forged part; fourth, primary cleaning; fifth, damage repairing; sixth, secondary finish forging, wherein the secondary finish forging is performed to manufacture a secondary finished forged part; seventy, secondary cleaning, wherein graphite on the surface is cleared away. The isothermal forging forming die and method are used for manufacturing of 7075 aluminum alloy tapered casing.

Owner:HARBIN INST OF TECH

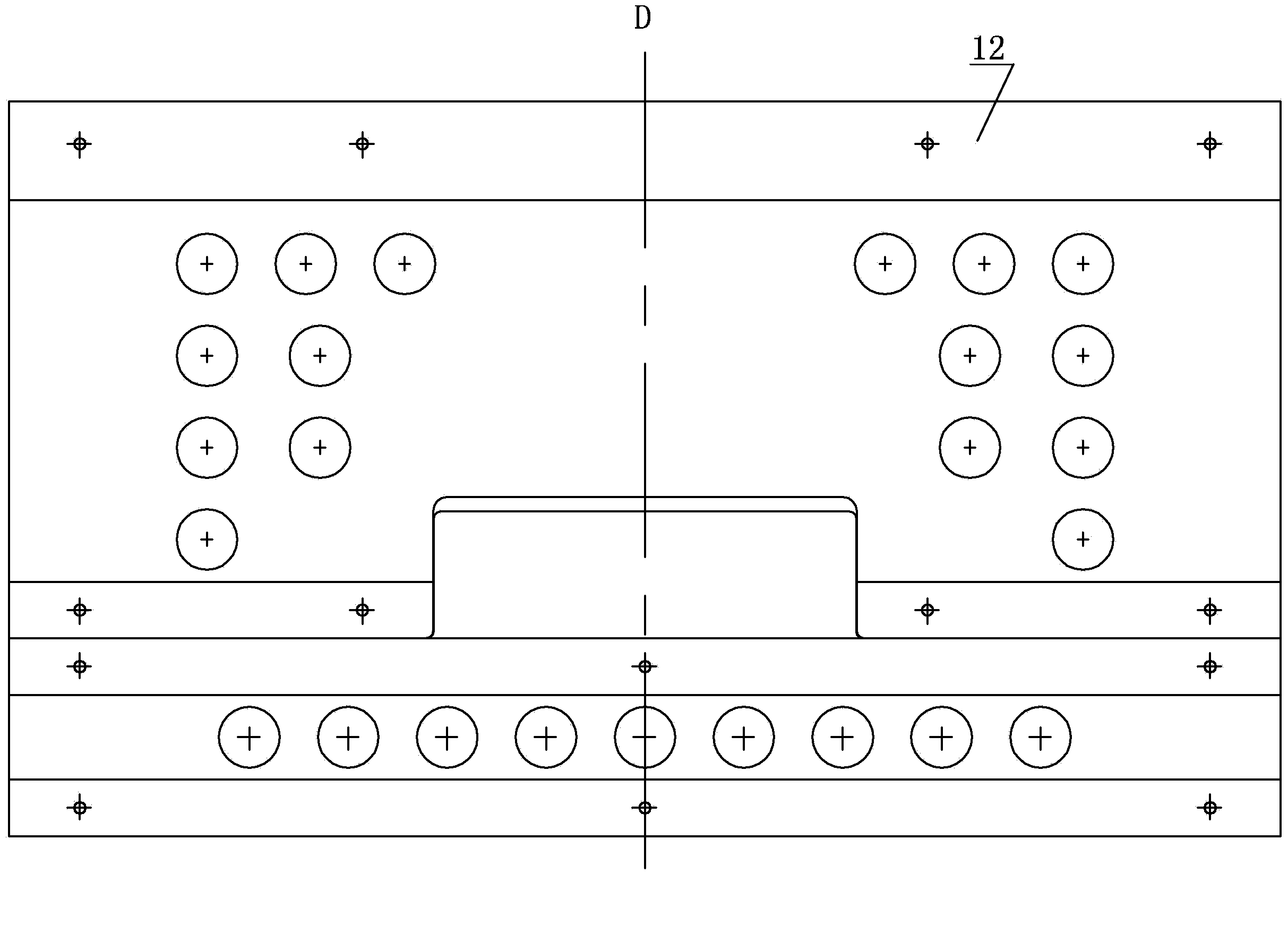

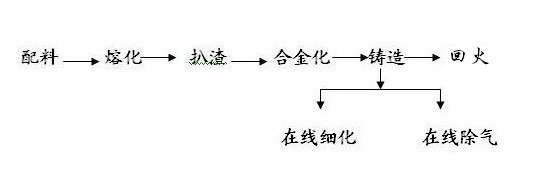

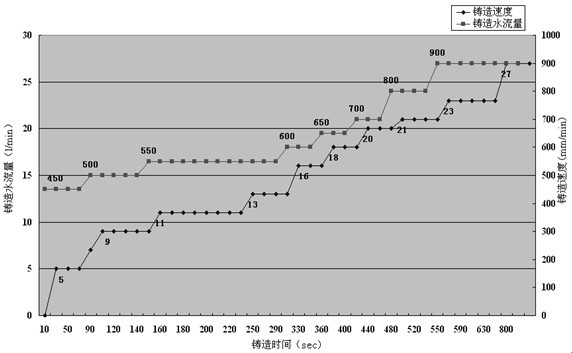

Hot-top casting process of 7075 aluminium alloy round rod with diameter of phi582 mm

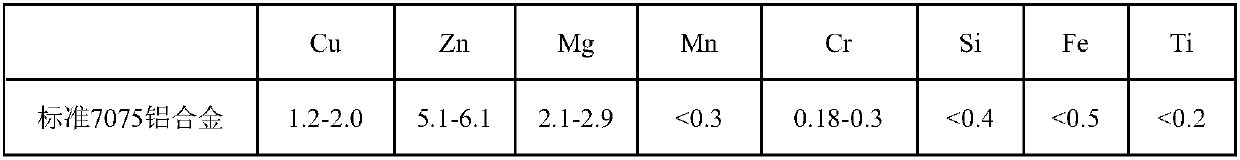

ActiveCN102328065AImprove bottom plasticityReasonable control of impurity contentRound bar7075 aluminium alloy

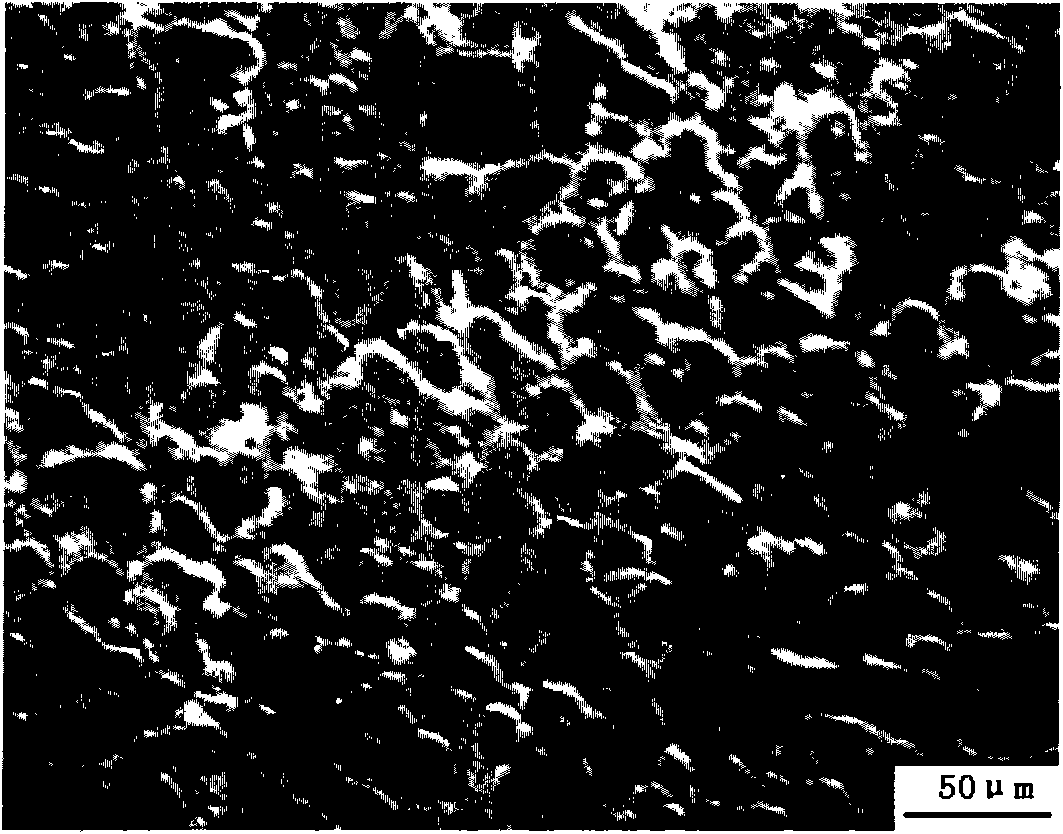

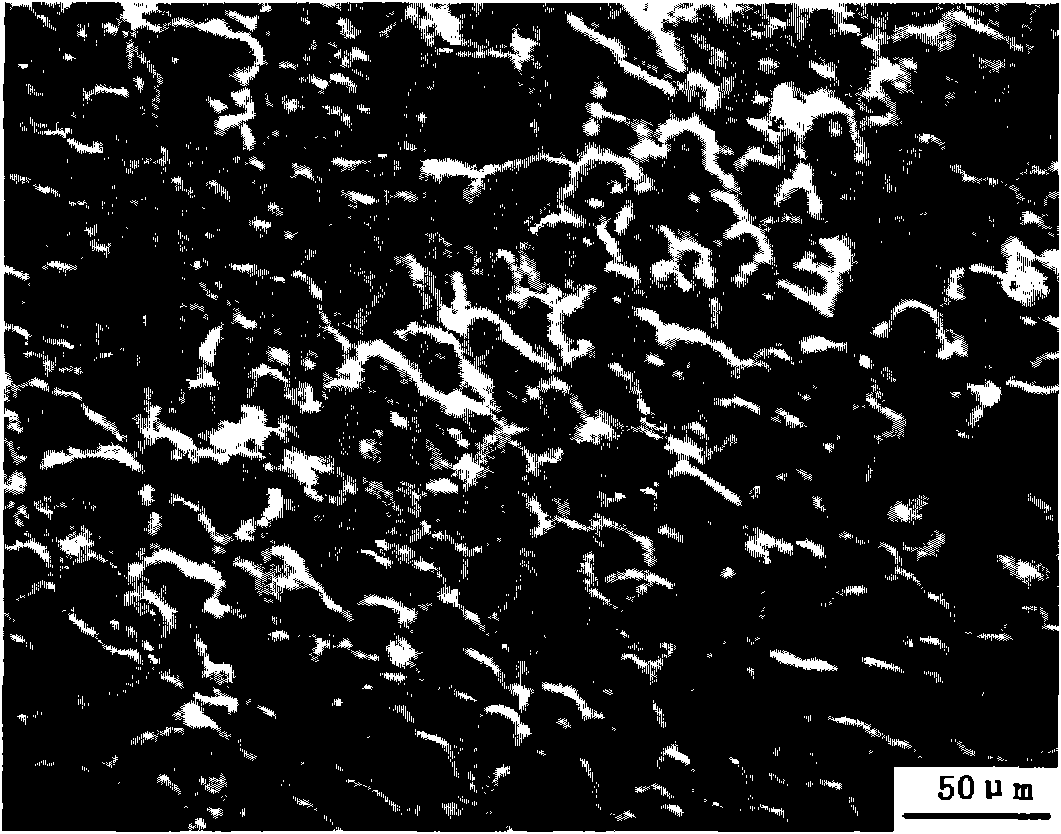

The invention discloses a hot-top casting process for casting a large-diameter hard aluminium alloy round rod by using a wiping disc. The process comprises the following steps of: a, batching; b, melting; and c, casting, wherein the casting step is a key process. The process protected by the invention is a casting process of a largest-diameter hard aluminium alloy which is put into operation in the country currently. Namely, the process comprises: hot-top casting equipment is used; the wiping disc is configured at the same time; step type casting process parameters are adopted; the suspension height of the wiping disc and the three casting process parameters are searched; and finally, the best casting process of the 7075 aluminium alloy round rod with a diameter of phi582 mm is established. According to the process disclosed by the invention, the crack tendency in the process of casting the large-diameter hard aluminium alloy can be greatly reduced without the bottoming process; the cast round bar has good grain size, thin coarse grain layer and good surface quality; and the turning quantity on the cast rod before extruding is reduced, therefore, the production cost is reduced, and the yield is increased.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

Dissimilar metal welding joint and welding method thereof

InactiveCN103008875AHigh strengthNo pollution in the processWelding/soldering/cutting articlesWorkpiece edge portionsMaterials scienceFriction stir welding

The invention relates to a dissimilar metal welding joint and a welding method thereof, and belongs to the technical field of welding. The welding joint is formed by friction stir welding of AZ31 magnesium alloy and 7075 aluminum alloy by taking tin as an interface layer, and the thicknesses range of the AZ31 magnesium alloy and the 7075 aluminum alloy is from 5 mm to 20 mm; the welding method comprises the following steps: the 7075 aluminum alloy and the AZ31 magnesium alloy are placed on an advancing side and a retreating side respectively, and fixed in a butted manner, and a tin with thickness of 0.1-0.3 mm is arranged on the welding interface; the axle center of a mixing needle deviates 10-45 percent of the diameter of the mixing needle from the AZ31 magnesium alloy; and a stirring head is inclined at an angle of 2.5-3.5 degrees, the insertion speed of the stirring head is 15-20 mm / min, when the insertion depth of the stirring head is 97-99 percent of thickness of the magnesium or the aluminum alloy, the stirring head moves after being stopped for 1-3 seconds, when the rotational speed of the stirring head is 250-450 r / min, the welding speed is 50-80 mm / min, the stirring head is stopped for 2-6 seconds, and the draw speed of the stirring head is 15-30 mm / min. The welding joint has higher strength and better forming effect; the method is stable, and no environmental pollution is realized; and the pre-welding treatment is simple.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

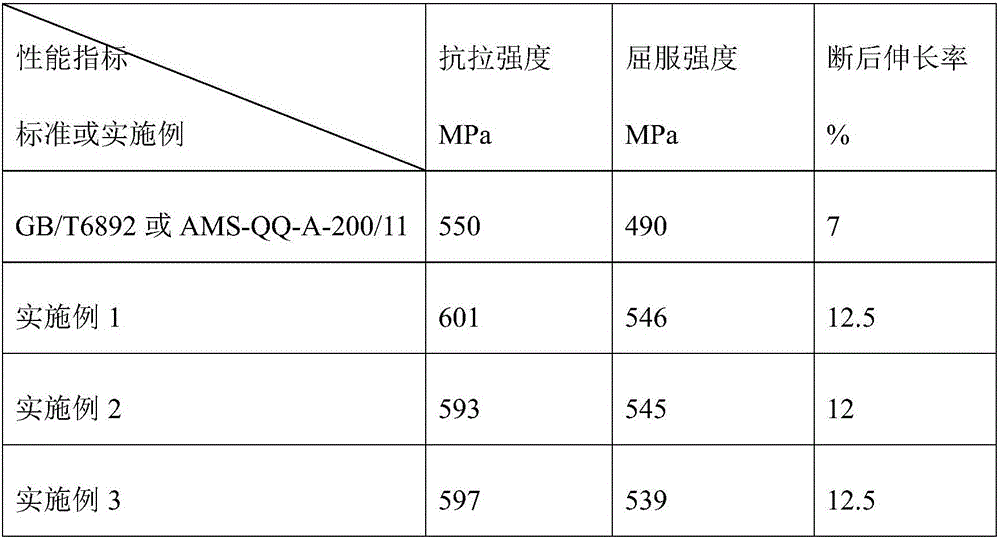

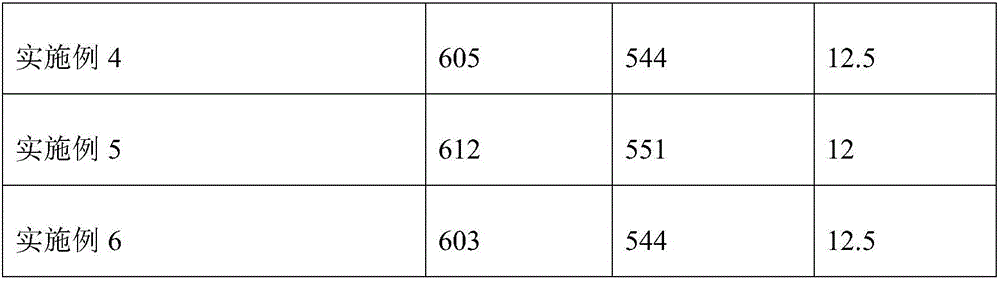

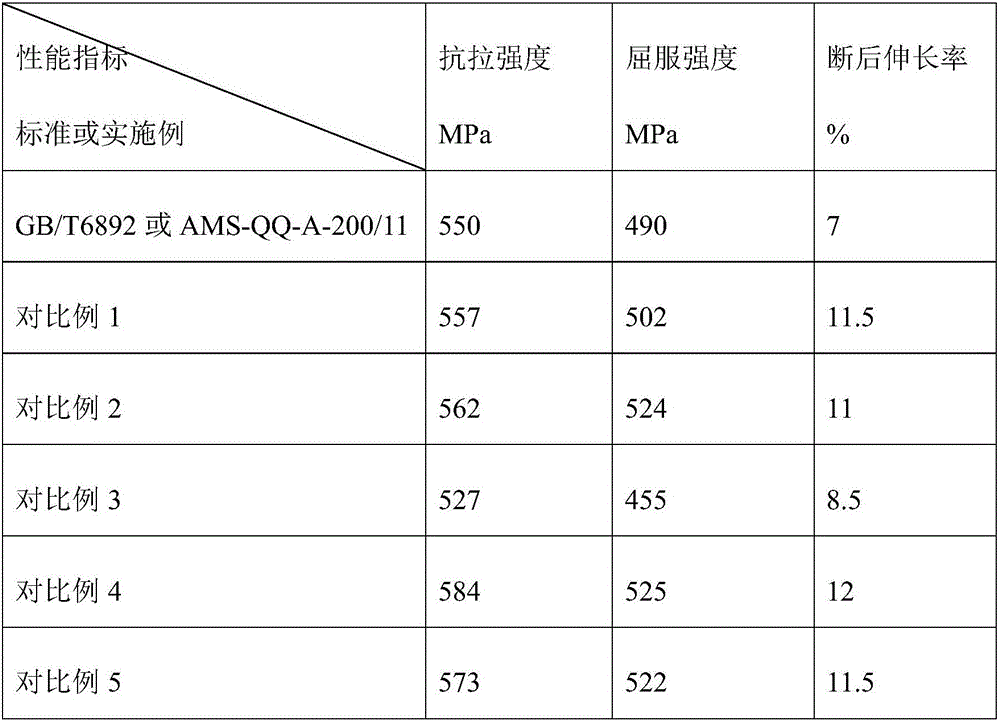

Technique for improving performances of 7075 aluminum alloy extruded material

InactiveCN106399881AShorten aging timeRaise the ratioExtrusion control devicesSolution treatmentIngot

The invention provides a technique for improving the performances of a 7075 aluminum alloy extruding material. The technique comprises the following concrete technological steps: heating an alloy ingot manufactured from the 7075 alloy material; heating a mold and an extruding cylinder; putting the heated mold and ingot into an extruder and extruding; performing solution treatment on the extruded extruding material; quenching the extruding material which is subjected to the solution treatment; stretching the quenched extruding material; ageing the stretched extruding material. The invention also provides the alloy ingot used in the method, and the ingot comprises the following components in percentage by weight: smaller than or equal to 0.40% of Si, smaller than or equal to 0.50% of Fe, 1.5% to 2.0% of Cu, smaller than or equal to 0.3% of Mn, 2.5% to 2.9% of Mg, 0.20% to 0.28% of Cr, 5.5% to 5.9% of Zn, smaller than or equal to 0.2% of Ti, smaller than or equal to 0.05% of other single elements, other impurity elements and the balance Al, wherein the total amount of other impurity elements is smaller than or equal to 0.15%.

Owner:SHANDONG NANSHAN ALUMINUM +1

Extrusion moulding mold and method in semi-solid state preparation method of aluminium-coating magnesium composite pipe

The invention relates to an extrusion moulding mold and method in a semi-solid state preparation method of an aluminium-coating magnesium composite pipe. The inner layer of the composite pipe is made from AZ91S magnesium alloy, and the outer layer of the composite pipe is made from 7075 aluminium alloy. The extrusion moulding method comprises preparation of blank, secondary heating and semi-solid state extrusion moulding, and specifically comprises the following steps: placing prepared aluminium alloy semi-solid state blank and magnesium alloy semi-solid state blank with solid fraction being 70%-90% into an extrusion cavity of an extrusion barrel through a hot charging process, and performing extrusion moulding to obtain the aluminium-coating magnesium composite pipe with the wall thickness of 4-8mm and the length of 1,200-3,000mm, wherein the preheating temperature of the mold is 250-300 DEG C, and the extrusion speed is 60-150mm / s. According to the invention, the bonding interface of the aluminium-coating magnesium composite pipe completely reaches the metallurgical bonding, and compared with other moulding methods, the extrusion moulding method has the advantages of high efficiency, short flow, good pipe quality, simple structure, and simplicity in implementation; the prepared aluminium-coating magnesium composite pipe is small in density, and high in specific strength and specific stiffness, the outer layer is corrosion-resistant, the inner layer is good in shock absorption and shock resistance, and the prepared aluminium-coating magnesium composite pipe is particularly suitable for the fields of manufacturing of baggage holders of high speed trains, seats, portable bicycle frames, high-grade lamps and lanterns, and the like, and has very wide application prospect.

Owner:UNIV OF SCI & TECH BEIJING

7075 aluminium alloy profile on line quenching method

InactiveCN1807004AGuaranteed potential for subsequent heat treatment (e.g. aging)Guaranteed performanceOther manufacturing equipments/toolsHeating furnaceQuenching

The invention discloses 7075 aluminum alloy section bar on-line quenching method and system. Using the method, it is not necessary to carry out vertical quenching heat treatment, the productivity is improved and the cost is reduced. The method comprises the following steps: adopting hot extrusion forming method, extruding the 7075 aluminum alloy bar to 7075 aluminum alloy section bar, then carrying out heating treatment. The 7075 aluminum alloy section bar on-line quenching system comprises extruding system, on-line hollow heater and water quench tank.

Owner:GUANGDONG XINGFA ALUMINUM

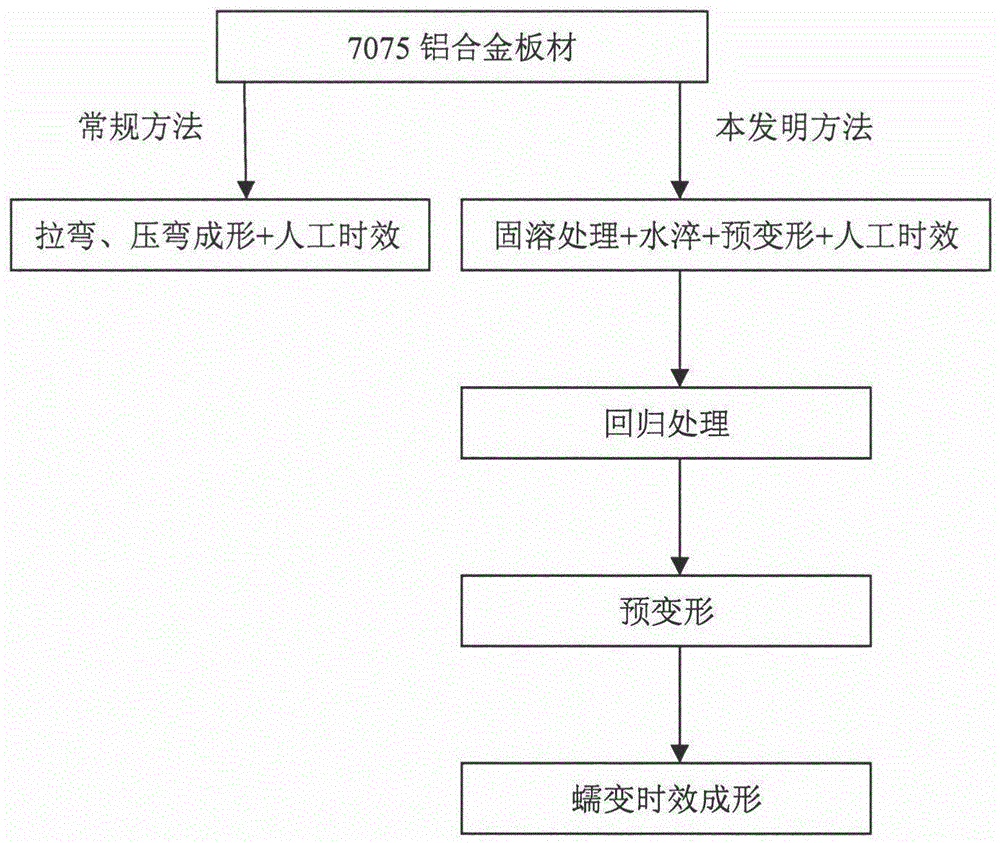

7075 aluminum alloy plate creep age forming method

InactiveCN104404414ARegulating Precipitation BehaviorImprove corrosion resistanceSolution treatmentPre deformation

The invention discloses a 7075 aluminum alloy plate creep age forming method. The method comprises the following steps: (1) carrying out solid-solution treatment on a 7075 aluminum alloy plate with a thickness of 2-40 mm for 30-90 minutes at a temperature of 466-480 DEG C, then water-quenching, subsequently carrying out 1-5 percent of pre-deformation and finally carrying out artificial aging treatment for 6-24 hours at a temperature of 80-120 DEG C; (2) carrying out retrogression treatment, wherein the retrogression treatment temperature is 160-200 DEG C, and the heat preservation time is 20-180 minutes, and then carrying out water quenching at a room temperature; (3) carrying out 1-5 percent of pre-deformation on the plate subjected to the retrogression treatment, then placing the plate in a mould and fixing; (4) carrying out creep age forming, wherein the creep age forming temperature is 120-160 DEG C, the applied stress is 200-260 MPa, and the forming time is 12-24 hours; (5) unloading the plate from the mould. When the method disclosed by the invention is utilized for processing the 7075 aluminum alloy plate, while the strength of the aluminum alloy plate is ensured, the corrosion resistance of the 7075 aluminum alloy plate can be effectively improved.

Owner:CENT SOUTH UNIV

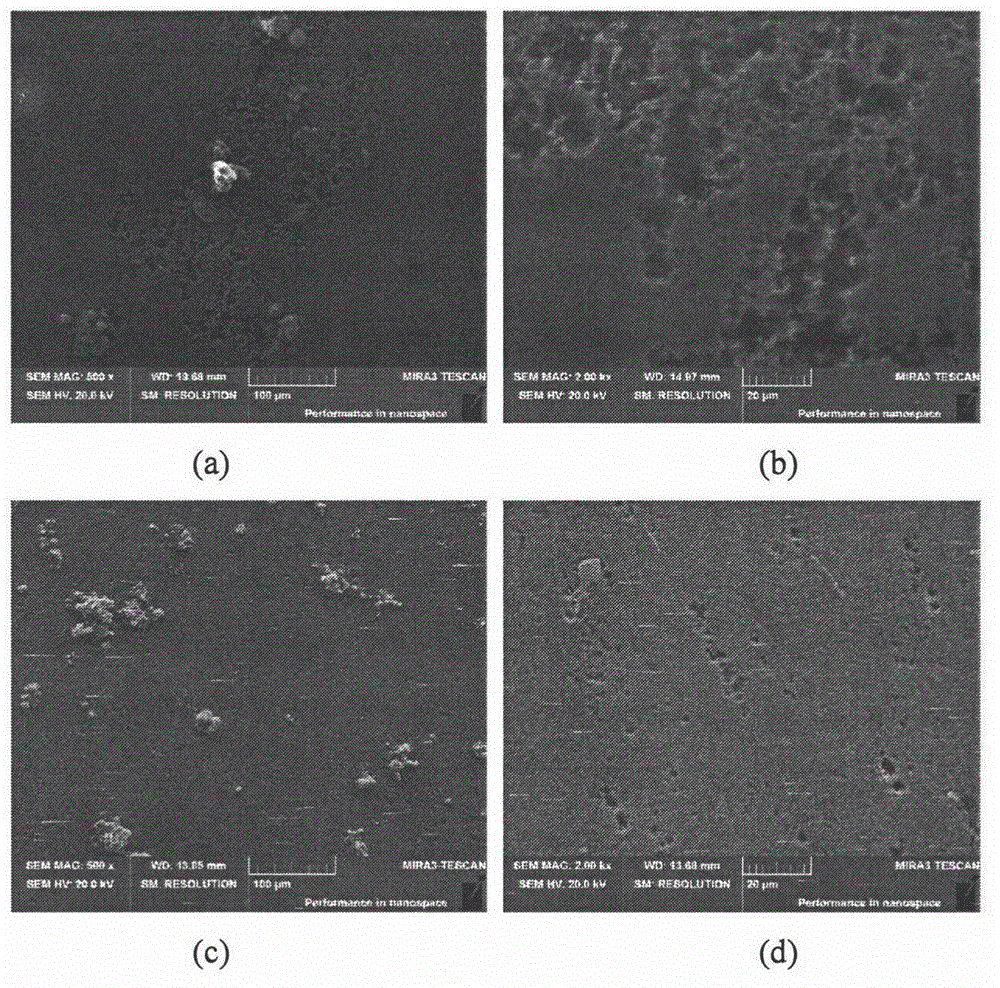

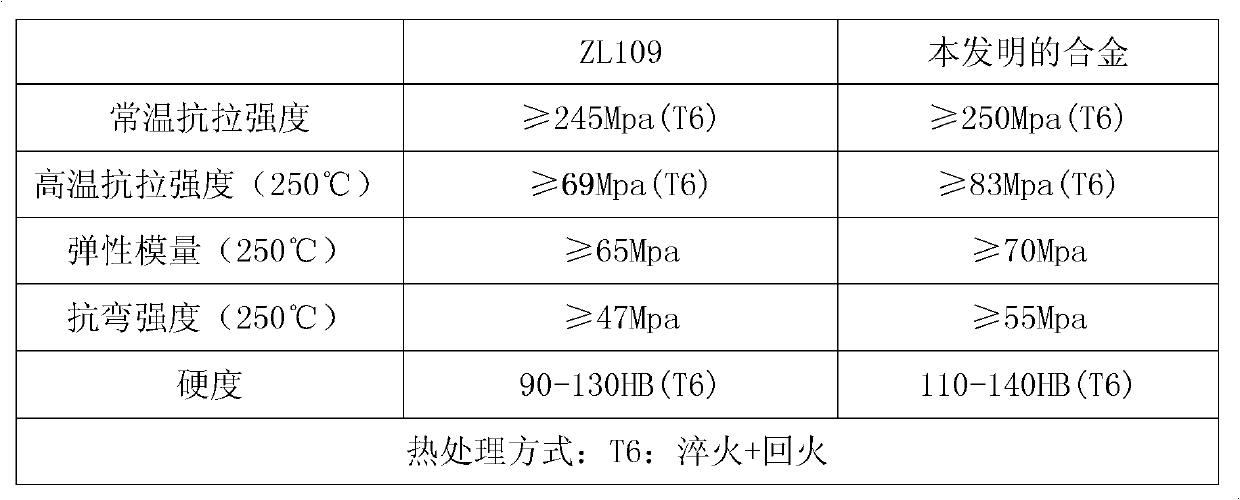

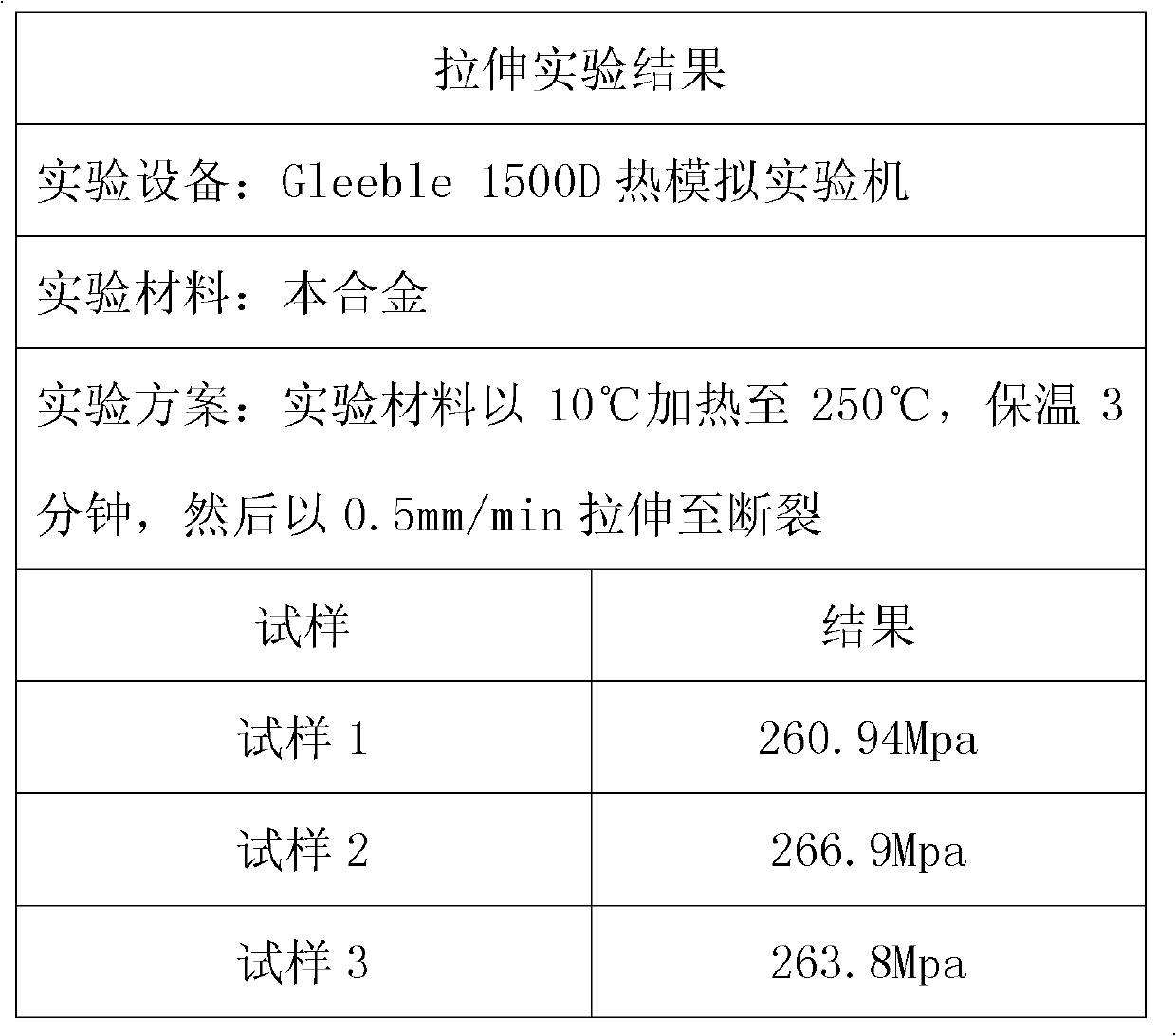

Novel casting aluminium alloy and preparation method thereof

The invention discloses a casting aluminium alloy and a preparation method thereof. The casting aluminium alloy comprises the following components in percentage by weight: 11-13wt% of Si, 2-4wt% of Cu, 0.5-1.2wt% of Mg, 2-3.5wt% of Ni, 0.08-0.18wt% of Ti, 0.1-0.2wt% of V and the balance of aluminium ingot, wherein the mark of the aluminium ingot is Al99.50. Compared with the existing casting aluminium alloy ZL109, the casting aluminium alloy has the advantages that comprehensive mechanical property is greatly improved, and high-temperature thermal fatigue strength is improved by 10%. Each index of the obtained aluminium alloy is far beyond the national criterion of acceptability after the aluminium alloy is tested by the aluminium alloy tensile property experiment of the environment experiment center of the China Academy of Engineering Physics. The casting aluminium alloy is used for manufacturing engine pistons, the working performance of the engine piston can be greatly improved, and the service life of the piston can be greatly prolonged.

Owner:四川渝邻汽车零部件有限公司

Fast 7075 aluminium alloy shape extruding process

The present invention discloses the fast extrusion process of type-7075 aluminum alloy shape suitable for use in different extruders of different sizes to produce aluminum alloy shape with homogeneous cooling and no extruded crack in high extrusion speed. The present invention features the hot extrusion process of producing type-7075 aluminum alloy shape in circular, rectangular or other cross section shape, and the cooling of extruding mold and extruded shape in the mold outlet with gaseous or liquid nitrogen to realize fast extrusion. During the extrusion, the flow rate of gaseous or liquid nitrogen is controlled with valve to 1-30 L / min, the nitrogen pipes are in the number and distribution determined by different cross section shape of the extruded shape, and extrusion speed is 4-12 m / min.

Owner:GUANGDONG XINGFA ALUMINUM

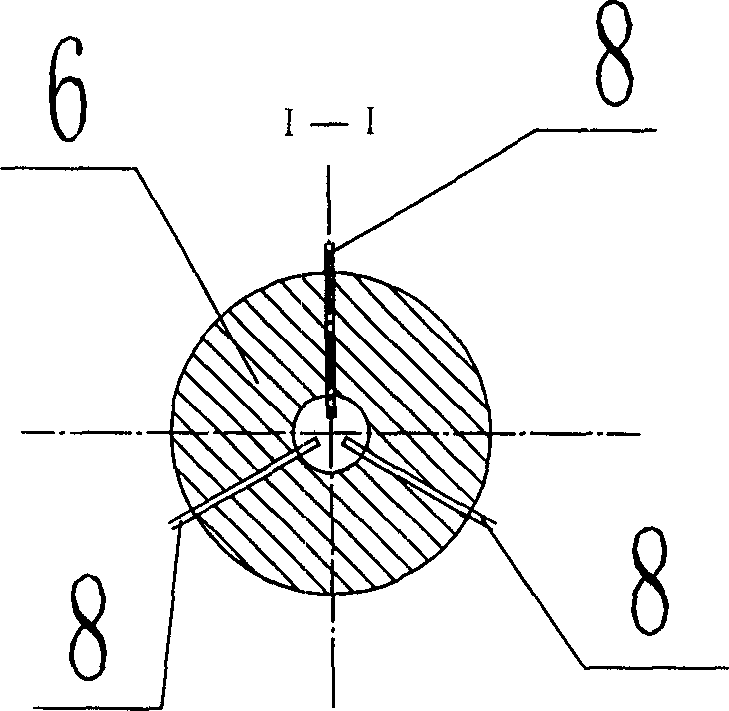

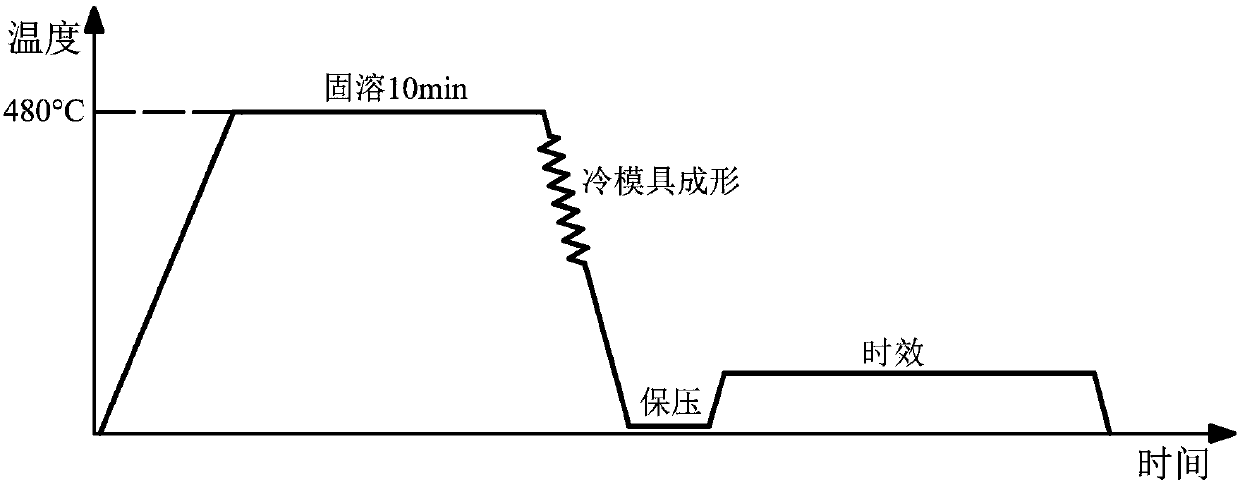

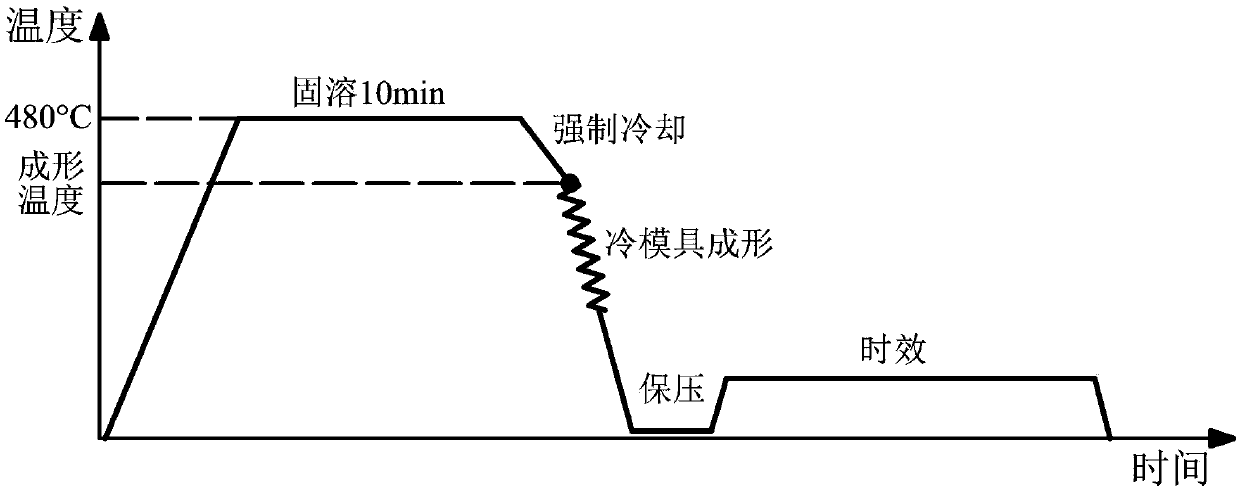

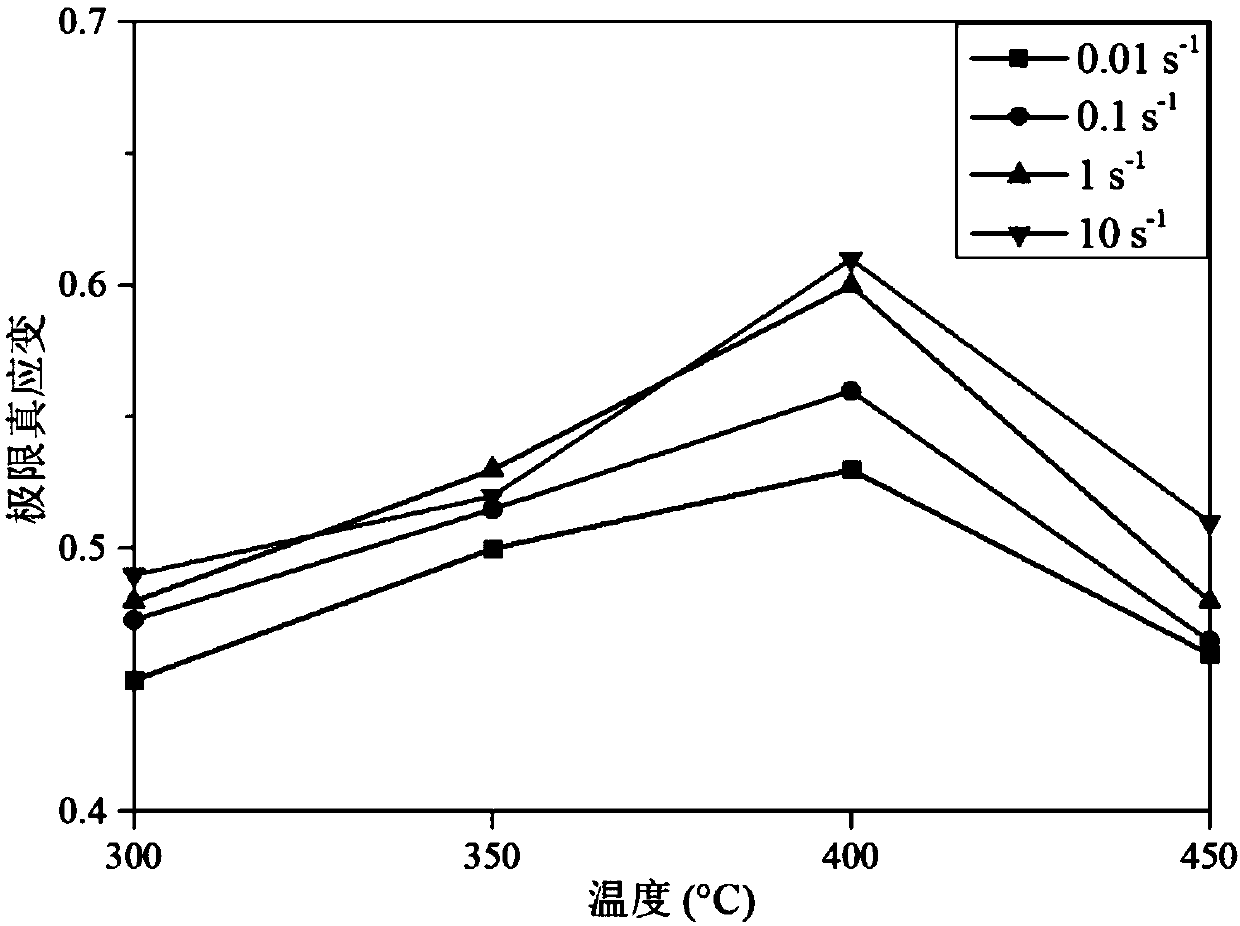

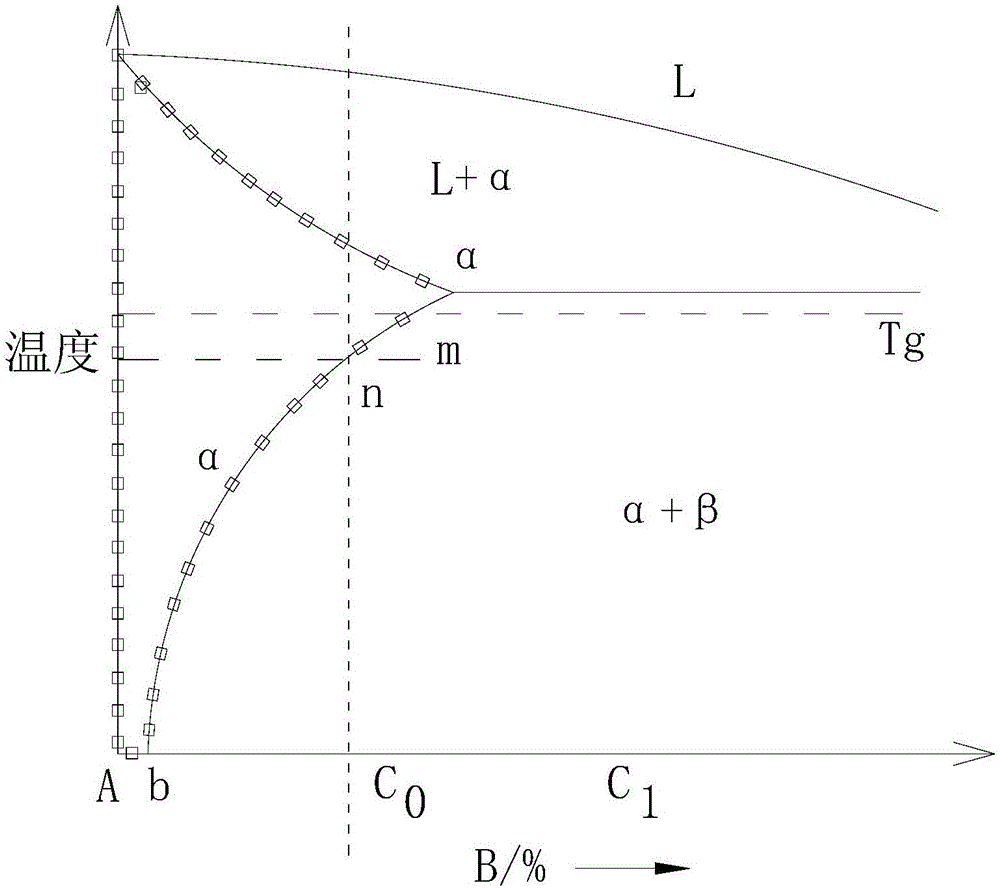

Heat treatment method for improving hot punching moldability of 7075 aluminum alloy

The invention mainly belongs to the field of plastic molding machining of metal materials and particularly relates to a heat treatment method for improving the hot punching moldability of 7075 aluminum alloy. The heat treatment method comprises the steps of solution treatment, cold mould molding, pressure-retaining quenching and ageing. The heat treatment method further comprises the step of sheetmetal forced cooling performed between the step of solution treatment and the step of cold mould molding. According to the step of forced cooling, sheet metal is cooled to a certain temperature and then deformed. By adopting the heat treatment method, the hot punching moldability of the aluminum alloy can be improved. By adopting the heat treatment method that after solution treatment, the sheetmetal is fast cooled to a molding temperature, the ductility of a material under a high temperature is fully used, and the moldability of the component is further improved on the basis of an existingaluminum alloy hot punching process.

Owner:UNIV OF SCI & TECH BEIJING

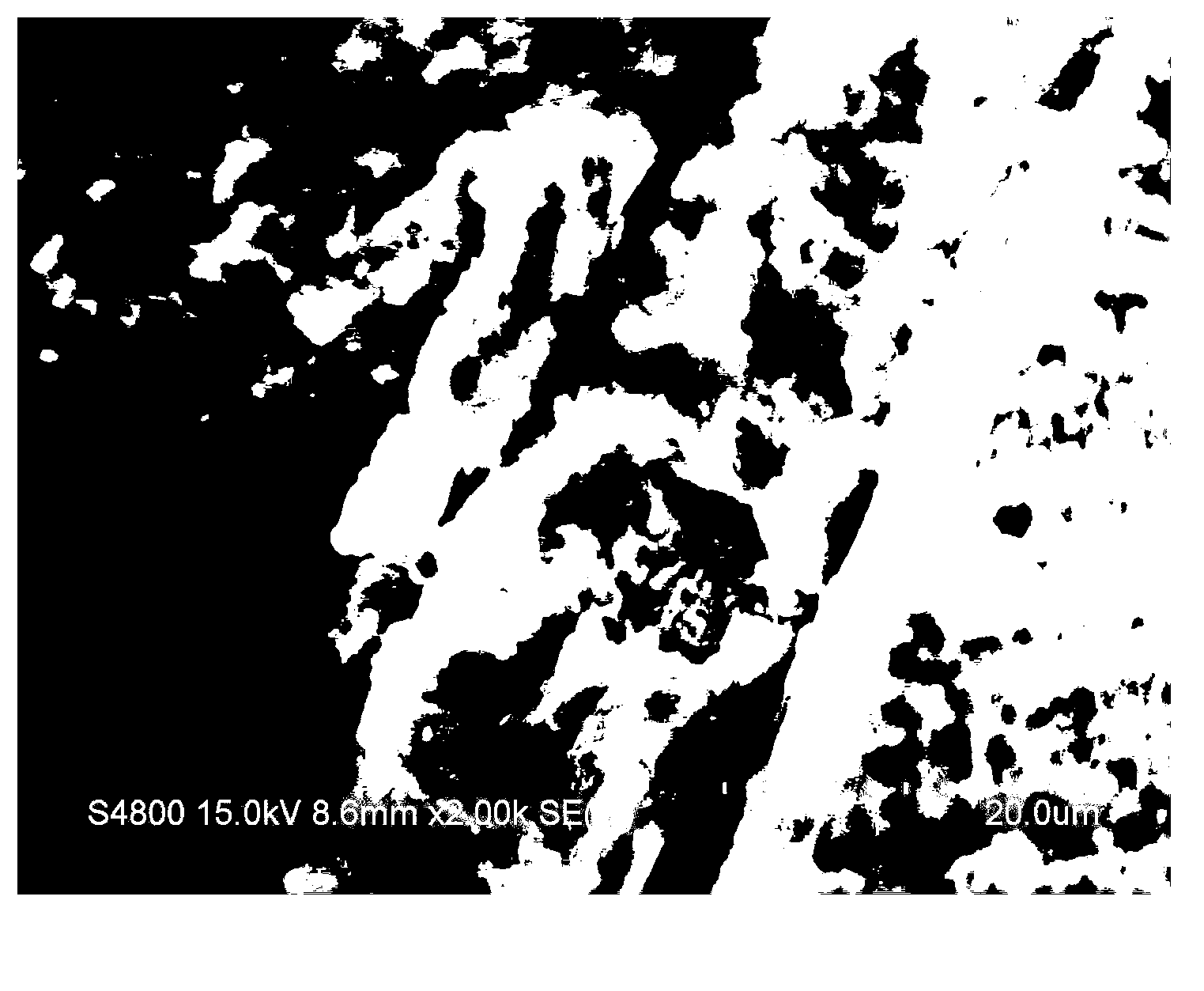

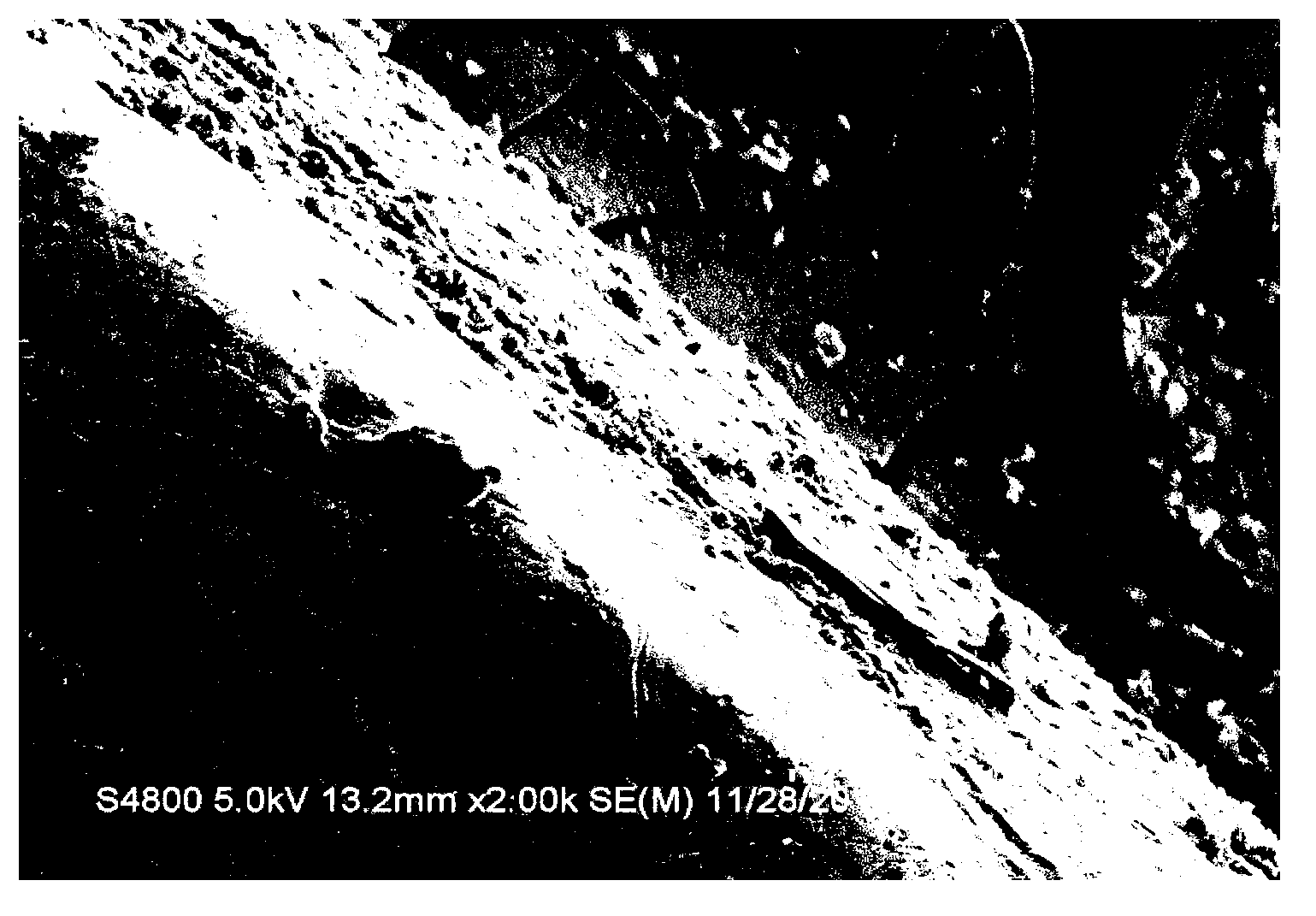

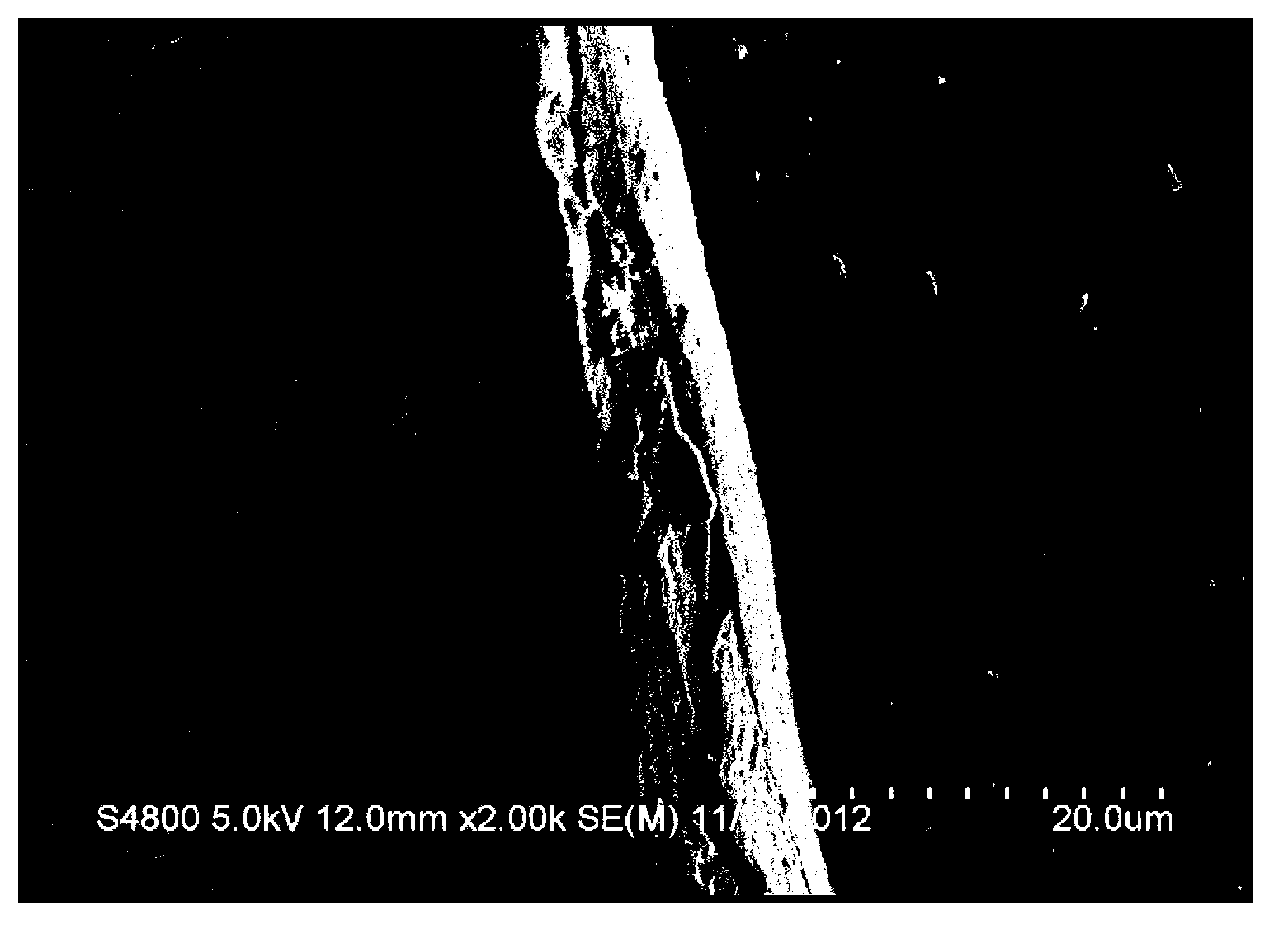

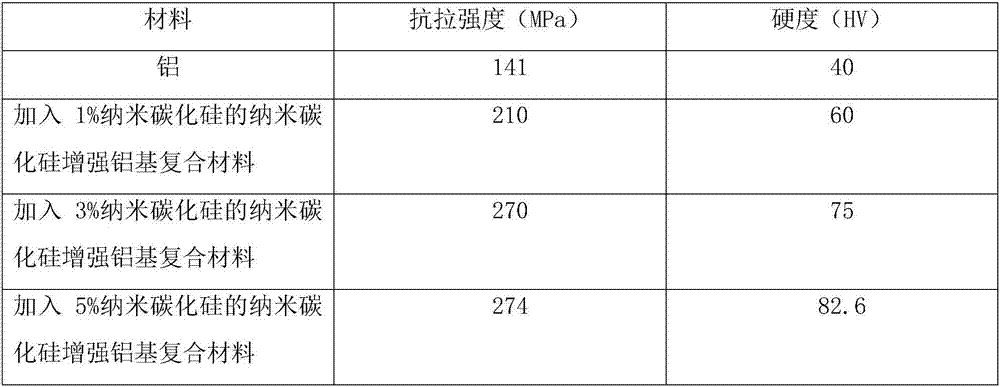

Nano silicon carbide reinforced aluminum matrix composite and preparing method thereof

The invention belongs to the field of materials, and discloses a nano silicon carbide reinforced aluminum matrix composite and a preparing method thereof. The problem that nano silicon carbide particles cannot be evenly dispersed in an aluminum matrix is solved. The composite is formed in a manner that 7075 aluminum alloy powder and nano silicon carbide powder are subject to solvent assisted dispersion, mechanical ball grinding, pressing forming, high-temperature sintering and cooling. The granularity of 7075 aluminum alloy powder ranges from 30 micrometers to 100 micrometers, the mass percent ranges from 95% to 99%, the granularity of the nano silicon carbide powder ranges from 20 nm to 40 nm, and the mass percent ranges from 1% to 5%. Nano silicon carbide particles are evenly dispersed in an aluminum matrix, and tensile strength and hardness of the composite are obviously improved.

Owner:JIANGSU UNIV

Wear resistant ceramic coated aluminum alloy article and method for making same

InactiveUS20080226938A1AnodisationElectrolytic inorganic material coatingWear resistantCeramic coating

A method for forming a wear resistant ceramic coating on an aluminum alloy article. The alloy preferably contains from about 85 to about 92 percent aluminum with a plurality of other oxidizable metals selected from copper, magnesium, zinc, and chromium. Less that about 2 percent total of other elements is usually present. In accordance with the invention, the alloy preferably contains less than 0.5 percent each of manganese, iron and silicon. An example of such an alloy is 7075 aluminum alloy. The method includes the steps of: a) immersing the article in an aqueous electrolyte containing from about 1.5 to about 2.5 grams per liter of alkali metal hydroxide and from about 6.5 to about 9.5 grams per liter of alkali metal silicate. In general no more than 1 g per liter of alkali metal pyrophosphate is present and no more than about 0.05 percent of hydrogen peroxide is present, and b) applying an alternating current through the electrolyte using the article as one electrode where a second electrode includes at least one of an electrically conductive container or an immersed separate electrode, where applied EMF is selected to provide a current density of from about 15 to about 25 A / dm2, for a sufficient time to obtain a wear resistant ceramic coating having a thickness of from about 125 to about 150 μm, as measured on a flat face of the article. The invention also includes wear resistant articles made by the method.

Owner:CALVARY DESIGN TEAM

Laminar compound aluminium alloy material with high intensity and preparation thereof

InactiveCN101279521AHigh strengthGood formabilityMetal rolling arrangementsMetal layered productsAviationMetallic materials

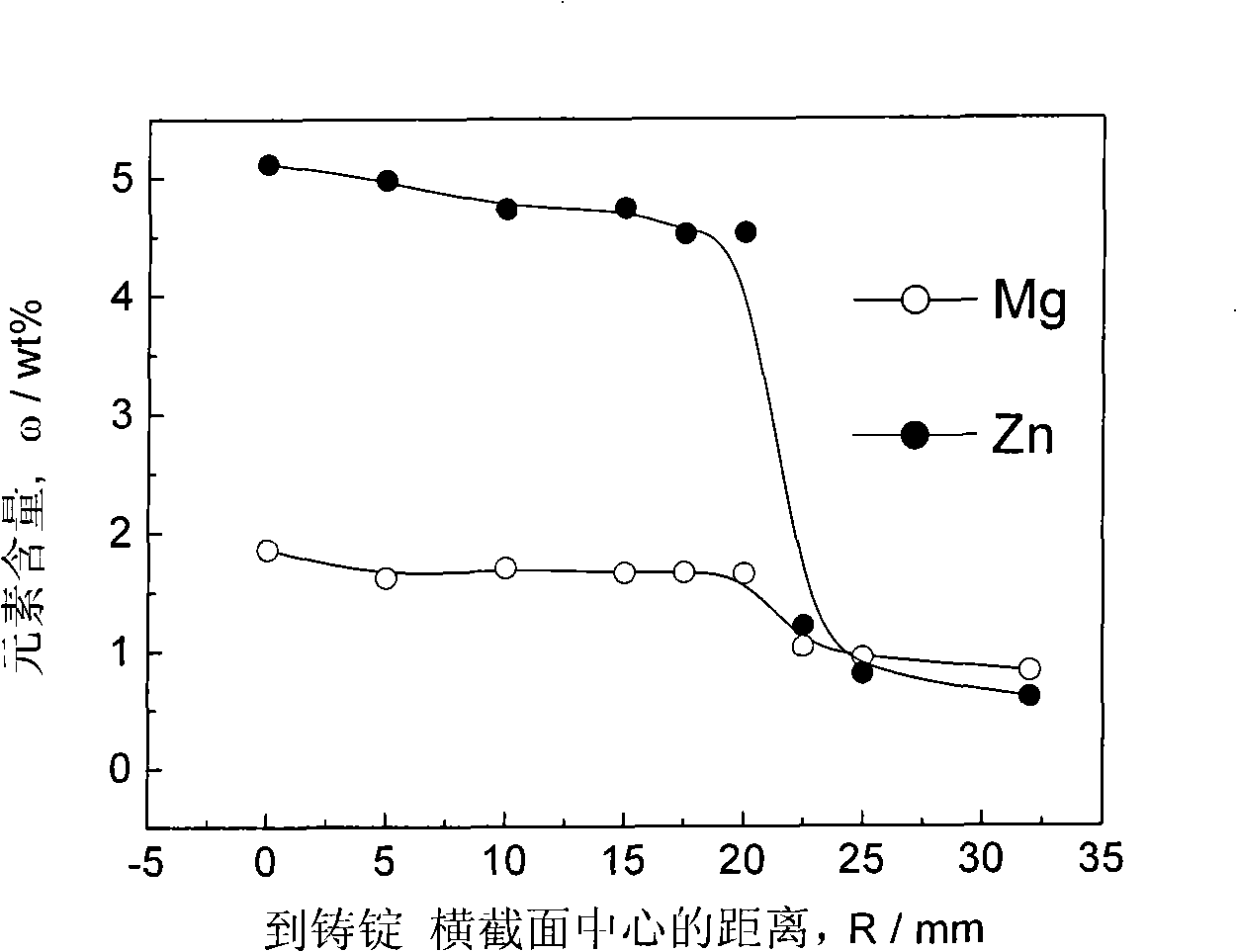

The invention relates to a metallic material and the technical field of the processing of the metallic material, in particular to a high-strength layered composite aluminum alloy material with excellent shaping performance and a preparation method; wherein, 6009 aluminum alloy with excellent shaping performance serves as the external layer of the material and 7075 aluminum alloy with high tenacious degree serves as the internal layer; a transition layer with a thickness of millimeter magnitude and components varying in gradient is arranged between the two layers; the contents of zinc and magnesium contained in the components of internal aluminum alloy are lowered in gradient from inside to outside; the material has excellent shaping performance as 6009 aluminum alloy does; besides, the anti-corrosion performance of the material corresponds to that of 6009 aluminum alloy, while the strength is 50 % higher than that of 6009 aluminum alloy. The material has the advantages of good shaping performance, anti-corrosion and high strength and can be widely used in the fields of automobile, petrochemical industry, aviation, etc.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of reclaimed 7075 aluminum alloy containing rare earth

The invention discloses a preparation method of reclaimed 7075 aluminum alloy containing rare earth. The invention belongs to the technical field of materials. the method comprises steps that: surface impurities are removed from waste 6063 aluminum; smelting material alloys are prepared; metal aluminum is heated until melted; a mixed salt is added to the melted aluminum; the waste 6063 aluminum is added to the mixture, and the mixture is melted; metal silicon, Al-30Cu alloy, Al-10Mn alloy, Al-2Cr alloy and Al-3Ti alloy are pressed in the mixture and are melted; Al-RE alloy, metal magnesium and excess metal magnesium and metal zinc are added to the mixture; the mixture is melted and heated; mixed gas of argon and nitrogen is delivered into the mixture; the mixture is settled and used for casting; a cast ingot is subject to preheating and hot rolling; the rolled material is subject to a solid solution treatment and water quenching; then the material is subject to an aging treatment for 15-20h under a temperature condition of 110-115 DEG C. With the method, the consumption of industrial pure aluminum is reduced, waste aluminum is cyclically utilized, and sustainable development of aluminum industries can be realized. The method has advantages of high recovery rate, low cost, and low pollution.

Owner:NORTHEASTERN UNIV

Micro-nano particle reinforced aluminum alloy core filler wire for welding 7075 aluminum alloy

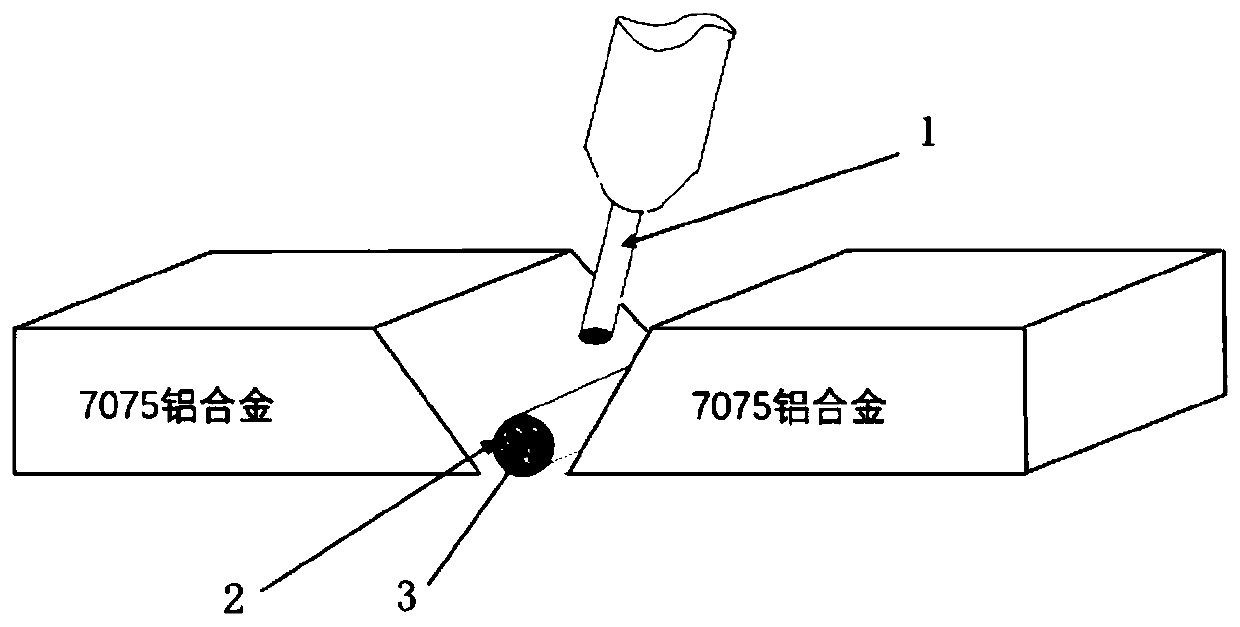

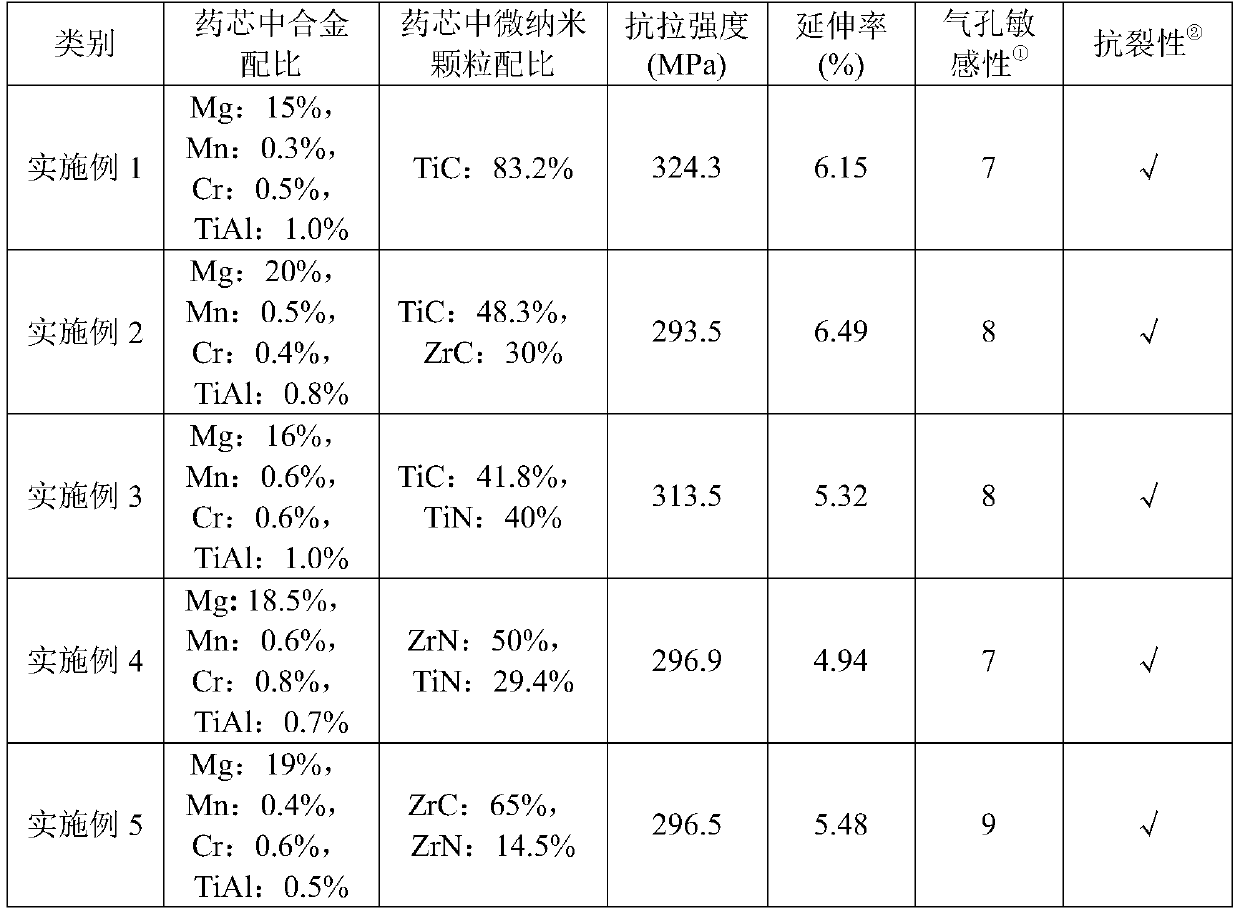

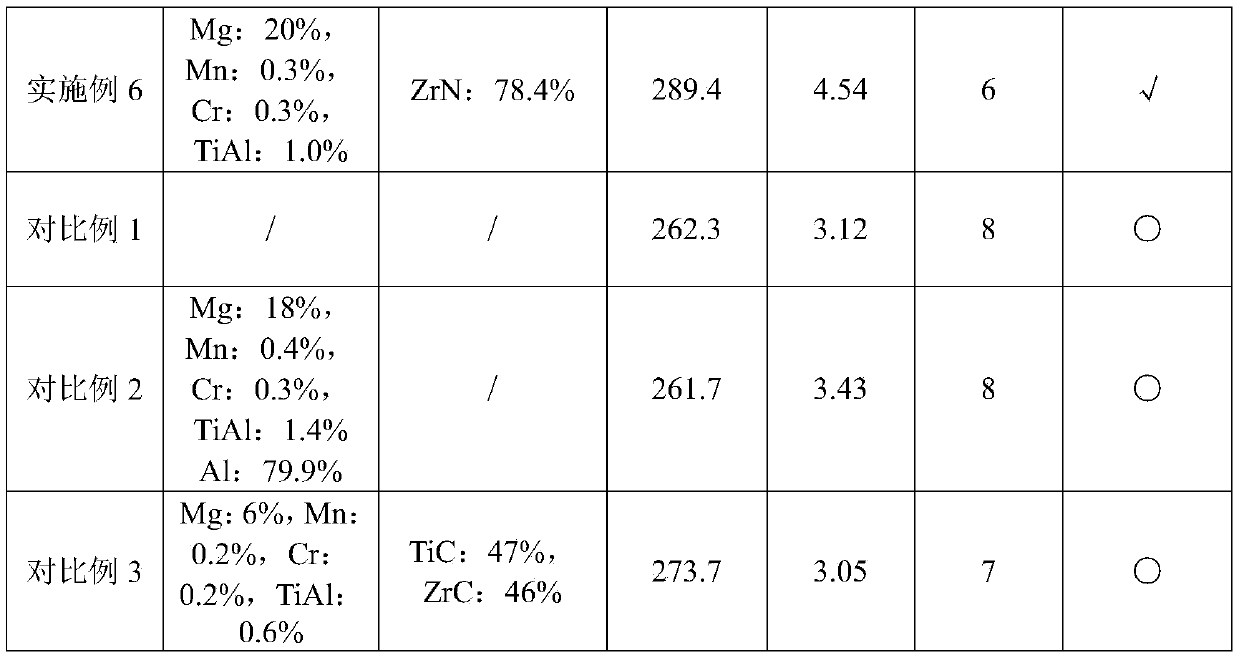

ActiveCN110560957AImprove adaptabilityEasy to processWelding/cutting media/materialsSoldering mediaMicro nanoWeld seam

The invention discloses a micro-nano particle reinforced aluminum alloy core filler wire for welding a 7075 aluminum alloy, and belongs to the technical field of material processing engineering. A pure aluminum strip or a 5052 aluminum alloy strip is adopted as a coating layer, alloy powder in the core comprises pure magnesium powder, manganese powder, chromium powder, titanium-aluminum alloy powder and the like, and ceramic particles such as TiC, ZrC, TiN, SiC and the like with micro-nano sizes are added into the core. When the aluminum alloy core filler wire is used, the aluminum alloy corefiller wire is placed in a groove or a welding seam, and the aluminum alloy core filler wire is welded by adopting a conventional MIG method. Compared with the prior art that an aluminum alloy solid-core welding wire is independently used for welding, the welding seam strength of the 7075 aluminum alloy can be improved, the strength matching degree of a welding joint is further improved, the sensitivity of hot cracks and air holes is reduced, the operation process is simple, and the welding process performance is excellent.

Owner:BEIJING UNIV OF TECH

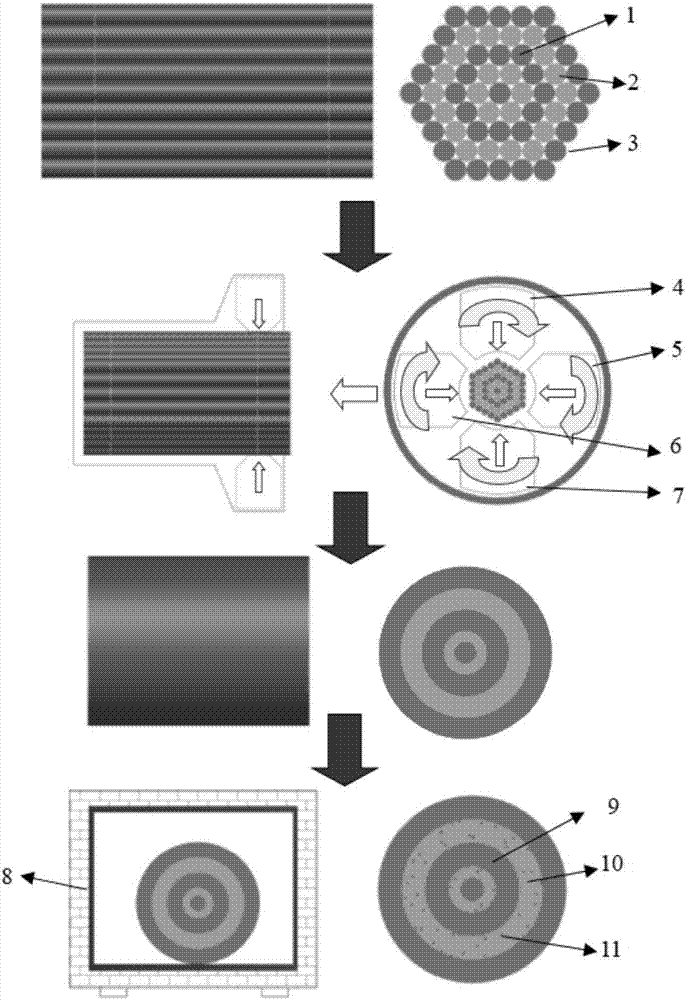

Preparation method for multi-scale precipitation of heterogeneous aluminum alloy bars

The invention provides a preparation method for multi-scale precipitation of heterogeneous aluminum alloy bars. According to the preparation method, a plurality of pure aluminum and 7075 aluminum alloy metal bars with the same length are mixed and bound, and then undergo rotating forging plastic deformation and multi-pass high-strain rotary forging deformation, so that the interfaces of initial aluminum alloy fine bars are combined to prepare pure aluminum and 7075 aluminum alloy mixed bar blanks, then multi-scale precipitation heat treatment on the bars is carried out by utilizing different age hardening behaviors of the pure aluminum and the 7075 aluminum alloy, and the heterogeneous Al and 7075 aluminum alloy bars with multi-scale precipitation phase density are finally obtained.

Owner:NANJING UNIV OF SCI & TECH

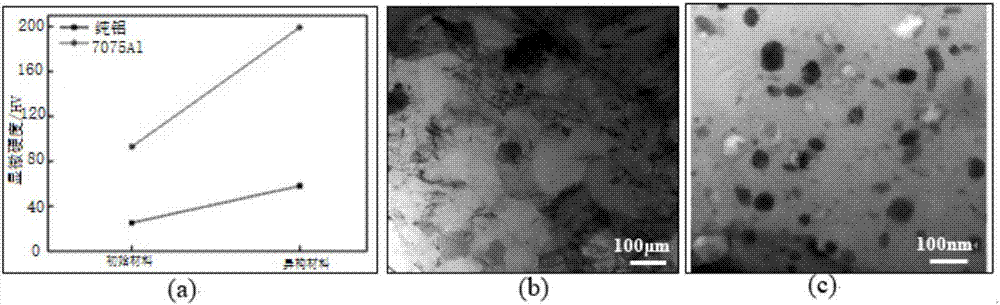

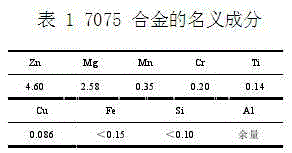

Two-stage aging treatment technology for 7075 aluminum alloy

InactiveCN105239028AImprove mechanical propertiesImprove conductivitySolution treatment7075 aluminium alloy

The invention discloses a two-stage aging treatment technology for 7075 aluminum alloy. The two-stage aging treatment technology for 7075 aluminum alloy is characterized by comprising the following steps that the 7075 aluminum alloy is kept at the temperature of 450 DEG C for 24 h to be homogenized, then the 7075 aluminum alloy is rolled to be a sheet of 5 mm thickness in a hot manner at the temperature of 420 DEG C, and the sheet is subjected to the two-stage solution treatment at the temperature of 460 DEG C for 2 h and the temperature of 480 DEG C for 1h, and finally subjected to the two-stage aging treatment at the temperature of 100-110 DEG C for 8-12 h and the temperature of 130-160 DEG C for 14-24 h. The optimal two-stage aging treatment technology is at the temperature of 105 DEG C for 8h and the temperature of 130 DEG C for 14h.

Owner:孟源

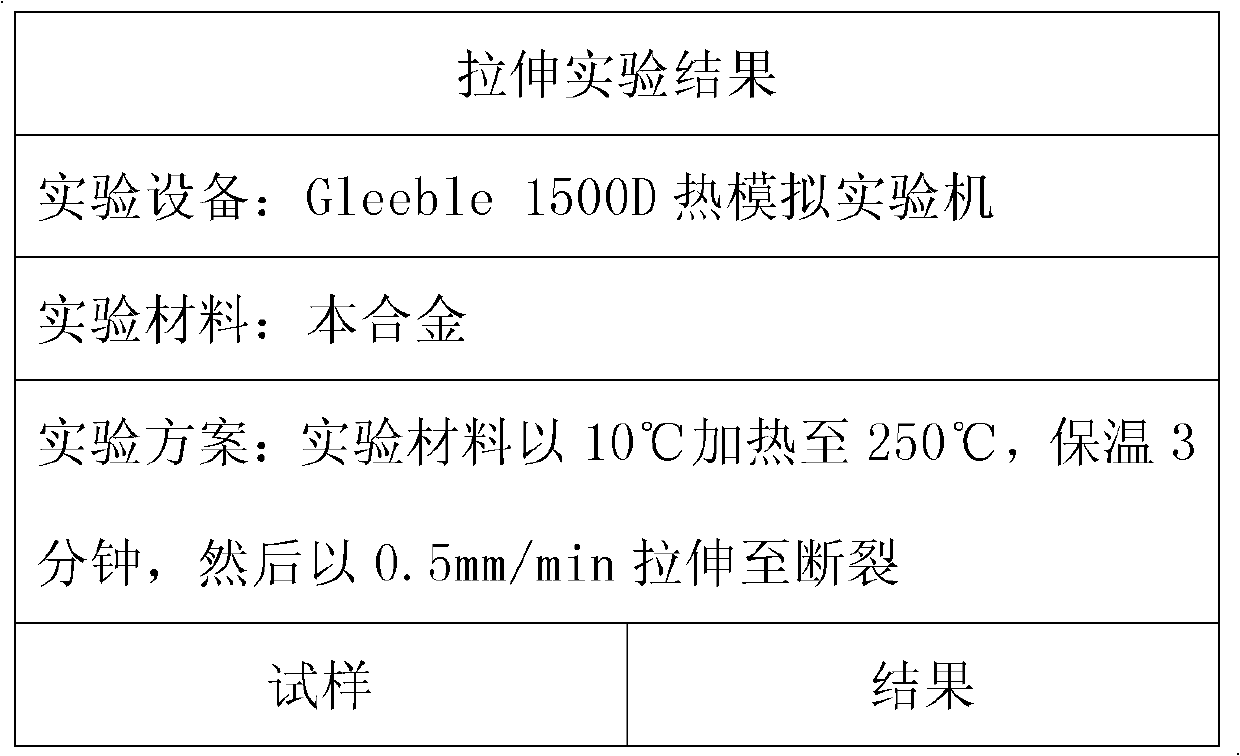

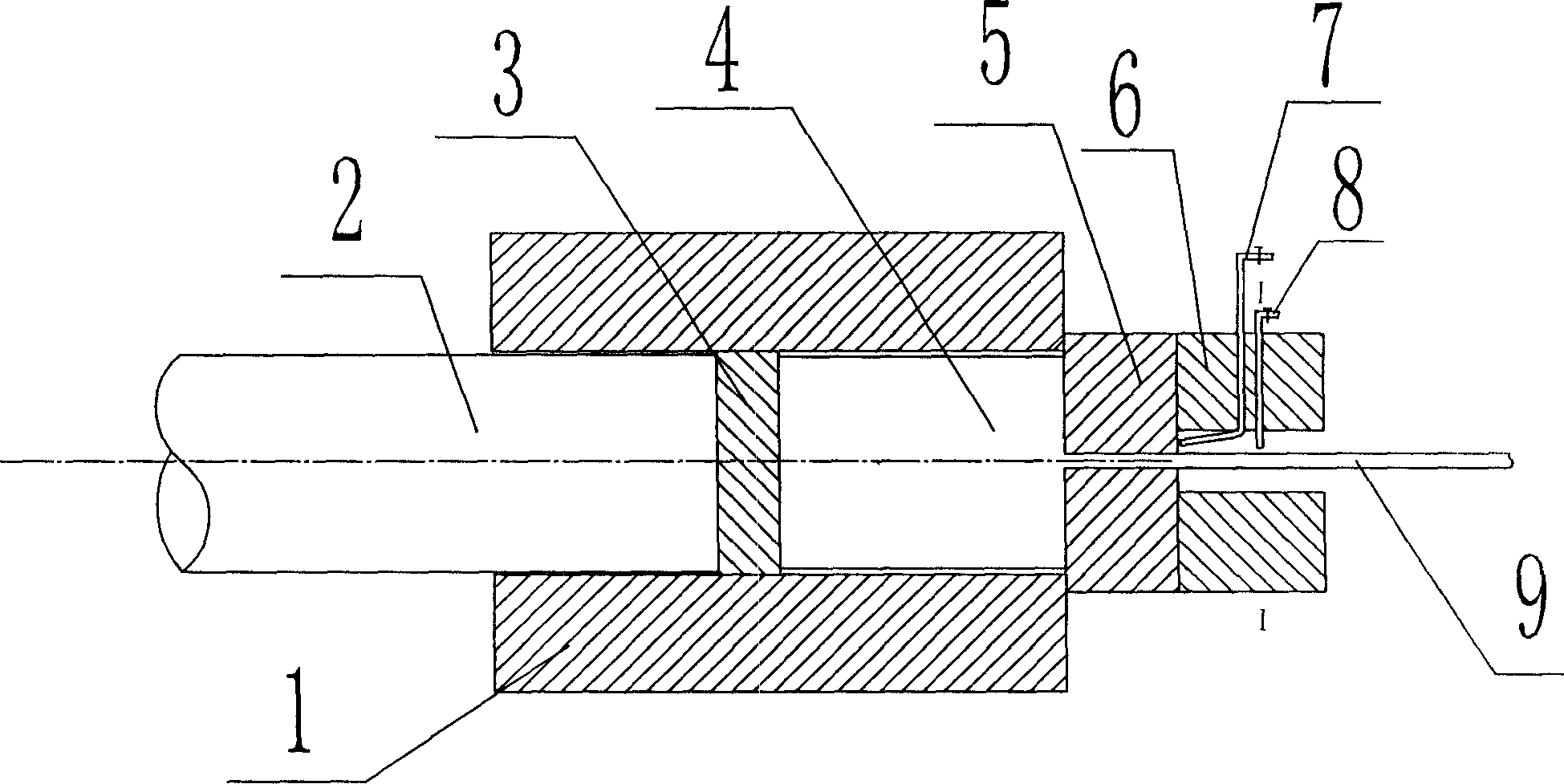

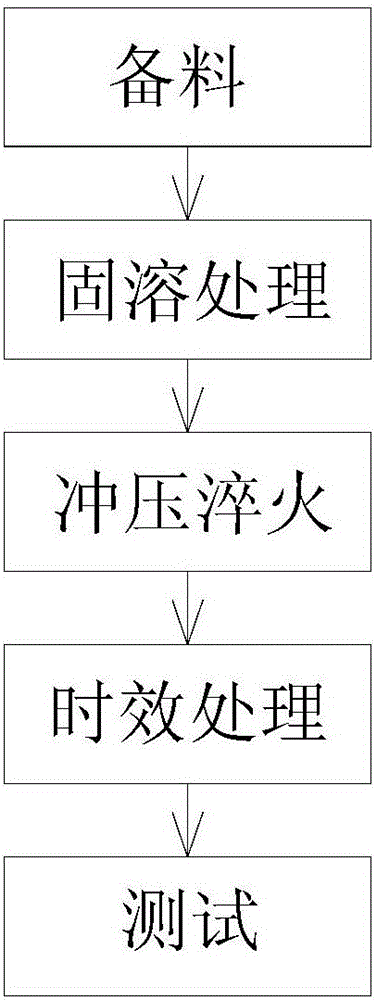

Automobile B column machining process by using 7075 aluminum alloy material

InactiveCN106756673AGood molding effectMeet the requirements for tensile strengthSolution treatmentMachining process

The invention provides an automobile B column machining process by using a 7075 aluminum alloy material. The automobile B column machining process comprises material preparing, solution treatment, stamping quenching, aging treatment and tensile testing. A sheet material is subjected to the solution treatment, stamping quenching and aging treatment under the specific condition, so that the formability of the sheet material is improved, and accordingly, an automobile B column meets the requirements for tensile strength and the percentage of elongation, thereby meeting the requirement of the lightweight of using.

Owner:上海赛科利汽车模具技术应用有限公司

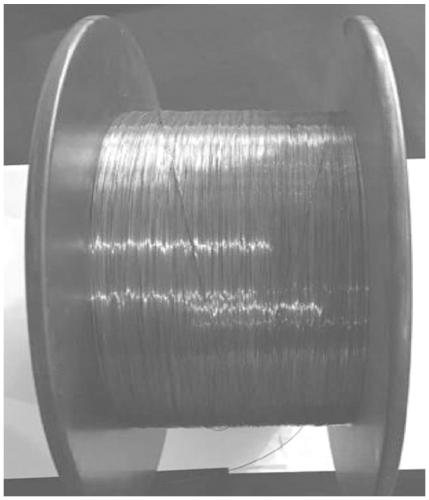

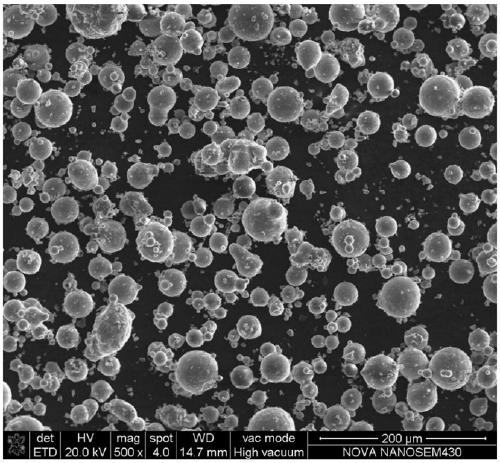

Preparation method of aluminum alloy wire for metal 3D printing

ActiveCN110273076AHigh strengthGuaranteed molding accuracyAdditive manufacturing apparatusIncreasing energy efficiencyVacuum induction furnace7075 aluminium alloy

The invention relates to a preparation method of an aluminum alloy wire for metal 3D printing. The method particularly aims at a 7075 aluminum alloy wire for metal 3D printing. The preparation method of the wire comprises the steps of alloy dosing, pressing forming, vacuum induction furnace smelting, alloy pouring, forging, rotary forging, wire drawing, continuous electrolytic washing and heat treatment straightening. The surface quality of the aluminum alloy wire obtained by the adoption of the method is improved remarkably, in the 3D printing process, the wire feeding speed is stable, and strength and mobility are good.

Owner:CHONGQING MATERIALS RES INST

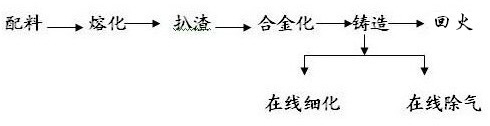

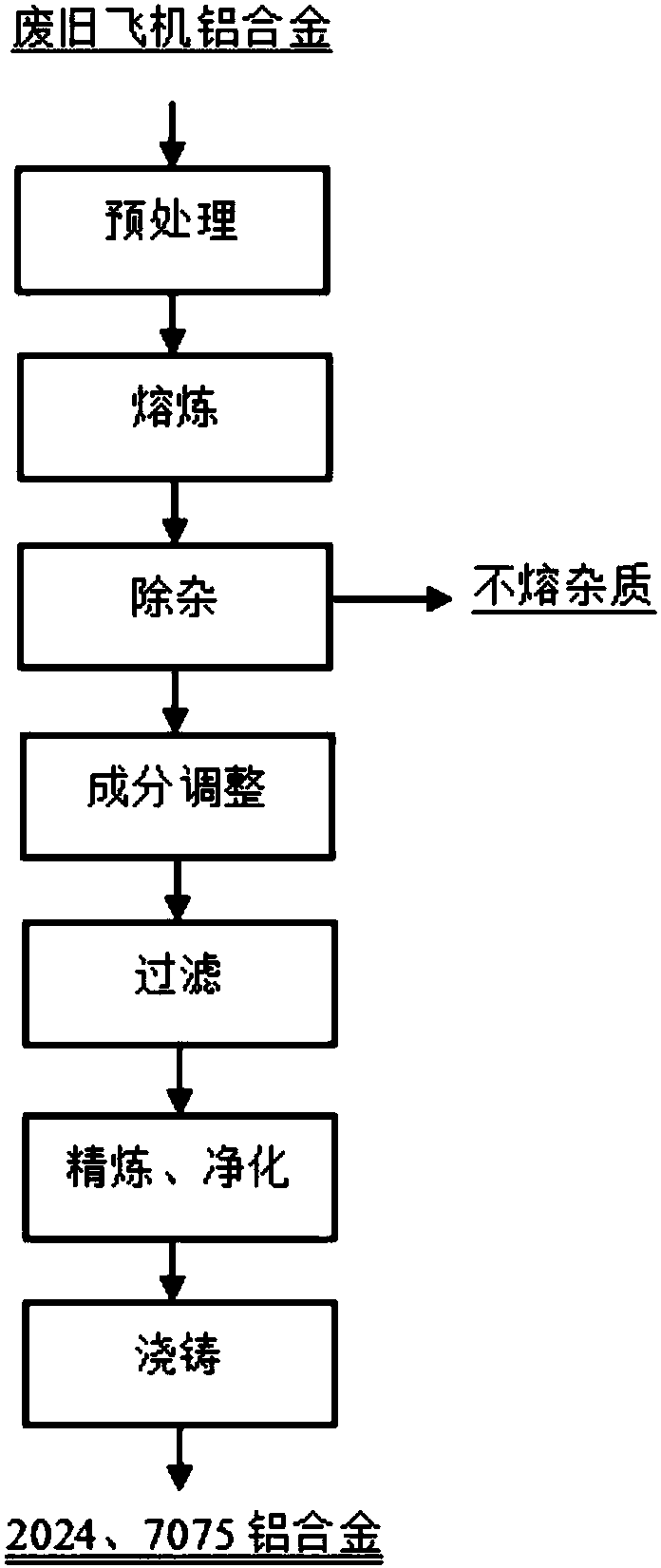

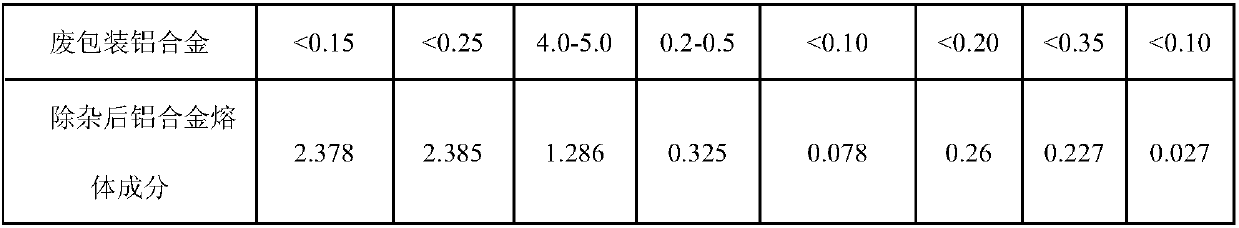

Method of aluminum alloys of scrap aircraft reused to produce 2024 or 7075 aluminum alloy

PendingCN109518045AReduce manufacturing costEase of industrial applicationFoundry mouldsCasting cleaning apparatus2024 aluminium alloyFiltration

The invention provides a method of an aluminum alloy of scrap aircraft reused to produce a 2024 or 7075 aluminum alloys, belongs to circular economy technologies, and particularly relates to a methodfor scrap aluminum alloys preservation and recycling. According to the method, the aluminum alloys of the scrap aircraft is adopted as a raw material, and the 7075 or 2024 aluminum alloys are obtainedafter pretreatment, smelting, impurity removal, composition adjustment, filtration, refining, purification, and casting; and in the composition adjustment step, low-cost preservation and recycling ofthe aluminum alloys of the scrap aircraft are realized by using other waste aluminum alloys and / or intermediate alloys for composition adjustment. According to the method of the aluminum alloys of the scrap aircraft reused to produce the 2024 or 7075 aluminum alloys, the production cost can be obviously lowered, and industrial application is facilitated.

Owner:UNIV OF SCI & TECH BEIJING +1

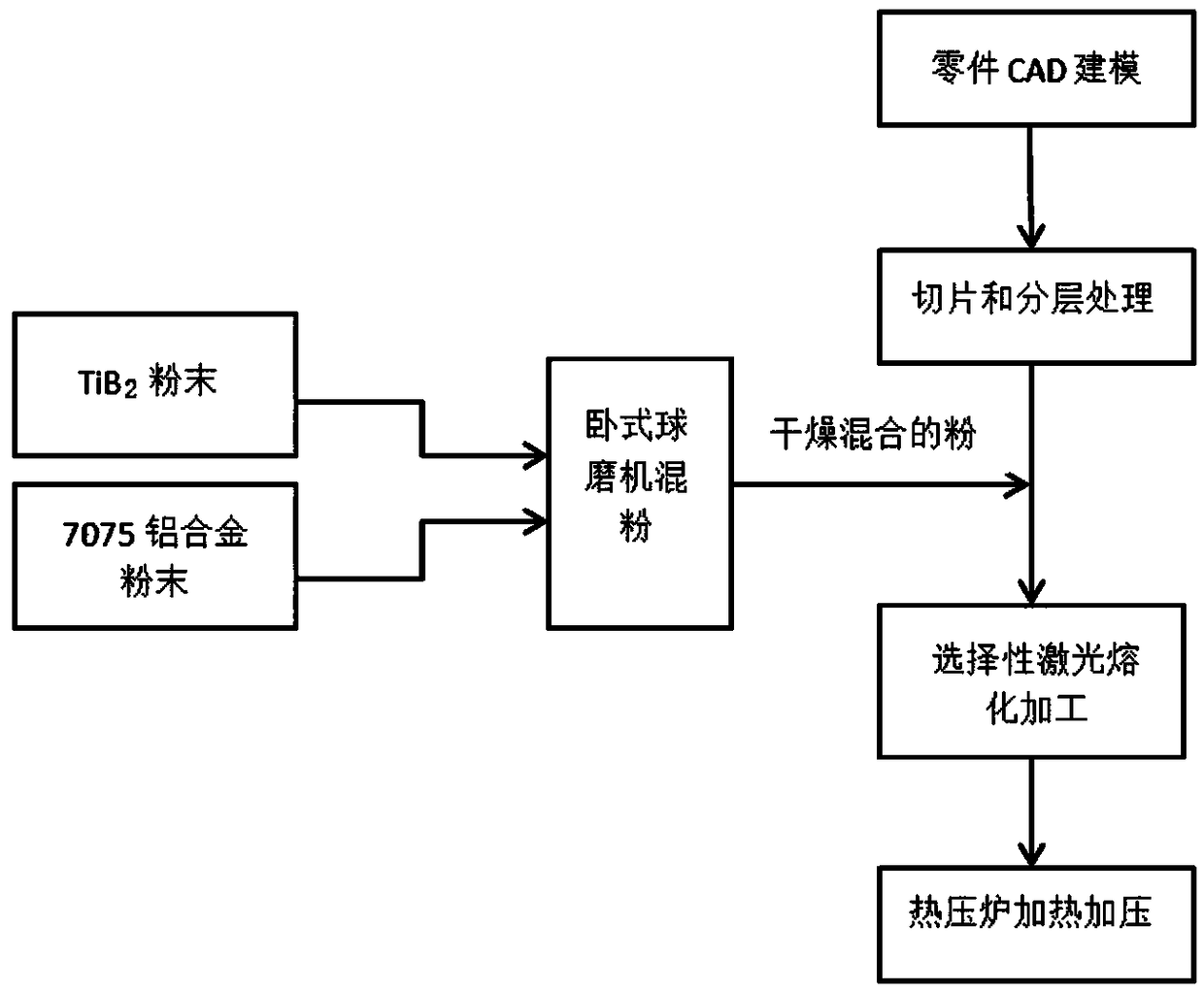

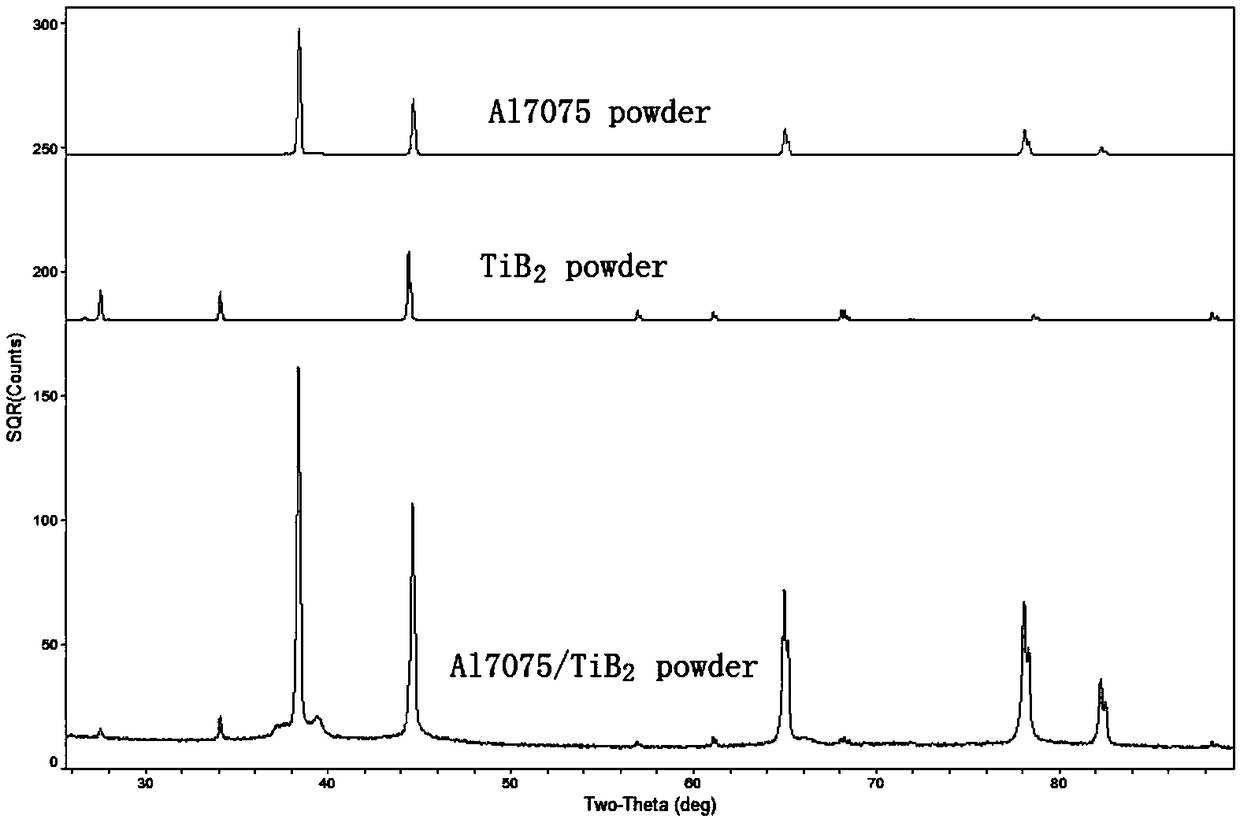

Method for eliminating selective laser melting molding cracks of 7075 aluminum alloy

ActiveCN109290583AImprove mechanical propertiesInhibition of hot cracksAdditive manufacturing apparatusIncreasing energy efficiencyVolumetric Mass Density7075 aluminium alloy

The invention discloses a method for eliminating selective laser melting molding cracks of a 7075 aluminum alloy. The method comprises the following steps that (1), under a protective atmosphere, 7075aluminum alloy raw powder and TiB2 submicron powder are subjected to ball milling and powder mixing, and powder obtained after ball milling and powder mixing is taken out and dried; and (2), the powder dried in the step (1) is added into a powder storing cylinder of selective laser melting molding equipment, selective laser melting is conducted after working parameters of the selective laser melting molding equipment are set, a 7075 aluminum alloy molded part is obtained, and finally heating and pressurizing treatment is conducted on the 7075 aluminum alloy molded part. According to the method, the TiB2 submicron powder capable of promoting nucleation is added into the 7075 aluminum alloy raw powder, the selective laser melting molding periodic cracks of the 7075 aluminum alloy are eliminated, and the molded part is put into a heating and pressurizing furnace to be heated and pressurized to improve the density of the part.

Owner:SOUTH CHINA UNIV OF TECH

High-performance 7075 aluminum alloy die forging method

ActiveCN109182822AImprove the bonding strength of the interfaceImprove mechanical propertiesAlcoholHigh energy

The invention provides a high-performance 7075 aluminum alloy die forging method. In a water-free environment, Ti ions are adsorbed under the action of functional groups of carbonylated graphene through alcohol thermal high pressure, and TiO2 (anatase type) clad carbonylated graphene is obtained during after-baking; the obtained powder and pure aluminum powder are mixed and cold-pressed accordingto a certain ratio to obtain an intermediate alloy; the intermediate alloy is added into aluminum alloy melt as required, and TiO2 clad carbonylated graphene particles are dispersed under the action of a high-energy ultrasonic instrument; an obtained composite is poured to the center position of a lower die cavity to conduct thixotropic forging to obtain a die forged blank, then the blank is subjected to T6 heat treatment, and finally, a high-performance product is obtained. The product produced through the method has the good comprehensive mechanical performance. Meanwhile, the technology hasthe advantages of being simple, safe, easy to operate, controllable and the like.

Owner:NANCHANG UNIV

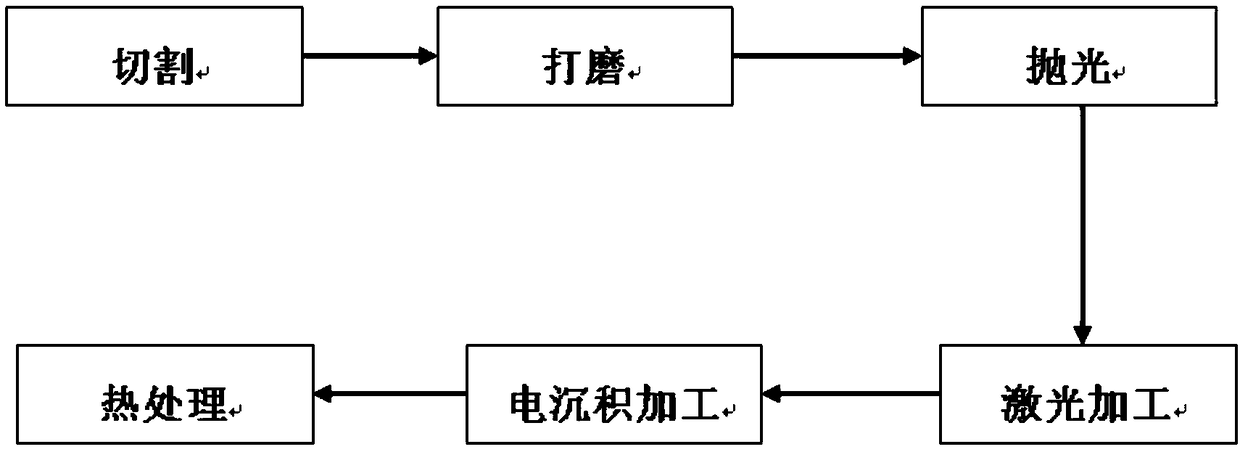

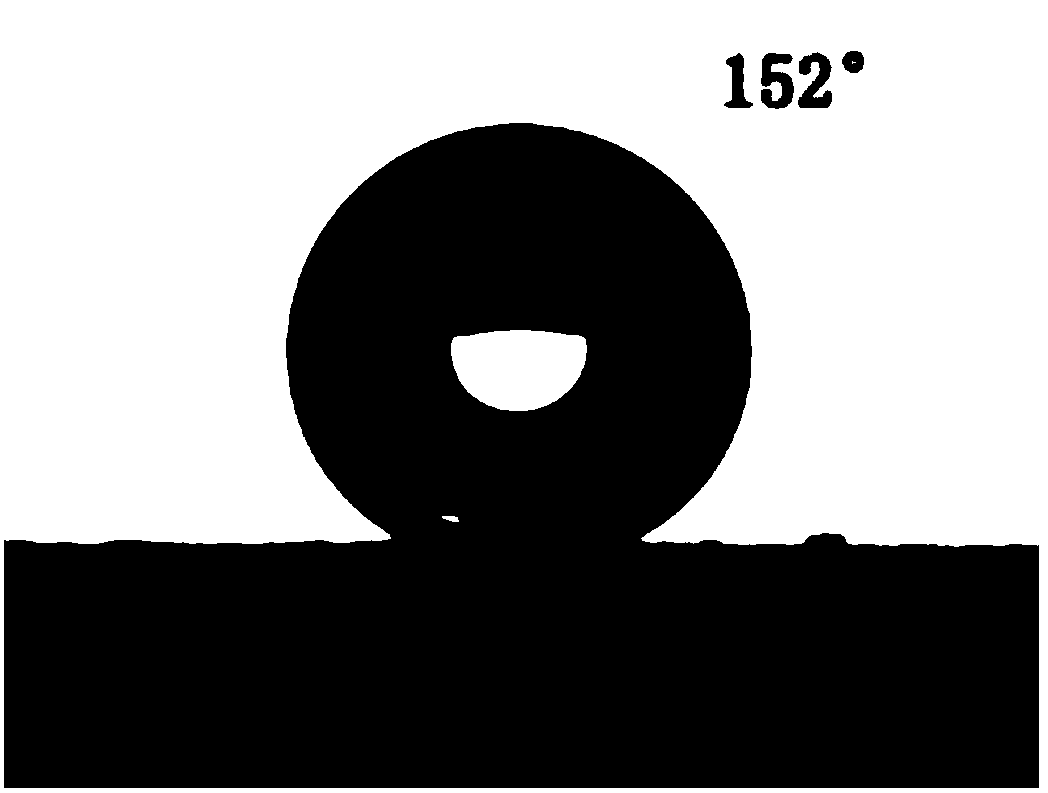

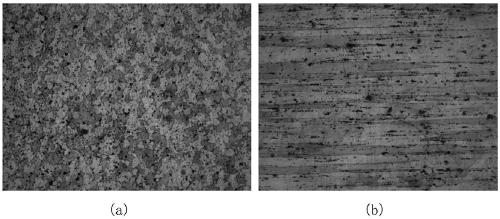

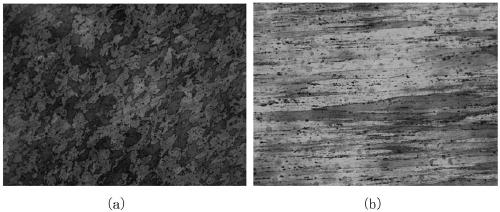

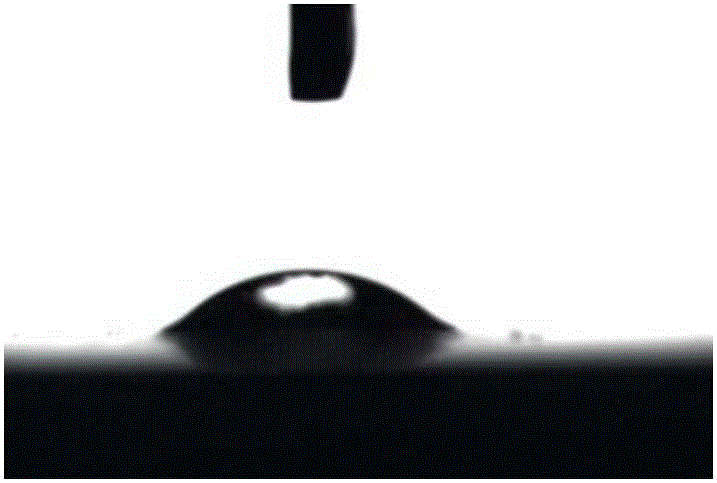

Preparation technology for super-hydrophobic surface of 7075 aluminum alloy

ActiveCN108857273ASmall grain sizeSuperhydrophobicLaser beam welding apparatusRoom temperatureMegasonic cleaning

The invention discloses a preparation technology for the super-hydrophobic surface of a 7075 aluminum alloy, and belongs to the field of electrodeposition application. The problems of super-hydrophobic structure preparing are solved. The preparation technology comprises the following steps that the surface of the aluminum alloy is ground through metallographic sandpaper to be smooth; the ground workpiece surface is polished through a metallographic sample polishing machine, and put into deionized water to be ultrasonically washed; a pit-shaped structure is constructed in the polished workpiecesurface through a laser marking machine, and the polished workpiece surface is placed in the deionized water to be ultrasonically washed and dried; a workpiece substrate subjected to laser treatmentis subjected to nickel ion electrodeposition, and placed in the deionized water to be ultrasonically washed, wherein the electrodeposition time of the workpiece is controlled at about 4 min, and the components of a plating solution comprise NiSO4.6H2O, ammonium citrate tribasic, ammonium hydroxide and ammonium acetate; and the deposited surface is placed in a dry box to be heated at the temperature of 150 DEG C, heat preservation is conducted for 2 hours, and the surface is cooled along with a furnace to the room temperature. The hydrophobicity of the surface reaches better, and the hydrophobic contact angle of the surface subjected to laser electrodeposition composite preparation reaches 152 degrees.

Owner:CHANGCHUN UNIV OF SCI & TECH

Preparation method of TiAl3 enhanced aluminum-based composite material

The invention discloses a preparation method of a TiAl3 enhanced aluminum-based composite material. The preparation method is characterized by comprising the following steps: uniformly mixing cryolite powder with titanium powder according to the mass ratio of 1-0.5:1 and drying; placing a 7075 aluminum alloy into a graphite crucible and heating and melting; adding the mixed powder into a 7075 aluminum alloy melt according to the ratio that titanium accounts for 1-6 weight percent of the mass fraction of the 7075 aluminum alloy at the temperature of 830-850DEG C; extending an ultrasound amplitude transformer into the aluminum alloy melt and carrying out the ultrasound at the ultrasound power of 800-1,000W for 20-35min; and reducing the melt temperature to be 740-760DEG C and continuously carrying out the ultrasound for 2-6min. The obtained TiAl3 / 7075 aluminum-based composite material has fine crystal grains in the tissue; and the generated TiAl3 enhanced phase has uniform distribution, is in a fine granule shape and has no macrosegregation phenomenon. The process has the advantages of low process cost, simple flow, safety, reliability and convenient operation.

Owner:NANCHANG UNIV

Low temperature ultrasonic aging treatment method for 7075 aluminium alloy

InactiveCN109023178AImprove heat treatment organizationImprove performance5005 aluminium alloyPhase number

The invention discloses a low temperature ultrasonic aginreatmentg t method for a 7075 aluminium alloy and relates to the technical field of aluminium alloy heat treatment. The low temperature ultrasonic aging treatment method for the 7075 aluminium alloy comprises the steps of oil bath liquid pre-heating, workpiece oil bath heat preservation, ultrasonic aging treatment, cooling and so on. According to the low temperature ultrasonic aging treatment method for the 7075 aluminium alloy, the aging temperature needed by 7075 aluminium alloy traditional aging heat treatment can be reduced, the aging time can be greatly shortened, and the precipitated phase number is increased, the precipitated phase distribution is more dispersed. Compared with a traditional aging heat treatment method, the lowtemperature ultrasonic aging treatment method for the 7075 aluminium alloy has the advantages that requirements on an aging process can be reduced, the heat treatment cost can be reduced, the efficiency can be enhanced, the aluminium alloy aging heat treatment structure can be improved, and the aluminium alloy comprehensive performance can be improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

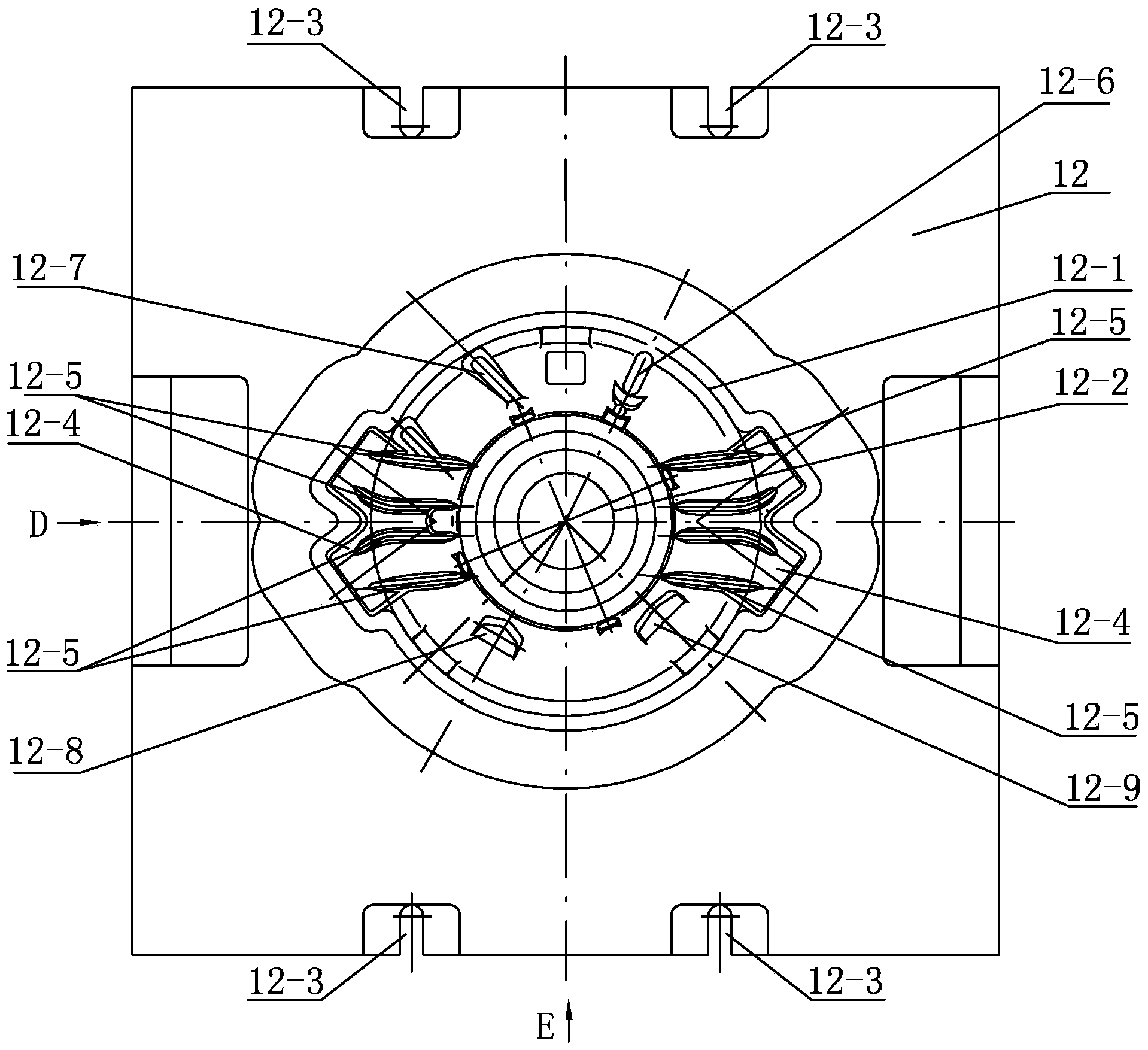

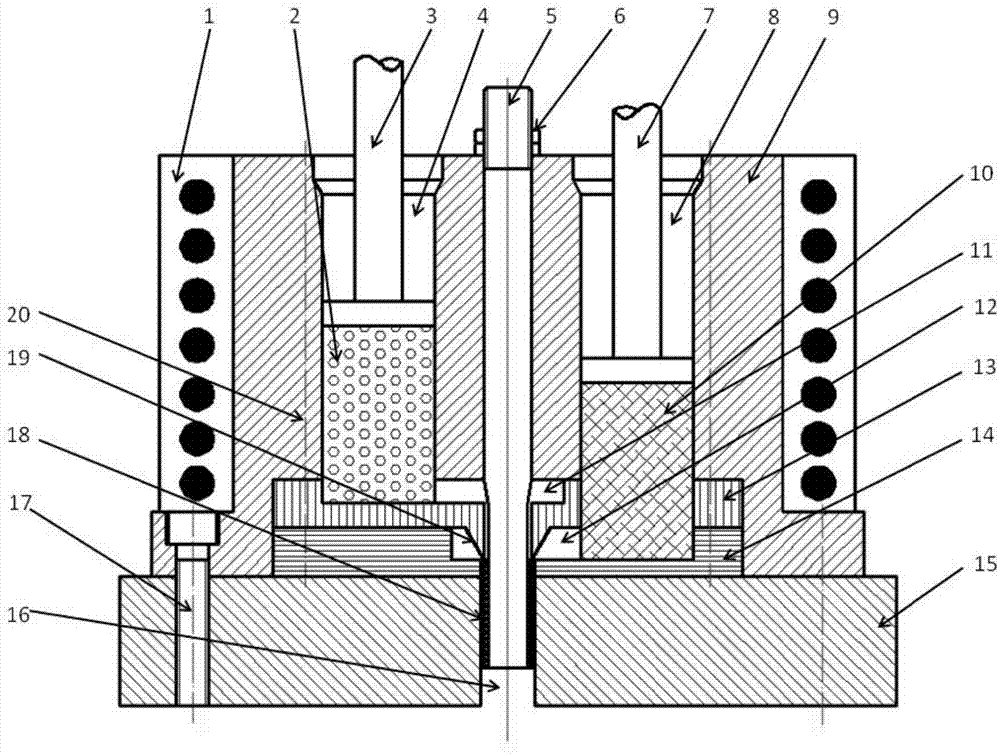

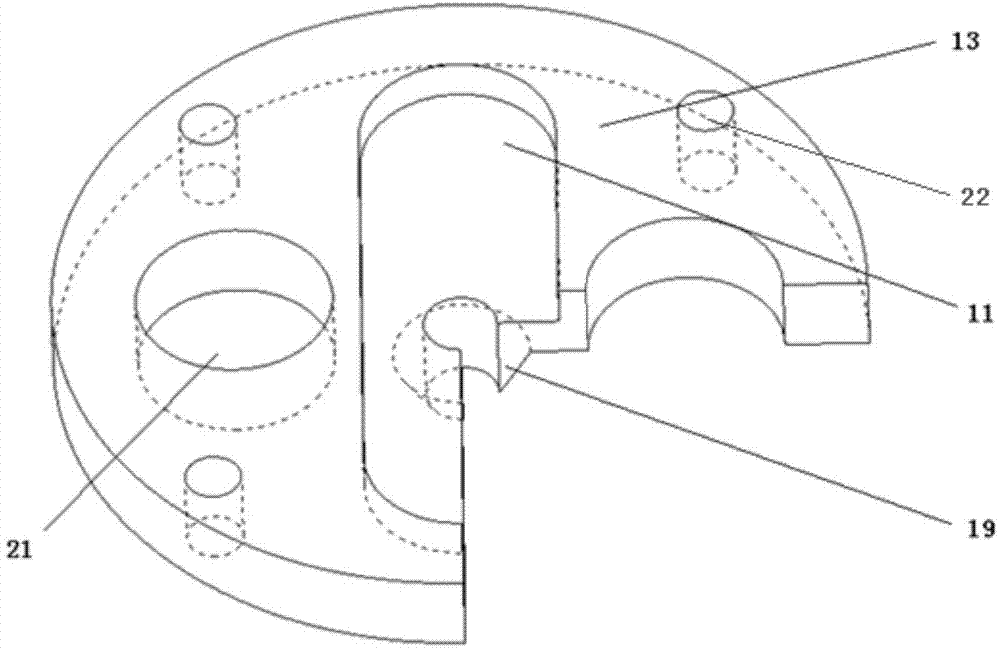

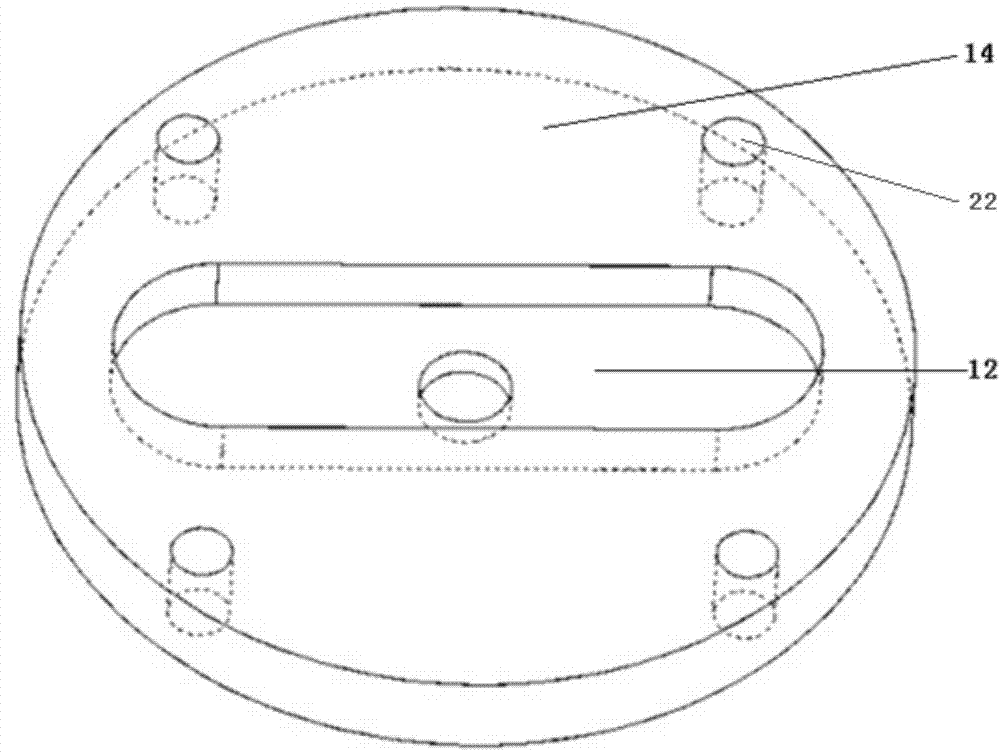

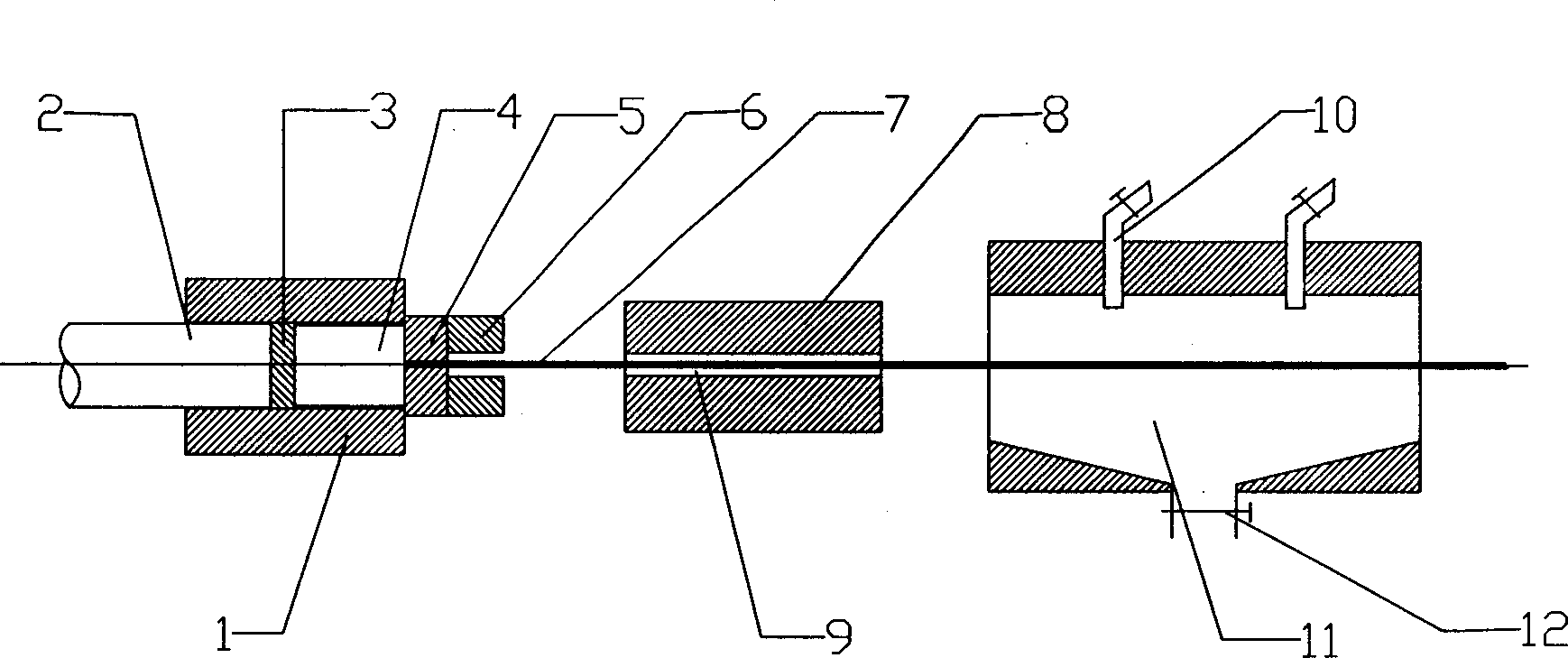

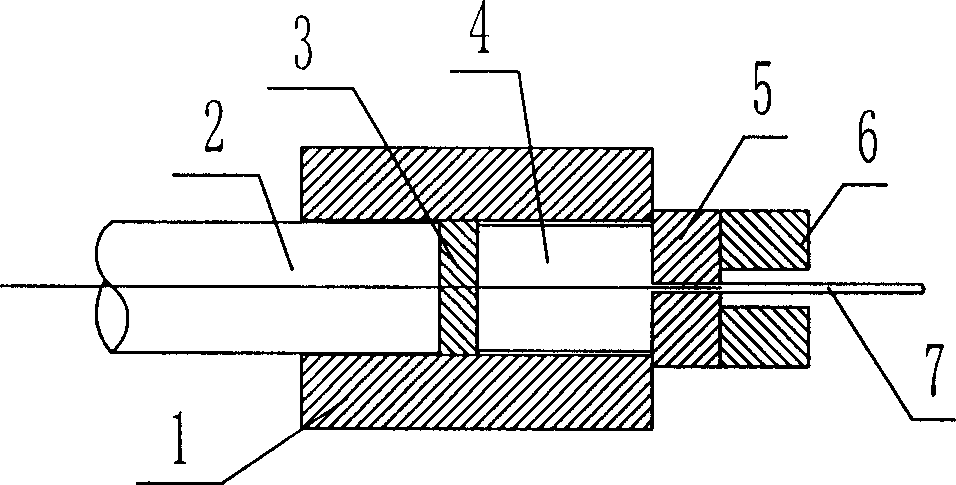

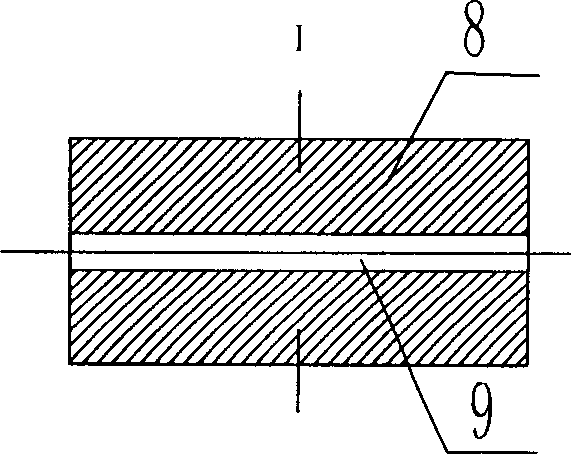

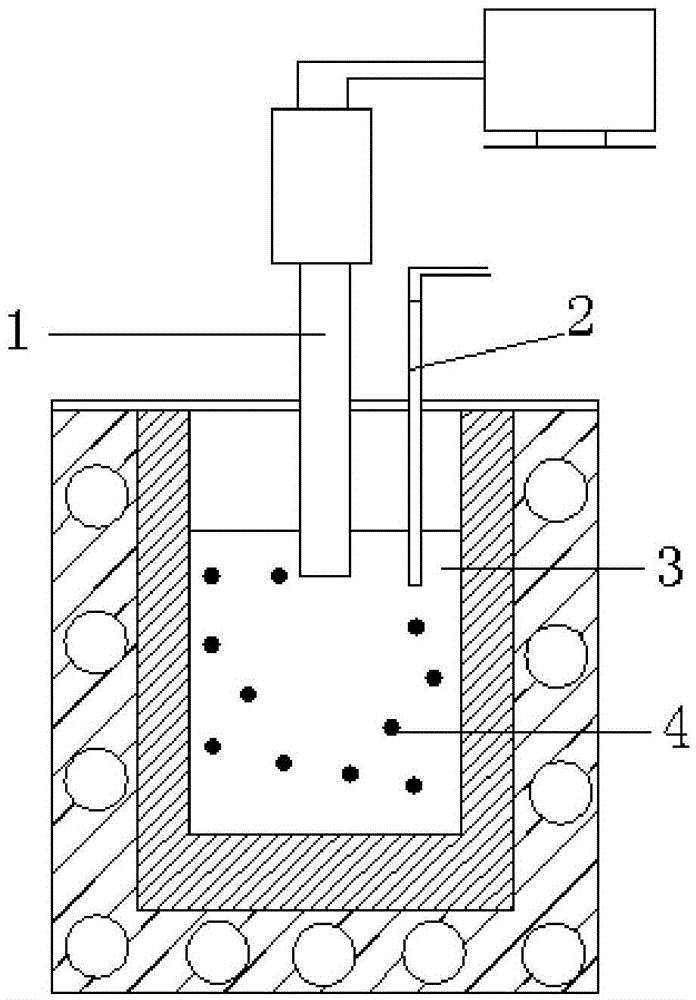

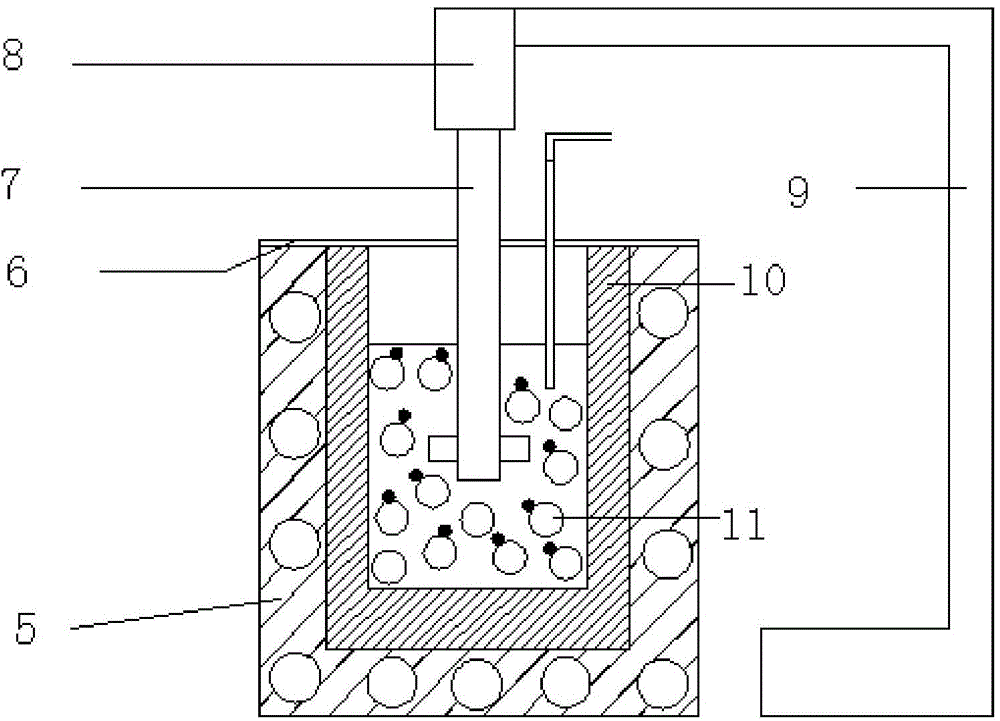

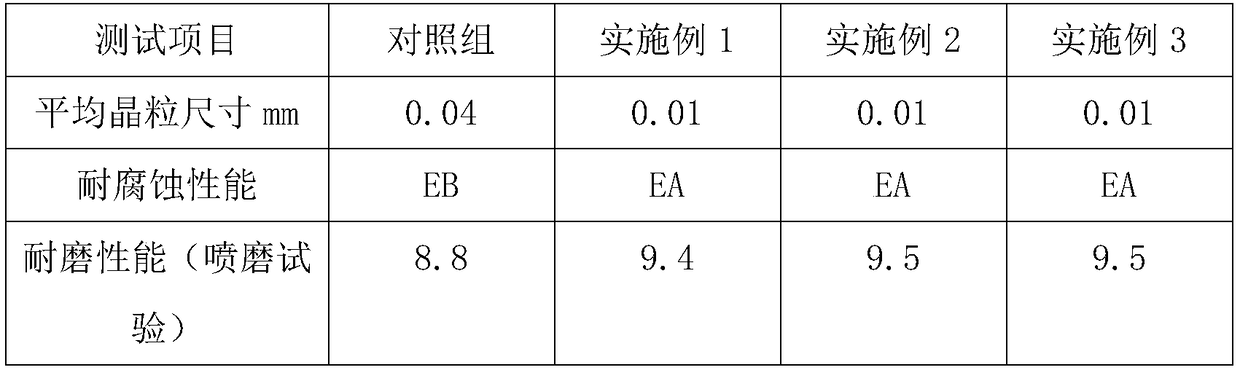

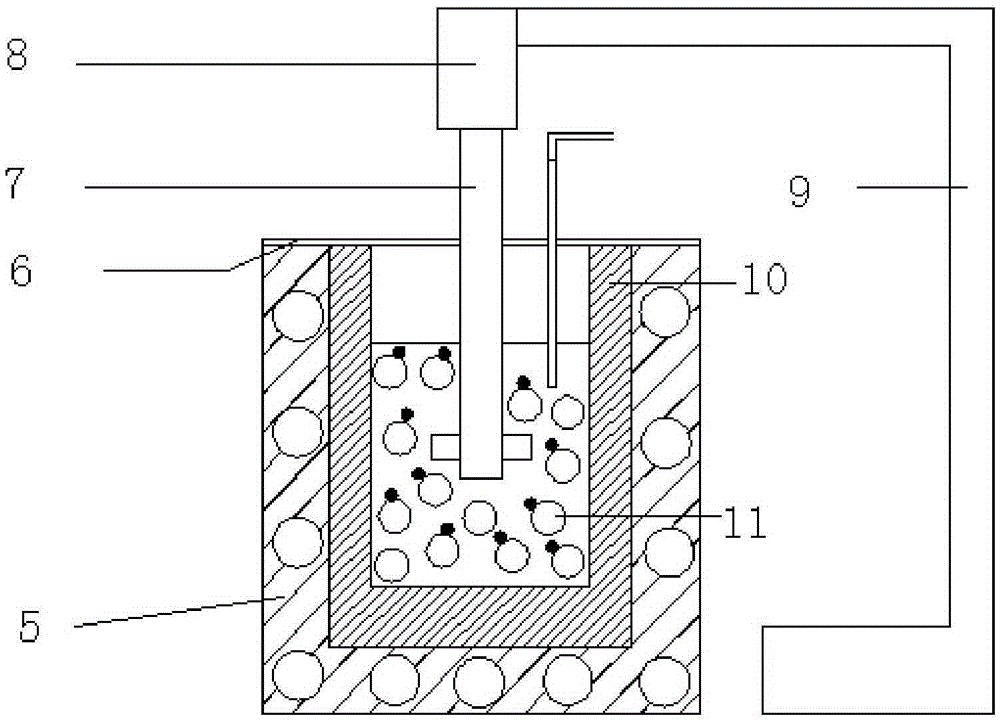

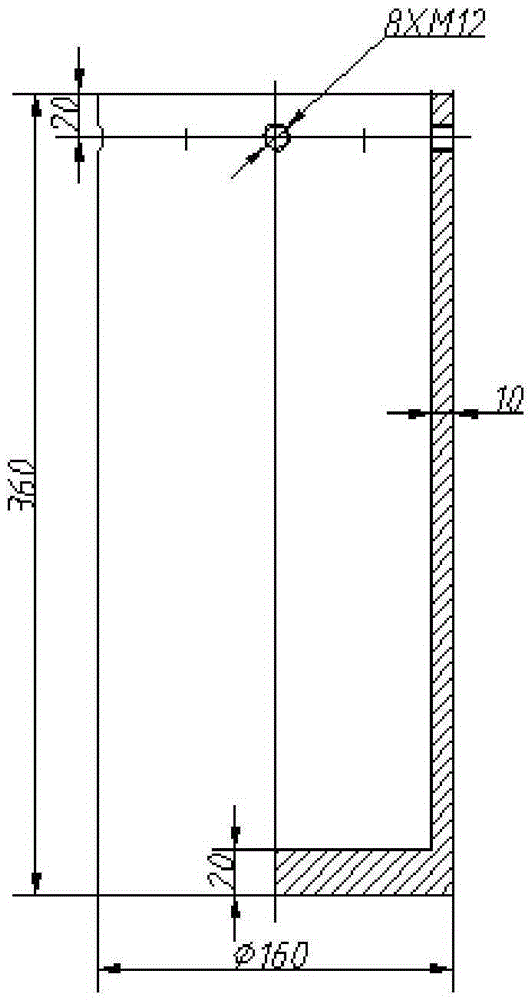

Preparing and molding devices and preparing and molding methods of nano SiC particle enhanced 7075 aluminum matrix composite material semi-solid slurry

The invention discloses preparing and molding devices and preparing and molding methods of nano SiC particle enhanced 7075 aluminum matrix composite material semi-solid slurry, relates to preparing and molding devices and preparing and molding methods of semi-solid slurry, and aims at solving the problems in the currently prepared particle enhanced aluminum matrix composite material semi-solid slurry that the interfacial wettability of nano particles and aluminum matrix is poor, nano particles are easy to flocculate, and the molding method is high in cost, long in technological process and poor in shape control. The preparation device comprises an oscillating device, a thermocouple, a resistance furnace, a cover board, a stirrer, a motor, a frame and a crucible. The preparation method comprises the following steps: preparing liquid 7075 aluminum alloy; carrying out ultrasonic cleaning; mixing and carrying out ultrasonic treatment; stirring and cooling; and preparing the semi-solid slurry. The molding device comprises a template, bolts, a heater, a pressure plate, a convex die, a fixing plate, a concave die sleeve, a concave die, a mold cavity and a top rod. The molding method comprises the following steps: preheating; heating; charging; pressurizing; taking out; and cooling. The preparing and molding devices and the preparing and molding methods are suitable for preparing and molding the semi-solid slurry.

Owner:HARBIN INST OF TECH

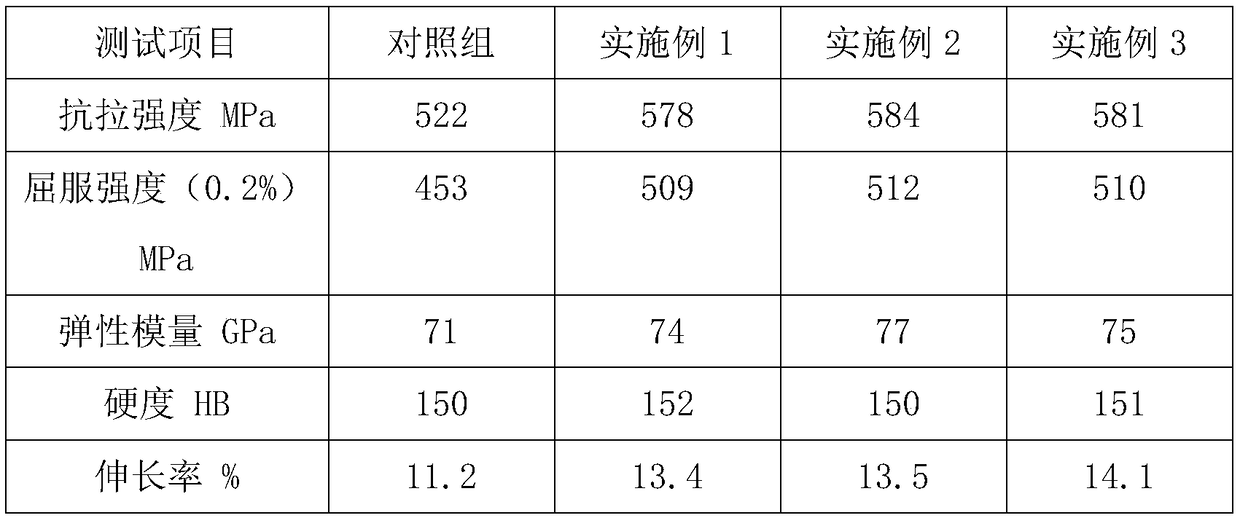

Ultra-fine crystal aluminum alloy used for preparing pipe fitting

The invention relates to the technical field of alloy materials, in particular to an ultra-fine crystal aluminum alloy used for preparing a pipe fitting. Raw material compositions of the aluminum alloy comprise 0.3-0.5 wt% of crystalline phase conditioning agent and 99.5-99.7 wt% of 7075 aluminum alloy, wherein the 7075 aluminum alloy contains the following elements including, by mass, 5.25-6.58%of Zn, 2.78-2.88% of Mg, 1.25-2.14% of Cu, 0.13-0.17% of Si, 0.15-0.22% of Fe, 0.09-0.16% of Cr, 0.08-0.15% of Zr, 0.05-0.07% of Mn, 0.02-0.03% of Ti, and the balance Al and inevitable impurities. Thecrystalline phase conditioning agent is a novel additive, the crystal particle refining effect is much better than that of a normal Al-Ti-B crystal particle refining agent. The aluminum alloy material has the beneficial effects of being high in hardness, good in strength and excellent in corrosion resistant performance, and due to the good refining effect of crystal particles in fine texture, thealuminum alloy has an excellent processing characteristic.

Owner:苏州新金相金属材料有限公司

Forming device and method for semi-solid slurry of nanometer SiC-particle-reinforced 7075-aluminum-based composite material

The invention relates to a forming device and method for semi-solid slurry, in particular to a forming device and method for semi-solid slurry of a nanometer SiC-particle-reinforced 7075-aluminum-based composite material. The forming device and method aim at solving the problems that as for existing prepared semi-solid slurry of the particle-reinforced aluminum-based composite material, the interface wettability of nano-particles and an aluminum base body is poor, the nano-particles are prone to flocculation, a forming method is high in cost, a technological process is long, and shape control is poor. A preparing device comprises a vibration device, a thermocouple, a resistance furnace, a cover plate, a stirrer, a motor, a frame and a crucible. A preparing method includes the steps of preparing of 7075 aluminum alloy; ultrasonic cleaning; mixing and ultrasonic treatment; stirring and cooling; preparing of the semi-solid slurry. The forming device comprises templates, bolts, a heater, a pressing plate, a male mold, a fixing plate, a female mold sleeve, a female mold, a cavity and an ejector rod. The forming method includes the steps of preheating; heating; material feeding; pressurizing; taking and cooling. The forming device and method are suitable for preparing and forming the semi-solid slurry.

Owner:HARBIN INST OF TECH

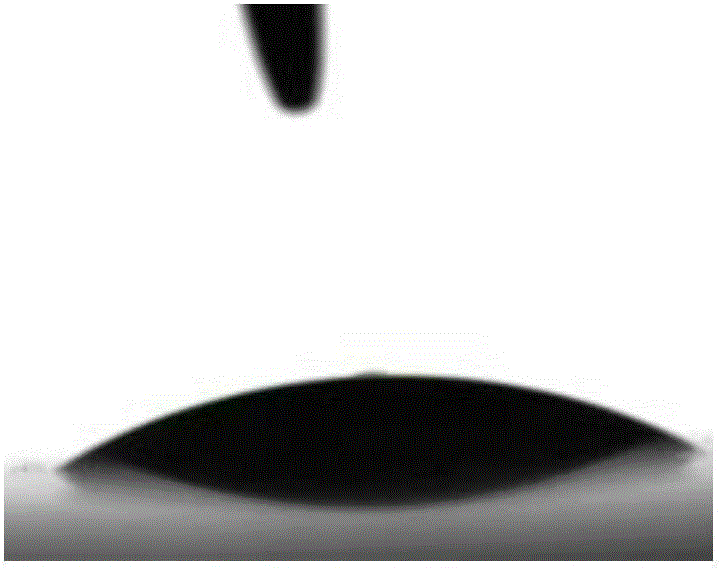

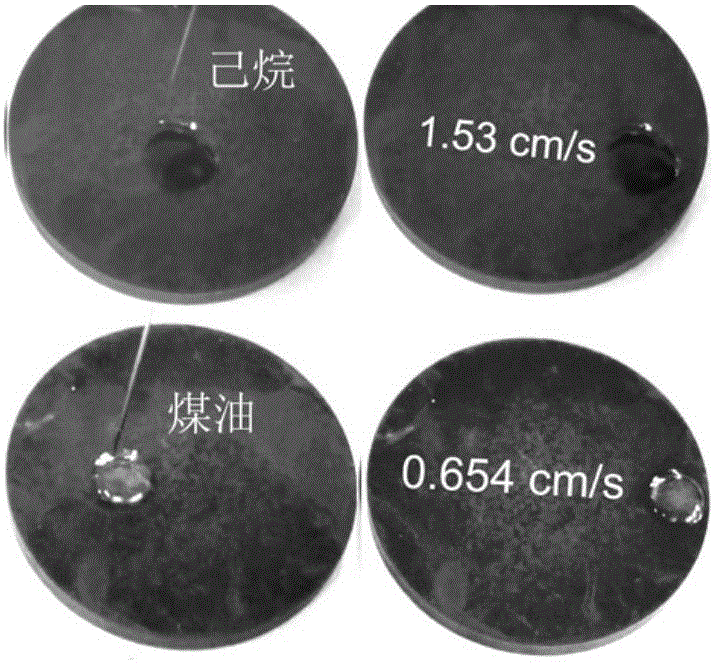

Lyophobic super-lubricant interface and preparation method thereof

ActiveCN106245011ASize is not requiredIncreased repellencyMetallic material coating processesMicro nanoSilanes

The invention discloses a lyophobic super-lubricant interface and a preparation method thereof. The lyophobic super-smooth interface is prepared by the steps of: by taking a 7075 aluminum alloy as a substrate, performing surface corrosion in an ultrasonic treatment state with nitric acid to form micro-nano structures; performing surface grafting with fluoroalkyl silane; and finally injecting a perfluoro lubricant into the micro-nano structures. The lyophobic super-lubricant interface disclosed by the invention is prepared by using a structural metal 7075 aluminum alloy which is widely applied. The prepared lyophobic super-lubricant interface has excellent repulsive interaction to water, oil and hexane with extremely low surface tension, and has a wide application prospect in the field of construction, machine manufacturing, aerospace, navigation and the like.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com