Lyophobic super-lubricant interface and preparation method thereof

An interface and lyophobic technology, applied in the field of materials, can solve the problems of cumbersome and complicated methods, complicated preparation methods, high sample size and shape requirements, etc., and achieve broad application prospects, simple preparation methods, and excellent repulsion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) After grinding and polishing the 7075 aluminum alloy, put it into a dilute nitric acid solution with a concentration of 1.2mol / L, and corrode it for 2 minutes under the assistance of 170W ultrasonic waves;

[0018] (2) Take out the sample obtained in step (1), wash it with alcohol, dry it at room temperature, put it into a hexane solution of 0.03mol / L heptadecafluorodecyltriethoxysilane, and modify it at 40°C for 2h , taken out, washed with hexane and dried at room temperature;

[0019] (3) Inject perfluorotripentylamine into the sample obtained in step (2), and the injection amount is 0.008g / cm 2 , a lyophobic superslippery interface is obtained.

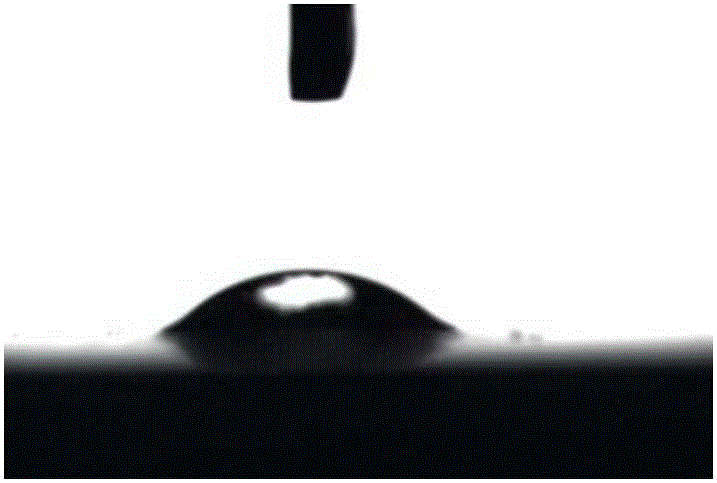

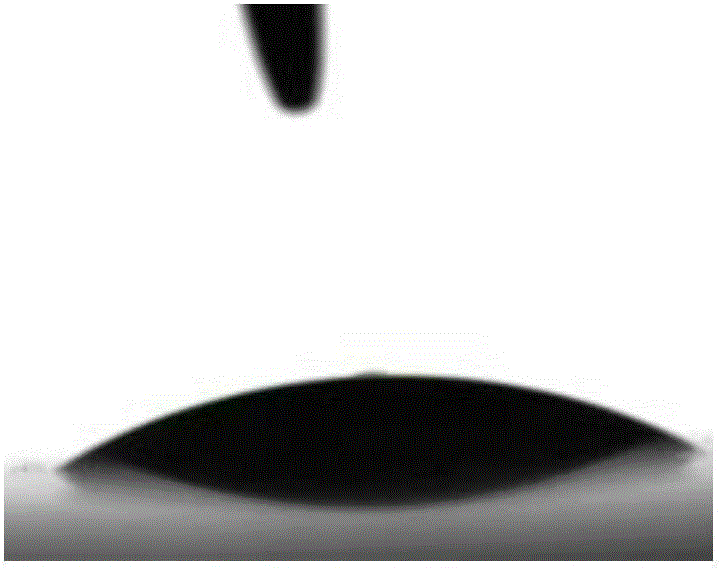

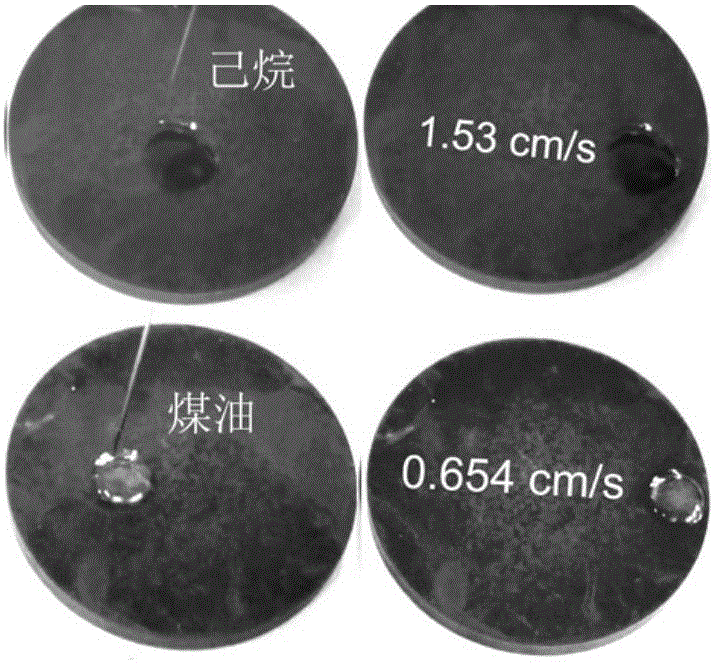

[0020] On the prepared liquid-repellent super-slip interface, the kerosene contact angle is 50° (such as figure 1 shown), the hexane contact angle is 30° (as figure 2 shown), and it can slide smoothly on the prepared super-slippery interface (such as image 3 As shown, kerosene was stained with Oil Red O), it can be...

Embodiment 2

[0022] (1) After grinding and polishing the 7075 aluminum alloy, put it into a dilute nitric acid solution with a concentration of 1.0mol / L, and corrode it for 1min under the assistance of 150W ultrasonic waves;

[0023] (2) Take out the sample obtained in step (1), wash it with alcohol and dry it at room temperature. Put it into a 0.01mol / L hexane solution of heptadecafluorodecyltriethoxysilane, modify it at 30°C for 2 hours, take it out, wash it with hexane, and dry it at room temperature;

[0024] (3) Inject perfluorotripentylamine into the sample obtained in step (2), and the injection amount is 0.005g / cm 2 , a lyophobic superslippery interface is obtained.

[0025] The prepared interface has a kerosene contact angle of 40° and a hexane contact angle of 20°, and can slide smoothly on the interface, indicating that a super-slippery interface with lyophobic effect has been obtained.

Embodiment 3

[0027] (1) After grinding and polishing the 7075 aluminum alloy, put it into a dilute nitric acid solution with a concentration of 1.4mol / L, and corrode it for 3 minutes under the assistance of 200W ultrasonic waves;

[0028] (2) Take out the sample obtained in step (1), wash it with alcohol and dry it at room temperature. Put 0.04mol / L heptadecafluorodecyltriethoxysilane in hexane, modify at 40°C for 1.5h, take it out, wash it with hexane and dry it at room temperature;

[0029] (3) Inject perfluorotripentylamine into the sample obtained in step (2), and the injection amount is 0.01g / cm 2 , a lyophobic superslippery interface is obtained.

[0030] The prepared interface has a kerosene contact angle of 35° and a hexane contact angle of 25°, and can slide smoothly on the interface, indicating that a super-slippery interface with lyophobic effect has been obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com