A visual recognition system and method for internal thread of pipe fittings based on gray level co-occurrence matrix

A gray-scale co-occurrence matrix and visual recognition technology, applied in image data processing, instruments, calculations, etc., can solve the problems of low stability of internal thread recognition algorithm, complex hardware system, slow recognition speed, etc. Simple composition and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

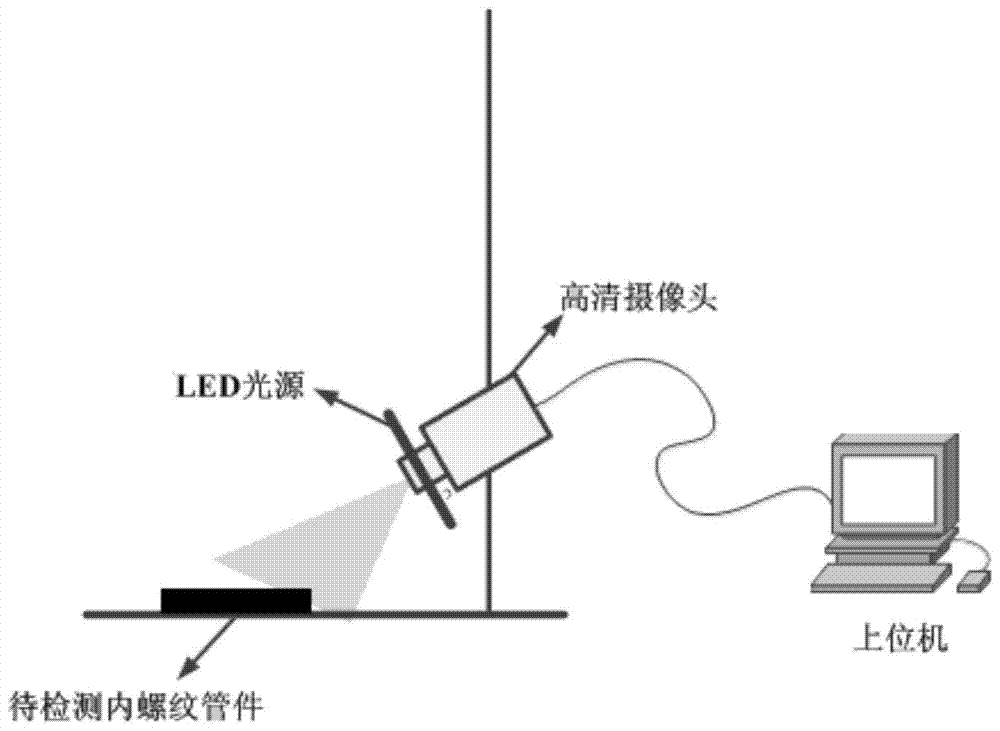

[0030] Specific implementation mode one: combine figure 1 Describe this specific embodiment, a visual recognition system for internal thread of pipe fittings based on gray scale co-occurrence matrix, characterized in that: the visual recognition system for internal thread of pipe fittings based on gray scale co-occurrence matrix consists of a host computer, a high-definition camera and an LED light source ;The upper computer is connected with the high-definition camera; the LED light source is an intensity-adjustable light source and is used to establish a lighting environment; the high-definition camera is used to capture images; the upper computer is used to control the high-definition camera for image acquisition and image processing.

specific Embodiment approach 2

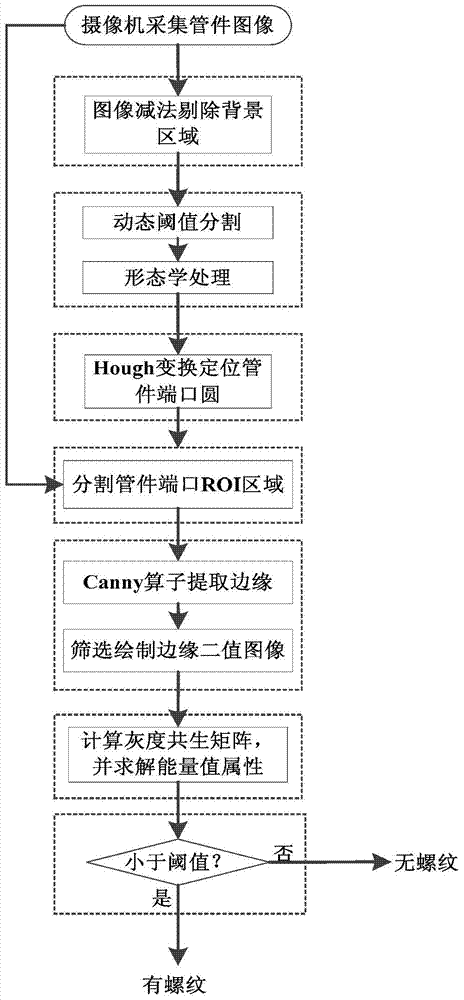

[0031] Specific implementation mode two: combination figure 2 To illustrate this specific implementation method, a method for visual recognition of internal thread of pipe fittings based on gray scale co-occurrence matrix is specifically carried out according to the following steps:

[0032] Step 1. Before the internal threaded pipe fitting is recognized for the first time, adjust the intensity of the LED light source until the image of the internal thread of the pipe nozzle captured by the high-definition camera is the clearest. The subsequent identification process does not need to adjust the intensity of the LED light source again. After adjusting the intensity of the LED light source, turn on the host computer The visual recognition program initializes the camera. During this process, the program automatically collects and saves a background image through the high-definition camera;

[0033] Step 2. The upper computer collects an original image of the internally threade...

specific Embodiment approach 3

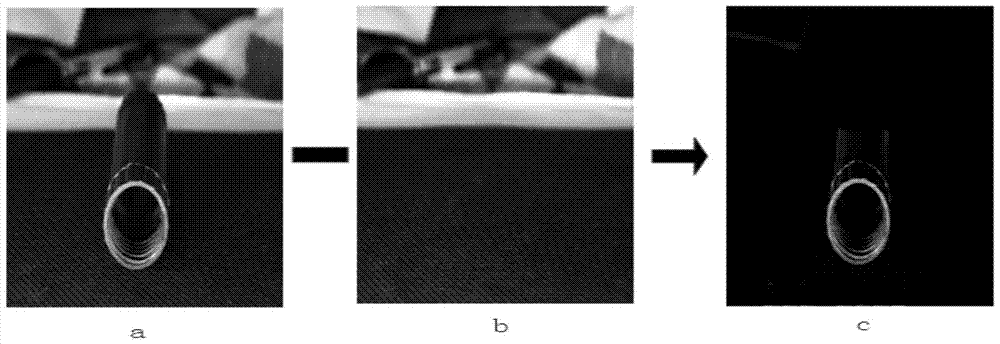

[0043] Specific implementation mode three: combination image 3 Describe this specific embodiment. The difference between this embodiment and specific embodiment 2 is that in the step 3, the original image of the internally threaded pipe fitting port collected in the step 2 and the background image collected and saved in the step 1 are subjected to image subtraction, thereby Eliminate the background on the original image of the internally threaded pipe fitting port, and only retain the image of the internally threaded pipe fitting port; the specific process is:

[0044] Image subtraction is represented by the following formula:

[0045] F(x,y)=I(x,y)-G(x,y)

[0046] In the formula, I(x,y) is the original image of the internally threaded pipe fitting collected by the camera, G(x,y) is the pre-stored background image, and F(x,y) is the port image of the internally threaded pipe fitting after removing the background.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com