Recovery method of ammonia from vent gas during ammonia synthesis

A technology for venting and ammonia recovery, applied in the preparation/separation of ammonia, etc., can solve the problems of no vent, loss of refining gas, and increased load of ammonia scrubber, etc., to achieve easy equipment installation, small equipment diameter, and no space occupation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

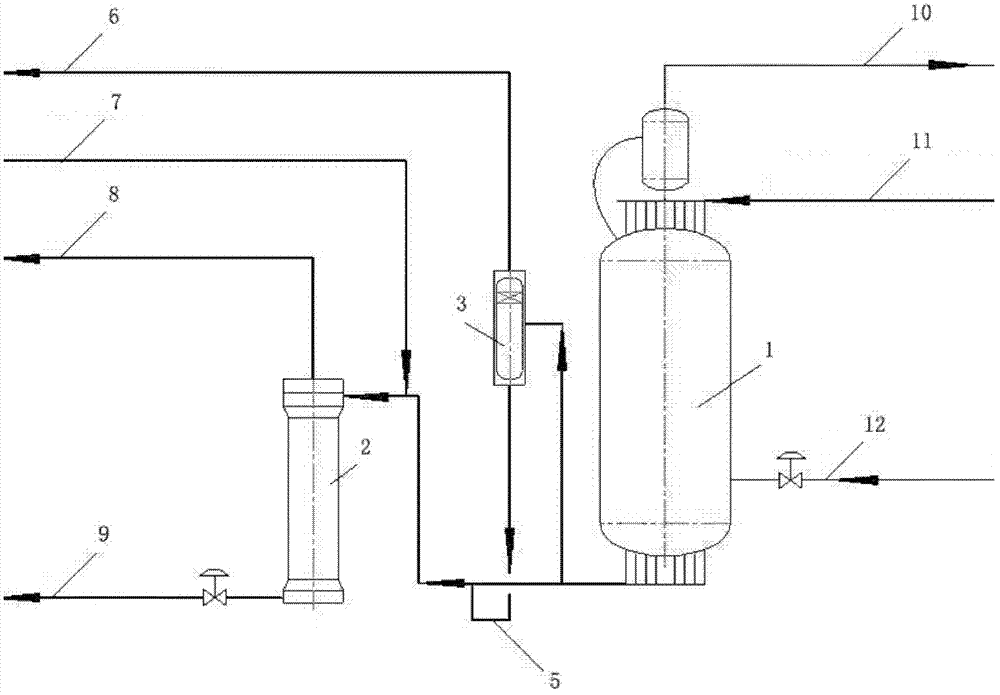

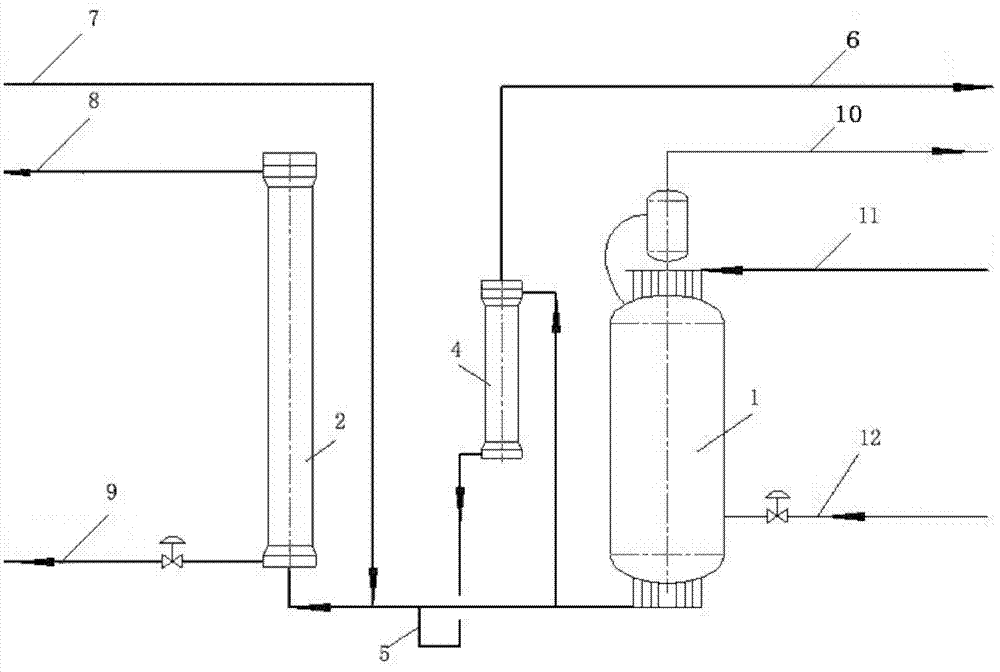

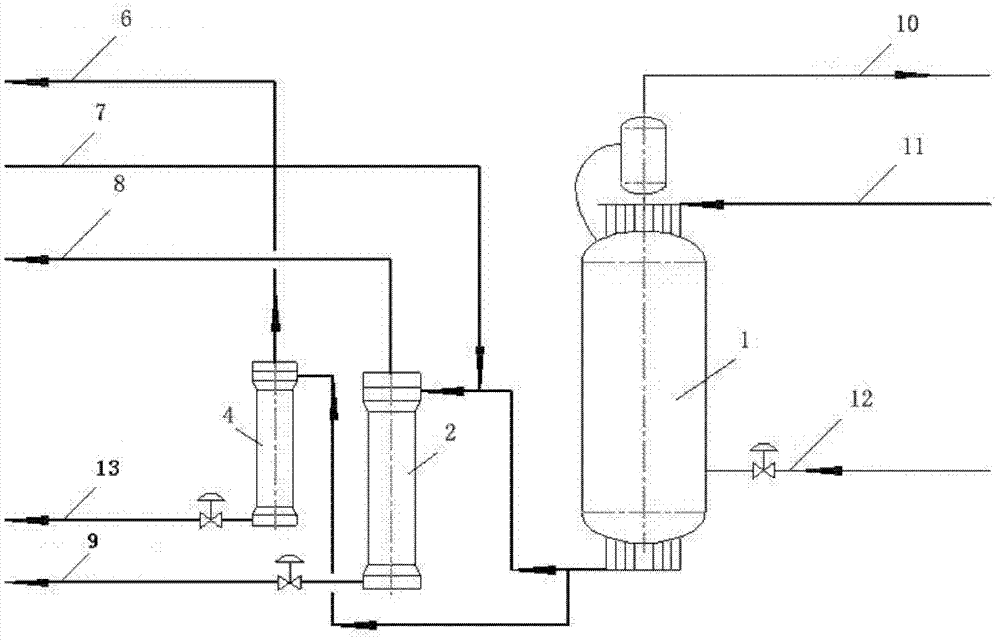

[0038] see figure 1 , 2 , 3,1-Ammonia cooler, 2-The third ammonia separator, 3-Small ammonia separator, 4-Old ammonia separator, 5-U-shaped liquid-sealed pipe, 6-Release the air to extract the ammonia scrubber, 7- Refining gas replenishment gas inlet pipe, 8- Circulating gas return cooling delivery inlet, 9- Third ammonia separator liquid ammonia removal ammonia main pipe, 10- Gas ammonia return freezing process, 11- Ammonia cooler inlet circulation gas pipe, 12 -Liquid ammonia comes from the freezing process, 13-Liquid ammonia from the old ammonia separator goes to the ammonia discharge main pipe.

[0039] see figure 1 , move the position of the vent port from the inlet pipe of the ammonia cooler 1 to the outlet of the ammonia cooler 1 and the inlet of the third ammonia separator 2, where the circulating gas is cooled by the ammonia cooler 1, The temperature has dropped to -5 ~ 0 ℃, most of the ammonia in the circulating gas is condensed into liquid ammonia, and the ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com