Technique for improving performances of 7075 aluminum alloy extruded material

A process method and extruded material technology, applied in the field of aluminum alloys, can solve the problems of low production energy consumption and high production efficiency, and achieve the effects of improving production efficiency, shortening aging time, and improving tensile strength and yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The produced product is an extruded round bar with a diameter of 50mm, and the extrusion ratio is 10.69.

[0036] (1) Alloy ingot heating: the heating temperature of the alloy ingot for 7075 alloy extrusion is 410°C, and the alloy composition of the alloy ingot used includes:

[0037] Si: 0.35%, Fe: 0.24%, Cu: 1.53%, Mn: 0.21%, Mg: 2.68%, Cr: 0.22%, Zn: 5.82%, Ti: 0.13%, other individual elements ≤ 0.05%, other impurity elements The total amount is ≤0.15%, and the balance is Al.

[0038] (2) Heating of the mold and the extrusion barrel: the heating temperature of the extrusion mold is 420°C, and the temperature of the extrusion barrel is 410°C.

[0039] (3) Extrusion: Put the mold and the alloy ingot with the required temperature into the extruder, adjust the extrusion rod speed to control the extrusion speed at 1-3m / min for extrusion.

[0040] (4) Solution treatment: heat the extruded round bar to 465°C±3°C for 150min.

[0041] (5) Quenching treatment: put the heat-...

Embodiment 2

[0045] The production product is 60*10mm flat row, and the extrusion ratio is 15.39.

[0046] (1) Alloy ingot heating: The heating temperature of the alloy ingot for 7075 alloy extrusion is 400°C, and the alloy composition of the alloy ingot used includes:

[0047] Si: 0.40%, Fe: 0.22%, Cu: 1.98%, Mn: 0.26%, Mg: 2.71%, Cr: 0.25%, Zn: 5.75%, Ti: 0.16%, other single elements ≤ 0.05%, other impurity elements The total amount is ≤0.15%, and the balance is Al.

[0048] (2) Heating of the mold and the extrusion barrel: the heating temperature of the extrusion mold is 460°C, and the temperature of the extrusion barrel is 440°C.

[0049] (3) Extrusion: put the mold and alloy ingot with the required temperature into the extruder, adjust the speed of the extrusion rod so that the extrusion speed is controlled at 2-5m / min for extrusion.

[0050] (4) Solution treatment: heat the extruded flat row to 472°C±3°C for heat preservation, and the heat preservation time is 30min.

[0051] (5) ...

Embodiment 3

[0055] The production product is 425*25mm flat row, and the extrusion ratio is 28.61.

[0056] (1) Alloy ingot heating: the heating temperature of the alloy ingot for 7075 alloy extrusion is 410°C, and the alloy composition of the alloy ingot used includes:

[0057] Si: 0.26%, Fe: 0.50%, Cu: 1.84%, Mn: 0.25%, Mg: 2.63%, Cr: 0.22%, Zn: 5.83%, Ti: 0.11%, other individual elements ≤ 0.05%, other impurity elements The total amount is ≤0.15%, and the balance is Al.

[0058] (2) Heating of the mold and the extrusion barrel: the heating temperature of the extrusion mold is 430°C, and the temperature of the extrusion barrel is 420°C.

[0059] (3) Extrusion: Put the mold and the alloy ingot with the required temperature into the extruder, adjust the extrusion rod speed to control the extrusion speed at 1-3m / min for extrusion.

[0060] (4) Solution treatment: heat the extruded flat row to 467°C±3°C for heat preservation, and the heat preservation time is 120min.

[0061] (5) Quenching ...

PUM

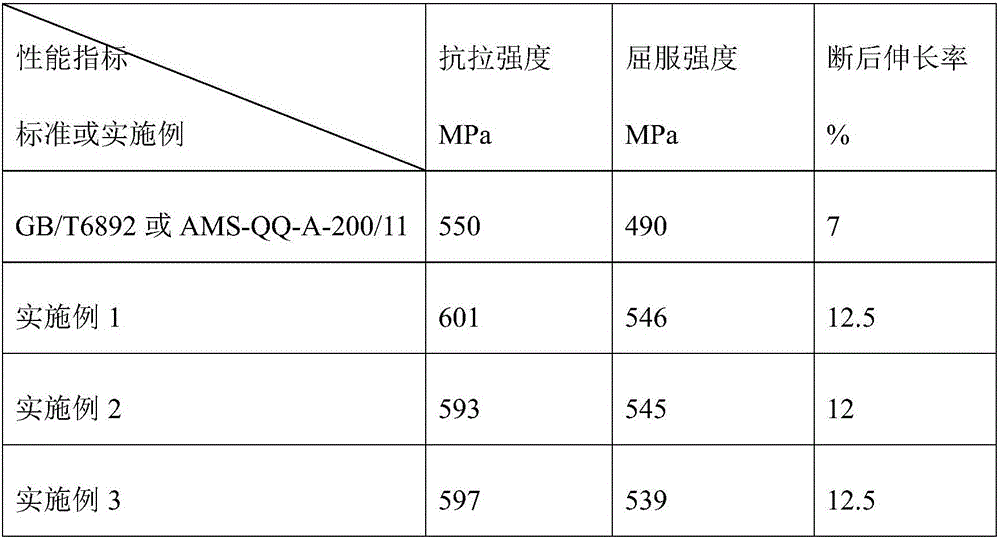

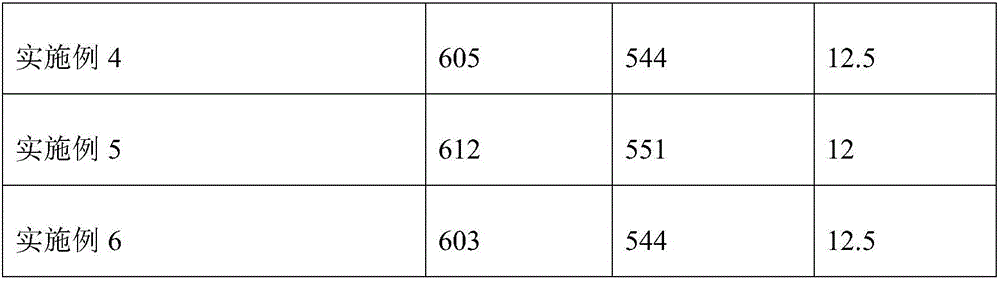

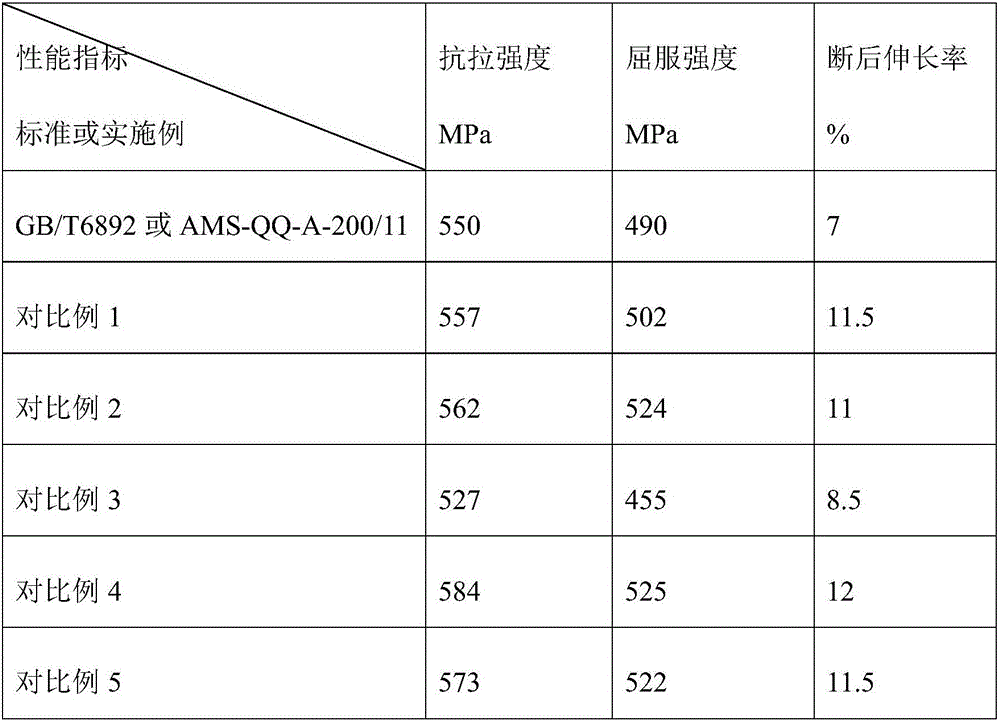

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com